Professional Documents

Culture Documents

Series D1VW Characteristics: Directional Control Valve

Series D1VW Characteristics: Directional Control Valve

Uploaded by

juanCopyright:

Available Formats

You might also like

- Online Gaming in Context - The Social and Cultural Significance of Online GamesDocument158 pagesOnline Gaming in Context - The Social and Cultural Significance of Online GamesHeartFilthyLesson100% (1)

- Denison Hydraulics Proportional Pressure Control Valves: Series P2 & 4VP01Document12 pagesDenison Hydraulics Proportional Pressure Control Valves: Series P2 & 4VP01abuzer1981No ratings yet

- Sinamics G110Document14 pagesSinamics G110alperdaNo ratings yet

- Chapter 1 RQDocument3 pagesChapter 1 RQAb C100% (2)

- D1VW UkDocument8 pagesD1VW UksureshllsNo ratings yet

- Series D3MW Characteristics: FeaturesDocument6 pagesSeries D3MW Characteristics: FeaturesPdroGsus Abregú TerronesNo ratings yet

- Hidraulica, Compones, Partes, para Uso en La Oleodinamica (118) MDocument10 pagesHidraulica, Compones, Partes, para Uso en La Oleodinamica (118) Mcarlosmedina111No ratings yet

- D 631 Series ValvesDocument12 pagesD 631 Series ValvesJosé OlaveNo ratings yet

- ALISON HIDRAULIC - Catalogue PDFDocument250 pagesALISON HIDRAULIC - Catalogue PDFbaba0% (1)

- SolenoidDocument11 pagesSolenoidPoovanaan Sathiya Seelan100% (1)

- SD 11 eDocument12 pagesSD 11 eseaqu3stNo ratings yet

- Duplo MaticDocument8 pagesDuplo MaticHENRYGALLEGOSNo ratings yet

- Atos Industrial ValvesDocument22 pagesAtos Industrial ValvesM S GokulNo ratings yet

- Solenoid Directional Valves Dhe and Dher: Direct Operated, ISO 4401 Size 06Document4 pagesSolenoid Directional Valves Dhe and Dher: Direct Operated, ISO 4401 Size 06RFIGUEROACNo ratings yet

- Sds 150 eDocument16 pagesSds 150 ejbsb1No ratings yet

- DCV 03 hk66t102Document15 pagesDCV 03 hk66t102seaqu3stNo ratings yet

- Proportional Control Valves D631 Series ISO 4401 Size 05Document8 pagesProportional Control Valves D631 Series ISO 4401 Size 05Devendra BangarNo ratings yet

- Functional Description: HA 5115 8/2005 Proportional Directional Control ValvesDocument19 pagesFunctional Description: HA 5115 8/2005 Proportional Directional Control ValvesgatodeftoneNo ratings yet

- Moog ServovalvesDocument8 pagesMoog Servovalvesdylan_dearing@hotmail.com100% (1)

- Re29061 4WREEDocument18 pagesRe29061 4WREEManuel VizcarraNo ratings yet

- 9 - 3RH, 3TH Contactor Realys PDFDocument6 pages9 - 3RH, 3TH Contactor Realys PDFsaina124796010No ratings yet

- Vickers DG4V-3 DG4V-3S 6xDocument32 pagesVickers DG4V-3 DG4V-3S 6xCarlos Javier Torrico BarreroNo ratings yet

- Series D1VW Characteristics: Directional Control ValveDocument8 pagesSeries D1VW Characteristics: Directional Control ValveJas SumNo ratings yet

- Rexroth FDDocument116 pagesRexroth FDIvan GudeljNo ratings yet

- DSG ValvesDocument17 pagesDSG ValvesChris RoederNo ratings yet

- SD 16 eDocument20 pagesSD 16 eseaqu3stNo ratings yet

- SD 25 eDocument20 pagesSD 25 eseaqu3stNo ratings yet

- ATOSs Valves DHI-0711Document4 pagesATOSs Valves DHI-0711Cardoso MalacaoNo ratings yet

- DSV 100 34TRDocument2 pagesDSV 100 34TRsgfdrfNo ratings yet

- SD 6 eDocument16 pagesSD 6 eseaqu3stNo ratings yet

- Rexroth电磁阀手册Document12 pagesRexroth电磁阀手册davidwang85120% (1)

- PARKER Valvula Direccional D3W UKDocument7 pagesPARKER Valvula Direccional D3W UKComassur SA de CVNo ratings yet

- 62 SeriesDocument8 pages62 SeriesDevendra BangarNo ratings yet

- Electrohydraulic: Solenoid ValvesDocument16 pagesElectrohydraulic: Solenoid ValvesluisbottonNo ratings yet

- MIL Control Valve Specification and Sizing CalculationDocument34 pagesMIL Control Valve Specification and Sizing CalculationRahulTewari67% (3)

- SD 5 eDocument12 pagesSD 5 eseaqu3stNo ratings yet

- fp50 fp100 fp200Document10 pagesfp50 fp100 fp200ducmanh83No ratings yet

- Ev DG05Document14 pagesEv DG05mtbecerrapNo ratings yet

- HVAC+Valves+and+Actuators+Catalogue+07 2011Document64 pagesHVAC+Valves+and+Actuators+Catalogue+07 2011Jafar JalladNo ratings yet

- 4/2-And 4/3 - Proportional Directional Valves Direct Operated, Type 4WRA, Series 1XDocument8 pages4/2-And 4/3 - Proportional Directional Valves Direct Operated, Type 4WRA, Series 1XlizbethdiosesNo ratings yet

- Series 10 Subplate Mounting ISO 4401-03 (CETOP 03) P Max: Bar Max (See Performances Table)Document4 pagesSeries 10 Subplate Mounting ISO 4401-03 (CETOP 03) P Max: Bar Max (See Performances Table)chekit9No ratings yet

- Series D1VW Characteristics: Directional Control ValveDocument8 pagesSeries D1VW Characteristics: Directional Control ValveFkrmcofmfmNo ratings yet

- Series D1MW Characteristics: Technical FeaturesDocument6 pagesSeries D1MW Characteristics: Technical FeaturesНикола КолаковићNo ratings yet

- Kv6/2-Way Directional ValvesDocument2 pagesKv6/2-Way Directional ValvesSaulo MoreiraNo ratings yet

- JCI Cataloge 2014Document60 pagesJCI Cataloge 2014KAZIMALI25No ratings yet

- Walvoil Cartridge Ventielen HICDocument20 pagesWalvoil Cartridge Ventielen HICddNo ratings yet

- D3W Stand - UKDocument8 pagesD3W Stand - UKYosmell Fritzan Paz UrbizagasteguiNo ratings yet

- Ec 1305 PDFDocument23 pagesEc 1305 PDFNguyen Van ChungNo ratings yet

- Atos HidraulicaDocument8 pagesAtos HidraulicaFabinhoTowerNo ratings yet

- Data JohnsonControlDocument233 pagesData JohnsonControlQuyết Nguyễn MạnhNo ratings yet

- ElectrovalvulasDocument8 pagesElectrovalvulasRaul Guevara TorresNo ratings yet

- Elettrovalvole Denison HydraulicsDocument62 pagesElettrovalvole Denison HydraulicsZMCONTROLNo ratings yet

- Parker D1VW Directional Control ValvesDocument13 pagesParker D1VW Directional Control ValvesCosma Petru-RaulNo ratings yet

- 3-En 2150-A - VV01Document5 pages3-En 2150-A - VV01mecambNo ratings yet

- Catalago PDFDocument12 pagesCatalago PDFGregory StewartNo ratings yet

- 19 102be PDFDocument6 pages19 102be PDFSani PoulouNo ratings yet

- D1SEDocument4 pagesD1SEMarcos BiegerNo ratings yet

- Moog D633Document16 pagesMoog D633Balu M100% (1)

- 4wre 6-10 Sew1xDocument12 pages4wre 6-10 Sew1x2267airportNo ratings yet

- Servovalve Andritz HydroDocument4 pagesServovalve Andritz HydroYhony Gamarra VargasNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Earth Potential RiseDocument5 pagesEarth Potential Risemyforum1No ratings yet

- 30RB-RQ Chiller Alarm CodeDocument3 pages30RB-RQ Chiller Alarm CodeSupol75% (4)

- Research, Design and Fabrication of 2.45 GHZ Microstrip Patch Antenna Arrays For Close-Range Wireless Power Transmission SystemsDocument5 pagesResearch, Design and Fabrication of 2.45 GHZ Microstrip Patch Antenna Arrays For Close-Range Wireless Power Transmission SystemsGiang PhạmNo ratings yet

- The BMW Active Hybrid X6Document58 pagesThe BMW Active Hybrid X6Paul100% (1)

- Electrical One Line Diag PDFDocument5 pagesElectrical One Line Diag PDFahs beinNo ratings yet

- EtherWAN M29060-A00 User ManualDocument177 pagesEtherWAN M29060-A00 User ManualJMAC SupplyNo ratings yet

- Electrical Safety For Qualified PersonDocument46 pagesElectrical Safety For Qualified Personanon_67491042No ratings yet

- Living Ring-Opening Metathesis PolymerizationDocument29 pagesLiving Ring-Opening Metathesis PolymerizationTiago Breve da SilvaNo ratings yet

- Vamp 57 Nrjed114608enDocument16 pagesVamp 57 Nrjed114608enqwertyui123321100% (1)

- Robots PDFDocument16 pagesRobots PDFMuthu KumaranNo ratings yet

- Gan Transistors For Efficient Power ConversionDocument3 pagesGan Transistors For Efficient Power ConversionMikhail LavrentyevNo ratings yet

- Digital Control System-1Document47 pagesDigital Control System-1Makesh MäKzNo ratings yet

- Timer 0Document2 pagesTimer 0andres felipe100% (1)

- Zenitel - VMP-430 - 1020603700 PDFDocument2 pagesZenitel - VMP-430 - 1020603700 PDFGlen Rix AlteradoNo ratings yet

- DH67GD DH67BL TechProdSpecDocument92 pagesDH67GD DH67BL TechProdSpecjagan2003No ratings yet

- Cathode Ray OscilloscopeDocument4 pagesCathode Ray OscilloscopesushilNo ratings yet

- Full Diagnostic Report: N/A N/A 08/10/2023 12:24:53Document2 pagesFull Diagnostic Report: N/A N/A 08/10/2023 12:24:53Costel CovaliNo ratings yet

- Instrumentation II (EX602)Document18 pagesInstrumentation II (EX602)Akashman ShakyaNo ratings yet

- Renewable Brochure en PDFDocument46 pagesRenewable Brochure en PDFandresboy123No ratings yet

- Comparison Matrix of VRF ManufacturersDocument3 pagesComparison Matrix of VRF Manufacturerszafar.ucNo ratings yet

- Chapter 16 - Motor Starting AnalysisDocument39 pagesChapter 16 - Motor Starting AnalysismasWIDINo ratings yet

- "Induction Generator": Gandhinagar Institute of TechnologyDocument14 pages"Induction Generator": Gandhinagar Institute of TechnologykamleshNo ratings yet

- 3070 Board Test Systems: System Installation Manual (MS Windows Version) June 2003Document116 pages3070 Board Test Systems: System Installation Manual (MS Windows Version) June 2003Miqueas PachecoNo ratings yet

- Computer FundamentalDocument19 pagesComputer Fundamentalredcard53No ratings yet

- ContactDocument65 pagesContactKhun Leang ChhunNo ratings yet

- Page 8 Report7Document39 pagesPage 8 Report7Akshay NaikNo ratings yet

- C To VHDL Converter in A Codesign Environment: June 1994Document11 pagesC To VHDL Converter in A Codesign Environment: June 1994Vivek SinghNo ratings yet

Series D1VW Characteristics: Directional Control Valve

Series D1VW Characteristics: Directional Control Valve

Uploaded by

juanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Series D1VW Characteristics: Directional Control Valve

Series D1VW Characteristics: Directional Control Valve

Uploaded by

juanCopyright:

Available Formats

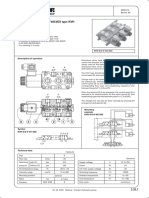

Directional Control Valve

Catalogue HY11-3500/UK

Series D1VW

Characteristics

The NG06 directional control valve series D1VW provides

high functional limits up to 80 l/min in combination with a

very low, energy-saving pressure drop.

A wide variety of spool options allows to design an unlimited number of hydraulic circuits.

Versions with 8 watt coils, position control, Atex approval,

surface protection and connector variants are shown in

the following chapters.

Technical data

General

Design

Actuation

Nominal size

Mounting interface

Mounting position

Ambient temperature

MTTFD value

Weight

Hydraulic

Max. operating pressure

Fluid

Fluid temperature

Viscosity permitted

Viscosity recommended

Filtration

Flow max.

Leakage at 50 bar

Static / Dynamic

Step response

Electrical characteristics

Directional spool valve

Solenoid

DIN NG06 / CETOP 03 / NFPA D03

DIN 24340 A6 / ISO 4401 / CETOP RP 121-H / NFPA D03

unrestricted, preferably horizontal

[C] -25...+50

[years] 150

[kg] 1.5 (1 solenoid), 2.1 (2 solenoids)

[bar] P, A, B: 350; T: 210 (DC), T: 140 (AC)

Hydraulic oil in accordance with DIN 51524 / 51525

[C] -25 ... +70

[cSt] / [mm/s] 2.8...400

[cSt] / [mm/s] 30...80

ISO 4406 (1999); 18/16/13 (meet NAS 1638: 7)

[l/min] 80 (see shift limits)

[ml/min] Up to 10 per flow path, depending on spool, up to 15 per flow path for spool type 008 + 009

see table response time

Duty ratio

Max. switching frequency

Protection class

100% ED; CAUTION: coil temperature up to 150 C possible

[1/h] 15000 (not for soft shift)

IP 65 in accordance with EN 60529 (with correctly mounted plug-in connector)

Code

K

J

U

G

Y

T

110V

at

50Hz/

230V

at

50Hz/

Supply voltage

[V]

12 V =

24 V =

98 V =

205 V =

120V at 60Hz 240V at 60Hz

Tolerance supply voltage

[%]

10

10

10

10

5

5

Current consumption hold

[A]

2.72

1.29

0.33

0.15

0.6 / 0.55

0.3 / 0.27

Current consumption in rush

[A]

2.72

1.29

0.33

0.15

2.5 / 2.4

1.25 / 1.2

Power consumption

hold

32.7 W

31 W

31.9 W

30.2 W

70 / 70 VA

70 / 70 VA

Power consumption

in rush

32.7 W

31 W

31.9 W

30.2 W

280 / 290 VA 280 / 290 VA

Solenoid connection

Connector as per EN 175301-803, solenoid identification as per ISO 9461 (code W).

Wiring min.

[mm] 3 x 1.5 recommended

Wiring length max.

[m] 50 recommended

With electrical connections the protective conductor (PE :) must be connected according to the relevant regulations.

D1VW UK.INDD RH 15.08.2011

2-7

Parker Hannifin Corporation

Hydraulics Group

Directional Control Valve

Catalogue HY11-3500/UK

Series D1VW

Ordering Code

Size 3-chamber Wet pin

Directional

armature

control DIN NG06 valve

CETOP 03

solenoid,

valve

NFPA D03

threaded

in tube

Spool

type

Spool

position

3 position spools

Code

001

002

Spool type

a

003

3 position spools

004

Code

Spool position

3 positions.

Spring offset in position 0.

Operated in position a or b.

005

006

Standard

007

008

009

Spool type 008,009,

204, 205

1)

1)

010

011

Operated in

position a.

Operated in

position b.

Spring offset in

Spring offset in

position b.

position a.

Operated in

position b.

Operated in

position a.

Spring offset in

Spring offset in

position a.

position b.

014

2 positions.

F

015

2 positions.

Spring offset in position 0.

Operated in position 0.

016

021

022

031

032

2 positions.

034

035

2 positions.

Spring offset in position 0.

Operated in position 0.

061

2 position spools

081

Code

082

102

204

1)

205

1)

020

a b

Spool type 083

2 position spools

Code

Spool position

Standard

Spool type

a

a b

2 positions.

Spring offset in position b.

Operated in position a.

2 positions.

Operated in position a or b.

No center or offset position.

2 positions.

Spring offset in position a.

Operated in position b.

026

030

083

1)

101

208

1)

Consider specific spool position.

D1VW UK.INDD RH 15.08.2011

2-8

Parker Hannifin Corporation

Hydraulics Group

Directional Control Valve

Catalogue HY11-3500/UK

Series D1VW

Ordering Code

W

Seals

Solenoid

voltage

Solenoid

Solenoid

connector as per option

EN 175301-803,

without plug

(other connectors

are available for

D1MW Series)

Design

series

(not required

for ordering)

Code

Solenoid option

Standard solenoid with

manual override

omit

T

without manual override

S2 3) Soft shift orifice size 0.5 mm.

S3 3) Soft shift orifice size 0.75 mm.

4N 3) with lockable manual override

3)

DC only

Code

Voltage

U 2)

G 2)

98V =

205V =

110V 50Hz /

120V 60Hz

230V 50Hz /

240V 60Hz

K

J

12V =

24V =

Y

T

2)

To be used in combination with

rectifier plugs at 120VAC / 230VAC

power supply.

Code

Seals

FPM

NBR

Further spool types, solenoid voltages and connectors on request.

D1VW UK.INDD RH 15.08.2011

2-9

Parker Hannifin Corporation

Hydraulics Group

Directional Control Valve

Catalogue HY11-3500/UK

Series D1VW

Flow Curve Diagram

Flow curve

14

24

10 9

13

8

7

20

6

5

16

11

12

Pressure drop [bar]

4

3

2

1

12

8

4

0

20

40

60

80

Flow [l/min]

All characteristic curves measured with HLP46 at 50C.

Spool

001

002

003

004

005

006

007

010

011

014

015

016

020B

026B

030B

034

035

081

082

101B

102

61

83H

104

208

008

009

83B

204

205

Spool

021

022

P-A

2

1

3

2

2

1

3

3

2

3

3

2

4

4

2

4

3

13

13

11

1

1

5

1

3

P-B

4

5

5

1

4

P-A

2

P-A

6

2

Position b

B-T

2

4

4

3

2

4

2

P-B

2

2

6

2

4

3

3

13

13

10

4

3

2

A-T

5

5

2

3

3

Position b

P-B

4

B-T

2

2

A-B

P-B

2

1

3

2

2

1

2

3

2

2

3

2

2

4

1

3

4

13

13

10

1

1

5

2

2

P-A

4

6

5

4

1

P-B

4

P-A

5

2

Position a

A-T

2

4

6

3

2

4

2

P-A

P-A

P-B

12

7

2

2

4

2

3

Position 0

A-T

B-T

P-T

5

7

7

7

3

2

14

2

14

5

7

7

5

13

13

9

4

3

2

5

1)

1)

5

3

5

2

B-T

5

7

2

3

3

P-A

7

12

2

3

14

P-B

A-T

14

B-T

P-T

9

7

Position a

A-T

2

P-B

2

A-B

1)

Only for pressure compensation,

no high flow possible.

D1VW UK.INDD RH 15.08.2011

2-10

Parker Hannifin Corporation

Hydraulics Group

7

5

Directional Control Valve

Catalogue HY11-3500/UK

Shift Limits

Series D1VW

The diagram below specifies the shift limits for valves with

DC solenoids. Valves with spool position F or M can

only be operated up to 70% of the limits. The specifications apply to a viscosity of 40mm2/s and balanced flow

conditions. The shift limits can be considerably lower at

unbalanced flow conditions. To avoid flow rates beyond

the shift limits, a plug-in orifice can be inserted in the

P-port.

Pressure [bar]

Pressure [bar]

Valve with standard DC solenoid

350

300

250

200

150

100

50

0

350

300

250

200

150

100

50

0

011

003, 004, 015

081

082

020, 030

021, 022

007, 008,

009, 014,

083

10

20

30

40

50

60

70

80

90

Flow [l/min]

001,002, 006

005, 016

010

026

10

20

30

40

50

60

70

Measured with HLP46 at 50C, 90% Unom and warm solenoids

90

80

Flow [l/min]

Pressure [bar]

Pressure [bar]

Valve with standard AC solenoid

350

300

250

200

150

100

50

0

350

300

250

200

150

100

50

0

005, 008,

016, 020

001

006, 030

004

002

007,

014, 081

026

20

30

10

101

082

10

20

005, 008,

016, 020

004

40

002

50

009,

011,

102

003, 015,

204, 205

30

60

70

80

90

Flow [l/min]

70

90

80

Flow [l/min]

010,021,

022

40

50

Measured with HLP46 at 50C, 95% Unom and warm solenoids

60

D1VW UK.INDD RH 15.08.2011

2-11

Parker Hannifin Corporation

Hydraulics Group

Directional Control Valve

Catalogue HY11-3500/UK

Series D1VW

Response Times

Supply pressure [bar]

Shift limit diagram - Soft shift with 1 DC solenoid

350

300

250

200

150

100

50

101

030

002,

020

10

20

009,

102

30

001, 004,

081

40

50

60

Supply pressure [bar]

Shift limit diagram - Soft shift with 2 DC solenoid

350

300

250

200

150

100

50

020D

10

002

20

081,

082

009

30

40

001,

004

50

60

Measured with HLP46 at 50C, 90% Unom and warm solenoids

Response times D1VW Standard and Soft Shift

Standard solenoid

Standard DC

Standard AC

Standard DC with rectifier plug

Response times

Soft Shift

Code

Orifice size

70

80

Flow [l/min]

70

80

Flow [l/min]

Orifice

Energize

De-energize

2 solenoid valve

3 positions

Center position: Closed

Energize

De-energize

2 solenoid valve

3 positions

Center position: Open

Energize

De-energize

1 solenoid valve

2 positions

w/o

w/o

w/o

45 - 60

13

60 -70

20 - 30

20

70- 90

Energize

S2

0.50mm

200 - 750

310 - 650

220 - 400

350 - 750

90 - 350

S3

0.75mm

180 - 300

300 - 400

200 - 350

300 - 500

90 - 350

The lower value applies to small flow rates and low pressure, the upper value to high flow rates and high pressure

De-energize

160 - 500

130 - 350

Step response times were obtained under the following conditions: HLP46 at 50C with the valve operating at nominal pressure and flow. Published

response times are nominal and may vary with spool, flow, pressure and temperature.

Acceleration for orifice size 0.75, code S3 (measured against a standard valve)

build-in orifice

For even softer shifting, the proportional spools 081, 082, 101 and 102 can be used.

D1VW UK.INDD RH 15.08.2011

2-12

Parker Hannifin Corporation

Hydraulics Group

Catalogue HY11-3500/UK

Directional Control Valve

Interface EN 175301-803, DC solenoid

B, E, F -style

H, K, M -style

Series D1VW

Dimensions

91.4

69

22

22

69

93

9.5

93

9.5

A B

5.5

A B

5.5

46

162

C, D -style

134.6

162

46

Option 4N, with lockable manual override

(available for all styles, DC only)

9.5

93

22

69

93

9.5

22

A B

5.5

91.4

226

119.4

46

Interface EN 175301-803, AC solenoid

B, E, F -style

A B

5.5

190

H, K, M -style

9.5

84

69.5

93.5

22

22

69.5

93.5

9.5

B

5.5

46

152

A B

5.5

127

152

46

C, D -style

22

69.5

93.5

9.5

84

B

5.5

211

46

Surface finish

BK375

4x M5x30

DIN 912 12.9

7.6 Nm

15%

NBR: SK-D1VW-N-91

FPM: SK-D1VW-V-91

The space necessary to remove the plug per EN 175301-803, design type AF is at least 15 mm.

The torque for the screw M3 of the plug has to be 0.5 to 0.6 Nm.

D1VW UK.INDD RH 15.08.2011

2-13

Parker Hannifin Corporation

Hydraulics Group

Catalogue HY11-3500/UK

Notes

2-14

Parker Hannifin Corporation

Hydraulics Group

Directional Control Valve

Catalogue HY11-3500/UK

Characteristics

Series D1VW 8 Watt

The D1VW 8 Watt series is based on the standard D1VW

design. The low watt, low current (<0.5 A) solenoid allows

direct connection to a PLC or a bus knot. The valves

are offered with standard solenoid connection (as per

EN175301-803) and M12 x 1 connection. The version

with M12 x 1 connection and LEDs are conform to the

DESINA standard (DistributEd and Standardised INstAllation technology) for machine tools and manufacturing

systems.

Technical data

General

Design

Actuation

Size

Mounting interface

Mounting position

Ambient temperature

MTTFD value

Weight

Hydraulic

Max. operating pressure

Fluid

Fluid temperature

Viscosity permitted

Viscosity recommended

Filtration

Flow max.

Leakage at 50 bar

Static / Dynamic

Step response at 95%

Electrical characteristics

Directional spool valve

Solenoid

DIN NG06 / CETOP 03 / NFPA D03

DIN 24340 A6 / ISO 4401 / CETOP RP 121-H / NFPA D03

unrestricted, preferably horizontal

[C] -25...+50

[years] 150

[kg] 1.5 (1 solenoid), 2.1 (2 solenoids)

[bar] P, A B: 350, T: 210

Hydraulic oil in accordance with DIN 51524 / 51525

[C] -25 ... +70

[cSt] / [mm/s] 2.8...400

[cSt] / [mm/s] 30...80

ISO 4406 (1999); 18/16/13 (meet NAS 1638: 7)

[l/min] 60 (see shift limits)

[ml/min] Up to 10 per flow path, depending on spool

[ms] Energized: 80...120; De-energized: 35...55

Duty ratio

Max. switching frequency

Protection class

100% ED; CAUTION: coil temperature up to 70 C possible

[1/h] 10000

IP 65 in acc. with EN 60529, M12x1 IP67 (each with correctly mounted plug-in connector)

Code J

Supply voltage

[V] 24 V =

Tolerance supply voltage

[%] 10

Current consumption

[A] 0.33

Power consumption

[W] 8

Solenoid connection

Connector as per EN 175301-803, solenoid identification as per ISO 9461 (code W).

Plug M12x1 on coil as per IEC 61076-2-101 (code D).

Wiring min.

[mm] 3 x 1.5 recommended

Wiring length max.

[m] 50 recommended

With electrical connections the protective conductor (PE :) must be connected according to the relevant regulations.

D1VW-8W UK.INDD RH 15.08.2011

2-15

Parker Hannifin Corporation

Hydraulics Group

You might also like

- Online Gaming in Context - The Social and Cultural Significance of Online GamesDocument158 pagesOnline Gaming in Context - The Social and Cultural Significance of Online GamesHeartFilthyLesson100% (1)

- Denison Hydraulics Proportional Pressure Control Valves: Series P2 & 4VP01Document12 pagesDenison Hydraulics Proportional Pressure Control Valves: Series P2 & 4VP01abuzer1981No ratings yet

- Sinamics G110Document14 pagesSinamics G110alperdaNo ratings yet

- Chapter 1 RQDocument3 pagesChapter 1 RQAb C100% (2)

- D1VW UkDocument8 pagesD1VW UksureshllsNo ratings yet

- Series D3MW Characteristics: FeaturesDocument6 pagesSeries D3MW Characteristics: FeaturesPdroGsus Abregú TerronesNo ratings yet

- Hidraulica, Compones, Partes, para Uso en La Oleodinamica (118) MDocument10 pagesHidraulica, Compones, Partes, para Uso en La Oleodinamica (118) Mcarlosmedina111No ratings yet

- D 631 Series ValvesDocument12 pagesD 631 Series ValvesJosé OlaveNo ratings yet

- ALISON HIDRAULIC - Catalogue PDFDocument250 pagesALISON HIDRAULIC - Catalogue PDFbaba0% (1)

- SolenoidDocument11 pagesSolenoidPoovanaan Sathiya Seelan100% (1)

- SD 11 eDocument12 pagesSD 11 eseaqu3stNo ratings yet

- Duplo MaticDocument8 pagesDuplo MaticHENRYGALLEGOSNo ratings yet

- Atos Industrial ValvesDocument22 pagesAtos Industrial ValvesM S GokulNo ratings yet

- Solenoid Directional Valves Dhe and Dher: Direct Operated, ISO 4401 Size 06Document4 pagesSolenoid Directional Valves Dhe and Dher: Direct Operated, ISO 4401 Size 06RFIGUEROACNo ratings yet

- Sds 150 eDocument16 pagesSds 150 ejbsb1No ratings yet

- DCV 03 hk66t102Document15 pagesDCV 03 hk66t102seaqu3stNo ratings yet

- Proportional Control Valves D631 Series ISO 4401 Size 05Document8 pagesProportional Control Valves D631 Series ISO 4401 Size 05Devendra BangarNo ratings yet

- Functional Description: HA 5115 8/2005 Proportional Directional Control ValvesDocument19 pagesFunctional Description: HA 5115 8/2005 Proportional Directional Control ValvesgatodeftoneNo ratings yet

- Moog ServovalvesDocument8 pagesMoog Servovalvesdylan_dearing@hotmail.com100% (1)

- Re29061 4WREEDocument18 pagesRe29061 4WREEManuel VizcarraNo ratings yet

- 9 - 3RH, 3TH Contactor Realys PDFDocument6 pages9 - 3RH, 3TH Contactor Realys PDFsaina124796010No ratings yet

- Vickers DG4V-3 DG4V-3S 6xDocument32 pagesVickers DG4V-3 DG4V-3S 6xCarlos Javier Torrico BarreroNo ratings yet

- Series D1VW Characteristics: Directional Control ValveDocument8 pagesSeries D1VW Characteristics: Directional Control ValveJas SumNo ratings yet

- Rexroth FDDocument116 pagesRexroth FDIvan GudeljNo ratings yet

- DSG ValvesDocument17 pagesDSG ValvesChris RoederNo ratings yet

- SD 16 eDocument20 pagesSD 16 eseaqu3stNo ratings yet

- SD 25 eDocument20 pagesSD 25 eseaqu3stNo ratings yet

- ATOSs Valves DHI-0711Document4 pagesATOSs Valves DHI-0711Cardoso MalacaoNo ratings yet

- DSV 100 34TRDocument2 pagesDSV 100 34TRsgfdrfNo ratings yet

- SD 6 eDocument16 pagesSD 6 eseaqu3stNo ratings yet

- Rexroth电磁阀手册Document12 pagesRexroth电磁阀手册davidwang85120% (1)

- PARKER Valvula Direccional D3W UKDocument7 pagesPARKER Valvula Direccional D3W UKComassur SA de CVNo ratings yet

- 62 SeriesDocument8 pages62 SeriesDevendra BangarNo ratings yet

- Electrohydraulic: Solenoid ValvesDocument16 pagesElectrohydraulic: Solenoid ValvesluisbottonNo ratings yet

- MIL Control Valve Specification and Sizing CalculationDocument34 pagesMIL Control Valve Specification and Sizing CalculationRahulTewari67% (3)

- SD 5 eDocument12 pagesSD 5 eseaqu3stNo ratings yet

- fp50 fp100 fp200Document10 pagesfp50 fp100 fp200ducmanh83No ratings yet

- Ev DG05Document14 pagesEv DG05mtbecerrapNo ratings yet

- HVAC+Valves+and+Actuators+Catalogue+07 2011Document64 pagesHVAC+Valves+and+Actuators+Catalogue+07 2011Jafar JalladNo ratings yet

- 4/2-And 4/3 - Proportional Directional Valves Direct Operated, Type 4WRA, Series 1XDocument8 pages4/2-And 4/3 - Proportional Directional Valves Direct Operated, Type 4WRA, Series 1XlizbethdiosesNo ratings yet

- Series 10 Subplate Mounting ISO 4401-03 (CETOP 03) P Max: Bar Max (See Performances Table)Document4 pagesSeries 10 Subplate Mounting ISO 4401-03 (CETOP 03) P Max: Bar Max (See Performances Table)chekit9No ratings yet

- Series D1VW Characteristics: Directional Control ValveDocument8 pagesSeries D1VW Characteristics: Directional Control ValveFkrmcofmfmNo ratings yet

- Series D1MW Characteristics: Technical FeaturesDocument6 pagesSeries D1MW Characteristics: Technical FeaturesНикола КолаковићNo ratings yet

- Kv6/2-Way Directional ValvesDocument2 pagesKv6/2-Way Directional ValvesSaulo MoreiraNo ratings yet

- JCI Cataloge 2014Document60 pagesJCI Cataloge 2014KAZIMALI25No ratings yet

- Walvoil Cartridge Ventielen HICDocument20 pagesWalvoil Cartridge Ventielen HICddNo ratings yet

- D3W Stand - UKDocument8 pagesD3W Stand - UKYosmell Fritzan Paz UrbizagasteguiNo ratings yet

- Ec 1305 PDFDocument23 pagesEc 1305 PDFNguyen Van ChungNo ratings yet

- Atos HidraulicaDocument8 pagesAtos HidraulicaFabinhoTowerNo ratings yet

- Data JohnsonControlDocument233 pagesData JohnsonControlQuyết Nguyễn MạnhNo ratings yet

- ElectrovalvulasDocument8 pagesElectrovalvulasRaul Guevara TorresNo ratings yet

- Elettrovalvole Denison HydraulicsDocument62 pagesElettrovalvole Denison HydraulicsZMCONTROLNo ratings yet

- Parker D1VW Directional Control ValvesDocument13 pagesParker D1VW Directional Control ValvesCosma Petru-RaulNo ratings yet

- 3-En 2150-A - VV01Document5 pages3-En 2150-A - VV01mecambNo ratings yet

- Catalago PDFDocument12 pagesCatalago PDFGregory StewartNo ratings yet

- 19 102be PDFDocument6 pages19 102be PDFSani PoulouNo ratings yet

- D1SEDocument4 pagesD1SEMarcos BiegerNo ratings yet

- Moog D633Document16 pagesMoog D633Balu M100% (1)

- 4wre 6-10 Sew1xDocument12 pages4wre 6-10 Sew1x2267airportNo ratings yet

- Servovalve Andritz HydroDocument4 pagesServovalve Andritz HydroYhony Gamarra VargasNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Earth Potential RiseDocument5 pagesEarth Potential Risemyforum1No ratings yet

- 30RB-RQ Chiller Alarm CodeDocument3 pages30RB-RQ Chiller Alarm CodeSupol75% (4)

- Research, Design and Fabrication of 2.45 GHZ Microstrip Patch Antenna Arrays For Close-Range Wireless Power Transmission SystemsDocument5 pagesResearch, Design and Fabrication of 2.45 GHZ Microstrip Patch Antenna Arrays For Close-Range Wireless Power Transmission SystemsGiang PhạmNo ratings yet

- The BMW Active Hybrid X6Document58 pagesThe BMW Active Hybrid X6Paul100% (1)

- Electrical One Line Diag PDFDocument5 pagesElectrical One Line Diag PDFahs beinNo ratings yet

- EtherWAN M29060-A00 User ManualDocument177 pagesEtherWAN M29060-A00 User ManualJMAC SupplyNo ratings yet

- Electrical Safety For Qualified PersonDocument46 pagesElectrical Safety For Qualified Personanon_67491042No ratings yet

- Living Ring-Opening Metathesis PolymerizationDocument29 pagesLiving Ring-Opening Metathesis PolymerizationTiago Breve da SilvaNo ratings yet

- Vamp 57 Nrjed114608enDocument16 pagesVamp 57 Nrjed114608enqwertyui123321100% (1)

- Robots PDFDocument16 pagesRobots PDFMuthu KumaranNo ratings yet

- Gan Transistors For Efficient Power ConversionDocument3 pagesGan Transistors For Efficient Power ConversionMikhail LavrentyevNo ratings yet

- Digital Control System-1Document47 pagesDigital Control System-1Makesh MäKzNo ratings yet

- Timer 0Document2 pagesTimer 0andres felipe100% (1)

- Zenitel - VMP-430 - 1020603700 PDFDocument2 pagesZenitel - VMP-430 - 1020603700 PDFGlen Rix AlteradoNo ratings yet

- DH67GD DH67BL TechProdSpecDocument92 pagesDH67GD DH67BL TechProdSpecjagan2003No ratings yet

- Cathode Ray OscilloscopeDocument4 pagesCathode Ray OscilloscopesushilNo ratings yet

- Full Diagnostic Report: N/A N/A 08/10/2023 12:24:53Document2 pagesFull Diagnostic Report: N/A N/A 08/10/2023 12:24:53Costel CovaliNo ratings yet

- Instrumentation II (EX602)Document18 pagesInstrumentation II (EX602)Akashman ShakyaNo ratings yet

- Renewable Brochure en PDFDocument46 pagesRenewable Brochure en PDFandresboy123No ratings yet

- Comparison Matrix of VRF ManufacturersDocument3 pagesComparison Matrix of VRF Manufacturerszafar.ucNo ratings yet

- Chapter 16 - Motor Starting AnalysisDocument39 pagesChapter 16 - Motor Starting AnalysismasWIDINo ratings yet

- "Induction Generator": Gandhinagar Institute of TechnologyDocument14 pages"Induction Generator": Gandhinagar Institute of TechnologykamleshNo ratings yet

- 3070 Board Test Systems: System Installation Manual (MS Windows Version) June 2003Document116 pages3070 Board Test Systems: System Installation Manual (MS Windows Version) June 2003Miqueas PachecoNo ratings yet

- Computer FundamentalDocument19 pagesComputer Fundamentalredcard53No ratings yet

- ContactDocument65 pagesContactKhun Leang ChhunNo ratings yet

- Page 8 Report7Document39 pagesPage 8 Report7Akshay NaikNo ratings yet

- C To VHDL Converter in A Codesign Environment: June 1994Document11 pagesC To VHDL Converter in A Codesign Environment: June 1994Vivek SinghNo ratings yet