Professional Documents

Culture Documents

Vapour Absorption Refrigeration

Vapour Absorption Refrigeration

Uploaded by

muthuCopyright:

Available Formats

You might also like

- Fire Alarm System - PresentationDocument19 pagesFire Alarm System - PresentationJaleel Desionics100% (2)

- Daikin Service Manual 8 PDFDocument120 pagesDaikin Service Manual 8 PDFgmlud100% (1)

- AIR BLOWERS Calculation-of-Air-Pipe-SizeDocument7 pagesAIR BLOWERS Calculation-of-Air-Pipe-SizeEngFaisal Alrai100% (3)

- Assignment On RefrigerationDocument11 pagesAssignment On RefrigerationRinta Moon100% (6)

- Refrigeration Moran Shapiro Solution ManualDocument10 pagesRefrigeration Moran Shapiro Solution ManualNovaCastilloNo ratings yet

- Vapour Absorption Refrigeration SystemDocument26 pagesVapour Absorption Refrigeration SystemRushikesh Dandagwhal100% (8)

- Basic Civil and Mechanical Engineering Unit V Refrigeration and Airconditioning Support NotesDocument9 pagesBasic Civil and Mechanical Engineering Unit V Refrigeration and Airconditioning Support NotesA.R. Pradeep Kumar100% (1)

- Vapor Absorption Refrigeration CycleDocument11 pagesVapor Absorption Refrigeration CycleUSHA PAWARNo ratings yet

- Vapour AbsorptionDocument15 pagesVapour AbsorptionSatheesh ChandranNo ratings yet

- Vapor Absorption SystemsDocument17 pagesVapor Absorption SystemsTalibHussainNo ratings yet

- Subcooling Superheating and Liquid Suction Heat ExchangerDocument4 pagesSubcooling Superheating and Liquid Suction Heat ExchangerDeniell Joyce MarquezNo ratings yet

- Ques 1Document6 pagesQues 1ANKIT KUMAR0% (1)

- R&AC Lecture 36Document25 pagesR&AC Lecture 36jadasaripNo ratings yet

- Rac Solution Set BDocument12 pagesRac Solution Set BxofigoNo ratings yet

- CH 3 Gas Refrigeration CycleDocument20 pagesCH 3 Gas Refrigeration CycleMeleseNo ratings yet

- Vapor Compression Cycle: Problems: DR Rabia ShaukatDocument35 pagesVapor Compression Cycle: Problems: DR Rabia ShaukatHafiz AbdulrehmanNo ratings yet

- Lecture 30 Thermal Engineering II (22.09.2020)Document36 pagesLecture 30 Thermal Engineering II (22.09.2020)Dr. BIBIN CHIDAMBARANATHANNo ratings yet

- M8 - Vapor Absorption RefrDocument29 pagesM8 - Vapor Absorption RefrAbraham KhaleedNo ratings yet

- RAC First Assignment 2019-20 - VI SemesterDocument7 pagesRAC First Assignment 2019-20 - VI Semesterkollan manivardhan reddyNo ratings yet

- Rac Lab ManualDocument36 pagesRac Lab ManualAftab Alam100% (2)

- Lecture 1 Refrigerating Machine Reversed Carnot Cycle Simple Vapor Compression CycleDocument14 pagesLecture 1 Refrigerating Machine Reversed Carnot Cycle Simple Vapor Compression CycleDeniell Joyce MarquezNo ratings yet

- Multi Pressure SystemDocument56 pagesMulti Pressure SystemAndrew PantaleonNo ratings yet

- Methods of DefrostingDocument13 pagesMethods of DefrostingPranav Acharya100% (1)

- Vapour AbsorptionDocument10 pagesVapour Absorptiongayakwad12_ramNo ratings yet

- Refrigeration Midterm Exam ###Document3 pagesRefrigeration Midterm Exam ###Patience LastyNo ratings yet

- Refrigeration Engineering PDFDocument85 pagesRefrigeration Engineering PDFanilkumarNo ratings yet

- Lecture-17: Multi-Stage Vapour Compression Refrigeration SystemsDocument13 pagesLecture-17: Multi-Stage Vapour Compression Refrigeration SystemsMuhaamad TiloNo ratings yet

- Air Refrigeration SystemDocument29 pagesAir Refrigeration SystemSumit KumarNo ratings yet

- 3-Multipressure Systems PDFDocument17 pages3-Multipressure Systems PDFjamkzieNo ratings yet

- Refrigeration Cycles Real Vapor Compression CycleDocument9 pagesRefrigeration Cycles Real Vapor Compression CyclePaul RodgersNo ratings yet

- Fluid MachineriesDocument49 pagesFluid MachineriesRafael Nazareno RivadeneiraNo ratings yet

- Ref Review ProblemsDocument3 pagesRef Review ProblemsGiancarlo SantosNo ratings yet

- Air Conditioning Systems Experiment: ProposalDocument16 pagesAir Conditioning Systems Experiment: ProposalShaktivell Letchumanan100% (1)

- Module 5 (Psychrometric Processes)Document19 pagesModule 5 (Psychrometric Processes)Shirley PelagioNo ratings yet

- Multi Pressure SystemsDocument14 pagesMulti Pressure SystemsDeepakNo ratings yet

- Refrigeration and Air ConditioningDocument24 pagesRefrigeration and Air ConditioningUtsav ParsanaNo ratings yet

- Design and Analysis of Central Air-Conditioning System With Air Cooled Chiller of Multi-Storey Office BuildingDocument16 pagesDesign and Analysis of Central Air-Conditioning System With Air Cooled Chiller of Multi-Storey Office BuildingSajjad HasanNo ratings yet

- Quality of Refrigerant ThermodynamicsDocument8 pagesQuality of Refrigerant ThermodynamicsPokemon BhalooNo ratings yet

- Experiment No. 1Document4 pagesExperiment No. 1subhamgupta7495100% (1)

- Innovative Vapor CompressionDocument13 pagesInnovative Vapor CompressionCj MoLanoNo ratings yet

- Ref Lec-2 (CH 4-5) PDFDocument45 pagesRef Lec-2 (CH 4-5) PDFمحمد متوليNo ratings yet

- Actual Vapor Compression Refrigeration Cycle Part 1Document12 pagesActual Vapor Compression Refrigeration Cycle Part 1jjNo ratings yet

- Air Cycle RefrigerationDocument15 pagesAir Cycle RefrigerationSyed Wajih Ul HassanNo ratings yet

- Steam Jet Refrigeration SystemDocument3 pagesSteam Jet Refrigeration Systematulyajyoti123100% (1)

- Chapter 5-Compounded Vapor Compression Cyclee-ExamplesDocument65 pagesChapter 5-Compounded Vapor Compression Cyclee-Examplesm_alodat6144100% (1)

- Refrigeration and Air ConditioningDocument52 pagesRefrigeration and Air ConditioningRavichandran GNo ratings yet

- Refrigeration SystemDocument37 pagesRefrigeration Systemdeepakdshenoy100% (1)

- Refrigeration CycleDocument85 pagesRefrigeration CycleNeha MiracleNo ratings yet

- Homework SteamDocument6 pagesHomework SteamCherry May Basinang-RamosNo ratings yet

- Rac Lab ManualDocument30 pagesRac Lab ManualPrakharGupta100% (1)

- Steam Turbine PowerpointDocument25 pagesSteam Turbine PowerpointD.P. MishraNo ratings yet

- Performance and Efficiency Test of A Refrigeration Plant (Lecture)Document56 pagesPerformance and Efficiency Test of A Refrigeration Plant (Lecture)Anonymous xjV1llZS75% (4)

- Untitled 12Document20 pagesUntitled 12Jehana NaolNo ratings yet

- Air Refrigeration CycleDocument16 pagesAir Refrigeration Cyclesuraj singhNo ratings yet

- Window - Air - Conditioning - Test - Rig Lab ManualDocument6 pagesWindow - Air - Conditioning - Test - Rig Lab ManualSandeep Saini100% (1)

- 18.multistage Systems and Cascade SystemsDocument9 pages18.multistage Systems and Cascade SystemsericNo ratings yet

- Simple Vapour Compression Refrigeration System: Advantages of Air RefrigerationDocument17 pagesSimple Vapour Compression Refrigeration System: Advantages of Air RefrigerationNikhil WaghalkarNo ratings yet

- RefrigerantDocument59 pagesRefrigerantObula Reddy KNo ratings yet

- Vapour Absorption Refrigeration Test RigDocument7 pagesVapour Absorption Refrigeration Test RigSwapnil DeyNo ratings yet

- Vapour Absorption SystemDocument5 pagesVapour Absorption Systemhwaj100% (1)

- Chapter 3 RACDocument26 pagesChapter 3 RACSameer AhmadNo ratings yet

- Unit IvDocument39 pagesUnit IvKalyan KalapalaNo ratings yet

- Refrigeration and Air ConditioningDocument9 pagesRefrigeration and Air ConditioningLuis Enrique Cervantes DominguezNo ratings yet

- RefrigrantsDocument41 pagesRefrigrantsmuthuNo ratings yet

- " We Architects - . Make Achitects - . ": Sample Set - 1Document1 page" We Architects - . Make Achitects - . ": Sample Set - 1muthuNo ratings yet

- Receipt of House RentDocument1 pageReceipt of House RentmuthuNo ratings yet

- GasDocument3 pagesGasmuthuNo ratings yet

- Characteristics of Turbulent FlowDocument30 pagesCharacteristics of Turbulent FlowmuthuNo ratings yet

- EquationsDocument3 pagesEquationsmuthuNo ratings yet

- BoilingDocument65 pagesBoilingmuthu100% (1)

- Cashclick Concepts: Please Choose One PlanDocument3 pagesCashclick Concepts: Please Choose One PlanmuthuNo ratings yet

- Gpa CalculatorDocument6 pagesGpa CalculatormuthuNo ratings yet

- Thermodynamics Competative QuestionsDocument2 pagesThermodynamics Competative QuestionsmuthuNo ratings yet

- Ec 2255 Control Systems 3 0 0 3Document4 pagesEc 2255 Control Systems 3 0 0 3muthuNo ratings yet

- I Year Cse-A SL - No Roll No Student NameDocument44 pagesI Year Cse-A SL - No Roll No Student NamemuthuNo ratings yet

- Lesson Plan: Unit SyllabusDocument6 pagesLesson Plan: Unit SyllabusmuthuNo ratings yet

- Anna University CHENNAI - 600 025: (Details To Be Typed)Document2 pagesAnna University CHENNAI - 600 025: (Details To Be Typed)muthuNo ratings yet

- Principles of CarburetionDocument39 pagesPrinciples of CarburetionmuthuNo ratings yet

- Energy ManagementDocument9 pagesEnergy Managementhasan_jafri_2No ratings yet

- Tarea 4.2Document2 pagesTarea 4.2Manuel Saez SellerNo ratings yet

- MEP SyllabusDocument5 pagesMEP SyllabushazihappyNo ratings yet

- C QuestionsDocument52 pagesC Questionsnasrqazi590No ratings yet

- Product Guide Duham - Bush 2013Document16 pagesProduct Guide Duham - Bush 2013Gamaliel Efren Santibañez RomeroNo ratings yet

- Datasheet PHEDocument11 pagesDatasheet PHEStefano BarbieriNo ratings yet

- D 746 - 98 - Rdc0ni1sruqDocument11 pagesD 746 - 98 - Rdc0ni1sruqMiguel Angel Perez EsparzaNo ratings yet

- Lab Report 9Document5 pagesLab Report 9mamoona noreenNo ratings yet

- Johnson 2017 PDFDocument240 pagesJohnson 2017 PDFbk2 dingoNo ratings yet

- Design of A 30K Single-Stage Free-Piston Stirling CryocoolerDocument8 pagesDesign of A 30K Single-Stage Free-Piston Stirling Cryocoolerpooriya zamaniNo ratings yet

- Air - Conditioning System With Electronic Regulatio... - Passat - 4motion - Santana (PA) (EUROPA 2013 Year)Document5 pagesAir - Conditioning System With Electronic Regulatio... - Passat - 4motion - Santana (PA) (EUROPA 2013 Year)Ovidiu VranceanuNo ratings yet

- DCMM Maintenance 2015 CoolingDocument1 pageDCMM Maintenance 2015 CoolingHarumNo ratings yet

- Ch3 TransientConductionEquationDocument20 pagesCh3 TransientConductionEquationAbhinash KumarNo ratings yet

- Evaporation: Isohyetal MethodDocument9 pagesEvaporation: Isohyetal MethodAnonymous aE0YYlCOKNo ratings yet

- Air Coolers Versus Shell-And-Tube Water CoolersDocument8 pagesAir Coolers Versus Shell-And-Tube Water CoolersBramJanssen76100% (1)

- HVAC - Energy Saving Case Study of A High RiseDocument8 pagesHVAC - Energy Saving Case Study of A High RisearkishineNo ratings yet

- VRF Pros and ConsDocument9 pagesVRF Pros and ConsRoshan ThamarakshanNo ratings yet

- Design and Analysis of Steam Turbine Rotor: M. Chandra Sekhar ReddyDocument7 pagesDesign and Analysis of Steam Turbine Rotor: M. Chandra Sekhar ReddyPinank PatelNo ratings yet

- Literature Supplement: Form No.: 160.00-M1 (LS03) 801Document2 pagesLiterature Supplement: Form No.: 160.00-M1 (LS03) 801Azar TajNo ratings yet

- Laser Flash MethodDocument11 pagesLaser Flash MethodKaitlyn NicholasNo ratings yet

- HES SERIES (High Efficiency) TUBE-ICE MACHINEDocument2 pagesHES SERIES (High Efficiency) TUBE-ICE MACHINEJosé Ernesto Sánchez VergaraNo ratings yet

- Lab Manual EBMV3103Document13 pagesLab Manual EBMV3103VOON KIN ONNNo ratings yet

- Modeling For Shell-Side Pressure Drop For Liquid Flow in Shell-And-Tube Heat ExchangerDocument10 pagesModeling For Shell-Side Pressure Drop For Liquid Flow in Shell-And-Tube Heat ExchangerAhmad Restian Adi NugrohoNo ratings yet

- Weber TriangleDocument1 pageWeber TriangleDavid BellelNo ratings yet

- Skid Mounted Unit InstallationDocument2 pagesSkid Mounted Unit Installationric leonisoNo ratings yet

- Thermocouple Type T TableDocument0 pagesThermocouple Type T TableMark SloanNo ratings yet

Vapour Absorption Refrigeration

Vapour Absorption Refrigeration

Uploaded by

muthuOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vapour Absorption Refrigeration

Vapour Absorption Refrigeration

Uploaded by

muthuCopyright:

Available Formats

11/22/2014

1

DR.A.M.SURENDRA KUMAR

INTRODUCTION

The major drawback of the vapour compression refrigeration

system is that it requires large volume of refrigerant vapour

which requires large mechanical power for its operation.

If some

methods are used to reduce this volume before

compression, there would be considerable reduction in weight

of the system and power requirement for its operation.

Heat energy can be used instead of work for producing

refrigeration because it gives high COP of the system with

machine operated with supply of work energy.

The absorption system differs fundamentally from vapour

compression system only in the method of employed for

compressing the refrigerant.

In the absorption system, the compressor is replaced by an

absorber, generator and a pump.

A French Scientist Ferdinand Cane developed the first

absorption refrigeration machine in early 1860.

Nowadays, units are developed upto 1500 tons capacity.

The units which are generally used for air conditioning

purposes are available from 100 tons capacity .

PRINCIPLE OF ABSORPTIN SYSTEM

There is the peculiar property of some substances to have

affinity for another substances at some temperature and

pressure conditions and less affinity at another conditions.

This idea for the working principle of a vapour absorption

system was generated by Michael Faraday in 1824.

He knew that silver chloride (AgCl)m a white powder , had a

property of absorbing large amount of ammonia gas at the

normal temperature and pressure.

Two chambers are combined with the help of a tube.

The white powder was kept inside the first chamber to which ammonia

gas was supplied and sealed.

The powder was heated up while other end was cooled using circulating

water.

Liquid ammonia was obtained in the cool end of the apparatus. After

stopping heat, it was observed that, the liquid ammonia instead of sitting

there, started boiling( bubbles produced) and vapour was reabsorbed by

the white powder.

Upon touching the boiling end , it was astonished to find that the vessel

was very cold.

He repeated the experiments and cooling was observed again.

This led to invention of the intermittent Vapour absorption system

having solid as an absorber.

REFRIGERANT ABSORBER PAIRS

REFRIGERANT

ABSORBER

STATE OF ABSORBER

AMMONIA

WATER

LIQUID

AMMONIA

SODIUMTHIOCYNATE

SOLID

AMMONIA

LITHIUM NITRATE

SOLID

AMMONIA

CALCIUM CHLORIDE

SOLID

AMMONIA

ISOBUTANE

SOLID

WATER

LITHIUM BROMIDE

SOLID

WATER

LITHIUM CHLORIDE

SOLID

METHYL

CHLORIDE

DIMETHYL ETHER OF TETRA

ETHYLENE GLYCOL

LIQUID

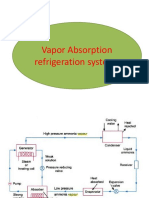

SIMPLE ABSORPTION SYSTEM

The basic absorption cycle employs two fluids, the absorbate or refrigerant,

and the absorbent.

The most commonly fluids are Water/Ammonia as the refrigerant and lithium

bromide/ water as the absorbent.

These fluids are separated and recombined in the absorption cycle.

In the absorption cycle the low-pressure refrigerant vapor is absorbed into

the absorbent releasing a large amount of heat.

The liquid refrigerant/absorbent solution is pumped to a high-operating

pressure generator using significantly less electricity than that for

compressing the refrigerant for an electric chiller.

Heat is added at the high-pressure generator from a gas burner, steam, hot

water or hot gases.

The added heat causes the refrigerant to desorbs from the absorbent and

vaporize..

The vapors flow to a condenser, where heat is rejected and

condense to a high-pressure liquid.

The liquid is then throttled though an expansion valve to the lower

pressure in the evaporator where it evaporates by absorbing heat

and provides useful cooling.

The remaining liquid absorbent, in the generator passes through a

valve, where its pressure is reduced, and then is recombined with

the low-pressure refrigerant vapors returning from the evaporator so

the cycle can be repeated.

Absorption Refrigeration Systems

Another form of refrigeration that becomes economically

attractive when there is a source of inexpensive heat energy at a

temperature of 100 to 200oC is absorption refrigeration, where the

refrigerant is absorbed by a transport medium and compressed in

liquid form. The most widely used absorption refrigeration system

is the ammonia-water system, where am-monia serves as the

refrigerant and water as the transport medium. The work input to

the pump is usually very small, and the COP of absorption

refriger-ation systems is defined as

Desired output Cooling effect

QL

QL

COPR

Required input Work input Qgen Wpump ,in Qgen

AMMONIA-WATER ABSORPTION REFRIGERATION SYSTEM

In this,

Ammonia is used as Refrigerant and Water as an Absorber.

The aqua ammonia (ammonia+Water)

from the absorber at

temperature, Ta is pumped into the generator at temperature, Tg.

The heat transfer to the Generator leads to the separation

of

ammonia vapour from aqua ammonia leaving behind the weak aqua

solution.

The weak aqua solution returns back to the absorber

through a

properly adjusted expansion valve. V.

On the other hand, the ammonia vapour condense in a heat

exchanger at a temperature, Ta. The liquid ammonia is throttled to

the evaporator

pressure where heat transfer from cold chamber

causes vaporization of the refrigerant.

ACTUAL AMMONIA-WATER ABSORPTION SYSTEM

ELECTROLUX REFRIGERATOR

LITHIUM- BROMIDE WATER VAPOUR ABSORPTION SYSTEM

Animation of a Direct-Fired Double-Effect Absorpton Chiller

Department of Energy.

Advantages over Vapour compression system

As there is no moving parts in the entire system, the operation

is essentially quiet and subjected to a very little wear, so that

the maintenance cost is low.

The pump motor is quite small compared with the compressor

motor.

Vapour absorption system is used the thermal energy, they

can be used in places, where electric power is hard to obtain.

Absorption unit can be built in capacities well above 1000 tons

Space requirement is less.

You might also like

- Fire Alarm System - PresentationDocument19 pagesFire Alarm System - PresentationJaleel Desionics100% (2)

- Daikin Service Manual 8 PDFDocument120 pagesDaikin Service Manual 8 PDFgmlud100% (1)

- AIR BLOWERS Calculation-of-Air-Pipe-SizeDocument7 pagesAIR BLOWERS Calculation-of-Air-Pipe-SizeEngFaisal Alrai100% (3)

- Assignment On RefrigerationDocument11 pagesAssignment On RefrigerationRinta Moon100% (6)

- Refrigeration Moran Shapiro Solution ManualDocument10 pagesRefrigeration Moran Shapiro Solution ManualNovaCastilloNo ratings yet

- Vapour Absorption Refrigeration SystemDocument26 pagesVapour Absorption Refrigeration SystemRushikesh Dandagwhal100% (8)

- Basic Civil and Mechanical Engineering Unit V Refrigeration and Airconditioning Support NotesDocument9 pagesBasic Civil and Mechanical Engineering Unit V Refrigeration and Airconditioning Support NotesA.R. Pradeep Kumar100% (1)

- Vapor Absorption Refrigeration CycleDocument11 pagesVapor Absorption Refrigeration CycleUSHA PAWARNo ratings yet

- Vapour AbsorptionDocument15 pagesVapour AbsorptionSatheesh ChandranNo ratings yet

- Vapor Absorption SystemsDocument17 pagesVapor Absorption SystemsTalibHussainNo ratings yet

- Subcooling Superheating and Liquid Suction Heat ExchangerDocument4 pagesSubcooling Superheating and Liquid Suction Heat ExchangerDeniell Joyce MarquezNo ratings yet

- Ques 1Document6 pagesQues 1ANKIT KUMAR0% (1)

- R&AC Lecture 36Document25 pagesR&AC Lecture 36jadasaripNo ratings yet

- Rac Solution Set BDocument12 pagesRac Solution Set BxofigoNo ratings yet

- CH 3 Gas Refrigeration CycleDocument20 pagesCH 3 Gas Refrigeration CycleMeleseNo ratings yet

- Vapor Compression Cycle: Problems: DR Rabia ShaukatDocument35 pagesVapor Compression Cycle: Problems: DR Rabia ShaukatHafiz AbdulrehmanNo ratings yet

- Lecture 30 Thermal Engineering II (22.09.2020)Document36 pagesLecture 30 Thermal Engineering II (22.09.2020)Dr. BIBIN CHIDAMBARANATHANNo ratings yet

- M8 - Vapor Absorption RefrDocument29 pagesM8 - Vapor Absorption RefrAbraham KhaleedNo ratings yet

- RAC First Assignment 2019-20 - VI SemesterDocument7 pagesRAC First Assignment 2019-20 - VI Semesterkollan manivardhan reddyNo ratings yet

- Rac Lab ManualDocument36 pagesRac Lab ManualAftab Alam100% (2)

- Lecture 1 Refrigerating Machine Reversed Carnot Cycle Simple Vapor Compression CycleDocument14 pagesLecture 1 Refrigerating Machine Reversed Carnot Cycle Simple Vapor Compression CycleDeniell Joyce MarquezNo ratings yet

- Multi Pressure SystemDocument56 pagesMulti Pressure SystemAndrew PantaleonNo ratings yet

- Methods of DefrostingDocument13 pagesMethods of DefrostingPranav Acharya100% (1)

- Vapour AbsorptionDocument10 pagesVapour Absorptiongayakwad12_ramNo ratings yet

- Refrigeration Midterm Exam ###Document3 pagesRefrigeration Midterm Exam ###Patience LastyNo ratings yet

- Refrigeration Engineering PDFDocument85 pagesRefrigeration Engineering PDFanilkumarNo ratings yet

- Lecture-17: Multi-Stage Vapour Compression Refrigeration SystemsDocument13 pagesLecture-17: Multi-Stage Vapour Compression Refrigeration SystemsMuhaamad TiloNo ratings yet

- Air Refrigeration SystemDocument29 pagesAir Refrigeration SystemSumit KumarNo ratings yet

- 3-Multipressure Systems PDFDocument17 pages3-Multipressure Systems PDFjamkzieNo ratings yet

- Refrigeration Cycles Real Vapor Compression CycleDocument9 pagesRefrigeration Cycles Real Vapor Compression CyclePaul RodgersNo ratings yet

- Fluid MachineriesDocument49 pagesFluid MachineriesRafael Nazareno RivadeneiraNo ratings yet

- Ref Review ProblemsDocument3 pagesRef Review ProblemsGiancarlo SantosNo ratings yet

- Air Conditioning Systems Experiment: ProposalDocument16 pagesAir Conditioning Systems Experiment: ProposalShaktivell Letchumanan100% (1)

- Module 5 (Psychrometric Processes)Document19 pagesModule 5 (Psychrometric Processes)Shirley PelagioNo ratings yet

- Multi Pressure SystemsDocument14 pagesMulti Pressure SystemsDeepakNo ratings yet

- Refrigeration and Air ConditioningDocument24 pagesRefrigeration and Air ConditioningUtsav ParsanaNo ratings yet

- Design and Analysis of Central Air-Conditioning System With Air Cooled Chiller of Multi-Storey Office BuildingDocument16 pagesDesign and Analysis of Central Air-Conditioning System With Air Cooled Chiller of Multi-Storey Office BuildingSajjad HasanNo ratings yet

- Quality of Refrigerant ThermodynamicsDocument8 pagesQuality of Refrigerant ThermodynamicsPokemon BhalooNo ratings yet

- Experiment No. 1Document4 pagesExperiment No. 1subhamgupta7495100% (1)

- Innovative Vapor CompressionDocument13 pagesInnovative Vapor CompressionCj MoLanoNo ratings yet

- Ref Lec-2 (CH 4-5) PDFDocument45 pagesRef Lec-2 (CH 4-5) PDFمحمد متوليNo ratings yet

- Actual Vapor Compression Refrigeration Cycle Part 1Document12 pagesActual Vapor Compression Refrigeration Cycle Part 1jjNo ratings yet

- Air Cycle RefrigerationDocument15 pagesAir Cycle RefrigerationSyed Wajih Ul HassanNo ratings yet

- Steam Jet Refrigeration SystemDocument3 pagesSteam Jet Refrigeration Systematulyajyoti123100% (1)

- Chapter 5-Compounded Vapor Compression Cyclee-ExamplesDocument65 pagesChapter 5-Compounded Vapor Compression Cyclee-Examplesm_alodat6144100% (1)

- Refrigeration and Air ConditioningDocument52 pagesRefrigeration and Air ConditioningRavichandran GNo ratings yet

- Refrigeration SystemDocument37 pagesRefrigeration Systemdeepakdshenoy100% (1)

- Refrigeration CycleDocument85 pagesRefrigeration CycleNeha MiracleNo ratings yet

- Homework SteamDocument6 pagesHomework SteamCherry May Basinang-RamosNo ratings yet

- Rac Lab ManualDocument30 pagesRac Lab ManualPrakharGupta100% (1)

- Steam Turbine PowerpointDocument25 pagesSteam Turbine PowerpointD.P. MishraNo ratings yet

- Performance and Efficiency Test of A Refrigeration Plant (Lecture)Document56 pagesPerformance and Efficiency Test of A Refrigeration Plant (Lecture)Anonymous xjV1llZS75% (4)

- Untitled 12Document20 pagesUntitled 12Jehana NaolNo ratings yet

- Air Refrigeration CycleDocument16 pagesAir Refrigeration Cyclesuraj singhNo ratings yet

- Window - Air - Conditioning - Test - Rig Lab ManualDocument6 pagesWindow - Air - Conditioning - Test - Rig Lab ManualSandeep Saini100% (1)

- 18.multistage Systems and Cascade SystemsDocument9 pages18.multistage Systems and Cascade SystemsericNo ratings yet

- Simple Vapour Compression Refrigeration System: Advantages of Air RefrigerationDocument17 pagesSimple Vapour Compression Refrigeration System: Advantages of Air RefrigerationNikhil WaghalkarNo ratings yet

- RefrigerantDocument59 pagesRefrigerantObula Reddy KNo ratings yet

- Vapour Absorption Refrigeration Test RigDocument7 pagesVapour Absorption Refrigeration Test RigSwapnil DeyNo ratings yet

- Vapour Absorption SystemDocument5 pagesVapour Absorption Systemhwaj100% (1)

- Chapter 3 RACDocument26 pagesChapter 3 RACSameer AhmadNo ratings yet

- Unit IvDocument39 pagesUnit IvKalyan KalapalaNo ratings yet

- Refrigeration and Air ConditioningDocument9 pagesRefrigeration and Air ConditioningLuis Enrique Cervantes DominguezNo ratings yet

- RefrigrantsDocument41 pagesRefrigrantsmuthuNo ratings yet

- " We Architects - . Make Achitects - . ": Sample Set - 1Document1 page" We Architects - . Make Achitects - . ": Sample Set - 1muthuNo ratings yet

- Receipt of House RentDocument1 pageReceipt of House RentmuthuNo ratings yet

- GasDocument3 pagesGasmuthuNo ratings yet

- Characteristics of Turbulent FlowDocument30 pagesCharacteristics of Turbulent FlowmuthuNo ratings yet

- EquationsDocument3 pagesEquationsmuthuNo ratings yet

- BoilingDocument65 pagesBoilingmuthu100% (1)

- Cashclick Concepts: Please Choose One PlanDocument3 pagesCashclick Concepts: Please Choose One PlanmuthuNo ratings yet

- Gpa CalculatorDocument6 pagesGpa CalculatormuthuNo ratings yet

- Thermodynamics Competative QuestionsDocument2 pagesThermodynamics Competative QuestionsmuthuNo ratings yet

- Ec 2255 Control Systems 3 0 0 3Document4 pagesEc 2255 Control Systems 3 0 0 3muthuNo ratings yet

- I Year Cse-A SL - No Roll No Student NameDocument44 pagesI Year Cse-A SL - No Roll No Student NamemuthuNo ratings yet

- Lesson Plan: Unit SyllabusDocument6 pagesLesson Plan: Unit SyllabusmuthuNo ratings yet

- Anna University CHENNAI - 600 025: (Details To Be Typed)Document2 pagesAnna University CHENNAI - 600 025: (Details To Be Typed)muthuNo ratings yet

- Principles of CarburetionDocument39 pagesPrinciples of CarburetionmuthuNo ratings yet

- Energy ManagementDocument9 pagesEnergy Managementhasan_jafri_2No ratings yet

- Tarea 4.2Document2 pagesTarea 4.2Manuel Saez SellerNo ratings yet

- MEP SyllabusDocument5 pagesMEP SyllabushazihappyNo ratings yet

- C QuestionsDocument52 pagesC Questionsnasrqazi590No ratings yet

- Product Guide Duham - Bush 2013Document16 pagesProduct Guide Duham - Bush 2013Gamaliel Efren Santibañez RomeroNo ratings yet

- Datasheet PHEDocument11 pagesDatasheet PHEStefano BarbieriNo ratings yet

- D 746 - 98 - Rdc0ni1sruqDocument11 pagesD 746 - 98 - Rdc0ni1sruqMiguel Angel Perez EsparzaNo ratings yet

- Lab Report 9Document5 pagesLab Report 9mamoona noreenNo ratings yet

- Johnson 2017 PDFDocument240 pagesJohnson 2017 PDFbk2 dingoNo ratings yet

- Design of A 30K Single-Stage Free-Piston Stirling CryocoolerDocument8 pagesDesign of A 30K Single-Stage Free-Piston Stirling Cryocoolerpooriya zamaniNo ratings yet

- Air - Conditioning System With Electronic Regulatio... - Passat - 4motion - Santana (PA) (EUROPA 2013 Year)Document5 pagesAir - Conditioning System With Electronic Regulatio... - Passat - 4motion - Santana (PA) (EUROPA 2013 Year)Ovidiu VranceanuNo ratings yet

- DCMM Maintenance 2015 CoolingDocument1 pageDCMM Maintenance 2015 CoolingHarumNo ratings yet

- Ch3 TransientConductionEquationDocument20 pagesCh3 TransientConductionEquationAbhinash KumarNo ratings yet

- Evaporation: Isohyetal MethodDocument9 pagesEvaporation: Isohyetal MethodAnonymous aE0YYlCOKNo ratings yet

- Air Coolers Versus Shell-And-Tube Water CoolersDocument8 pagesAir Coolers Versus Shell-And-Tube Water CoolersBramJanssen76100% (1)

- HVAC - Energy Saving Case Study of A High RiseDocument8 pagesHVAC - Energy Saving Case Study of A High RisearkishineNo ratings yet

- VRF Pros and ConsDocument9 pagesVRF Pros and ConsRoshan ThamarakshanNo ratings yet

- Design and Analysis of Steam Turbine Rotor: M. Chandra Sekhar ReddyDocument7 pagesDesign and Analysis of Steam Turbine Rotor: M. Chandra Sekhar ReddyPinank PatelNo ratings yet

- Literature Supplement: Form No.: 160.00-M1 (LS03) 801Document2 pagesLiterature Supplement: Form No.: 160.00-M1 (LS03) 801Azar TajNo ratings yet

- Laser Flash MethodDocument11 pagesLaser Flash MethodKaitlyn NicholasNo ratings yet

- HES SERIES (High Efficiency) TUBE-ICE MACHINEDocument2 pagesHES SERIES (High Efficiency) TUBE-ICE MACHINEJosé Ernesto Sánchez VergaraNo ratings yet

- Lab Manual EBMV3103Document13 pagesLab Manual EBMV3103VOON KIN ONNNo ratings yet

- Modeling For Shell-Side Pressure Drop For Liquid Flow in Shell-And-Tube Heat ExchangerDocument10 pagesModeling For Shell-Side Pressure Drop For Liquid Flow in Shell-And-Tube Heat ExchangerAhmad Restian Adi NugrohoNo ratings yet

- Weber TriangleDocument1 pageWeber TriangleDavid BellelNo ratings yet

- Skid Mounted Unit InstallationDocument2 pagesSkid Mounted Unit Installationric leonisoNo ratings yet

- Thermocouple Type T TableDocument0 pagesThermocouple Type T TableMark SloanNo ratings yet