Professional Documents

Culture Documents

06 Plan&p

06 Plan&p

Uploaded by

tga0 ratings0% found this document useful (0 votes)

30 views3 pagesThe document outlines control objectives and risk issues for planning and production control. The objectives are to ensure that (1) production requirements are accurately determined, authorized, and planned for; (2) adequate facilities and resources are available on time; and (3) the required quantity and quality of products are manufactured efficiently while complying with relevant regulations. Key risks include inaccurate or unauthorized production requirements, inadequate communication or resource planning, quality or compliance issues, and inefficient utilization of production facilities and resources. The document identifies specific control issues in each of these areas that management must address.

Original Description:

Original Title

06plan&p

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document outlines control objectives and risk issues for planning and production control. The objectives are to ensure that (1) production requirements are accurately determined, authorized, and planned for; (2) adequate facilities and resources are available on time; and (3) the required quantity and quality of products are manufactured efficiently while complying with relevant regulations. Key risks include inaccurate or unauthorized production requirements, inadequate communication or resource planning, quality or compliance issues, and inefficient utilization of production facilities and resources. The document identifies specific control issues in each of these areas that management must address.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0 ratings0% found this document useful (0 votes)

30 views3 pages06 Plan&p

06 Plan&p

Uploaded by

tgaThe document outlines control objectives and risk issues for planning and production control. The objectives are to ensure that (1) production requirements are accurately determined, authorized, and planned for; (2) adequate facilities and resources are available on time; and (3) the required quantity and quality of products are manufactured efficiently while complying with relevant regulations. Key risks include inaccurate or unauthorized production requirements, inadequate communication or resource planning, quality or compliance issues, and inefficient utilization of production facilities and resources. The document identifies specific control issues in each of these areas that management must address.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 3

Planning and Production Control

Control Objectives for Planning and Production Control

(a) To ensure that production and manufacturing requirements are accurately

determined, authorised, effectively communicated and suitably planned for;

(b) To ensure that adequate facilities and resources are made available at the

appropriate time in order to meet the agreed production and manufacturing

obligations;

(c) To ensure that the required quantity of products is manufactured to the

required quality standards;

(d) To ensure that the actions of all affected departments and functions are

adequately coordinated to achieve the defined objectives;

(e) To ensure that production resources and facilities are efficiently utilised

and that waste is avoided/minimised;

(f) To ensure that the necessary production equipment is fully operational

and operated efficiently;

(g) To ensure that production staff are suitably trained and experienced in

order to maximise their contribution;

(h) To ensure that production downtime is minimised, suitably monitored and

reacted to;

(i) To ensure that all materials, resources and finished goods are accurately

accounted for;

(j) Ensure that production activities are effectively monitored, reported to

management and shortfalls and problems are promptly detected and resolved;

(k) To ensure that all relevant legislation, Health & Safety and other

regulations are complied with; and

(l) To ensure that actual production plant efficiency and performance are

adequately monitored for management information and action.

Risk and Control Issues for Planning and Production Control

1 Key Issues

1.1 How can management be assured that the production and

manufacturing requirements are accurately defined and suitably

authorised?

1.2 What mechanisms ensure that authorised production/manufacturing

requirements are effectively communicated to all affected parties, and that

suitable plans are agreed and implemented to meet the defined obligations?

1.3 What processes ensure that all the required resources and facilities

(i.e. materials, staff, machines, knowledge, etc.) are available to meet the

required production obligations?

1.4 How can management be assured that actual progress and use of

production facilities are effectively monitored and that problems, shortfalls

and delays would be promptly detected and corrected?

1.5 What measures ensure that the required quantity of products is

actually manufactured and accounted for?

1.6 How can management be sure that the items produced conform to

the required quality standards, and are defect rates effectively monitored?

1.7 What measures have management taken to minimise and avoid

disruption of production caused by machine breakdown, poorly experienced

staff, and absence of raw materials and components?

1.8 Is the utilisation of all resources (materials and workforce) fully

accounted for and would waste be promptly identified and appropriate

action taken? (How is this evidenced?).

1.9 Are management kept informed of overall production performance

and efficiency, and what evidence is there of corrective action being taken to

address shortcomings, etc.?

1.10 What mechanisms ensure that compliance with all the prevailing

legislation and regulations is confirmed?

2 Detailed Issues

2.1 Are all amendments to customer orders, production requirements,

forecasts, etc. promptly and accurately identified and reported in order to modify

the relevant production activities?

2.2 What measures are in place to ensure that adequate and accurate

information flows are established for all affected parties?

2.3 How would uneconomic or unrealistic production runs be prevented?

2.4 How would unauthorised production activity be prevented or identified?

2.5 How can management be certain that the practical manufacturing

implications of new product lines have been identified, assessed and planned for?

2.6 Are plant utilisation records maintained and would surplus capacity be

identified and reacted to?

2.7 How can management be assured that the layout of the production line

maximises efficiency and avoids unnecessary movements and processes?

2.8 What processes ensure the correct flow of raw materials to the production

area?

2.9 Are materials and components adequately protected from loss and

damage in the production areas?

2.10 What steps are taken to avoid/minimise machine failures and downtime?

2.11 Is downtime recorded, attributed and effectively monitored by

management (and how is this evidenced)?

2.12 What mechanisms ensure that the skills of the workforce are adequately

maintained in line with the current requirements?

2.13 Are staff skills suitably balanced to provide adequate cover during

holidays, etc.?

2.14 Would production delays be promptly detected?

2.15 Are all finished goods accounted for and trailed into the stock control

system?

2.16 Are all damaged, spoilt, scrap and rejected items identified, authorised and

accounted for?

2.17 How can management be assured that all production activities are

accurately costed and that reliable product costings are generated?

2.18 Would uneconomic products/production runs be prevented or promptly

detected?

2.19 Are machine utilisation and performance statistics accurately produced,

circulated and reacted to?

2.20 Are employee productivity levels effectively monitored?

2.21 Does management periodically evaluate the adequacy of production

facilities?

2.22 How does management confirm compliance with all the relevant Heath

and Safety regulations?

2.23 How does management ensure that their awareness of the relevant

regulations is up-to-date and complete?

2.24 How would violations of regulations be detected?

2.25 Have realistic and workable contingency and disaster plans been

established, and are they regularly tested for their effectiveness?

2.26 How is the accuracy of data input from other systems (i.e. Sales Orders,

Planning, etc.) confirmed?

2.27 How is the accuracy of data output to other systems (i.e. Time recording

to payroll, Product Accounting, etc.) confirmed?

You might also like

- ABM-BUSINESS ETHICS - SOCIAL RESPONSIBILITY 12 - Q1 - W1 - Mod1 PDFDocument18 pagesABM-BUSINESS ETHICS - SOCIAL RESPONSIBILITY 12 - Q1 - W1 - Mod1 PDFHannah Joy Lontayao84% (19)

- Cost Control ManualDocument34 pagesCost Control Manualtga67% (3)

- Internal Audit Checklist ProductionDocument9 pagesInternal Audit Checklist Productiondhir.ankur100% (3)

- The 22 Immutable Laws of Marketing SummaryDocument10 pagesThe 22 Immutable Laws of Marketing SummaryDaniel RomeroNo ratings yet

- Basic Accounting Concepts and Case StudiesDocument114 pagesBasic Accounting Concepts and Case Studiesgajiniece429No ratings yet

- 07 FaciliDocument3 pages07 FacilitgaNo ratings yet

- 14 MaintDocument3 pages14 MainttgaNo ratings yet

- 08 PersonDocument2 pages08 PersontgaNo ratings yet

- 09 Mat&enDocument4 pages09 Mat&entgaNo ratings yet

- 45 PlantDocument2 pages45 PlanttgaNo ratings yet

- PPCDocument19 pagesPPCAnchuNo ratings yet

- 44 ProjecDocument2 pages44 ProjectgaNo ratings yet

- 46dev PRDocument2 pages46dev PRtgaNo ratings yet

- 15prod DDocument3 pages15prod DtgaNo ratings yet

- 27 SpareDocument2 pages27 SparetgaNo ratings yet

- 26 MaintDocument3 pages26 MainttgaNo ratings yet

- Auditing Business Process Part 2 Slides.Document44 pagesAuditing Business Process Part 2 Slides.Lindsay RegalaNo ratings yet

- 10 QualitDocument2 pages10 QualittgaNo ratings yet

- 40 H&safeDocument3 pages40 H&safetgaNo ratings yet

- Production Risk StudyDocument8 pagesProduction Risk StudySenthilmani MuthuswamyNo ratings yet

- Unit - 1Document148 pagesUnit - 1Dhamotharan SNo ratings yet

- BuildingDocument11 pagesBuildingA OmairaNo ratings yet

- Form - Job Description - Supervisor ProductionDocument7 pagesForm - Job Description - Supervisor ProductionYudhi LesmanaNo ratings yet

- 32 HumanDocument3 pages32 HumantgaNo ratings yet

- Production Planning AND Production ControlDocument21 pagesProduction Planning AND Production ControlIsheanesu HungweNo ratings yet

- 8.1-2 Handover Management Measures (AT-HSSE-P-8-02V0-2022 Release)Document8 pages8.1-2 Handover Management Measures (AT-HSSE-P-8-02V0-2022 Release)Geyko RuslanNo ratings yet

- R&DProduct DevelopmentDocument14 pagesR&DProduct DevelopmentmufidanNo ratings yet

- PomDocument8 pagesPomtanuNo ratings yet

- 31 WareDocument3 pages31 WaretgaNo ratings yet

- Warehousing & Storage ChecklistDocument3 pagesWarehousing & Storage ChecklistGayan WeligallaNo ratings yet

- GMP Audit ChecklistDocument4 pagesGMP Audit ChecklistMohamad IsmailNo ratings yet

- 25 WarranDocument2 pages25 WarrantgaNo ratings yet

- Chapters PDFDocument54 pagesChapters PDFAbhishek SainiNo ratings yet

- Nisha - PPCDocument59 pagesNisha - PPCBabu RajNo ratings yet

- Steps in Production PlanningDocument12 pagesSteps in Production PlanningriteshvijhNo ratings yet

- QA Unit 1Document24 pagesQA Unit 1Abhishek SharmaNo ratings yet

- Unit 4 Notes (PM) by SSDocument24 pagesUnit 4 Notes (PM) by SSupadhyaypriyam.50No ratings yet

- PBL Session 4 - Production CycleDocument5 pagesPBL Session 4 - Production CycleSITI NURHIDAYAH BINTI AZMEENo ratings yet

- Module V - Operations Management: Dr.A.Abirami / OmDocument10 pagesModule V - Operations Management: Dr.A.Abirami / OmBalujagadishNo ratings yet

- EMC 4512 Planning and ControlDocument14 pagesEMC 4512 Planning and Controlstephen mwendwaNo ratings yet

- Steps in Production Planning & ControlDocument4 pagesSteps in Production Planning & ControlrohitpkNo ratings yet

- Understanding of Operations Management Learning Objectives: Summing Up Self-AssessmentDocument7 pagesUnderstanding of Operations Management Learning Objectives: Summing Up Self-Assessmentraj_tgfNo ratings yet

- Sem-6 BA CH-7 - CompressedDocument26 pagesSem-6 BA CH-7 - CompressednothingtoseethisNo ratings yet

- Production Planning and ControlDocument42 pagesProduction Planning and ControlVishwaMohanNo ratings yet

- Homework IndestrialDocument6 pagesHomework IndestrialMahmud L. MusaNo ratings yet

- Unit 1 - 15 Marks, ModerateDocument2 pagesUnit 1 - 15 Marks, ModerateBipul VermaNo ratings yet

- Sy - Bcom CP Sem 4Document14 pagesSy - Bcom CP Sem 4Akki GalaNo ratings yet

- TOPIC-III-Intro-to-IE 17Document16 pagesTOPIC-III-Intro-to-IE 17Princess joy De RuedaNo ratings yet

- GMP+FSA Ts-1-1-Prerequisite-ProgrammeDocument18 pagesGMP+FSA Ts-1-1-Prerequisite-ProgrammeAri arsiyantiNo ratings yet

- Maintenance EngineeringDocument15 pagesMaintenance EngineeringAswinNo ratings yet

- Audit Checklist: Audit Question S MR MN C Comments Clause 3.1: Management ResponsibilityDocument8 pagesAudit Checklist: Audit Question S MR MN C Comments Clause 3.1: Management ResponsibilityASMIDA BINTI SYAMSIDINo ratings yet

- Roles Responsibilities FerozpurDocument4 pagesRoles Responsibilities FerozpurRahul SunilNo ratings yet

- Production Management: Directorate of Distance Education Guru Jambheshwar University HISAR-125001Document218 pagesProduction Management: Directorate of Distance Education Guru Jambheshwar University HISAR-125001Ashish KumarNo ratings yet

- Mes JDDocument3 pagesMes JDJunaid AliNo ratings yet

- SWP 03 Heavy EquipmentDocument7 pagesSWP 03 Heavy Equipmentমমিন মানব100% (1)

- Production ManagementDocument218 pagesProduction ManagementGaneshNo ratings yet

- Production Planning & Control-AbridgedDocument21 pagesProduction Planning & Control-AbridgedShanky Jain100% (1)

- Production Planning and ControlDocument34 pagesProduction Planning and ControlAkanksha RanjanNo ratings yet

- PRODUCTION - and - MATERIAL - MANAGEMENT - 2nd - B.B.ADocument7 pagesPRODUCTION - and - MATERIAL - MANAGEMENT - 2nd - B.B.ANoah JonesNo ratings yet

- Designation: Assistant Manager - Production Reporting To: Senior Manager - ProductionDocument5 pagesDesignation: Assistant Manager - Production Reporting To: Senior Manager - Productionvishal9patel-63No ratings yet

- 1-Interview Guide - Facility Manager GSDocument21 pages1-Interview Guide - Facility Manager GSgeorges succarNo ratings yet

- ISO 22000 - PrerequisisteDocument3 pagesISO 22000 - PrerequisisteMarlon OlpindoNo ratings yet

- Apparel Production Planning and Control Assignment 1 PDFDocument28 pagesApparel Production Planning and Control Assignment 1 PDFvigtex2No ratings yet

- Practical Guide To Production Planning & Control [Revised Edition]From EverandPractical Guide To Production Planning & Control [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- 00title 03 Wiring Diagram ESCAPE-LHDDocument33 pages00title 03 Wiring Diagram ESCAPE-LHDtga100% (1)

- Title 08MY J87 01 Product GuideDocument39 pagesTitle 08MY J87 01 Product GuidetgaNo ratings yet

- 01title 03 Wiring Diagram ESCAPE-LHDDocument53 pages01title 03 Wiring Diagram ESCAPE-LHDtgaNo ratings yet

- 03title 03 Wiring Diagram ESCAPE-LHDDocument3 pages03title 03 Wiring Diagram ESCAPE-LHDtgaNo ratings yet

- 09title 03 Wiring Diagram ESCAPE-LHDDocument103 pages09title 03 Wiring Diagram ESCAPE-LHDtga100% (1)

- Sp-Rm-Bu-A064-Peak Hrs Floor Standby-SrsDocument2 pagesSp-Rm-Bu-A064-Peak Hrs Floor Standby-SrstgaNo ratings yet

- 08title 03 Wiring Diagram ESCAPE-LHDDocument5 pages08title 03 Wiring Diagram ESCAPE-LHDtgaNo ratings yet

- Sp-Rm-Bu-A045-Handling Request For Confirmation of Airline Tickets-SrsDocument3 pagesSp-Rm-Bu-A045-Handling Request For Confirmation of Airline Tickets-SrstgaNo ratings yet

- SP RM Bu A061 Handlingextrabed SrsDocument2 pagesSP RM Bu A061 Handlingextrabed SrstgaNo ratings yet

- Audit Matrix Program - Revenue: Test Area: Management ReportingDocument4 pagesAudit Matrix Program - Revenue: Test Area: Management ReportingtgaNo ratings yet

- Sp-Rm-Bu-A066-Courtesy Call To Next Day's Due Out Gst-SrsDocument2 pagesSp-Rm-Bu-A066-Courtesy Call To Next Day's Due Out Gst-SrstgaNo ratings yet

- Sp-Rm-Bu-A053-How To Handle Maintenance Problems-SrsDocument3 pagesSp-Rm-Bu-A053-How To Handle Maintenance Problems-SrstgaNo ratings yet

- Sp-Rm-Bu-A060-How To Handle DDocument2 pagesSp-Rm-Bu-A060-How To Handle DtgaNo ratings yet

- Sp-Rm-Bu-A057-Vip Check-In-SrsDocument2 pagesSp-Rm-Bu-A057-Vip Check-In-SrstgaNo ratings yet

- Sp-Rm-Bu-A058-Butler Information Whiteboard-SrsDocument1 pageSp-Rm-Bu-A058-Butler Information Whiteboard-SrstgaNo ratings yet

- Sp-Rm-Bu-A056-How To Handle Room Change Request-SrsDocument2 pagesSp-Rm-Bu-A056-How To Handle Room Change Request-SrstgaNo ratings yet

- Sp-Rm-Bu-A052-How To Handle A Request of Sexual Content-SrsDocument2 pagesSp-Rm-Bu-A052-How To Handle A Request of Sexual Content-SrstgaNo ratings yet

- Sp-Rm-Bu-A047-How To Packingunpacking A Guest Luggage-SrsDocument2 pagesSp-Rm-Bu-A047-How To Packingunpacking A Guest Luggage-SrstgaNo ratings yet

- Sp-Rm-Bu-A034-Teamwork and Cooperation-SrsDocument3 pagesSp-Rm-Bu-A034-Teamwork and Cooperation-SrstgaNo ratings yet

- SP RM Bu A051 Howtosetupwelcomefruit SrsDocument2 pagesSP RM Bu A051 Howtosetupwelcomefruit SrstgaNo ratings yet

- Sp-Rm-Bu-A040-Handling Request For Business Center-SrsDocument2 pagesSp-Rm-Bu-A040-Handling Request For Business Center-SrstgaNo ratings yet

- Sp-Rm-Bu-A042-Handling Request For Reception-SrsDocument2 pagesSp-Rm-Bu-A042-Handling Request For Reception-SrstgaNo ratings yet

- Sp-Rm-Bu-A035-Requesing Assistance With Associates-SrsDocument2 pagesSp-Rm-Bu-A035-Requesing Assistance With Associates-SrstgaNo ratings yet

- Sp-Rm-Bu-A041-Handlingrequest Forconceirge-SrsDocument2 pagesSp-Rm-Bu-A041-Handlingrequest Forconceirge-SrstgaNo ratings yet

- Sp-Rm-Bu-A043-Handling Request For Fitness Center-SrsDocument3 pagesSp-Rm-Bu-A043-Handling Request For Fitness Center-SrstgaNo ratings yet

- Sp-Rm-Bu-A033-Supervision of Room Attendants-SrsDocument2 pagesSp-Rm-Bu-A033-Supervision of Room Attendants-SrstgaNo ratings yet

- Sp-Rm-Bu-A032-Collect Guests Needs & Preferences-SrsDocument2 pagesSp-Rm-Bu-A032-Collect Guests Needs & Preferences-SrstgaNo ratings yet

- Sp-Rm-Bu-A031-Anticipation of Gts Needs-SrsDocument2 pagesSp-Rm-Bu-A031-Anticipation of Gts Needs-SrstgaNo ratings yet

- SP RM Bu A030 Organize&cleanlinesspantryroom SrsDocument2 pagesSP RM Bu A030 Organize&cleanlinesspantryroom SrstgaNo ratings yet

- Retail Solutions GuideDocument16 pagesRetail Solutions Guideapi-264384207No ratings yet

- Management Accounting Monday 3-6 Sir Fahim QaziDocument21 pagesManagement Accounting Monday 3-6 Sir Fahim QaziMuhammad Hamza AijaziNo ratings yet

- Part Submission WarrantDocument1 pagePart Submission WarrantMahes kumarNo ratings yet

- Ipsas 1 Presentation of F 3Document64 pagesIpsas 1 Presentation of F 3Ng Mei YeeNo ratings yet

- Mba International Business 2018Document113 pagesMba International Business 2018RãmãKrîshñã RãmNo ratings yet

- ICT Application To Technical Report Writing, RecordDocument14 pagesICT Application To Technical Report Writing, Recordanon_230653802100% (1)

- AlleppeyDocument2 pagesAlleppeyVidya Adsule100% (1)

- Quality StandardsDocument15 pagesQuality Standardsmandelaria0150% (2)

- 6 Steps To Write MBA ThesisDocument3 pages6 Steps To Write MBA ThesisRexMichael1226No ratings yet

- The Sale of Goods Act-LectureDocument11 pagesThe Sale of Goods Act-LectureAmar ChauhanNo ratings yet

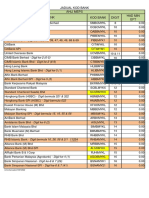

- JADUAL KOD BANK TERKINI (Kemaskini 10012022)Document1 pageJADUAL KOD BANK TERKINI (Kemaskini 10012022)DygKuNormarzuraNo ratings yet

- Responsibility Accounting and Transfer PricingDocument68 pagesResponsibility Accounting and Transfer PricingMari Louis Noriell MejiaNo ratings yet

- FMCGDocument39 pagesFMCGANKITA NAIRNo ratings yet

- Cce Freshers AccountDocument2 pagesCce Freshers AccountABUDUAOA KOOA9WNo ratings yet

- Insurance Pres 1Document26 pagesInsurance Pres 1sujata dawadiNo ratings yet

- LTO V City of ButuanDocument2 pagesLTO V City of ButuanAriel LunzagaNo ratings yet

- Or, Deposit Slip and Withdrawl SlipDocument4 pagesOr, Deposit Slip and Withdrawl SlipJessica Rose AlbaracinNo ratings yet

- COA PresentationDocument19 pagesCOA PresentationJim B Punz100% (1)

- Adoption of E-CommerceDocument35 pagesAdoption of E-CommerceRajivparaj 李瑞杰0% (1)

- Insurance Capsule For LIC ADO ExDocument10 pagesInsurance Capsule For LIC ADO ExSIVA KRISHNA PRASAD ARJANo ratings yet

- Issue Log Summary 31 DEC 2015 v1Document48 pagesIssue Log Summary 31 DEC 2015 v1ahmed_sftNo ratings yet

- Practice Problem - LeasesDocument2 pagesPractice Problem - LeasesNitinNo ratings yet

- CB Insights Global Unicorn Club 2021Document80 pagesCB Insights Global Unicorn Club 2021ДарьяNo ratings yet

- 5rd Sessiom - Audit of LeaseDocument20 pages5rd Sessiom - Audit of LeaseRUFFA SANCHEZNo ratings yet

- Cau Hỏi Vấn Đáp Logistics-VT-2Document2 pagesCau Hỏi Vấn Đáp Logistics-VT-2Adornable ShopNo ratings yet

- Mohammad Abu Taher: Apply For: QA/QC (Senior Piping Welding Inspector) Personal DetailsDocument10 pagesMohammad Abu Taher: Apply For: QA/QC (Senior Piping Welding Inspector) Personal DetailsRajkumar ANo ratings yet

- IMC Project State Bank of IndiaDocument18 pagesIMC Project State Bank of IndiaRinni Shukla0% (1)

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-1-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)