Professional Documents

Culture Documents

GD&T Training Pyramid

GD&T Training Pyramid

Uploaded by

dramiltOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GD&T Training Pyramid

GD&T Training Pyramid

Uploaded by

dramiltCopyright:

Available Formats

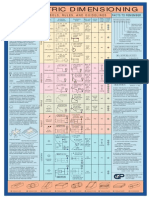

GD&T TRAINING LEVELS

Workshops and Services from Effective Training

Services

SYSTEM

APPROACH

TO

COMPONENT

TOLERANCING

www.etinews.com

Prerequisites:

Adv. Concepts/Applications

For product development teams,

product engineers, designers

/A

na

lys

is

Ap

pli

ca

tio

n

Co

re

Co

m

pe

t

en

c ie

- Systems thinking for component tolerancing

- A process for converting product requirements

into component tolerances

MENTORING / CONSULTING

TOLERANCE

STACKS

Prerequisite: Adv. Concepts

For individuals who create or

interpret engineering drawings

- Calculate tolerance stacks

- Analyze cumulative effect of

tolerances

- Show how to account for GD&T

in tolerance stacks

STATISTICAL

TOLERANCE STACKS

Prerequisite: Tolerance Stacks

For design, layout, assembly,

checking and inspection teams

- Calculate statistical tolerance stacks

- RSS, realistic, RPL, and Monte

Carlo methods

MENTORING / CONSULTING

GD&T APPLICATIONS USING COMPANY DRAWINGS

Prerequisite(s): GD&T Fundamentals (Preferred Advanced Concepts)

For design, layout, assembly, checking, and inspection teams

Interpret GD&T applications; analyze drawing requirements; discuss inspection approach;

identify problems; apply GD&T to drawings

MENTORING / CONSULTING

For engineers, designers, inspectors, or others who use drawings. For mgt teams to establish

company standards, GD&T implementation plans, relate GD&T to corporate strategies, etc.

Consulting may involve a variety of project activities. It solves real on-the-job problems,

provides feedback on application of class principles, and benefits both employee and project.

We create or review drawings, tolerance stacks, inspection reports, gauging designs; resolve

interdepartmental issues or work processes to ensure the dimensioning is specified and

interpreted.

Career-Specific Courses and Updates

ISO GEOMETRICAL

TOLERANCING

FUNDAMENTALS OF GD&T

FOR INSPECTORS

Prerequisite: Engineering

Drawing Requirements

For inspectors, quality people,

CMM operators

Skills and strategies for inspecting

GD&T on drawings

Prerequisite: Engineering

Drawing Requirements

For design, layout, assembly, checking and

inspection teams

- Understand part requirements

- Interpret GD&T on drawings

SOLID MODEL TOLERANCING

Prerequisite: GD&T Fundamentals

For designers, engineers, managers

considering math-based dev process

- Definitions, concepts, methods

from ASME Y14.41-2003

- Benefits of math-based product

development process

FUNCTIONAL GAGING AND

MEASUREMENT

Prerequisite: Fund of GD&T for Inspectors

For product/process engineers, inspectors,

CMM operators, supplier quality engineers

- Meas. uncertainty impact on part verification

- Verifying part requirement w/ various

measurement methods

Int

erp

ret

ati

on

MENTORING / CONSULTING

GD&T ADVANCED CONCEPTS

Prerequisite: GD&T Fundamentals

For design, layout, assembly, checking, and inspection teams

Assign part tolerances; relate function to part dimensions. Covers GD&T applications on drawings, datum

selection, composite tolerancing, simultaneous requirements, and intro to functional tolerancing.

MENTORING / CONSULTING

GD&T FUNDAMENTALS

Prerequisite: Engineering Drawing Requirements

For design, layout, assembly, checking and inspection teams

Aw

are

ne

ss

Understand part requirements and interpret GD&T on drawings

GD&T OVERVIEW

Prerequisite: Engineering Drawing Requirements

For design, layout, assembly, checking and inspection teams

Understand part requirements and interpret GD&T on drawings

ENGINEERING DRAWING REQUIREMENTS

A basic class that is useful for all drawing creators and users

The overview course covers drawing standards, drawing types, format, views, dimensioning, surface texture, weld symbols, and electrical diagrams.

ASME Y14.5 Update (1994-2009)

Prerequisite: Knowledge of Y14.5-1994

For anyone involved in creation/interpretation

of drawings

- Understand changes in standard

- New symbols/how to apply them

- Impact of the new standard

ASME-ISO COMPARISON

Prerequisite: GD&T Fundamentals

For designers, engineers, inspectors,

checkers, and machinists

How the standards compare when dealing

with symbols, feature control frames,

tolerances, form controls, datums

For Managers

GD&T EXECUTIVE OVERVIEW

For engineering directors; chief engineers;

project, engineering, mfg, quality mgrs

- How GD&T affects the product

development process

- Skills and strategies for maximizing

ROI from using GD&T

- How to support and grow GD&T skills

This pyramid explains the different levels of GD&T proficiency. ETI recommends that training be taken in this order, with our mentoring and/or consulting services being utilized to reinforce the training on the job.

Arrange for ETI to bring onsite GD&T training, mentoring, or consulting to your organization. We also offer public workshops in Michigan. For more information about ETIs training, resources, and materials,

call 1-800-886-0909 or visit www.etinews.com.

You might also like

- FSAA Quiz 2023Document6 pagesFSAA Quiz 2023Hao Ming TengNo ratings yet

- Advanced Concepts of GD&T PDFDocument1 pageAdvanced Concepts of GD&T PDFPritam PolekarNo ratings yet

- CETOL 6 O Basic Training Manual V8 1 For ProENGINEER 3 52 MB PDFDocument177 pagesCETOL 6 O Basic Training Manual V8 1 For ProENGINEER 3 52 MB PDFasif100% (1)

- Tolerance Stack UpDocument5 pagesTolerance Stack Upavisid9150100% (1)

- Y14 43Document1 pageY14 43Adrian JoelNo ratings yet

- GDT-True PositionDocument32 pagesGDT-True Positionhamartinez100% (1)

- Gd&t-Multi MetricsDocument356 pagesGd&t-Multi MetricsdramiltNo ratings yet

- Resume-Rahul Sah2Document5 pagesResume-Rahul Sah2Rahul SahNo ratings yet

- GD&T TrainingDocument4 pagesGD&T TrainingSunny SonawaneNo ratings yet

- Finite To InfiniteDocument1 pageFinite To InfinitedramiltNo ratings yet

- GD&TDocument356 pagesGD&TSanjeeb Sinha100% (4)

- One-Dimensional Assembly Tolerance Stack-UpDocument26 pagesOne-Dimensional Assembly Tolerance Stack-UpKakoDa100% (2)

- Basic GD&T DesmukhDocument236 pagesBasic GD&T DesmukhDineshCaddNo ratings yet

- GDT Geometric Dimensioning & Tolerancing Training ASME Y14.5-2009Document8 pagesGDT Geometric Dimensioning & Tolerancing Training ASME Y14.5-2009Giv MeeNo ratings yet

- The New Y14.5: We've Improved The Gold StandardDocument9 pagesThe New Y14.5: We've Improved The Gold StandardVignesh PanneerselvamNo ratings yet

- BookGD T PDFDocument14 pagesBookGD T PDFAbsolute ElectronicsNo ratings yet

- Dr. Greg Hetland - Profile Tolerancing Proof of Compliance - Vs - Process FeedbackDocument38 pagesDr. Greg Hetland - Profile Tolerancing Proof of Compliance - Vs - Process FeedbackpdmnbraoNo ratings yet

- Introduction To Geometric Dimensioning and TolerancingDocument3 pagesIntroduction To Geometric Dimensioning and TolerancinganandparasuNo ratings yet

- Latest Report 2Document13 pagesLatest Report 2Piyush BariNo ratings yet

- Basic GD&T - Datums PDFDocument35 pagesBasic GD&T - Datums PDFtnchsgNo ratings yet

- Calypso Maquina de CoordenadasDocument16 pagesCalypso Maquina de CoordenadasIvonne LunaNo ratings yet

- IIGDT - Tolerancing Optimization Examples With $ SignsDocument9 pagesIIGDT - Tolerancing Optimization Examples With $ Signsநளின் கான்No ratings yet

- Floating Fasteners Applications & CalculationsDocument12 pagesFloating Fasteners Applications & Calculationsvasanth_paul8508No ratings yet

- Lecture 8 - Position TolerancingDocument26 pagesLecture 8 - Position TolerancingEdgar IvanNo ratings yet

- Dimensional Quality Engineering PowerpointDocument15 pagesDimensional Quality Engineering PowerpointSalman JavedNo ratings yet

- DVA Capability For KiranDocument10 pagesDVA Capability For Kirandorage2008No ratings yet

- Flat Ness: Our Comprehensive List of GD&T SymbolsDocument29 pagesFlat Ness: Our Comprehensive List of GD&T SymbolsMidhilesh RavikindiNo ratings yet

- GD&T Training BrochureDocument5 pagesGD&T Training BrochurePritam PolekarNo ratings yet

- Fit and Tolerance PDFDocument15 pagesFit and Tolerance PDFLevi J SandyNo ratings yet

- Dimensional Engineering Seminar: Geometric Dimensioning and Tolerancing Variation Simulation ModelingDocument71 pagesDimensional Engineering Seminar: Geometric Dimensioning and Tolerancing Variation Simulation Modelingprasungovindan100% (1)

- Geometric Dimensioning and Tolerancing (GD&T) : College of Engineering and TechnologyDocument7 pagesGeometric Dimensioning and Tolerancing (GD&T) : College of Engineering and TechnologyDienies TorresNo ratings yet

- Krulikowski Chapter 03Document17 pagesKrulikowski Chapter 03Preet BadwalNo ratings yet

- Geometric Dimensioning and Tolerancing: Navigation Search Citations Reliable and Independent SourcesDocument8 pagesGeometric Dimensioning and Tolerancing: Navigation Search Citations Reliable and Independent SourcesDeepak LogesonNo ratings yet

- GD&T Fundamentals: Who Should AttendDocument4 pagesGD&T Fundamentals: Who Should AttendThiru MuruganNo ratings yet

- Composite Tolerance GDTDocument67 pagesComposite Tolerance GDTGanesanGovindarjNo ratings yet

- Geometric Dimensioning and Tolerancing (GD&T) : Part Production Communication ModelDocument76 pagesGeometric Dimensioning and Tolerancing (GD&T) : Part Production Communication Modelmariappan128No ratings yet

- Geometric Dimensioning & Tolerancing (GD&T)Document89 pagesGeometric Dimensioning & Tolerancing (GD&T)Vijay PawarNo ratings yet

- (A) "Basics of GD&T + Advanced GD&T" SyllabusDocument4 pages(A) "Basics of GD&T + Advanced GD&T" SyllabusSwapnil GujarathiNo ratings yet

- GD&T Color ChartDocument1 pageGD&T Color ChartayalpaniyanNo ratings yet

- Rule #1 Explained: 2.7.1 Variations of Form (Rule #1: Envelope Principle)Document6 pagesRule #1 Explained: 2.7.1 Variations of Form (Rule #1: Envelope Principle)Anonymous 7ZTcBnNo ratings yet

- CETOL by SigmetrixDocument6 pagesCETOL by SigmetrixnmjboseNo ratings yet

- GD&T: Theory To Reality: Mission StatementDocument67 pagesGD&T: Theory To Reality: Mission StatementCharlie Tej100% (1)

- Microsoft PowerPoint - G D & T 17.11Document96 pagesMicrosoft PowerPoint - G D & T 17.11vijaykkhal100% (1)

- Zeiss M3 Catalog PDFDocument82 pagesZeiss M3 Catalog PDFAnonymous IGpzRYsP0100% (1)

- GD&T Symbols - GD&T Terms - Geometric Dimensioning and Tolerancing Glossary - GD&T Free ResourceDocument5 pagesGD&T Symbols - GD&T Terms - Geometric Dimensioning and Tolerancing Glossary - GD&T Free Resourcebbbsample0% (1)

- GD&T Self Evaluation Test - Difficulty Level - 9 (Of 10)Document27 pagesGD&T Self Evaluation Test - Difficulty Level - 9 (Of 10)dilipbangaruNo ratings yet

- GD&T 1Document41 pagesGD&T 1Sai CharanNo ratings yet

- What Is The Tolerance Analysis - QRDocument15 pagesWhat Is The Tolerance Analysis - QRAnonymous tQhtrPbNo ratings yet

- GD&T Hierarachy PyramidDocument1 pageGD&T Hierarachy PyramidSunil BaliNo ratings yet

- Geometric Dimensioning and Tolerancing, Concentricity, Runout Tolerances, Circular Runout, Total RunoutDocument3 pagesGeometric Dimensioning and Tolerancing, Concentricity, Runout Tolerances, Circular Runout, Total Runoutmick.pride81No ratings yet

- Composte TolDocument5 pagesComposte TolJuan Posada G100% (1)

- Dimensional Engineering PDFDocument71 pagesDimensional Engineering PDFAvneet MaanNo ratings yet

- Agi Zeiss Day 2016 Gdandt Presentation HandoutsDocument20 pagesAgi Zeiss Day 2016 Gdandt Presentation HandoutsJuan Posada G100% (1)

- GD&T Pre Post TestDocument3 pagesGD&T Pre Post TestVaibhav GadhaweNo ratings yet

- Tolerance Stack-Up 1Document21 pagesTolerance Stack-Up 1Brent PerezNo ratings yet

- GD&T GlossaryDocument4 pagesGD&T GlossarythindmanmohanNo ratings yet

- GDT Spring 2010tDocument278 pagesGDT Spring 2010tYanaki HristovNo ratings yet

- GD&TDocument26 pagesGD&TUsman ansarNo ratings yet

- GD&T QuestionsDocument3 pagesGD&T Questionsbkattimani0% (1)

- Features Located To A PatternDocument4 pagesFeatures Located To A PatternJuan Posada GNo ratings yet

- GD&TDocument33 pagesGD&TShasank PramodeNo ratings yet

- GDT Training PyramidDocument1 pageGDT Training PyramidkhalidcosmosNo ratings yet

- Suggested KeywordsDocument6 pagesSuggested KeywordsHomer Texido FrangioniNo ratings yet

- Santosh ResumeDocument4 pagesSantosh ResumeSantosh KumarNo ratings yet

- Job Skill NeedDocument2 pagesJob Skill NeedRajvikashNo ratings yet

- GD&T TrainingDocument3 pagesGD&T TrainingKeith AdminNo ratings yet

- P10 PDFDocument167 pagesP10 PDFdramiltNo ratings yet

- Solid Finite Elements Through Three Decades: S&than&Document17 pagesSolid Finite Elements Through Three Decades: S&than&dramiltNo ratings yet

- What Are LoadsDocument2 pagesWhat Are LoadsdramiltNo ratings yet

- Q7 PDFDocument3 pagesQ7 PDFdramiltNo ratings yet

- (2008 Course) : S.E. (Mech.) (Ii Seni,) Examination, 2010 Strength of Machine ElementsDocument10 pages(2008 Course) : S.E. (Mech.) (Ii Seni,) Examination, 2010 Strength of Machine ElementsdramiltNo ratings yet

- Q4Document15 pagesQ4dramiltNo ratings yet

- Four Day Workshop On Practical Finite Element Analysis - Concepts & ApplicationsDocument2 pagesFour Day Workshop On Practical Finite Element Analysis - Concepts & ApplicationsdramiltNo ratings yet

- Q1Document12 pagesQ1dramiltNo ratings yet

- Finite Element Methods in EngineeringDocument1 pageFinite Element Methods in EngineeringdramiltNo ratings yet

- Safe Powder Coating Guideline: 7 EditionDocument16 pagesSafe Powder Coating Guideline: 7 EditiondramiltNo ratings yet

- Thermal and Waterjet Cutting Processes PDFDocument5 pagesThermal and Waterjet Cutting Processes PDFdramiltNo ratings yet

- Powder Coating ResinsDocument28 pagesPowder Coating Resinsdramilt100% (1)

- Grammar CBSE Class 4 WorksheetDocument6 pagesGrammar CBSE Class 4 WorksheetdramiltNo ratings yet

- Gap Fills Exercise-5Document6 pagesGap Fills Exercise-5dramiltNo ratings yet

- Healthy Weight Loss PDFDocument5 pagesHealthy Weight Loss PDFdramiltNo ratings yet

- GD&T Training PyramidDocument1 pageGD&T Training PyramiddramiltNo ratings yet

- Etimail Vol2 Issue3Document9 pagesEtimail Vol2 Issue3Mau TauNo ratings yet

- Sciencedirect: Influence of Tolerancing Methods and Aspects of Perceived Quality On Side Closures of Luxury CarsDocument6 pagesSciencedirect: Influence of Tolerancing Methods and Aspects of Perceived Quality On Side Closures of Luxury CarsBabu PonnuswamyNo ratings yet

- Exact Constraint Design Using Tolerance Analysis Methods: Danny Smith Brigham Young University 15 June 2001Document40 pagesExact Constraint Design Using Tolerance Analysis Methods: Danny Smith Brigham Young University 15 June 2001mohanmech2006886No ratings yet

- Tolerance Stack-Up AnalysisDocument14 pagesTolerance Stack-Up Analysispradeep kNo ratings yet

- Design Methodology Datum Referenc Tolerance AnalysisDocument40 pagesDesign Methodology Datum Referenc Tolerance AnalysisIonut EduardNo ratings yet

- Stephen Werst Tolerance StackDocument23 pagesStephen Werst Tolerance StackvikeshmNo ratings yet

- Design For Fit Second EditionDocument415 pagesDesign For Fit Second EditionZiaullahLiaqatNo ratings yet

- Transactions of The Canadian Society For Mechanical Engineering, Vol. 33, No. 3, 2009 459Document27 pagesTransactions of The Canadian Society For Mechanical Engineering, Vol. 33, No. 3, 2009 459smg26thmayNo ratings yet

- Tolerance Stackup Course Module - ISquareDocument2 pagesTolerance Stackup Course Module - ISquareNishad PkNo ratings yet

- GD & T Stack Up Analysis PDFDocument12 pagesGD & T Stack Up Analysis PDFANILNo ratings yet

- Tolerance Analysis of 2-D and 3-D AssembliesDocument31 pagesTolerance Analysis of 2-D and 3-D AssembliesSehzadNo ratings yet

- Tolerance Analysis 09.04.03Document26 pagesTolerance Analysis 09.04.03maddy_scribdNo ratings yet

- Internship Plan 2023Document2 pagesInternship Plan 2023xinyinNo ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument21 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistshiimamanenuNo ratings yet

- Tolerance Stack UpDocument3 pagesTolerance Stack Upmohanrajjercy71No ratings yet

- Tolerance Stack Up Analysis in Manufacturing Based Capstone ProjectsDocument10 pagesTolerance Stack Up Analysis in Manufacturing Based Capstone ProjectsAmirtharaaj VijayanNo ratings yet

- Tolerance Stack Up Statistics PDFDocument92 pagesTolerance Stack Up Statistics PDFMani KandanNo ratings yet

- Your Source For GD&T Training and MaterialsDocument26 pagesYour Source For GD&T Training and MaterialsGiridharPogalaGiridharPogalaNo ratings yet

- Tolerance Analysis-6SigmaDocument22 pagesTolerance Analysis-6SigmaBoby SaputraNo ratings yet

- 31295015251746Document181 pages31295015251746Mani KandanNo ratings yet

- Question Bank - Part A: Unit I - Fundamentals of Computer GraphicsDocument48 pagesQuestion Bank - Part A: Unit I - Fundamentals of Computer GraphicsshaileshNo ratings yet

- Tolerance Stack-Up Analysis Complete PaperDocument26 pagesTolerance Stack-Up Analysis Complete Papersantoshlad80% (5)

- Tolerance Analysis of Deformable AssemblyDocument287 pagesTolerance Analysis of Deformable Assemblymamunruet100% (2)

- Analysis of Several Body in White Parameters 1606920680 2Document4 pagesAnalysis of Several Body in White Parameters 1606920680 2sopanNo ratings yet