Professional Documents

Culture Documents

Production Supervisor Planner Aviation in Atlanta GA Resume Nancy Cash

Production Supervisor Planner Aviation in Atlanta GA Resume Nancy Cash

Uploaded by

NancyCashOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Production Supervisor Planner Aviation in Atlanta GA Resume Nancy Cash

Production Supervisor Planner Aviation in Atlanta GA Resume Nancy Cash

Uploaded by

NancyCashCopyright:

Available Formats

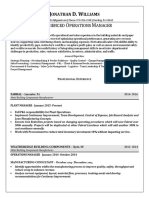

NANCY CASH

678.552.9176 h 678-542-4533 c

nscash01@gmail.com

https:www.linkedin.com/in/nscash01

PRODUCTION SUPERVISOR

Attain Production Goals | Maintain Safe and Clean Environment

Develop, motivate, and lead employee productivity to ensure company's success. Extensive experience in

warehouse production in industries including gas turbine engine components for energy, aerospace and

military applications and aluminum extrusion. Skilled in performance analysis, policy and procedures

analysis, production scheduling, and purchasing. Effective problem- solving, training and coaching skills.

Reputation for strong work ethic and high energy level. Passion and commitment to leading team in

achieving goals.

EXPERIENCE

CHROMALLOY GAS TURBINES LLC

2007 to 2016

Production Supervisor, Newnan, GA

2013 to 2016

Production Supervisor, LaGrange, GA

2007 to 2011

Hired and managed staff of up to 15-20 employees, overseeing grievances. Assessed and trained individuals

for promotion to cross-functional operations. Coached staff in developing and achieving individual

performance goals.

Guaranteed 100% of orders were shipped on-time. Improved OTD from 85% to 100% by managing

production activities.

Contributed to achieving company goals by supporting production workers. Implemented 5S lean

management, organizing work cells with visual aids for prioritizing work queues, Kanbans with reordering point, and ordering information, and point of use boards.

Solved problems and minimized obstacles in daily operations which were preventing staff from

completing work.

Revised operating instructions to Technical Data for entry into computer system for visual aid to staff.

Supported preventive maintenance of machinery by creating binders of relevant information and

pictures.

Detected production problems by utilizing production tracking and quality control systems, analyzing

production, quality control, maintenance and operational reports. Maintained proper stock levels for

processes within work cells.

Met production and schedule requirements by monitoring production processes and scheduled /

adjusted work assignments. Collaborated with the engineering team adjusting and modifying production

equipment.

Maintained and enforced safe and clean work environment. Adhered to regulations, policies and

procedures for health, safety and environmental compliance.

Implemented root cause and corrective actions for removing production constraints and improving

product quality. Fostered culture of lean manufacturing and continuous improvement while providing

operational leadership.

Business Unit Planner, LaGrange GA

Coordinated flow of incoming materials and timely flow of jobs between departments.

Planned production and sales based on forecasts and customer demand.

2011 to 2013

NANCY CASH

nscash01@gmail.com

PAGE TWO

CHROMALLOY GAS TURBINES LLC (Continued)

Supported department managers in purchase of raw materials, and search for new suppliers.

Satisfied customer shipping requirements by processing orders, tracking deliveries, providing quality

assurance, answering queries.

Released job orders based on availability of materials, equipment.

WILLIAM L BONNELL

1989 to 2007

Process Coordinator

2004 to 2007

Provided pictures and written instruction for packaging, racking for anodizing, table loads for buffing,

racking for paint line, and stacking for extrusion presses. Downloaded for Employees to access the

information from computers located within their work areas. As well as printed on operators worksheets.

Manufacturing Supervisor

1997 to 2004

Oversaw manufacturing operations including safety, production, planning, quality assurance and training,

evaluating staff of up to 25-30 employees. Maintained operations data and prepared production reports for

management.

Resolved worker problems / complaints / grievances by conferring with management and staff.

Conferred with supervisors in coordinating operations within and between departments.

Demonstrated equipment operations work and safety procedures, assigned new employees to

experienced workers for training. Interpreted specifications, blueprints, job orders, and company policies

and procedures for workers.

Met production goals by planning / establishing work schedules, assignments, and production

sequences. Analyzed production schedules to determine production requirements.

Additional roles at WILLIAM L BONNELL:

1989 to 1997

Fabrication working with drill and punch presses, and saws, shipping and receiving, coating and packaging.

RELATED EXPERIENCE

STARCREST OF NEWNAN NURSING HOME, Newnan, GA

Payroll Specialist / Insurance Clerk / Receptionist

1991 to 1995

BELLE MAISON NURSING HOME, Hammond, LA

Office Manager and Bookkeeper

1985 to 1989

EDUCATION AND CERTIFICATIONS

American School (General High School Studies) | JTPA Computer School, Hammond, LA

AIRMAN Certificate, Federal Aviation Administration

Georgia Certificate: Communication & Conflict, West Central Technical College

Georgia Certificate: Presentation Skills for First-Line Managers, Eagles Consulting Group

Certificate: Adult CPR (32 hours), West Central Technical College

Georgia Certificate: Positive Employee Relations Program, Alpha Associates, Inc.

OSHA 10-hour training

TECHNICAL SKILLS

AS/400 Inventory Management / JD Edwards Material Management /Word, Excel and PowerPoint

You might also like

- Communication Law Outline - 2015Document57 pagesCommunication Law Outline - 2015ifplaw0% (1)

- Production Manager Operations Supervisor in New York City Resume Ariel GatewoodDocument3 pagesProduction Manager Operations Supervisor in New York City Resume Ariel GatewoodArielGatewoodNo ratings yet

- Manufacturing Plant Manager Resume SampleDocument0 pagesManufacturing Plant Manager Resume SamplePrem Singh LaishangbamNo ratings yet

- Factory JDDocument16 pagesFactory JDSatyam DixitNo ratings yet

- Plant Manager Director Operations Quality in Washington DC Resume Sanders HolstonDocument3 pagesPlant Manager Director Operations Quality in Washington DC Resume Sanders HolstonSandersHolstonNo ratings yet

- Thomas Clark: - Director of ManufacturingDocument2 pagesThomas Clark: - Director of ManufacturingHitendra Nath BarmmaNo ratings yet

- Mohammad ShukriDocument5 pagesMohammad ShukriMohammed Shukri Al QudraNo ratings yet

- Quality Manager in Chicago IL Resume Kevin McMahonDocument2 pagesQuality Manager in Chicago IL Resume Kevin McMahonKevinMcMahon100% (2)

- Joseph BorrelliDocument5 pagesJoseph BorrelliIndustalent FamilyNo ratings yet

- Alan Miner 2010Document3 pagesAlan Miner 2010ajminerNo ratings yet

- Production Manager or Production SupervisorDocument3 pagesProduction Manager or Production Supervisorapi-121382640No ratings yet

- MfranciscoresumeDocument2 pagesMfranciscoresumeapi-297781257No ratings yet

- VP General Manager in United States Resume Art ChristiansonDocument2 pagesVP General Manager in United States Resume Art ChristiansonArtChristiansonNo ratings yet

- Vice President Manufacturing Operations in Chicago IL Resume Timothy KelleherDocument2 pagesVice President Manufacturing Operations in Chicago IL Resume Timothy KelleherTimothyKelleherNo ratings yet

- Resume Brian YoungerDocument8 pagesResume Brian Youngerprathmesh kashumareNo ratings yet

- Sue KlassenDocument3 pagesSue Klassensuzie48No ratings yet

- Operations Continuous Improvement Manager in Phoenix AZ Resume Paul RobertsDocument2 pagesOperations Continuous Improvement Manager in Phoenix AZ Resume Paul RobertsPaulRoberts2No ratings yet

- Hussain CV To The Public PDFDocument2 pagesHussain CV To The Public PDFali hussainNo ratings yet

- Field Quality Services Engineer in Houston TX Resume Nanut Panpreuk GreenDocument1 pageField Quality Services Engineer in Houston TX Resume Nanut Panpreuk GreenNanutPanpreukGreenNo ratings yet

- HVAC TechnicianDocument2 pagesHVAC Technicianapi-121313522No ratings yet

- Owen Lucero Bautista - 2017 ResumeDocument6 pagesOwen Lucero Bautista - 2017 ResumeOwen Lucero BautistaNo ratings yet

- Quality Technical Leader in Marietta GA Resume Wayne BoldenDocument2 pagesQuality Technical Leader in Marietta GA Resume Wayne BoldenWayneBoldenNo ratings yet

- ResumeDocument2 pagesResumeapi-317503462No ratings yet

- Facilities Manager Manufacturing Director in Orange County CA Resume Mark LevitzDocument2 pagesFacilities Manager Manufacturing Director in Orange County CA Resume Mark LevitzMarkLevitzNo ratings yet

- Manufacturing Engineer Production Manager in New York City Resume Ivan DominguezDocument2 pagesManufacturing Engineer Production Manager in New York City Resume Ivan DominguezIvanDominguezNo ratings yet

- Manufacturing Operations Plant Manager in Cedar Rapids IA Resume Larry HuinkerDocument3 pagesManufacturing Operations Plant Manager in Cedar Rapids IA Resume Larry HuinkerLarryHuinkerNo ratings yet

- VP Quality Lean Sigma Development in TX OK MO KS Resume Mark FellerDocument2 pagesVP Quality Lean Sigma Development in TX OK MO KS Resume Mark FellerMark FellerNo ratings yet

- Plant HeadDocument25 pagesPlant Headpankajmpawar1986No ratings yet

- Director Operations Manufacturing Production in Philadelphia PA Resume Charles AltmanDocument3 pagesDirector Operations Manufacturing Production in Philadelphia PA Resume Charles AltmanCharlesAltmanNo ratings yet

- Plant Manager Sample ResumeDocument2 pagesPlant Manager Sample ResumeR HNo ratings yet

- Quality Improvement Manager Engineer in Lincoln NE Resume Monte BainterDocument2 pagesQuality Improvement Manager Engineer in Lincoln NE Resume Monte BainterMonteBainterNo ratings yet

- Manufacturing Manager Aerospace Electronics RF in San Jose CA Resume William CaryDocument3 pagesManufacturing Manager Aerospace Electronics RF in San Jose CA Resume William CaryWilliamCaryNo ratings yet

- Manuel Felipe Solís Serra Rojas IDMA07-B 6385: The ChallengeDocument6 pagesManuel Felipe Solís Serra Rojas IDMA07-B 6385: The ChallengeManuel SolisNo ratings yet

- Operations Manager in Wilkes-Barre Scranton PA Resume Jonathan WilliamsDocument3 pagesOperations Manager in Wilkes-Barre Scranton PA Resume Jonathan WilliamsJonathanWilliamsNo ratings yet

- Supervisor, ManagerDocument2 pagesSupervisor, Managerapi-76937070No ratings yet

- Director Operations Account Manager in Philadelphia PA Resume David SieglerDocument2 pagesDirector Operations Account Manager in Philadelphia PA Resume David SieglerDavidSieglerNo ratings yet

- Operations Logistics Manager in Newport News Hampton Norfolk VA Resume Tracy WatkinsDocument2 pagesOperations Logistics Manager in Newport News Hampton Norfolk VA Resume Tracy WatkinsTracyWatkinsNo ratings yet

- Customer Service Operations Manager in Calgary AB Canada Resume Randy ScottDocument3 pagesCustomer Service Operations Manager in Calgary AB Canada Resume Randy ScottRandyScottNo ratings yet

- Director Quality Assurance Operations in Tampa ST Petersburg FL Resume Gary SteinerDocument5 pagesDirector Quality Assurance Operations in Tampa ST Petersburg FL Resume Gary SteinerGarySteinerNo ratings yet

- Senior Purchasing Manager Director in San Antonio TX Resume Edward RiveraDocument3 pagesSenior Purchasing Manager Director in San Antonio TX Resume Edward RiveraEdwardRiveraNo ratings yet

- Michael B. Stusak ResumeDocument2 pagesMichael B. Stusak Resumestusak69No ratings yet

- Plant Operations Director Manager in Dallas FT Worth TX Resume Kevin HuurmanDocument2 pagesPlant Operations Director Manager in Dallas FT Worth TX Resume Kevin HuurmanKevinHuurmanNo ratings yet

- Plant Manager Operations in Rochester NY Resume Mark AsbrandDocument3 pagesPlant Manager Operations in Rochester NY Resume Mark AsbrandMark AsbrandNo ratings yet

- Job OverviewDocument4 pagesJob OverviewSrinivasarao YadlapalliNo ratings yet

- Pearl Pet MahadDocument2 pagesPearl Pet MahadShree RangaNo ratings yet

- Quality Engineering Operations Director in Toledo OH Resume Kelly OkdieDocument2 pagesQuality Engineering Operations Director in Toledo OH Resume Kelly OkdieKellyOkdieNo ratings yet

- Professional Resume For Tom RandallDocument3 pagesProfessional Resume For Tom RandalltomrandallNo ratings yet

- VP Director Operations Manufacturing in Chicago IL Resume Erik PetersonDocument2 pagesVP Director Operations Manufacturing in Chicago IL Resume Erik PetersonErikPeterson1No ratings yet

- Vice President Operations in FL Resume Christopher HawaDocument2 pagesVice President Operations in FL Resume Christopher HawaChristopherHawaNo ratings yet

- Operations ManagerDocument3 pagesOperations Managerapi-79229412No ratings yet

- SALIHU Ibrahim RESUMEA - 001Document5 pagesSALIHU Ibrahim RESUMEA - 001favowritesNo ratings yet

- Resume Sample For Quality Control ManagerDocument5 pagesResume Sample For Quality Control Managerxokcccifg100% (2)

- Director Food Manufacturing Operations in USA Resume Alan GoldsteinDocument3 pagesDirector Food Manufacturing Operations in USA Resume Alan GoldsteinAlanGoldsteinNo ratings yet

- Nguyen Minh Son-CvDocument3 pagesNguyen Minh Son-CvNguyễn Tiến DũngNo ratings yet

- 5.3.1 & 5.3.2 - Responsibilities AuthoritiesDocument5 pages5.3.1 & 5.3.2 - Responsibilities Authoritiesrc2834338No ratings yet

- Plant Manager ResumeDocument7 pagesPlant Manager Resumebdg8266a100% (2)

- Resume Ajaykoul.Document3 pagesResume Ajaykoul.Monica KanganNo ratings yet

- Certified Quality Systems Manager in Homosassa FL Resume Douglas SmithDocument1 pageCertified Quality Systems Manager in Homosassa FL Resume Douglas SmithDouglasSmith2No ratings yet

- Senior Manager Lead Engineer in Orlando FL Resume Christian GonzalezDocument3 pagesSenior Manager Lead Engineer in Orlando FL Resume Christian GonzalezChristianGonzalez2No ratings yet

- The Production Manager 'S Job Summary:: General and AdministrativeDocument2 pagesThe Production Manager 'S Job Summary:: General and AdministrativeDe Silva ShmapkNo ratings yet

- Alternative Risk Premia October 2019 1575682443 PDFDocument12 pagesAlternative Risk Premia October 2019 1575682443 PDFCaden LeeNo ratings yet

- Jadwal Kuliah Ganjil 2019-2020 (Reg) BaruDocument5 pagesJadwal Kuliah Ganjil 2019-2020 (Reg) BarufikryNo ratings yet

- October ManifestoDocument17 pagesOctober ManifestoTaylor ShawNo ratings yet

- Wallenius Wilhelmsen HistoryDocument28 pagesWallenius Wilhelmsen Historymanayani52100% (1)

- Module 13 - Transparent Public ProcurementDocument63 pagesModule 13 - Transparent Public ProcurementJordani MikeNo ratings yet

- Thesis All RightDocument14 pagesThesis All Rightdarodawa100% (1)

- Add 7 Days To The First Day of Last Menstrual PeriodDocument16 pagesAdd 7 Days To The First Day of Last Menstrual PeriodRojean MartinezNo ratings yet

- 2008 ROJ Mirth Missives Mailing List As of Feb 1 2008Document62 pages2008 ROJ Mirth Missives Mailing List As of Feb 1 2008api-19965136No ratings yet

- Reaching Post ModernsDocument96 pagesReaching Post Modernsapi-3735458100% (1)

- Soal CPNS Paket 7Document3 pagesSoal CPNS Paket 7yulius caesarNo ratings yet

- Bhopal To Indore by Bus 1-9-2015Document2 pagesBhopal To Indore by Bus 1-9-2015Er Rohit VermaNo ratings yet

- Presentation On Insider TradingDocument8 pagesPresentation On Insider TradingCA Gaurav KanudawalaNo ratings yet

- EA1124 AIO - Id 376077 PDFDocument37 pagesEA1124 AIO - Id 376077 PDFPolitécnico Internacional De OccidenteNo ratings yet

- Electrotel Spectracell WRFDocument41 pagesElectrotel Spectracell WRFLaurentiu CatalinNo ratings yet

- Puente Temburong, Brunei - Diseño de Dos Puentes AtirantadosDocument7 pagesPuente Temburong, Brunei - Diseño de Dos Puentes AtirantadosRONALD ABRAHAM SAMCA MONTAÑONo ratings yet

- Insti 1Document97 pagesInsti 1Cristina S. BalanquitNo ratings yet

- ENSC 1113 The Science of Global Challenges NotesDocument21 pagesENSC 1113 The Science of Global Challenges Notestalhahassanalvi786100% (2)

- Promotional Campaigns & Ideas: Marketing StrategiesDocument9 pagesPromotional Campaigns & Ideas: Marketing StrategiesEe Yern NgNo ratings yet

- Batas Militar Part IDocument12 pagesBatas Militar Part IGenesis GuerreroNo ratings yet

- MPRA Paper 74730Document15 pagesMPRA Paper 74730soundarya mahalingamNo ratings yet

- Domalsin v. Valenciano (G.R. No. 158687)Document2 pagesDomalsin v. Valenciano (G.R. No. 158687)Rache Gutierrez0% (1)

- CV Aylin CALIK Project ManagerDocument1 pageCV Aylin CALIK Project ManagerAnna PeckNo ratings yet

- Fujitsu M10/SPARC M10 Systems: Product Notes For XCP Version 2353Document320 pagesFujitsu M10/SPARC M10 Systems: Product Notes For XCP Version 2353sonneNo ratings yet

- Lesson 1 - PhilosophyDocument47 pagesLesson 1 - PhilosophyKotch LupasiNo ratings yet

- BugkalotDocument3 pagesBugkalotADMIN OFFICERNo ratings yet

- The History of Indian LanguagesDocument14 pagesThe History of Indian LanguagesAbhishek BhardwajNo ratings yet

- Group 4 - The Rizal Law OutlineDocument3 pagesGroup 4 - The Rizal Law OutlineBaculio Janine G.No ratings yet

- Transformations of The Indo Iranian Snake Man Myth Language Ethnoarcheology and Iranian IdentityDocument6 pagesTransformations of The Indo Iranian Snake Man Myth Language Ethnoarcheology and Iranian Identitysajad amiriNo ratings yet

- PNU Final Coaching Gen - EdDocument10 pagesPNU Final Coaching Gen - EdJammie Aure EsguerraNo ratings yet