Professional Documents

Culture Documents

Safety Valve - 118CSS Specification

Safety Valve - 118CSS Specification

Uploaded by

Manuel Pimentel Del CampoCopyright:

Available Formats

You might also like

- Mapiful - How To Make Your Home More YouDocument35 pagesMapiful - How To Make Your Home More YouElina100% (1)

- Courier Service AgreementDocument1 pageCourier Service AgreementSabu ThomasNo ratings yet

- ราคาอ้างอิงของยา เดือนมกราคม-มีนาคม 2561Document143 pagesราคาอ้างอิงของยา เดือนมกราคม-มีนาคม 2561Tommy PanyaratNo ratings yet

- Technical Note Guidance On Corrosion Assessment of Ex EquipmentDocument7 pagesTechnical Note Guidance On Corrosion Assessment of Ex EquipmentParthiban NagarajanNo ratings yet

- Caterpillar Generator Data C15Document12 pagesCaterpillar Generator Data C15Aditya PratamaNo ratings yet

- Amco CR4000Document4 pagesAmco CR4000Arwin TroconisNo ratings yet

- Wilkerson Filter Model B08-02-FKG0 Spec Sheet 9EM-B08Document7 pagesWilkerson Filter Model B08-02-FKG0 Spec Sheet 9EM-B08donsterthemonsterNo ratings yet

- Api Plan 11Document6 pagesApi Plan 11johnsaballaNo ratings yet

- Regulador American Meter PDFDocument6 pagesRegulador American Meter PDFjmcg1974No ratings yet

- CKV 05 Ex PDFDocument4 pagesCKV 05 Ex PDFengp3077No ratings yet

- RVC 05 NPT Product SpecsDocument6 pagesRVC 05 NPT Product SpecsAnonymous WVJNMWNo ratings yet

- L&T ButterflyValves Triple OffsetDocument16 pagesL&T ButterflyValves Triple OffsetvarathapandianNo ratings yet

- AV13 Air Vent For Steam Systems: DescriptionDocument2 pagesAV13 Air Vent For Steam Systems: DescriptionUtku KepcenNo ratings yet

- Gate, Globe & Check ValvesDocument52 pagesGate, Globe & Check ValvesBabar Manzoor GhauriNo ratings yet

- Econ Gate ValvesDocument20 pagesEcon Gate ValvesEngr.Mmosaad100% (1)

- Main DrainDocument4 pagesMain DrainAndrea Devky KresnaNo ratings yet

- Cain Bolt & Gasket Techinical ManualDocument16 pagesCain Bolt & Gasket Techinical ManualgirishnitwNo ratings yet

- Series LF288A Specification SheetDocument2 pagesSeries LF288A Specification SheetWattsNo ratings yet

- Sure Flow StrainersDocument13 pagesSure Flow StrainersNinad SherawalaNo ratings yet

- Regulador 1253 B - American M.Document8 pagesRegulador 1253 B - American M.Jheysson FloresNo ratings yet

- Series 8 Specification SheetDocument2 pagesSeries 8 Specification SheetWattsNo ratings yet

- Spirax Sarco Commissioning Strainer 1Document3 pagesSpirax Sarco Commissioning Strainer 1swaraj4uNo ratings yet

- Series 1070, P1070 Specification SheetDocument2 pagesSeries 1070, P1070 Specification SheetWattsNo ratings yet

- Wedge and Slab Gate ValvesDocument8 pagesWedge and Slab Gate Valvesgad30100% (1)

- RVC 05 FLG PDFDocument5 pagesRVC 05 FLG PDFengp3077No ratings yet

- Cokebuster: A Proven SolutionDocument11 pagesCokebuster: A Proven Solutionengg_mech77No ratings yet

- Model BPS-05-NPT: Stainless Steel Back Pressure Regulator ValveDocument8 pagesModel BPS-05-NPT: Stainless Steel Back Pressure Regulator ValveNet WalkerNo ratings yet

- Series G1070, GP1070 Specification SheetDocument2 pagesSeries G1070, GP1070 Specification SheetWattsNo ratings yet

- RVC05 150FLG Ex PDFDocument5 pagesRVC05 150FLG Ex PDFengp3077No ratings yet

- Series 957, 957N, 957ZDocument4 pagesSeries 957, 957N, 957ZWattsNo ratings yet

- Series SS07F Specification SheetDocument2 pagesSeries SS07F Specification SheetWattsNo ratings yet

- Ul - Viza - Ex15228 - Fittings Grooved PDFDocument3 pagesUl - Viza - Ex15228 - Fittings Grooved PDFJulio Rosas PezoNo ratings yet

- 160.75-RP1 (210) - Yk (G)Document92 pages160.75-RP1 (210) - Yk (G)JayashtonNo ratings yet

- Model BPS-09: Back Pressure-Reducing ValveDocument4 pagesModel BPS-09: Back Pressure-Reducing Valveengp3077No ratings yet

- Custom Engineered StrainersDocument37 pagesCustom Engineered StrainersJames Mink Sr.No ratings yet

- RVC 05 PDFDocument6 pagesRVC 05 PDFengp3077No ratings yet

- Model"Dc": Dual Chamber Orifice FittingDocument13 pagesModel"Dc": Dual Chamber Orifice FittingFrankNo ratings yet

- ButterflyDocument6 pagesButterflysachin2010No ratings yet

- DWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)Document3 pagesDWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)RamanNegiNo ratings yet

- Tour & Andersson Circuit Balancing Valves and Koil-Kit ComponentsDocument1 pageTour & Andersson Circuit Balancing Valves and Koil-Kit ComponentslesnikimagesNo ratings yet

- Metal Seated Sampling ValvesDocument4 pagesMetal Seated Sampling ValvesGiovanni TrinidadNo ratings yet

- Brochure 2010Document20 pagesBrochure 2010shankarsreekumarNo ratings yet

- Válvulas Bola SegmentadaDocument12 pagesVálvulas Bola SegmentadarehynaldoNo ratings yet

- SS2800 Side Pocket Mandrel GaugesDocument2 pagesSS2800 Side Pocket Mandrel GaugesGonza PfNo ratings yet

- Rva 05 PDFDocument4 pagesRva 05 PDFengp3077No ratings yet

- Manual Spirax SarcoDocument2 pagesManual Spirax SarcoAlex CarreraNo ratings yet

- Es LF777Document2 pagesEs LF777WattsNo ratings yet

- Codeline, 150 PSI, Drawing - 80S15Document3 pagesCodeline, 150 PSI, Drawing - 80S15RamanNegiNo ratings yet

- (2012) Complete IELTS Bands 5-6.5 Student's BookDocument3 pages(2012) Complete IELTS Bands 5-6.5 Student's BookAhmed Hamdy0% (1)

- 13 - Jesse Meisterling Gaskets and Leaks PVRC Recommendations and StudiesDocument0 pages13 - Jesse Meisterling Gaskets and Leaks PVRC Recommendations and StudiesVicky GautamNo ratings yet

- Singer ValveDocument5 pagesSinger ValveDGWNo ratings yet

- Series 008PCQT Specification SheetDocument2 pagesSeries 008PCQT Specification SheetWattsNo ratings yet

- B-313 Series E-1510 Technical BrochureDocument8 pagesB-313 Series E-1510 Technical BrochureAnonymous 7xHNgoKE6eNo ratings yet

- Series 774DCDA Specification SheetDocument2 pagesSeries 774DCDA Specification SheetWattsNo ratings yet

- Air Preparation ProductsDocument6 pagesAir Preparation ProductssenamotoNo ratings yet

- AmeritoolBroch Aug21Document12 pagesAmeritoolBroch Aug21hiscoke69No ratings yet

- Plumbing and Propane CatalogDocument40 pagesPlumbing and Propane Catalogdannyboy738No ratings yet

- Burst Plug Tubing Drain - Technical DatasheetDocument8 pagesBurst Plug Tubing Drain - Technical DatasheetEvolution Oil ToolsNo ratings yet

- Drawing 80H30Document3 pagesDrawing 80H30kpranjal15No ratings yet

- Flowserve Lined Flush BottomDocument32 pagesFlowserve Lined Flush BottomDevdatt WaghuleNo ratings yet

- RssDocument1 pageRssgenial72No ratings yet

- PRH09 PDFDocument4 pagesPRH09 PDFengp3077No ratings yet

- CTA Pocket CardDocument2 pagesCTA Pocket CardBreitbart News100% (1)

- EDUC 3 Module 1-Lesson 1Document12 pagesEDUC 3 Module 1-Lesson 1Ma. Kristel OrbocNo ratings yet

- SRS Template ExampleDocument16 pagesSRS Template ExampleabcNo ratings yet

- Safety Data Sheet Versamul Ic: 1. Identification of The Substance/Preparation and Company/UndertakingDocument4 pagesSafety Data Sheet Versamul Ic: 1. Identification of The Substance/Preparation and Company/UndertakingJose Rafael Martinez PerezNo ratings yet

- ONX 620 QuickStart Guide v10Document133 pagesONX 620 QuickStart Guide v10Haiward RinconNo ratings yet

- Foit LabDocument50 pagesFoit LabWAREKARNo ratings yet

- Ebook - Electronics Tutorial PDFDocument213 pagesEbook - Electronics Tutorial PDFHari Laxman M100% (1)

- Warid Telecom ReportDocument49 pagesWarid Telecom ReporthusnainjafriNo ratings yet

- Class 3: For More Such Worksheets VisitDocument4 pagesClass 3: For More Such Worksheets VisitSan BrothersNo ratings yet

- Summary WordingDocument5 pagesSummary WordingDaniel JenkinsNo ratings yet

- 5E Lesson Plan Template: Replace These Directions With Your WorkDocument4 pages5E Lesson Plan Template: Replace These Directions With Your Workapi-583088531No ratings yet

- SP6 MB Tutorial 01Document20 pagesSP6 MB Tutorial 01Nikola PetrakNo ratings yet

- LemleyDocument64 pagesLemleyMeshandren NaidooNo ratings yet

- UntitledDocument292 pagesUntitledD17CQAT01-N LE THANH TUANNo ratings yet

- 2010 Nissan Versa S Fluid CapacitiesDocument2 pages2010 Nissan Versa S Fluid CapacitiesRubenNo ratings yet

- Heresite Corrosion ProtectionDocument2 pagesHeresite Corrosion ProtectionDANIEL PEREZNo ratings yet

- Security SolutionsDocument3 pagesSecurity SolutionsclubedovarNo ratings yet

- 3 Methods For Crack Depth Measurement in ConcreteDocument4 pages3 Methods For Crack Depth Measurement in ConcreteEvello MercanoNo ratings yet

- Fevo 10 828503 1Document10 pagesFevo 10 828503 1keilazache2780No ratings yet

- Addmrpt 1 36558 36559Document7 pagesAddmrpt 1 36558 36559Anonymous ZGcs7MwsLNo ratings yet

- PR200241Document12 pagesPR200241Michaela CatacutanNo ratings yet

- Kariru - Contemporary Trends and Issues in The HospitalityDocument17 pagesKariru - Contemporary Trends and Issues in The Hospitalitygorgo.incNo ratings yet

- Water Flow and Heat Transport Including Icewater Phase Change in Porous Media Numerical Simulation and ApplicationDocument11 pagesWater Flow and Heat Transport Including Icewater Phase Change in Porous Media Numerical Simulation and ApplicationNorick CahyaNo ratings yet

- HRM1Document13 pagesHRM1Niomi GolraiNo ratings yet

- Math4190 Lecture-04-02 HDocument11 pagesMath4190 Lecture-04-02 Hchandan.thakurNo ratings yet

Safety Valve - 118CSS Specification

Safety Valve - 118CSS Specification

Uploaded by

Manuel Pimentel Del CampoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safety Valve - 118CSS Specification

Safety Valve - 118CSS Specification

Uploaded by

Manuel Pimentel Del CampoCopyright:

Available Formats

K KINGSTON

Est.1908

118CSS

Manufacturing reliable industrial valves for industry since 1908.

Kingston Safety Valve

Model 118CSS

ASME Code High Flow Safety Valve

Brass, Stainless Steel Ball

Features

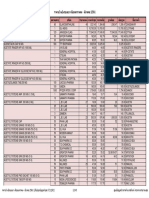

Model

Inlet Size

Orifice

118CSS

1/4" NPT

3/8" NPT

1/2" NPT

3/4" NPT

1" NPT

.295

.343

0.343

0.578

0.578

Dimensions (inches)

Height (A) Hex (B)

3-3/16"

5/8"

3-9/16"

3/4"

3-13/16"

7/8"

5-7/16"

1 - 1/2"

5-3/4"

1 - 5/6"

High Flow Capacity

Precision Machined Hard Seat

Stainless Steel Ball & Spring

Pull Ring for Manual Testing

ASME Certified- Stamped UV + NB

Registered in All Canadian Provinces & Territories

Maximum Temperature 400F

Set Pressure Range 25-300 PSIG

Set Pressure Range

(PSIG)

Approx. Ship Wt.

25-300

3oz.

5 oz.

9 oz.

1 lb. 2 oz.

1 lb. 5 oz.

Max Temp.

(F)

400 F

Figure/Part No.

118CSS-2-000

118CSS-3-000

118CSS-4-000

118CSS-5-000

118CSS-6-000

Materials

No.

Part Name

Materials

Body

Brass

Seal

Vinyl

Stem Assembly

Brass Stem,

Stainless Steel Ball

Spring

Stainless Steel

Adjusting Screw

Brass

Lock Nut

Brass

Cap

Brass

Pull Ring

Stainless Steel

Storm Manufacturing Group, Inc. 23201 Normandie Ave. Torrance, CA 90501 Tel: 800.210.2525 Fax: 800.997.0500 www.KingstonValves.com

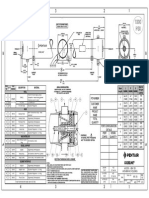

Kingston Model 118CSS Kingston Safety Valve

Flow Capacity Information

Fig. 118C - 1/4, 3/8 & 1/2

SET

PRESSURE

Fig. 118C - 3/4 & 1

SET

PRESSURE

STAMPED CAPACITY CFM

psi

1/4"

3/8", 1/2" 3/4"

25

45

65

30

51

35

57

40

STAMPED CAPACITY CFM

1"

psi

1/4"

155

155

165

210

3/8", 1/2" 3/4"

302

720

720

1"

73

175

175

170

216

311

740

740

82

195

195

175

222

319

760

460

63

215

215

180

228

328

781

781

45

69

99

236

236

185

233

336

801

801

50

75

107

256

256

190

239

344

821

821

55

80

116

276

276

195

245

353

841

841

60

86

124

296

296

200

251

361

861

861

65

92

133

316

316

205

257

370

882

882

70

98

141

336

336

210

263

378

902

902

75

104

150

357

357

215

269

387

922

922

80

110

158

377

377

220

275

395

942

942

85

116

167

397

397

225

281

404

962

962

90

122

175

417

417

230

286

412

982

982

95

128

184

437

437

235

292

421

1003

1003

100

133

192

458

458

240

298

429

1023

1023

105

139

201

478

478

245

304

438

1043

1043

110

145

209

498

498

250

310

446

1063

1063

115

151

217

518

518

255

316

455

1083

1083

120

157

226

538

538

260

322

463

1104

1104

125

163

234

559

559

265

328

472

1124

1124

130

169

243

579

579

270

334

480

1144

1144

135

175

251

599

599

275

339

488

1164

1164

140

181

260

619

619

280

345

497

1184

1184

145

186

268

639

639

285

351

505

1202

1202

150

192

277

659

659

290

357

514

1225

1225

155

198

285

680

680

295

363

522

1245

1245

60

204

294

700

700

300

369

531

1265

1265

Ordering Information

Kingston Safety Relief Valve

Part Number Codes

Ordering Information

Materials

Valve Family

Size

- 118CSS

2= 1/4 NPT

3= 3/8NPT

4= NPT

5= 3/4 NPT

ASME Code

- C Code Certified

Material Codes

Relief Pressure Setting

5 psi increments

Ex.

25 psi = -025

150 psi = -150

- SS Brass, Stainless Steel Ball

Special Processing Codes

Product Notes

Set pressure can deviate from the marked by 2 psig at or below 70 psig set pressures and 3% psig above 70 psig.

Factory standard seat tightness for hard seat valves: no audible leakage at 10% below nameplate set. It is normal for spring-operated safety valves to exhibit leakage or

simmer/warn, as the system operating pressure approaches the set pressure. For hard seat valves this is typically occurs at pressure at or above 80% of nameplate set

pressure.

At very low set pressure (20 psig and below), the ratio of the downward spring force as compared to the upward pressure force is very small. In these cases it may be

impossible to achieve seat tightness.

Storm Manufacturing reserves all rights. Product specifications are subject to change without notice.

The information contained herein by Storm Manufacturing Group (SMG) is provided in good faith and as a product guide only. Further, SMG makes no representation as to

the completeness or accuracy of the information contained herein. Any person or persons using the information contained herein must exercise their own judgement and

consider all local, regional, national and global safety standards in evaluating valve selection options. Final application design and integration of Kingston Products are the

sole responsibility of the end user.

K

Est.1908

www.KingstonValves.com

KINGSTON

Copyright 2016 Storm Manufacturing Group. All rights reserved. Product

designs and specifications subject to change without notice.01.118CSS.16.r1

You might also like

- Mapiful - How To Make Your Home More YouDocument35 pagesMapiful - How To Make Your Home More YouElina100% (1)

- Courier Service AgreementDocument1 pageCourier Service AgreementSabu ThomasNo ratings yet

- ราคาอ้างอิงของยา เดือนมกราคม-มีนาคม 2561Document143 pagesราคาอ้างอิงของยา เดือนมกราคม-มีนาคม 2561Tommy PanyaratNo ratings yet

- Technical Note Guidance On Corrosion Assessment of Ex EquipmentDocument7 pagesTechnical Note Guidance On Corrosion Assessment of Ex EquipmentParthiban NagarajanNo ratings yet

- Caterpillar Generator Data C15Document12 pagesCaterpillar Generator Data C15Aditya PratamaNo ratings yet

- Amco CR4000Document4 pagesAmco CR4000Arwin TroconisNo ratings yet

- Wilkerson Filter Model B08-02-FKG0 Spec Sheet 9EM-B08Document7 pagesWilkerson Filter Model B08-02-FKG0 Spec Sheet 9EM-B08donsterthemonsterNo ratings yet

- Api Plan 11Document6 pagesApi Plan 11johnsaballaNo ratings yet

- Regulador American Meter PDFDocument6 pagesRegulador American Meter PDFjmcg1974No ratings yet

- CKV 05 Ex PDFDocument4 pagesCKV 05 Ex PDFengp3077No ratings yet

- RVC 05 NPT Product SpecsDocument6 pagesRVC 05 NPT Product SpecsAnonymous WVJNMWNo ratings yet

- L&T ButterflyValves Triple OffsetDocument16 pagesL&T ButterflyValves Triple OffsetvarathapandianNo ratings yet

- AV13 Air Vent For Steam Systems: DescriptionDocument2 pagesAV13 Air Vent For Steam Systems: DescriptionUtku KepcenNo ratings yet

- Gate, Globe & Check ValvesDocument52 pagesGate, Globe & Check ValvesBabar Manzoor GhauriNo ratings yet

- Econ Gate ValvesDocument20 pagesEcon Gate ValvesEngr.Mmosaad100% (1)

- Main DrainDocument4 pagesMain DrainAndrea Devky KresnaNo ratings yet

- Cain Bolt & Gasket Techinical ManualDocument16 pagesCain Bolt & Gasket Techinical ManualgirishnitwNo ratings yet

- Series LF288A Specification SheetDocument2 pagesSeries LF288A Specification SheetWattsNo ratings yet

- Sure Flow StrainersDocument13 pagesSure Flow StrainersNinad SherawalaNo ratings yet

- Regulador 1253 B - American M.Document8 pagesRegulador 1253 B - American M.Jheysson FloresNo ratings yet

- Series 8 Specification SheetDocument2 pagesSeries 8 Specification SheetWattsNo ratings yet

- Spirax Sarco Commissioning Strainer 1Document3 pagesSpirax Sarco Commissioning Strainer 1swaraj4uNo ratings yet

- Series 1070, P1070 Specification SheetDocument2 pagesSeries 1070, P1070 Specification SheetWattsNo ratings yet

- Wedge and Slab Gate ValvesDocument8 pagesWedge and Slab Gate Valvesgad30100% (1)

- RVC 05 FLG PDFDocument5 pagesRVC 05 FLG PDFengp3077No ratings yet

- Cokebuster: A Proven SolutionDocument11 pagesCokebuster: A Proven Solutionengg_mech77No ratings yet

- Model BPS-05-NPT: Stainless Steel Back Pressure Regulator ValveDocument8 pagesModel BPS-05-NPT: Stainless Steel Back Pressure Regulator ValveNet WalkerNo ratings yet

- Series G1070, GP1070 Specification SheetDocument2 pagesSeries G1070, GP1070 Specification SheetWattsNo ratings yet

- RVC05 150FLG Ex PDFDocument5 pagesRVC05 150FLG Ex PDFengp3077No ratings yet

- Series 957, 957N, 957ZDocument4 pagesSeries 957, 957N, 957ZWattsNo ratings yet

- Series SS07F Specification SheetDocument2 pagesSeries SS07F Specification SheetWattsNo ratings yet

- Ul - Viza - Ex15228 - Fittings Grooved PDFDocument3 pagesUl - Viza - Ex15228 - Fittings Grooved PDFJulio Rosas PezoNo ratings yet

- 160.75-RP1 (210) - Yk (G)Document92 pages160.75-RP1 (210) - Yk (G)JayashtonNo ratings yet

- Model BPS-09: Back Pressure-Reducing ValveDocument4 pagesModel BPS-09: Back Pressure-Reducing Valveengp3077No ratings yet

- Custom Engineered StrainersDocument37 pagesCustom Engineered StrainersJames Mink Sr.No ratings yet

- RVC 05 PDFDocument6 pagesRVC 05 PDFengp3077No ratings yet

- Model"Dc": Dual Chamber Orifice FittingDocument13 pagesModel"Dc": Dual Chamber Orifice FittingFrankNo ratings yet

- ButterflyDocument6 pagesButterflysachin2010No ratings yet

- DWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)Document3 pagesDWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)RamanNegiNo ratings yet

- Tour & Andersson Circuit Balancing Valves and Koil-Kit ComponentsDocument1 pageTour & Andersson Circuit Balancing Valves and Koil-Kit ComponentslesnikimagesNo ratings yet

- Metal Seated Sampling ValvesDocument4 pagesMetal Seated Sampling ValvesGiovanni TrinidadNo ratings yet

- Brochure 2010Document20 pagesBrochure 2010shankarsreekumarNo ratings yet

- Válvulas Bola SegmentadaDocument12 pagesVálvulas Bola SegmentadarehynaldoNo ratings yet

- SS2800 Side Pocket Mandrel GaugesDocument2 pagesSS2800 Side Pocket Mandrel GaugesGonza PfNo ratings yet

- Rva 05 PDFDocument4 pagesRva 05 PDFengp3077No ratings yet

- Manual Spirax SarcoDocument2 pagesManual Spirax SarcoAlex CarreraNo ratings yet

- Es LF777Document2 pagesEs LF777WattsNo ratings yet

- Codeline, 150 PSI, Drawing - 80S15Document3 pagesCodeline, 150 PSI, Drawing - 80S15RamanNegiNo ratings yet

- (2012) Complete IELTS Bands 5-6.5 Student's BookDocument3 pages(2012) Complete IELTS Bands 5-6.5 Student's BookAhmed Hamdy0% (1)

- 13 - Jesse Meisterling Gaskets and Leaks PVRC Recommendations and StudiesDocument0 pages13 - Jesse Meisterling Gaskets and Leaks PVRC Recommendations and StudiesVicky GautamNo ratings yet

- Singer ValveDocument5 pagesSinger ValveDGWNo ratings yet

- Series 008PCQT Specification SheetDocument2 pagesSeries 008PCQT Specification SheetWattsNo ratings yet

- B-313 Series E-1510 Technical BrochureDocument8 pagesB-313 Series E-1510 Technical BrochureAnonymous 7xHNgoKE6eNo ratings yet

- Series 774DCDA Specification SheetDocument2 pagesSeries 774DCDA Specification SheetWattsNo ratings yet

- Air Preparation ProductsDocument6 pagesAir Preparation ProductssenamotoNo ratings yet

- AmeritoolBroch Aug21Document12 pagesAmeritoolBroch Aug21hiscoke69No ratings yet

- Plumbing and Propane CatalogDocument40 pagesPlumbing and Propane Catalogdannyboy738No ratings yet

- Burst Plug Tubing Drain - Technical DatasheetDocument8 pagesBurst Plug Tubing Drain - Technical DatasheetEvolution Oil ToolsNo ratings yet

- Drawing 80H30Document3 pagesDrawing 80H30kpranjal15No ratings yet

- Flowserve Lined Flush BottomDocument32 pagesFlowserve Lined Flush BottomDevdatt WaghuleNo ratings yet

- RssDocument1 pageRssgenial72No ratings yet

- PRH09 PDFDocument4 pagesPRH09 PDFengp3077No ratings yet

- CTA Pocket CardDocument2 pagesCTA Pocket CardBreitbart News100% (1)

- EDUC 3 Module 1-Lesson 1Document12 pagesEDUC 3 Module 1-Lesson 1Ma. Kristel OrbocNo ratings yet

- SRS Template ExampleDocument16 pagesSRS Template ExampleabcNo ratings yet

- Safety Data Sheet Versamul Ic: 1. Identification of The Substance/Preparation and Company/UndertakingDocument4 pagesSafety Data Sheet Versamul Ic: 1. Identification of The Substance/Preparation and Company/UndertakingJose Rafael Martinez PerezNo ratings yet

- ONX 620 QuickStart Guide v10Document133 pagesONX 620 QuickStart Guide v10Haiward RinconNo ratings yet

- Foit LabDocument50 pagesFoit LabWAREKARNo ratings yet

- Ebook - Electronics Tutorial PDFDocument213 pagesEbook - Electronics Tutorial PDFHari Laxman M100% (1)

- Warid Telecom ReportDocument49 pagesWarid Telecom ReporthusnainjafriNo ratings yet

- Class 3: For More Such Worksheets VisitDocument4 pagesClass 3: For More Such Worksheets VisitSan BrothersNo ratings yet

- Summary WordingDocument5 pagesSummary WordingDaniel JenkinsNo ratings yet

- 5E Lesson Plan Template: Replace These Directions With Your WorkDocument4 pages5E Lesson Plan Template: Replace These Directions With Your Workapi-583088531No ratings yet

- SP6 MB Tutorial 01Document20 pagesSP6 MB Tutorial 01Nikola PetrakNo ratings yet

- LemleyDocument64 pagesLemleyMeshandren NaidooNo ratings yet

- UntitledDocument292 pagesUntitledD17CQAT01-N LE THANH TUANNo ratings yet

- 2010 Nissan Versa S Fluid CapacitiesDocument2 pages2010 Nissan Versa S Fluid CapacitiesRubenNo ratings yet

- Heresite Corrosion ProtectionDocument2 pagesHeresite Corrosion ProtectionDANIEL PEREZNo ratings yet

- Security SolutionsDocument3 pagesSecurity SolutionsclubedovarNo ratings yet

- 3 Methods For Crack Depth Measurement in ConcreteDocument4 pages3 Methods For Crack Depth Measurement in ConcreteEvello MercanoNo ratings yet

- Fevo 10 828503 1Document10 pagesFevo 10 828503 1keilazache2780No ratings yet

- Addmrpt 1 36558 36559Document7 pagesAddmrpt 1 36558 36559Anonymous ZGcs7MwsLNo ratings yet

- PR200241Document12 pagesPR200241Michaela CatacutanNo ratings yet

- Kariru - Contemporary Trends and Issues in The HospitalityDocument17 pagesKariru - Contemporary Trends and Issues in The Hospitalitygorgo.incNo ratings yet

- Water Flow and Heat Transport Including Icewater Phase Change in Porous Media Numerical Simulation and ApplicationDocument11 pagesWater Flow and Heat Transport Including Icewater Phase Change in Porous Media Numerical Simulation and ApplicationNorick CahyaNo ratings yet

- HRM1Document13 pagesHRM1Niomi GolraiNo ratings yet

- Math4190 Lecture-04-02 HDocument11 pagesMath4190 Lecture-04-02 Hchandan.thakurNo ratings yet