Professional Documents

Culture Documents

Product Environmental Profile: Canalis KBB 25 A

Product Environmental Profile: Canalis KBB 25 A

Uploaded by

GabriyelCopyright:

Available Formats

You might also like

- Chapter Notes - Our Environment - Class 10 Science - PANTOMATHDocument9 pagesChapter Notes - Our Environment - Class 10 Science - PANTOMATHsourav9823No ratings yet

- Heal Yourself With SunlightDocument5 pagesHeal Yourself With SunlightCurry, William Lawrence III, agent100% (1)

- Product Environmental Profile: Modular ContactorDocument4 pagesProduct Environmental Profile: Modular ContactorAbdellah SamadiNo ratings yet

- Product Environmental Profile: Magelis Rack PCDocument5 pagesProduct Environmental Profile: Magelis Rack PCRazvan NedelescuNo ratings yet

- Contactor Cap Lc1dDocument4 pagesContactor Cap Lc1dAlfiansyah Dharma Setia DjaketraNo ratings yet

- Patch Panel - Envpep111246en - v0Document4 pagesPatch Panel - Envpep111246en - v0arnabzicoNo ratings yet

- EPD AMG0900 EN RevB PDFDocument4 pagesEPD AMG0900 EN RevB PDFamk2009No ratings yet

- Condition Assesment 2015 D10 2 LIFE CYCLE ASSESSMENT MEDIUM VOLTAGE FOR FRENCH MARKET PDFDocument5 pagesCondition Assesment 2015 D10 2 LIFE CYCLE ASSESSMENT MEDIUM VOLTAGE FOR FRENCH MARKET PDFZellagui EnergyNo ratings yet

- Environmental Product Declaration: Epd I - Anpa - 6Document6 pagesEnvironmental Product Declaration: Epd I - Anpa - 6karian32000No ratings yet

- How Does An EPD Consider Embodied CarbonDocument5 pagesHow Does An EPD Consider Embodied Carbonjane AndersonNo ratings yet

- Product Environmental Profile: Modicon M340Document5 pagesProduct Environmental Profile: Modicon M340Leonardo NeiraNo ratings yet

- Bio-Based Engineering Plastics A Tool To Reduce Carbon FootprintDocument4 pagesBio-Based Engineering Plastics A Tool To Reduce Carbon FootprintSteve JenkinsNo ratings yet

- EPD H2O2-Eka ChemicalsDocument4 pagesEPD H2O2-Eka ChemicalsnhangocNo ratings yet

- Eco-Sheet 1.6 MVA Industrial Transformer Designs With Increasing EfficiencyDocument5 pagesEco-Sheet 1.6 MVA Industrial Transformer Designs With Increasing EfficiencySeyed IbrahimNo ratings yet

- CT TPDocument5 pagesCT TPcesarchiletNo ratings yet

- Epd For Ams Rev 6Document4 pagesEpd For Ams Rev 6Umair AfzalNo ratings yet

- Kingspan EPDs Paper ALCAS 2013Document11 pagesKingspan EPDs Paper ALCAS 2013Ingeniero Mac DonnellNo ratings yet

- 4 ReducingCO2 PDFDocument6 pages4 ReducingCO2 PDFAshutosh ShakyaNo ratings yet

- Product Environmental Profile: VW3E20 Feedback CableDocument6 pagesProduct Environmental Profile: VW3E20 Feedback CableLebongoNo ratings yet

- Greenhouse Gas Accounting and Reporting GuidanceDocument51 pagesGreenhouse Gas Accounting and Reporting Guidancebenjyy2008No ratings yet

- Life Cycle Assessment of Carbon Dioxide Capture For Enhanced Oil RecoveryDocument20 pagesLife Cycle Assessment of Carbon Dioxide Capture For Enhanced Oil RecoveryfsnexussNo ratings yet

- The E-Mission - Definitions and ValidationDocument6 pagesThe E-Mission - Definitions and ValidationSilviu TrebuianNo ratings yet

- Embodied Carbon Specification Clauses - Structural SteelDocument14 pagesEmbodied Carbon Specification Clauses - Structural SteelDarren LathamNo ratings yet

- Life Cycle Analysis of A Solar Module Recycling ProcessDocument3 pagesLife Cycle Analysis of A Solar Module Recycling ProcessEva VictoriaNo ratings yet

- Section 09250 - Gypsum Board: Whole Building Design Guide Federal Green Construction Guide For SpecifiersDocument3 pagesSection 09250 - Gypsum Board: Whole Building Design Guide Federal Green Construction Guide For SpecifiersAnonymous NMytbMiDNo ratings yet

- Envpep100401en V0Document4 pagesEnvpep100401en V0mesbah mNo ratings yet

- Envpep1511005 V2Document5 pagesEnvpep1511005 V2Jesús BenitezNo ratings yet

- 4401-Lca-Summary-1Document20 pages4401-Lca-Summary-1Rebaz AzizNo ratings yet

- Envpep1312016en V3Document5 pagesEnvpep1312016en V3Najwa NajwaNo ratings yet

- Scho1209brnz e e PDFDocument76 pagesScho1209brnz e e PDFmunawarNo ratings yet

- Evaluation of Greenhouse Gas Emissions From The European Urban Wastewater Sector, and Options For Their ReductionDocument13 pagesEvaluation of Greenhouse Gas Emissions From The European Urban Wastewater Sector, and Options For Their ReductiongbenincaNo ratings yet

- Distribution Transformer: Environmental Product DeclarationDocument3 pagesDistribution Transformer: Environmental Product DeclarationRafat ThongNo ratings yet

- Section 16500 - Lighting: Whole Building Design Guide Federal Green Construction Guide For SpecifiersDocument8 pagesSection 16500 - Lighting: Whole Building Design Guide Federal Green Construction Guide For SpecifiersAnonymous NMytbMiDNo ratings yet

- Open House 2Document13 pagesOpen House 2Edin ZahirovićNo ratings yet

- Acoustic Thermal GuideDocument67 pagesAcoustic Thermal GuideRadu GalNo ratings yet

- Product Environmental Profile: Switch 63A 2P BiconnectDocument5 pagesProduct Environmental Profile: Switch 63A 2P BiconnectMadusanka WeebeddaNo ratings yet

- BCMOE WTE Emissions FinalDocument325 pagesBCMOE WTE Emissions FinalJoseph Riley100% (1)

- Resource Management: toxicity/IEQ:: Section 15800 - Air DistributionDocument5 pagesResource Management: toxicity/IEQ:: Section 15800 - Air DistributionAnonymous NMytbMiDNo ratings yet

- Quantification of Greenhouse Gas Emissions From WoDocument13 pagesQuantification of Greenhouse Gas Emissions From WoRecky PahleviNo ratings yet

- Arval Acoustic SystemsDocument67 pagesArval Acoustic SystemscosminducaNo ratings yet

- Environment Life Cycle AssessmentDocument4 pagesEnvironment Life Cycle Assessmentshreya royNo ratings yet

- Feasibility Study Into A Gisborne Facility To Convert Waste Into EnergyDocument10 pagesFeasibility Study Into A Gisborne Facility To Convert Waste Into EnergyAnaya RantaNo ratings yet

- Envpep100301en V0Document4 pagesEnvpep100301en V0gogoNo ratings yet

- EPD TRAINingDocument110 pagesEPD TRAINingCharaf Eddine NakhiliNo ratings yet

- ENVPEP110202ENDocument5 pagesENVPEP110202ENckhg978No ratings yet

- DVVCXCVXCVXCVXCVXDocument5 pagesDVVCXCVXCVXCVXCVXImplantacion MovilNo ratings yet

- Cradle To Grave Report Window FramesDocument16 pagesCradle To Grave Report Window FramesblominoqueNo ratings yet

- Pol Bref 0807Document314 pagesPol Bref 0807dalia_bitan4847No ratings yet

- GH G ConversionDocument146 pagesGH G ConversionjorgeNo ratings yet

- 1 EPD Family OptaDocument14 pages1 EPD Family OptaAswin KurupNo ratings yet

- Envpep1512017 enDocument6 pagesEnvpep1512017 enRafaelNo ratings yet

- One-Way Switch FL Ush-Mounted: UnicaDocument4 pagesOne-Way Switch FL Ush-Mounted: UnicanedoosmaNo ratings yet

- Chapter 2 Life Cycle AssessmentDocument24 pagesChapter 2 Life Cycle AssessmentDaniel SonNo ratings yet

- HV Assignment 5Document5 pagesHV Assignment 5moosa meharNo ratings yet

- Envpep060406en V3Document5 pagesEnvpep060406en V3zetamieNo ratings yet

- 12M4 Gl-Glossary-030510Document7 pages12M4 Gl-Glossary-030510Martha Judith SeguraNo ratings yet

- High Density Polyethylene (HDPE) : Environmental Product Declarations of The European Plastics ManufacturersDocument4 pagesHigh Density Polyethylene (HDPE) : Environmental Product Declarations of The European Plastics ManufacturersMuhd AmirfaridNo ratings yet

- 2021-01 Biorefineries With CCSDocument69 pages2021-01 Biorefineries With CCSPeace100% (1)

- BREF Manufacture of Organic Fine Chemicals enDocument456 pagesBREF Manufacture of Organic Fine Chemicals enIrina MorosanuNo ratings yet

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementFrom EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNo ratings yet

- Predicting the Price of Carbon Supplement 1: Hinkley Point C Nuclear Power Station Enhanced Carbon Audit LCA Case StudyFrom EverandPredicting the Price of Carbon Supplement 1: Hinkley Point C Nuclear Power Station Enhanced Carbon Audit LCA Case StudyNo ratings yet

- Acer Aspire 5750 5750g SM PDFDocument293 pagesAcer Aspire 5750 5750g SM PDFGabriyelNo ratings yet

- Zubadan Inverter PUHZ-SHW230YHADocument2 pagesZubadan Inverter PUHZ-SHW230YHAGabriyelNo ratings yet

- A DEH PR-2014-0112-GB Hydraulik-Handbuch BR R2!02!2017 150dpiDocument84 pagesA DEH PR-2014-0112-GB Hydraulik-Handbuch BR R2!02!2017 150dpiGabriyelNo ratings yet

- Fisa Tehnica Cazan in Condensatie C230 PDFDocument16 pagesFisa Tehnica Cazan in Condensatie C230 PDFGabriyelNo ratings yet

- JumpPoint 12-21-2012 Mayan End of The World EditionDocument24 pagesJumpPoint 12-21-2012 Mayan End of The World EditionGabriyelNo ratings yet

- Filtair 400: The Power of BlueDocument4 pagesFiltair 400: The Power of BlueGabriyelNo ratings yet

- Dictionar Economic Roman Englez RomanDocument736 pagesDictionar Economic Roman Englez Romanddhenriett100% (12)

- Life Science Summary Grade 9 2019Document68 pagesLife Science Summary Grade 9 2019andrejankowski9No ratings yet

- Environment Yearly 2023 VisionDocument244 pagesEnvironment Yearly 2023 Visionmukeshsgf5No ratings yet

- Current Environmental Issues - Ahm 2Document108 pagesCurrent Environmental Issues - Ahm 2Mich KidNo ratings yet

- Harvard Bhatt Habermann Aff Texas OctasDocument40 pagesHarvard Bhatt Habermann Aff Texas OctasPeter ZhangNo ratings yet

- Updated MODULE - 4 NOTES 18ME751 ENERGY & ENVIRONMENTDocument18 pagesUpdated MODULE - 4 NOTES 18ME751 ENERGY & ENVIRONMENTNaru MNo ratings yet

- Chapter 9.... 1 MarkerDocument5 pagesChapter 9.... 1 MarkerShreya PushkarnaNo ratings yet

- STS ReviewerDocument11 pagesSTS ReviewerTresha CosmeñoNo ratings yet

- Cambridge Preparation For The TOEFL (R) Test, 3/E: Test 2 Listening Answer KeyDocument6 pagesCambridge Preparation For The TOEFL (R) Test, 3/E: Test 2 Listening Answer KeyLUIS GARCIANo ratings yet

- Atmosphere Study Guide 2013Document4 pagesAtmosphere Study Guide 2013api-205313794No ratings yet

- Unit No. 1 Evs Mcq-1Document7 pagesUnit No. 1 Evs Mcq-1AbcNo ratings yet

- 1-Exercise 21-9Document6 pages1-Exercise 21-9Hoang QuyenNo ratings yet

- Safety, Security and Environmental Considerations During PreDocument55 pagesSafety, Security and Environmental Considerations During PreJoel AlcantaraNo ratings yet

- English Record Sem 4-Pages-DeletedDocument36 pagesEnglish Record Sem 4-Pages-DeletedSundar GaneshNo ratings yet

- How To Write A Seminar PaperDocument7 pagesHow To Write A Seminar Papertemujin03No ratings yet

- 12 Regulation 12 Ozone Depleting SubstancesDocument2 pages12 Regulation 12 Ozone Depleting SubstancesMauzer777No ratings yet

- 1,1-DIFLUOROETHANE (HFC-152a) : CAS N°: 75-37-6Document81 pages1,1-DIFLUOROETHANE (HFC-152a) : CAS N°: 75-37-6Fadillatul Nissa100% (1)

- Evs PPT Uo-1d-1eDocument23 pagesEvs PPT Uo-1d-1emy pcNo ratings yet

- Cbleecpl 02Document8 pagesCbleecpl 02AdityaNo ratings yet

- Resources and DevelopmentDocument32 pagesResources and DevelopmentSwastiNo ratings yet

- Academic Reading Practice Test 7Document12 pagesAcademic Reading Practice Test 7ArshBrarNo ratings yet

- The Greenhouse EffectDocument4 pagesThe Greenhouse EffectMari2117No ratings yet

- Enviromental ChemistryDocument6 pagesEnviromental Chemistrymayashankarjha100% (1)

- USC Schedule Fall 2015 Courses PicksDocument4 pagesUSC Schedule Fall 2015 Courses Picksdanya_1997No ratings yet

- 200G1-Environmental Awareness (UG Computer Science)Document20 pages200G1-Environmental Awareness (UG Computer Science)gaurav gautamNo ratings yet

- 18civ59 Complete Notes QBDocument25 pages18civ59 Complete Notes QBJai PrakashNo ratings yet

- International Studies-Final Exam-PinkihanDocument17 pagesInternational Studies-Final Exam-PinkihanBielan Fabian GrayNo ratings yet

- Strange West FailureDocument10 pagesStrange West FailureMarianna TuriNo ratings yet

- Progress in Clean EnergyDocument941 pagesProgress in Clean EnergyMehul BansalNo ratings yet

Product Environmental Profile: Canalis KBB 25 A

Product Environmental Profile: Canalis KBB 25 A

Uploaded by

GabriyelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Environmental Profile: Canalis KBB 25 A

Product Environmental Profile: Canalis KBB 25 A

Uploaded by

GabriyelCopyright:

Available Formats

Product

Environmental

Profile

Canalis

KBB 25 A

Product Environmental Profile - PEP

Product Overview

The main purpose of the Canalis KBB product range is to distribute electrical power for

lighting (with luminaire support brackets).

This range consists of: Canalis KBB, 25 to 40 A, IP55.

The representative product used for the analysis is the typical product, KBB 25 A, which

consists of:

p 1 x 40 A power feed box (cat. no. KBB40ABG4)

p 7 x 3 m straight lengths, 1 m modules for tap-off units (cat. no. KBB25ED4303)

p 7 connectors (cat. no. KBC10DCB20)

p 22 fixing devices (cat. no. KBB40ZFU).

The environmental impacts of this referenced product are representative of the impacts of the

other products in the range for which the same technology is used.

The environmental analysis was performed in conformity with ISO 14040 "Environmental

management: Life cycle assessment Principle and framework".

This analysis takes the stages in the life cycle of the product into account.

Constituent materials

Substance assessment

Manufacturing

Distribution

The total mass of the typical product, KBB 25 A, is 32870 g, not including

the packaging, for the product analysed.

The constituent materials are distributed as follows:

Products of this range are designed in conformity with the requirements

of the RoHS directive (European Directive 2002/95/EC of 27 January

2003) and do not contain, or in the authorised proportions, lead, mercury,

cadmium, chromium hexavalent, flame retardant (polybromobiphenyles

PBB, polybromodiphenylthers PBDE) as mentioned in the Directive.

The Canalis KBB product range is manufactured at a SchneiderElectric

production site on which an ISO 14001 certified environmental

management system has been established.

The weight and volume of the packaging have been reduced in

compliance with the European Unions packaging directive.

The weight of the packaging of the typical product, KBB, is 1570 g.

Itconsists of 1130 g of cardboard and 440 g of wood.

The product distribution flows have been optimised by setting up the

Internal Distribution Centre on the production site and Local Distribution

Centres close to the market areas.

Product Environmental Profile - PEP

Utilization

End of life

Environmental impacts

The products in the Canalis KBB range do not generate any

environmental pollution requiring special precautionary measures (noise,

emissions, etc.).

The dissipated power depends on the conditions under which the product

is implemented and used.

The dissipated power is 218 W for the typical product, KBB, referenced,

i.e. 10.4 W/metre.

This heat dissipation accounts for less than 0.2 % of the total power

passing through the product.

At end of life, the products in the Canalis KBB range can either be

dismantled or crushed to facilitate the recovery of the various constituent

materials.

The recycling potential is higher than 95 %. This percentage includes

ferrous metals, copper, aluminium and marked thermoplastic resins not

containing brominated flame retardants, such as those mentioned in the

RoHS directive, or halogenated flame retardants.

The end of life data appears on the product end-of-life sheet.

The EIME (Environmental Impact and Management Explorer) software,

version 1.6 and its database were used for the Life Cycle Assessment

(LCA).

The assumed service life of the product is 20 years with an installation

utilisation rate of 30 % and a load rate of 50 %. The EUROPEAN

electrical power model is used.

The analysis focused on a "typical product", the KBB, consisting of

7straight lengths, cat. no. KBB25ED4303, a power feed box, cat.

no.KBB40ABG4, 7 standard connectors cat. no. KBC10DCB20 and

22standard fixing devices cat. no. KBB40ZFU.

The environmental impacts were analysed for the Manufacturing (M)

phase including the processing of raw materials, the Distribution (D)

phase including transport and the Utilisation (U) phase including energy

consumption.

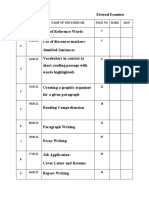

Presentation of product environmental impacts

Environmental indicators

Raw Material Depletion

Unit

Y-1

For a Canalis KBB 25 A (1,000 unit)

S=M+D+U M

D

1.54 10-13

9.97 10-14

1.43 10-16

U

5.44 10-14

Energy consumption

MJ

1.35 105

1.63 103

1.03 102

1.33 105

Water Depletion

dm

2.83 10

1.20 10

9.96

2.71E 104

Global Warming

gCO2

1.00 10

1.41 10

8.98 10

Ozone Depletion

Photochemical Ozone Creation

Air Acidification

Hazardous Waste Production

8.54 105

gCFC-11

8.90 10-2

1.61 10-2

5.88 10-3

6.70 10-2

gC2H4

4.68 10

28.3

11.2

4.28 102

gH+

1.91 10

21.9

kg

11.1

9.03 10

2.13

-2

3.18 10

1.67 102

-3

11

The life cycle analysis showed that the Utilisation phase is the life cycle

phase that has the greatest impact on the majority of the environmental

indicators and the environmental parameters of this phase were optimised

at the design stage, with the specific aim of reducing energy losses.

Product Environmental Profile - PEP

System approach

As the product of the range are designed in accordance with the RoHS

Directive (European Directive 2002/95/EC of 27 January 2003),

they can be incorporated without any restriction within an assembly or

an installation submitted to this Directive.

N.B.: please note that the environmental impacts of the product depend on the use and

installation conditions of the product.

Impacts values given above are only valid within the context specified and cannot be directly

used to draw up the environmental assessment of the installation.

Raw Material Depletion (RMD)

This indicator quantifies the consumption of raw materials during the life

cycle of the product. It is expressed as the fraction of natural resources

that disappear each year, with respect to all the annual reserves of

the material.

Energy Depletion (ED)

This indicator gives the quantity of energy consumed, whether it be from

fossil, hydroelectric, nuclear or other sources.

This indicator takes into account the energy from the material produced

during combustion. It is expressed in MJ.

Water Depletion (WD)

This indicator calculates the volume of water consumed, including

drinking water and water from industrial sources. It is expressed in dm3.

Global Warming (GW)

The global warming of the planet is the result of the increase in

the greenhouse effect due to the sunlight reflected by the earths surface

being absorbed by certain gases known as "greenhouse-effect" gases.

The effect is quantified in gram equivalent of CO2.

Ozone Depletion (OD)

This indicator defines the contribution to the phenomenon of

the disappearance of the stratospheric ozone layer due to the emission

of certain specific gases. The effect is expressed in gram equivalent

of CFC-11.

Photochemical Ozone Creation (POC)

This indicator quantifies the contribution to the "smog" phenomenon

(the photochemical oxidation of certain gases which generates ozone)

and is expressed in gram equivalent of ethylene (C2H4).

Air Acidification (AA)

The acid substances present in the atmosphere are carried by rain.

A high level of acidity in the rain can cause damage to forests.

The contribution of acidification is calculated using the acidification

potentials of the substances concerned and is expressed in mode

equivalent of H+.

Hazardous Waste Production (HWP)

This indicator calculates the quantity of specially treated waste created

during all the life cycle phases (manufacturing, distribution and utilization).

For example, special industrial waste in the manufacturing phase, waste

associated with the production of electrical power, etc.

It is expressed in kg.

Registration No.: SCHN-2011-076-V0

Programme information: www.pep-ecopassport.org

PEP in compliance with PEPecopassport according to PEP-AP0011 rules

ACV rules are available from PEP editor on request

Schneider Electric Industries SAS

35, rue Joseph Monier

CS30323

F - 92506 Rueil Malmaison Cedex

RCS Nanterre 954 503 439

Capital social 896 313 776

www.schneider-electric.com

ENVPEP061102EN

We are committed to safeguarding

our planet by "Combining

innovation and continuous

improvement to meet the new

environmental challenges".

Published by: Schneider Electric

02-2010

2010 - Schneider Electric - All rights reserved

Glossary

You might also like

- Chapter Notes - Our Environment - Class 10 Science - PANTOMATHDocument9 pagesChapter Notes - Our Environment - Class 10 Science - PANTOMATHsourav9823No ratings yet

- Heal Yourself With SunlightDocument5 pagesHeal Yourself With SunlightCurry, William Lawrence III, agent100% (1)

- Product Environmental Profile: Modular ContactorDocument4 pagesProduct Environmental Profile: Modular ContactorAbdellah SamadiNo ratings yet

- Product Environmental Profile: Magelis Rack PCDocument5 pagesProduct Environmental Profile: Magelis Rack PCRazvan NedelescuNo ratings yet

- Contactor Cap Lc1dDocument4 pagesContactor Cap Lc1dAlfiansyah Dharma Setia DjaketraNo ratings yet

- Patch Panel - Envpep111246en - v0Document4 pagesPatch Panel - Envpep111246en - v0arnabzicoNo ratings yet

- EPD AMG0900 EN RevB PDFDocument4 pagesEPD AMG0900 EN RevB PDFamk2009No ratings yet

- Condition Assesment 2015 D10 2 LIFE CYCLE ASSESSMENT MEDIUM VOLTAGE FOR FRENCH MARKET PDFDocument5 pagesCondition Assesment 2015 D10 2 LIFE CYCLE ASSESSMENT MEDIUM VOLTAGE FOR FRENCH MARKET PDFZellagui EnergyNo ratings yet

- Environmental Product Declaration: Epd I - Anpa - 6Document6 pagesEnvironmental Product Declaration: Epd I - Anpa - 6karian32000No ratings yet

- How Does An EPD Consider Embodied CarbonDocument5 pagesHow Does An EPD Consider Embodied Carbonjane AndersonNo ratings yet

- Product Environmental Profile: Modicon M340Document5 pagesProduct Environmental Profile: Modicon M340Leonardo NeiraNo ratings yet

- Bio-Based Engineering Plastics A Tool To Reduce Carbon FootprintDocument4 pagesBio-Based Engineering Plastics A Tool To Reduce Carbon FootprintSteve JenkinsNo ratings yet

- EPD H2O2-Eka ChemicalsDocument4 pagesEPD H2O2-Eka ChemicalsnhangocNo ratings yet

- Eco-Sheet 1.6 MVA Industrial Transformer Designs With Increasing EfficiencyDocument5 pagesEco-Sheet 1.6 MVA Industrial Transformer Designs With Increasing EfficiencySeyed IbrahimNo ratings yet

- CT TPDocument5 pagesCT TPcesarchiletNo ratings yet

- Epd For Ams Rev 6Document4 pagesEpd For Ams Rev 6Umair AfzalNo ratings yet

- Kingspan EPDs Paper ALCAS 2013Document11 pagesKingspan EPDs Paper ALCAS 2013Ingeniero Mac DonnellNo ratings yet

- 4 ReducingCO2 PDFDocument6 pages4 ReducingCO2 PDFAshutosh ShakyaNo ratings yet

- Product Environmental Profile: VW3E20 Feedback CableDocument6 pagesProduct Environmental Profile: VW3E20 Feedback CableLebongoNo ratings yet

- Greenhouse Gas Accounting and Reporting GuidanceDocument51 pagesGreenhouse Gas Accounting and Reporting Guidancebenjyy2008No ratings yet

- Life Cycle Assessment of Carbon Dioxide Capture For Enhanced Oil RecoveryDocument20 pagesLife Cycle Assessment of Carbon Dioxide Capture For Enhanced Oil RecoveryfsnexussNo ratings yet

- The E-Mission - Definitions and ValidationDocument6 pagesThe E-Mission - Definitions and ValidationSilviu TrebuianNo ratings yet

- Embodied Carbon Specification Clauses - Structural SteelDocument14 pagesEmbodied Carbon Specification Clauses - Structural SteelDarren LathamNo ratings yet

- Life Cycle Analysis of A Solar Module Recycling ProcessDocument3 pagesLife Cycle Analysis of A Solar Module Recycling ProcessEva VictoriaNo ratings yet

- Section 09250 - Gypsum Board: Whole Building Design Guide Federal Green Construction Guide For SpecifiersDocument3 pagesSection 09250 - Gypsum Board: Whole Building Design Guide Federal Green Construction Guide For SpecifiersAnonymous NMytbMiDNo ratings yet

- Envpep100401en V0Document4 pagesEnvpep100401en V0mesbah mNo ratings yet

- Envpep1511005 V2Document5 pagesEnvpep1511005 V2Jesús BenitezNo ratings yet

- 4401-Lca-Summary-1Document20 pages4401-Lca-Summary-1Rebaz AzizNo ratings yet

- Envpep1312016en V3Document5 pagesEnvpep1312016en V3Najwa NajwaNo ratings yet

- Scho1209brnz e e PDFDocument76 pagesScho1209brnz e e PDFmunawarNo ratings yet

- Evaluation of Greenhouse Gas Emissions From The European Urban Wastewater Sector, and Options For Their ReductionDocument13 pagesEvaluation of Greenhouse Gas Emissions From The European Urban Wastewater Sector, and Options For Their ReductiongbenincaNo ratings yet

- Distribution Transformer: Environmental Product DeclarationDocument3 pagesDistribution Transformer: Environmental Product DeclarationRafat ThongNo ratings yet

- Section 16500 - Lighting: Whole Building Design Guide Federal Green Construction Guide For SpecifiersDocument8 pagesSection 16500 - Lighting: Whole Building Design Guide Federal Green Construction Guide For SpecifiersAnonymous NMytbMiDNo ratings yet

- Open House 2Document13 pagesOpen House 2Edin ZahirovićNo ratings yet

- Acoustic Thermal GuideDocument67 pagesAcoustic Thermal GuideRadu GalNo ratings yet

- Product Environmental Profile: Switch 63A 2P BiconnectDocument5 pagesProduct Environmental Profile: Switch 63A 2P BiconnectMadusanka WeebeddaNo ratings yet

- BCMOE WTE Emissions FinalDocument325 pagesBCMOE WTE Emissions FinalJoseph Riley100% (1)

- Resource Management: toxicity/IEQ:: Section 15800 - Air DistributionDocument5 pagesResource Management: toxicity/IEQ:: Section 15800 - Air DistributionAnonymous NMytbMiDNo ratings yet

- Quantification of Greenhouse Gas Emissions From WoDocument13 pagesQuantification of Greenhouse Gas Emissions From WoRecky PahleviNo ratings yet

- Arval Acoustic SystemsDocument67 pagesArval Acoustic SystemscosminducaNo ratings yet

- Environment Life Cycle AssessmentDocument4 pagesEnvironment Life Cycle Assessmentshreya royNo ratings yet

- Feasibility Study Into A Gisborne Facility To Convert Waste Into EnergyDocument10 pagesFeasibility Study Into A Gisborne Facility To Convert Waste Into EnergyAnaya RantaNo ratings yet

- Envpep100301en V0Document4 pagesEnvpep100301en V0gogoNo ratings yet

- EPD TRAINingDocument110 pagesEPD TRAINingCharaf Eddine NakhiliNo ratings yet

- ENVPEP110202ENDocument5 pagesENVPEP110202ENckhg978No ratings yet

- DVVCXCVXCVXCVXCVXDocument5 pagesDVVCXCVXCVXCVXCVXImplantacion MovilNo ratings yet

- Cradle To Grave Report Window FramesDocument16 pagesCradle To Grave Report Window FramesblominoqueNo ratings yet

- Pol Bref 0807Document314 pagesPol Bref 0807dalia_bitan4847No ratings yet

- GH G ConversionDocument146 pagesGH G ConversionjorgeNo ratings yet

- 1 EPD Family OptaDocument14 pages1 EPD Family OptaAswin KurupNo ratings yet

- Envpep1512017 enDocument6 pagesEnvpep1512017 enRafaelNo ratings yet

- One-Way Switch FL Ush-Mounted: UnicaDocument4 pagesOne-Way Switch FL Ush-Mounted: UnicanedoosmaNo ratings yet

- Chapter 2 Life Cycle AssessmentDocument24 pagesChapter 2 Life Cycle AssessmentDaniel SonNo ratings yet

- HV Assignment 5Document5 pagesHV Assignment 5moosa meharNo ratings yet

- Envpep060406en V3Document5 pagesEnvpep060406en V3zetamieNo ratings yet

- 12M4 Gl-Glossary-030510Document7 pages12M4 Gl-Glossary-030510Martha Judith SeguraNo ratings yet

- High Density Polyethylene (HDPE) : Environmental Product Declarations of The European Plastics ManufacturersDocument4 pagesHigh Density Polyethylene (HDPE) : Environmental Product Declarations of The European Plastics ManufacturersMuhd AmirfaridNo ratings yet

- 2021-01 Biorefineries With CCSDocument69 pages2021-01 Biorefineries With CCSPeace100% (1)

- BREF Manufacture of Organic Fine Chemicals enDocument456 pagesBREF Manufacture of Organic Fine Chemicals enIrina MorosanuNo ratings yet

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementFrom EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNo ratings yet

- Predicting the Price of Carbon Supplement 1: Hinkley Point C Nuclear Power Station Enhanced Carbon Audit LCA Case StudyFrom EverandPredicting the Price of Carbon Supplement 1: Hinkley Point C Nuclear Power Station Enhanced Carbon Audit LCA Case StudyNo ratings yet

- Acer Aspire 5750 5750g SM PDFDocument293 pagesAcer Aspire 5750 5750g SM PDFGabriyelNo ratings yet

- Zubadan Inverter PUHZ-SHW230YHADocument2 pagesZubadan Inverter PUHZ-SHW230YHAGabriyelNo ratings yet

- A DEH PR-2014-0112-GB Hydraulik-Handbuch BR R2!02!2017 150dpiDocument84 pagesA DEH PR-2014-0112-GB Hydraulik-Handbuch BR R2!02!2017 150dpiGabriyelNo ratings yet

- Fisa Tehnica Cazan in Condensatie C230 PDFDocument16 pagesFisa Tehnica Cazan in Condensatie C230 PDFGabriyelNo ratings yet

- JumpPoint 12-21-2012 Mayan End of The World EditionDocument24 pagesJumpPoint 12-21-2012 Mayan End of The World EditionGabriyelNo ratings yet

- Filtair 400: The Power of BlueDocument4 pagesFiltair 400: The Power of BlueGabriyelNo ratings yet

- Dictionar Economic Roman Englez RomanDocument736 pagesDictionar Economic Roman Englez Romanddhenriett100% (12)

- Life Science Summary Grade 9 2019Document68 pagesLife Science Summary Grade 9 2019andrejankowski9No ratings yet

- Environment Yearly 2023 VisionDocument244 pagesEnvironment Yearly 2023 Visionmukeshsgf5No ratings yet

- Current Environmental Issues - Ahm 2Document108 pagesCurrent Environmental Issues - Ahm 2Mich KidNo ratings yet

- Harvard Bhatt Habermann Aff Texas OctasDocument40 pagesHarvard Bhatt Habermann Aff Texas OctasPeter ZhangNo ratings yet

- Updated MODULE - 4 NOTES 18ME751 ENERGY & ENVIRONMENTDocument18 pagesUpdated MODULE - 4 NOTES 18ME751 ENERGY & ENVIRONMENTNaru MNo ratings yet

- Chapter 9.... 1 MarkerDocument5 pagesChapter 9.... 1 MarkerShreya PushkarnaNo ratings yet

- STS ReviewerDocument11 pagesSTS ReviewerTresha CosmeñoNo ratings yet

- Cambridge Preparation For The TOEFL (R) Test, 3/E: Test 2 Listening Answer KeyDocument6 pagesCambridge Preparation For The TOEFL (R) Test, 3/E: Test 2 Listening Answer KeyLUIS GARCIANo ratings yet

- Atmosphere Study Guide 2013Document4 pagesAtmosphere Study Guide 2013api-205313794No ratings yet

- Unit No. 1 Evs Mcq-1Document7 pagesUnit No. 1 Evs Mcq-1AbcNo ratings yet

- 1-Exercise 21-9Document6 pages1-Exercise 21-9Hoang QuyenNo ratings yet

- Safety, Security and Environmental Considerations During PreDocument55 pagesSafety, Security and Environmental Considerations During PreJoel AlcantaraNo ratings yet

- English Record Sem 4-Pages-DeletedDocument36 pagesEnglish Record Sem 4-Pages-DeletedSundar GaneshNo ratings yet

- How To Write A Seminar PaperDocument7 pagesHow To Write A Seminar Papertemujin03No ratings yet

- 12 Regulation 12 Ozone Depleting SubstancesDocument2 pages12 Regulation 12 Ozone Depleting SubstancesMauzer777No ratings yet

- 1,1-DIFLUOROETHANE (HFC-152a) : CAS N°: 75-37-6Document81 pages1,1-DIFLUOROETHANE (HFC-152a) : CAS N°: 75-37-6Fadillatul Nissa100% (1)

- Evs PPT Uo-1d-1eDocument23 pagesEvs PPT Uo-1d-1emy pcNo ratings yet

- Cbleecpl 02Document8 pagesCbleecpl 02AdityaNo ratings yet

- Resources and DevelopmentDocument32 pagesResources and DevelopmentSwastiNo ratings yet

- Academic Reading Practice Test 7Document12 pagesAcademic Reading Practice Test 7ArshBrarNo ratings yet

- The Greenhouse EffectDocument4 pagesThe Greenhouse EffectMari2117No ratings yet

- Enviromental ChemistryDocument6 pagesEnviromental Chemistrymayashankarjha100% (1)

- USC Schedule Fall 2015 Courses PicksDocument4 pagesUSC Schedule Fall 2015 Courses Picksdanya_1997No ratings yet

- 200G1-Environmental Awareness (UG Computer Science)Document20 pages200G1-Environmental Awareness (UG Computer Science)gaurav gautamNo ratings yet

- 18civ59 Complete Notes QBDocument25 pages18civ59 Complete Notes QBJai PrakashNo ratings yet

- International Studies-Final Exam-PinkihanDocument17 pagesInternational Studies-Final Exam-PinkihanBielan Fabian GrayNo ratings yet

- Strange West FailureDocument10 pagesStrange West FailureMarianna TuriNo ratings yet

- Progress in Clean EnergyDocument941 pagesProgress in Clean EnergyMehul BansalNo ratings yet