Professional Documents

Culture Documents

Hexane Safe Handling Tips PDF

Hexane Safe Handling Tips PDF

Uploaded by

aminOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hexane Safe Handling Tips PDF

Hexane Safe Handling Tips PDF

Uploaded by

aminCopyright:

Available Formats

PROCESSING-Round table

Solvent Safety

L.W. SHOEMAKER, The French Oil Mill Machinery Company, Piqua, OH 45356

The safe handling of flammable petroleum solvents used in

the solvent extraction of oilseeds begins with the design of

a new plant. The areas requiring strict attention deal with

receiving, storage and handling the solvent. Strict operating

procedures should be prepared and followed. Employees

must constantly be made aware of the hazards involved in

handling flammable solvents. Recognized groups have outlined the requirements in both design and operating practice

which will help managers and superintendents insure and

enhance their plant operating safety.

Hexane (C6H14) is a paraffinic hydrocarbon and a colorless liquid with an obvious odor which has been described

as good to pleasant. Its specific gravity is ca..685, or slightly

less than 5.6 lb/gal. It has a boiling range of 150-156 F

(65.6-68.9 C). Unfortunately, these are the only benign

characteristics of this liquid. Its open cup flash point,

defined as the temperature at which the vapors of a volatile

liquid mixed with air spontaneously ignite, is -14.4 F

(-25.8 C) and a closed cup flash point of -7 F (-21.7 C).

The rate of flame propagation in an open air vapor conflagration is more than 15 ft/sec (4.6 m/sec). In an open air

vapor explosion, 20 gal of hexane has an equivalent explosive force as 1 lb of TNT. This statistic means that the

amount of hexane normally stored at an oilseed processing

plant, when mixed with adequate oxygen for combustion,

could level a normal-sized city block.

Why would we wish to subject ourselves to close proximity to such a dangerous material? If anyone were to tell

me that he has no concern at all about working around

hexane, I would question his mental competence. Even

before the first fire or explosion occurred at a plant using

hexane as the solvent, people were exploring the range of

available solvents for one which is nonflammable and functional for the extraction of vegetable oils. A variety of

solvents has been tried in the extraction of vegetable oil.

Trichloroethylene (TCE) is nonflammable, has a reasonably

high boiling point, and does a superb job of extracting o i l

from oilseeds; however, it has one significant drawback.

During the extraction process, it participates in a chemical

process which leaves the resultant meal with certain constituents which are toxic to animals. Methylene chloride

also does an excellent job of extracting vegetable oil and

does not have the toxic effects of TCE, but has a boiling

range of 90-100 F (32-37.8 C), which makes it unmanageable in warm climates.

Normal hexane has the best compromise of solubility,

low latent heat of vaporization and boiling range, and until

another solvent which is nonflammable meets these requirements and is approved by the appropriate agencies of government, we will continue to deal with hazardous, flammable solvents.

F o r ease of demonstrating some of the safety procedures,

I would like to review the basic elements of combustion.

There are three elements necessary to produce normal

combustion. These are.- fuel, oxygen and heat. The objective of most safety procedures and standards in solvent

extraction plants is designed to prevent the combination of

these three conditions. If at all possible, the a t t e m p t must

be made to prevent a combination of even two of these

elements.

The National Fire Protection Association Bulletin #36

(National Fire Protection Association, 470 Atlantic Ave.,

Boston, MA 02210) should always be on hand to remind

you of information you may not remember.

A method of isolating fuel (hexane) from oxygen is to

keep the hexane confined in the vessels which were designed

for this purpose. This is done by maintaining effective

gaskets and seals on all vessels and pumps. A regular maintenance procedure should involve checking these gaskets

and seals and when they are removed for maintenance, they

should not be reused or replaced. When the seals separating

the oxygen from hexane during maintenance procedures are

broken, the protective barrier separating these two elements

o f combustion is gone. Thus, prior to removing this barrier,

hexane should be purged from the vessel.

There is a variety of heat sources that must be prevented

from contacting hexane. The most obvious of these, of

course, is open flames. For this reason, boilers, internal

combustion engines and smoking is prohibited within 100

ft of a solvent extraction plant. Within this same 100-ft

area, electrical power cables and switches must be within

explosion-proof enclosures. This definition of explosionproof does not imply a total prevention of hexane coming

into contact with electrical sparks, but means that, should

an explosion occur, it will be confined to the explosionproof enclosure. Static electricity also is a source of heat

for the combustion triangle. Static electricity can be produced in at least three ways. It can be mechanically induced

by rotating machinery, personally produced by wearing of

improper clothing and shoes, o r - t h e one source over which

we have no c o n t r o l - i t can be weather-induced. The precautions which can be taken against mechanically induced

static electricity are the proper grounding of all machinery,

and the prohibition of belt drives in the extraction area.

For the weather-related static electricity in the form of

lightning, lightning rods and grounding of the equipment

and building to a c o m m o n point offers the most protection. Training of personnel is the best way to avoid the

static electricity produced by people. It is recommended

that synthetic fiber clothing not be worn, i.e., that clothing

be made of cotton. Footwear should be of a type with no

exposed steel nails, and it is also recommended that rubbersoled shoes not be worn, because these insulate the wearer

so that a charge will accumulate on his body.

This is not a large number of rules to remember; let us

then see how they can be practically applied.

The first danger is in the receiving, unloading and storage

of hexane. The same rules apply, whether ,ou receive

hexane b y truck or by railcar. In the hexane receiving area,

signs should be posted prohibiting open flames within 100

ft of the point of unloading. Both the tank and the truck or

railcar must be grounded to a c o m m o n point. The truck or

railcar wheels should be blocked and the brake set to prevent any movement. The truck m o t o r must be turned off

during the unloading and the driver should not leave his

vehicle unattended. Of utmost importance during this

period is that a responsible supervisor be present to insure

that these procedures are enforced during the entire unloading operation. After this unloading operation, the

solvent is once again confined with a steel wall as a barrier

separating the hexane and oxygen.

The next dangerous period during which it is difficult

to separate the elements of combustion is in the shutdown

process. A detailed analysis of shutdown procedures is

JAOCS March 1981 / 197

WORLD CONFERENCE ON SOYA PROCESSING AND UTILIZATION

pointless at this time, because all solvent extraction installations are different from each other in one way or another.

The objective of an orderly shutdown is to remove the

hexane from process vessels, and transfer it once again to

a safe storage point. This storage point may be in a vessel

within the extraction plant, if it is to be a short duration

shutdown, or back to the hexane storage tank outside of

the plant if the shutdown is to be of long duration.

In the shutting-down process, vessels are emptied in an

orderly manner by first stopping the feed of raw materials

to the extractor. The extractor continues to run until raw

material has been extracted and desolventized and moved

out of the extraction plant. Because most extraction systems are the countercurrent type, solvent and miscella

cannot be removed from the extraction vessel until after

the spent materials are completely processed. After the

spent material is removed from the extractor, the supply

of fresh solvent is stopped. The pumping of the various

stages continues until the wells or containers for these

stages are emptied, at which time the appropriate pumps

are stopped. While the extractor is being emptied and afterward, the distillation and solvent recovery systems continue

to run until all miscella has been evaporated, and the solvent condensed. This is the point at which the decision is

made for purging either the entire plant or only the vessel

on which work is required.

At this point, flammable vapor should be mentioned. We

are all familiar with the flooded carburetor of a car. This is

the case where the proportion of air and fuel is too rich to

make an explosive mixture. The opposite case also can

occur when there is too little fuel in the fuel and air mixture for explosion to occur. The same is true of the mixture

of hexane and air. This explosive mixture is the range from

1.1 to 7.5% by wt. These percentages are referred to as

the lower explosive limit and the upper explosive limit, or

LEL and UEL.

Prior to opening a vessel containing hexane in liquid or

vapor form, the mixture is well above the upper explosive

limit and approaches 100% concentration. The purging of

vessels (particularly the extractor) is designed to keep this

mixture outside the explosive limits. We can do this by

using another gas which is not flammable to displace the

hexane vapor, prior to the admittance of air. Nitrogen and

carbon dioxide, when put into a vessel, will displace the

hexane vapor from that vessel. Once this is accomplished,

air can be admitted, and the hexane vapor will have been

removed from the vessel having never entered the explosive

range.

This same procedure can be used in reverse during startup by displacing air with the inert gas before admitting

hexane to the vessel.

Heat sources of all types are used in maintenance, e.g.,

welding equipment, torches and steel tools. For this reason,

absolute control is required and it is recommended that a

system be established whereby these tools are not permitted

in the extraction area without written authorization of the

supervisor. This authorization should be given only after a

thorough inspection is made and the area has been tested

and shown to be free of hexane vapors. For light maintenance iri areas which are not free from hexane vapor, sparkproof tools made of brass or aluminum alloy must be used.

Visitors to a solvent extraction installation should be

strictly controlled. Visitors must certainly be advised of

the danger of working around hexane, and must leave any

matches or other smoking materials in a safe place prior

to entering this area. Visitors should receive badges or other

198 / JAOCS March 1981

identification so that workers in the area will know they are

authorized. Workers must also be instructed to challenge

anyone visiting who does not have this badge.

It is possible that all of these precautions may fail and a

fire will start. There is a variety of systems for fire protection. I am not an expert on any of them, and, thus, will not

offer my opinion on which is the best. I suggest, however,

that whichever system is installed, its main purpose is protecting people, not equipment. The systems are heatactivated, and when activated, may put out a small fire, but

mainly will offer protection for people within the building

and allow adequate time for escape. Whichever system is

used, it is vital that all people working in the area be thoroughly familiar with the operation of the system, so that if

they become aware of a fire before it is sensed by the

system, they may activate it.

Fire fighting equipment is equally important, because

most solvent extraction plants are located in relatively

remote areas for aesthetic considerations. All people working

in this area must be familiar with the location and operation of hydrants and extinguishers so that they may, once

they are safe from the fire, make every effort to extinguish

it. This should be part of a regular training program for

employees.

Hexane vapor has a characteristic that is quite often

ignored, even by those very used to working with hexane.

That is, hexane is dangerous to breathe in high concentrations. Areas with high concentrations of hexane are very

intoxicating, and because it is more dense than air, hexane

displaces air which can lead to asphyxiation in people

breathing the vapors. For this reason, when it is necessary

to work in areas of high concentration, the workers should

be supplied with a portable air supply, or a mask and hose

connected to an outside air supply. This alone is not a

sufficient precaution, because the equipment may malfunction. Also, the worker's judgement cannot be relied upon

because hexane is an intoxicant and will affect his reasoning. Thus, it is mandatory that an observer outside the vessel

constantly be present to observe the worker or workers

inside the vessel and determine if a dangerous condition

exists and then go for help, if necessary.

Preventing the combination of the three elements of

combustion is simple enough to master. However, the

numerous points at which this combination can occur make

the job complicated. For this reason, a regular system of

inspections and reporting must be implemented. In addition

to this regular reporting system, a safety committee within

the plant is suggested. This committee could have rotating

positions, so that all employees have an opportunity to

become familiar with and feel a personal responsibility for

their own and their coworkers' safety. Meetings of this

committee should be held on a monthly basis and minutes

of the meeting should be published for all employees to

read. Recommendations of the committee for improving

safety standards should carry high priority with the management of the plant, and observations of safety violations

should be dealt with immediately.

REFERENCES

1.

2.

3.

Gugan, K. "Unconfined Vapor Cloud Explosions," Gulf Publishers, 1979.

"Fire Protection Manual for Hydrocarbon Processing Plants,"

edited by C. Vervalin Gulf Publishers, 1974.

"Solvent Extraction Plants, 1978," National Fire Protection

Association, Boston, MA, 1978.

You might also like

- As 3780-2008 The Storage and Handling of Corrosive Substances - PDF (Personal Use)Document57 pagesAs 3780-2008 The Storage and Handling of Corrosive Substances - PDF (Personal Use)daveNo ratings yet

- On-Site Generation of Hypochlorite: First EditionDocument173 pagesOn-Site Generation of Hypochlorite: First EditiontestNo ratings yet

- Lawsuit Against C6 Zero For ExplosionDocument5 pagesLawsuit Against C6 Zero For ExplosionA.W. CarrosNo ratings yet

- PROPASECDocument5 pagesPROPASECMeravigliorso76No ratings yet

- Precision Extraction: Hemp Process FlowDocument1 pagePrecision Extraction: Hemp Process Flowsandydocs0% (1)

- Paraffin DispersantDocument11 pagesParaffin DispersantWael FaragNo ratings yet

- Petroleum Refinery HSE ManualDocument11 pagesPetroleum Refinery HSE ManualFarrukh TouheedNo ratings yet

- SAFETY - Data Sheet For PetrolDocument13 pagesSAFETY - Data Sheet For Petroluday_khandavilliNo ratings yet

- Brochure TDS RedicoteE 4819Document1 pageBrochure TDS RedicoteE 4819Research and DevelopmentNo ratings yet

- US9260541 Methods of Catalyst ActivationDocument22 pagesUS9260541 Methods of Catalyst ActivationyamakunNo ratings yet

- Operation and Maintenance Manual For The Lo/Pro Odor Control SystemDocument48 pagesOperation and Maintenance Manual For The Lo/Pro Odor Control SystemVinish HARIDAS NAIRNo ratings yet

- Safety Data Sheet: Product Trade NameDocument10 pagesSafety Data Sheet: Product Trade NameAlejandro VescovoNo ratings yet

- GAPS Guidelines: Electrostatic PrecipitatorsDocument4 pagesGAPS Guidelines: Electrostatic PrecipitatorsAsad KhanNo ratings yet

- 1 SOCAR Chemical List - 20151223Document1 page1 SOCAR Chemical List - 20151223Ley LaNo ratings yet

- Fas 13Document6 pagesFas 13LPG Equipment Consulting and ServicesNo ratings yet

- Bio-Soft N-Series PDFDocument9 pagesBio-Soft N-Series PDFGina AriasNo ratings yet

- In-Line Balanced Pressure Proportioning SystemDocument4 pagesIn-Line Balanced Pressure Proportioning SystemsenkuttuvanNo ratings yet

- REP - 11352 Good Practices Care and Custody of Propane PDFDocument38 pagesREP - 11352 Good Practices Care and Custody of Propane PDFdimasNo ratings yet

- Ball Valves Versus Gate ValvesDocument4 pagesBall Valves Versus Gate Valvesrenjithv_4No ratings yet

- Sodium Sulfite SolubilityDocument8 pagesSodium Sulfite SolubilitydhavaleshNo ratings yet

- Production Operators - Ii Oil Production SafetyDocument50 pagesProduction Operators - Ii Oil Production SafetyZeeshan Jabbar ChanaNo ratings yet

- Guide For Loading and Unloading of Cryogenic Liquid TankersDocument14 pagesGuide For Loading and Unloading of Cryogenic Liquid Tankersmohsin husen BargirNo ratings yet

- Probat Burns Thermal Afterburner Brochure 2016Document2 pagesProbat Burns Thermal Afterburner Brochure 2016Argenis BravoNo ratings yet

- Vertical 2 PhaseDocument4 pagesVertical 2 PhaseSterling GordianNo ratings yet

- Deluge Valve SystemDocument16 pagesDeluge Valve SystemAob AprilNo ratings yet

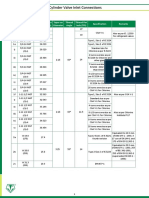

- Cylinder Valve Inlet TypeDocument2 pagesCylinder Valve Inlet TypeGore JiangNo ratings yet

- Texas Sampling Product Presentation 2013Document78 pagesTexas Sampling Product Presentation 2013afroznishatNo ratings yet

- HyDeX Technical Data SheetDocument4 pagesHyDeX Technical Data SheetIqbal Safirul BarqiNo ratings yet

- Breakaways enDocument20 pagesBreakaways enAcid HadiNo ratings yet

- PETRO TCS Ops Manual 700-40 45Document52 pagesPETRO TCS Ops Manual 700-40 45paulm3565No ratings yet

- Development of Air Purifier For Closed RoomsDocument5 pagesDevelopment of Air Purifier For Closed RoomsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Area Deluge Skid No Deluge Valve No Equipments ProtectedDocument4 pagesArea Deluge Skid No Deluge Valve No Equipments ProtectedRiyadh SalehNo ratings yet

- Rim Seal Pourer Data SheetDocument3 pagesRim Seal Pourer Data Sheetadilmomin45No ratings yet

- DANFLO Family of Control ValvesDocument4 pagesDANFLO Family of Control ValvesdmitosNo ratings yet

- Comparative Study of Preparation of Oxalic Acid From Molases (Sem6) ShekharDocument12 pagesComparative Study of Preparation of Oxalic Acid From Molases (Sem6) ShekharShweta ChaudhariNo ratings yet

- TBV Cryogenic Ball Valves CAMERONDocument20 pagesTBV Cryogenic Ball Valves CAMERONboudissaNo ratings yet

- Flare Gas Recovery Data Sheet PDFDocument1 pageFlare Gas Recovery Data Sheet PDFMohamed AdelNo ratings yet

- Oisd 161Document37 pagesOisd 161poojaupesNo ratings yet

- San Juanico, Mexico Disaster - 1984: I) How Did It Happen?Document3 pagesSan Juanico, Mexico Disaster - 1984: I) How Did It Happen?Falcon WingNo ratings yet

- R410a IceloongDocument6 pagesR410a IceloongMarco Ruales100% (2)

- 10" Motorized Bench Saw: To Learn More About DELTA MACHINERYDocument77 pages10" Motorized Bench Saw: To Learn More About DELTA MACHINERYdon baileyNo ratings yet

- AntiSkin BDocument3 pagesAntiSkin BLê TiếnNo ratings yet

- GAPS Guidelines: Special Extinguishing System ReviewDocument2 pagesGAPS Guidelines: Special Extinguishing System Reviewasad khanNo ratings yet

- STD 184 PDFDocument27 pagesSTD 184 PDFGaapchuNo ratings yet

- FCI ST98 Series Thermal Mass Flow Meters: Gas Flow Measurement Solutions For Process and Plant ApplicationsDocument12 pagesFCI ST98 Series Thermal Mass Flow Meters: Gas Flow Measurement Solutions For Process and Plant ApplicationsAbi NdustryNo ratings yet

- Fertilizers Industry Ammonia PlantDocument75 pagesFertilizers Industry Ammonia Plantnayear100% (1)

- Theory and Utility of FT-NIR Spectroscopy: An Introduction To Nicolet Antaris FT-NIR AnalyzersDocument105 pagesTheory and Utility of FT-NIR Spectroscopy: An Introduction To Nicolet Antaris FT-NIR Analyzersmirzaripon100% (1)

- Co2dh20 - 22B - 204 - IsocontenedorDocument5 pagesCo2dh20 - 22B - 204 - IsocontenedorLuis CortezNo ratings yet

- Air Blow CleaningDocument5 pagesAir Blow CleaningTaher MassahNo ratings yet

- M02 - Product SpecificationDocument8 pagesM02 - Product Specificationhoghost123No ratings yet

- Mercury RemovalDocument15 pagesMercury RemovalannaNo ratings yet

- 2-Production & Test ManifoldsDocument1 page2-Production & Test ManifoldsBuonQuaBuonQuaNo ratings yet

- K-VD-024102 - 202 Glycol Flash DrumDocument1 pageK-VD-024102 - 202 Glycol Flash Drumhicher lahcenNo ratings yet

- DMA BrochureDocument20 pagesDMA BrochurelongttNo ratings yet

- Irganox 3114: Technical Data SheetDocument3 pagesIrganox 3114: Technical Data SheetWing ZenandNo ratings yet

- Trac Loc BrochureDocument4 pagesTrac Loc Brochureulas100% (1)

- Waysmos Fm200 Agent Ma Ekm - BBKPN I 16 001 r0Document8 pagesWaysmos Fm200 Agent Ma Ekm - BBKPN I 16 001 r0afie pio pioNo ratings yet

- Ensuring LNG Liquefaction Facilities Sys PDFDocument12 pagesEnsuring LNG Liquefaction Facilities Sys PDFdhurjatibhuteshNo ratings yet

- Thermal Oxidiser HazardsDocument14 pagesThermal Oxidiser HazardsMohammed AlShammasiNo ratings yet

- Equipment Operation: Safety GuidelinesDocument4 pagesEquipment Operation: Safety GuidelinesasxceNo ratings yet

- Overview SilresDocument22 pagesOverview SilresiysernaNo ratings yet

- Cognis College: Fatty AcidsDocument22 pagesCognis College: Fatty AcidsRidhuan Dion100% (4)

- Medina Et Al 2007Document7 pagesMedina Et Al 2007Ezel Galindo PérezNo ratings yet

- Graycor WPS 19 SampleDocument5 pagesGraycor WPS 19 SampleRaul SebastiamNo ratings yet

- Clinical Chemistry 1: Finals TLA No.3 - Nonprotein Nitrogen CompoundsDocument4 pagesClinical Chemistry 1: Finals TLA No.3 - Nonprotein Nitrogen CompoundsBRYAN M. MOLDENo ratings yet

- Aaron Choco de Guzman - BOSH LA 1Document3 pagesAaron Choco de Guzman - BOSH LA 1Aaron Choco De GuzmanNo ratings yet

- MCM Assignment 1Document5 pagesMCM Assignment 1arnabgogoiNo ratings yet

- Methods of Paragraph DevelopmentDocument6 pagesMethods of Paragraph DevelopmentJacqueline Gregorio RamosNo ratings yet

- Paracetamol (7457)Document11 pagesParacetamol (7457)Prakashkumar PatelNo ratings yet

- 22 CH106 Metabolic Paths For Carbohydrates Timberlake 2ndDocument70 pages22 CH106 Metabolic Paths For Carbohydrates Timberlake 2ndEnrique LiKeNo ratings yet

- Chemistry Project: Synthesis and Property AnalysisDocument19 pagesChemistry Project: Synthesis and Property AnalysisUtkarsh PatelNo ratings yet

- Kiwi Seed Extract: Food and Cosmetic Ingredients With Anti-Acne, Wrinkles and Under Eye Darkness PropertiesDocument35 pagesKiwi Seed Extract: Food and Cosmetic Ingredients With Anti-Acne, Wrinkles and Under Eye Darkness Propertiesyudha91No ratings yet

- IOCG in GreenlandDocument12 pagesIOCG in GreenlandHenrry Chipana Poma100% (1)

- Defining Engineers: How Engineers Think About The WorldDocument9 pagesDefining Engineers: How Engineers Think About The Worldranajit.gngl2542No ratings yet

- GEI41042 Rev O - Washing-Cleaning PDFDocument12 pagesGEI41042 Rev O - Washing-Cleaning PDFKorcan ÜnalNo ratings yet

- Mechanical Engineering - Workshop Practice - Laboratory ManualDocument77 pagesMechanical Engineering - Workshop Practice - Laboratory Manualrajeevranjan_br100% (4)

- Human Anatomy and Physiology NotesDocument33 pagesHuman Anatomy and Physiology NotesFLORLYN VERALNo ratings yet

- Competitive Catalytic Hydrogenation of Benzene Toluene and TheDocument144 pagesCompetitive Catalytic Hydrogenation of Benzene Toluene and Themuyodi yahayaNo ratings yet

- Tikidan Tds - Tiki Aquaseal Pu-She, r9Document3 pagesTikidan Tds - Tiki Aquaseal Pu-She, r9sandeepNo ratings yet

- 02 Samss 011 PDFDocument35 pages02 Samss 011 PDFDheeraj E MohananNo ratings yet

- S BlockDocument27 pagesS BlockAditya BansalNo ratings yet

- BAMBOO - A Rural Development and Climate Change Mitigation Crop For Malawi PDFDocument17 pagesBAMBOO - A Rural Development and Climate Change Mitigation Crop For Malawi PDFAdrianHeathGeoffreySutton100% (1)

- Papercrete Brick As An Alternate Building MaterialDocument9 pagesPapercrete Brick As An Alternate Building MaterialHhuNo ratings yet

- Corroseal Rust Converter Is An EliteDocument13 pagesCorroseal Rust Converter Is An EliteNanaba Nanayaw DwomohNo ratings yet

- Polymerization of Acrylic MonomersDocument7 pagesPolymerization of Acrylic MonomersarsenalmctNo ratings yet

- Toxins of Animal OriginDocument36 pagesToxins of Animal OriginThe AbyssinicansNo ratings yet

- Welder Theory 2nd Sem EngDocument121 pagesWelder Theory 2nd Sem EngGtxpreet100% (1)

- Datasheet Toluene Aromatics eDocument1 pageDatasheet Toluene Aromatics eHanan AmarkiNo ratings yet

- Aquarium Disease PreventionDocument48 pagesAquarium Disease PreventionZoran BunčićNo ratings yet

- Raman Spectroscopy of Green Minerals and Reaction Products With An Application in Cultural Heritage ResearchDocument15 pagesRaman Spectroscopy of Green Minerals and Reaction Products With An Application in Cultural Heritage Researchmiranfu3No ratings yet