Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

8 viewsOptima Pet Series e

Optima Pet Series e

Uploaded by

Rahul AroraOptima

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Liberty XL2 Cockpit Layout PDFDocument7 pagesLiberty XL2 Cockpit Layout PDFRahul AroraNo ratings yet

- Liberty XL2 Pim Manual PDFDocument12 pagesLiberty XL2 Pim Manual PDFRahul Arora100% (1)

- SM 38467340Document1 pageSM 38467340Rahul AroraNo ratings yet

- Liberty Xl2 ChecklistsDocument14 pagesLiberty Xl2 ChecklistsRahul AroraNo ratings yet

- Garmin Gns 530 ManualDocument38 pagesGarmin Gns 530 ManualRahul AroraNo ratings yet

- Garmin Gns 430 ManualDocument36 pagesGarmin Gns 430 ManualRahul Arora100% (2)

- Garmin Gma 340 - 330 ManualDocument9 pagesGarmin Gma 340 - 330 ManualRahul AroraNo ratings yet

- Chhatrapati ShivajiDocument1 pageChhatrapati ShivajiRahul AroraNo ratings yet

Optima Pet Series e

Optima Pet Series e

Uploaded by

Rahul Arora0 ratings0% found this document useful (0 votes)

8 views2 pagesOptima

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentOptima

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

8 views2 pagesOptima Pet Series e

Optima Pet Series e

Uploaded by

Rahul AroraOptima

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 2

Ss

electronica

Plastic Machines

OPTIMA PETLINE

Injection Moulding Machines

... THE OPTIMIZED PETLINE

> Adastional ore puling control set for hydraulic cores.

» Airblast -Single/Doubl

> Electrical un-scrowing interface.

> Roboticarm interface.

> Interface for ejector retract (back) verication with limit

switeh.

> Hydraulic motor forhigherplasticizing speed,

> Insulated energy saving heater bands,

> Water battery with flow rate control and tomporature

inlcator.

> Ejector on ly

> Hot runner Temp. controller,

> Proumatic/ Hydraulic sequential vake gates.

> Variable displacement pumo,

> In buil, "Elektra Power Saver" (EPS) with thermal cut-off

swith forelecric motor protection.

> Water battery with flow rate control and temperature

indicator.

> Fecdthroat temperature indication.

> Set of electrical output - single phase (1 x 10) and three

phase (1 x 164).

» Dehumiaiier Dyer, Hopper Loader & Colouring Unit

> Chiller for Moula.

> Crystalizer.

IEEE

POS

> Intellgent operator-machine interface with large, 7° TFT,

‘mult-color display, with aloha numeric keyboard.

» Actual position measuring incicating system for moving

platen and screw travel

> Overview screen with lve display of machine operations.

> Continuous process control via monitoring of important

process parameters with selectable tolerance band.

> Shot (molding) counter pro-solection with automatic

switch off feature.

» Batch production counter with alarm indication,

» Fault lagnostics in the event of machine matfunction or

‘operator error with plain text messages and recording of

soureect error.

> Data storage on removable flash or memory car.

» Separate single screen (page) for quick setting of all

important process parameters,

> Internal storage of up to 200 sets of mold data.

> 06important parameters monitoring for last 200 cycles.

» Hourly production monitoring data

> Multi-level password for preventing tampering of

paramotors.

» Flash lamp and acoustic alam,

» 1/0 diagnosis -analog & digital

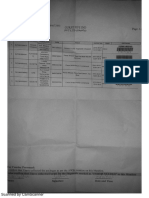

‘Machine Model ‘Optima-100 PET Optima-O0W PET Optima-125 PET Optima-125W PET Optime-175 PET.

Injection Unit number 15 415 526 526 995

Serew Diameter mm 50 50 5 5 °7

Sevow L/D ratio 24 24 2 2 24

Serow Stroke mm 182 182 100 100 240

Stroke volume oe 318 318 428 428 6

Injection weight max (PET) gm 350 350 an an 931

Injection rate cise 178 178 316 316 351

Injection Pressure bar 1307 1307 1231 va a8

Plastcising Rate isee 3 37 2 2 82

(Clamping Unit

Clamoing fore AN 1000 1000 1280 1260 1750

Clamaing stroke mm 340 400 400 460 460

Dist. at Tie bars mm 410x370 450x285 450x285 520% 450 520 450

Platen Dimensions mm 600x560) 675 605, 675X605 710X700 770X700

MineMax mol hie mm 150-360 60-400 60-400 200-480, 200-480

Elector Stroke mm 80 100 100 100 100

Ector Force AN 2 45 45 4a “a

No. of Ejector Pins Nos. 5 5 5 ° 9

General Data

Pump eve ew 185 185 2 2 9

Heater eapaciy kw 143 149 129 189 25.22

“Total Connected Loss kw sae sae 409 409 55.22

Nationwide Sales & Service Network

Doth office: Tel: 491-11-22756924, 1919910082972 Fardabad Tel:4918911950982 Gurgaon ‘Tel.91891922899% Chandigarh: To 919516037648.

‘chennal Office a.

491-14-26185508, -919S80270287 Colmbatore: Te 919362351358 Bangalore Office Tel: +91-80-25461244, 4919842305718

Secunderabad Tl: +91-40-27716080, 1919397058008 Kolkata Office: Te: +91-38-24542480,-0T9380680608 Nagpur. Tal +9T-9325857270

wo

electronica

plastic machines

ogistered Offce & Factory:

ELECTRONICA PLASTIC MACHINES LTD.

Gat No, 399, Hissa No, 1 & 2, Bhar, Tal. Mus, Dist, Pune - 412011

‘Tel: 491-20 - 22922799 22097029 Fax: +91- 20 - 20927074 / 20201168

Email: opmltoloctronicapmd.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Liberty XL2 Cockpit Layout PDFDocument7 pagesLiberty XL2 Cockpit Layout PDFRahul AroraNo ratings yet

- Liberty XL2 Pim Manual PDFDocument12 pagesLiberty XL2 Pim Manual PDFRahul Arora100% (1)

- SM 38467340Document1 pageSM 38467340Rahul AroraNo ratings yet

- Liberty Xl2 ChecklistsDocument14 pagesLiberty Xl2 ChecklistsRahul AroraNo ratings yet

- Garmin Gns 530 ManualDocument38 pagesGarmin Gns 530 ManualRahul AroraNo ratings yet

- Garmin Gns 430 ManualDocument36 pagesGarmin Gns 430 ManualRahul Arora100% (2)

- Garmin Gma 340 - 330 ManualDocument9 pagesGarmin Gma 340 - 330 ManualRahul AroraNo ratings yet

- Chhatrapati ShivajiDocument1 pageChhatrapati ShivajiRahul AroraNo ratings yet