Professional Documents

Culture Documents

CIP Session I Quiz-2

CIP Session I Quiz-2

Uploaded by

munnaCopyright:

Available Formats

You might also like

- I Corr Inspector Exam Sample Questions Level 2Document1 pageI Corr Inspector Exam Sample Questions Level 2Gabriel Pana83% (6)

- The Andhra Pradesh Factories Rules, 1950Document392 pagesThe Andhra Pradesh Factories Rules, 1950Rubal Saxena69% (29)

- SSPC PCS Exam Preparation GuideDocument4 pagesSSPC PCS Exam Preparation Guidetaimoor faisal100% (1)

- CBT CoatingDocument23 pagesCBT CoatingJagdishNo ratings yet

- I Corr Inspector Exam Sample Questions Level 3Document1 pageI Corr Inspector Exam Sample Questions Level 3Gabriel Pana67% (3)

- CBT QuestionsDocument20 pagesCBT Questionsmohammed amjad ali100% (1)

- 424QUIZ2Document6 pages424QUIZ2Magd Badr100% (1)

- CBT 12Document7 pagesCBT 12SUNIL RAJPUT100% (1)

- CIP Level 1 Quiz 4Document6 pagesCIP Level 1 Quiz 4antonioviamontNo ratings yet

- Bgas g2 QustionDocument32 pagesBgas g2 QustionMina Remon100% (1)

- CIP Session I Quiz-3Document4 pagesCIP Session I Quiz-3munna100% (6)

- CIP Session II Quiz-4Document5 pagesCIP Session II Quiz-4munna88% (8)

- CIP Session I Quiz-1Document5 pagesCIP Session I Quiz-1sahadik bahadur86% (7)

- Latihan NacecongratulationsDocument13 pagesLatihan NacecongratulationsPadma Pangreksa75% (4)

- Quiz - Quizizz 002Document6 pagesQuiz - Quizizz 002Ramon Velasco Jr.100% (3)

- BGAS Grade 2 PaintingDocument57 pagesBGAS Grade 2 PaintingNiranjan khatuaNo ratings yet

- Api 510 Preparatory ExamDocument13 pagesApi 510 Preparatory Exameldobie3100% (1)

- Pre Welding ChecklistDocument2 pagesPre Welding Checklistmunna100% (3)

- Schedule I Company Attachment IDocument1 pageSchedule I Company Attachment ImunnaNo ratings yet

- AnaJet Mpower™ Digital Apparel Printer Ver 2.5Document143 pagesAnaJet Mpower™ Digital Apparel Printer Ver 2.5JoelLeGendreNo ratings yet

- Pack House Guid Lines 8. - SopsDocument22 pagesPack House Guid Lines 8. - Sopsphase_shekhar21100% (1)

- Coating Inspection Training - Quizzes - 2Document8 pagesCoating Inspection Training - Quizzes - 2ian toro100% (2)

- CIP Session I Quiz-2Document5 pagesCIP Session I Quiz-2sahadik bahadurNo ratings yet

- CIP Session I Quiz-3Document4 pagesCIP Session I Quiz-3sahadik bahadur100% (1)

- Coating Inspector Specific Examination Candidate Name: Signature: Examinations Start Time: Signature of Authorized Evaluator 20Document8 pagesCoating Inspector Specific Examination Candidate Name: Signature: Examinations Start Time: Signature of Authorized Evaluator 20sanathNo ratings yet

- CBT 22Document16 pagesCBT 22SUNIL RAJPUTNo ratings yet

- CBT 19Document3 pagesCBT 19SUNIL RAJPUTNo ratings yet

- CIP Session I Quiz-4Document5 pagesCIP Session I Quiz-4munna100% (6)

- Nace Cip Level 3 Qtpcqtpcqapdfnace Cip Level 3pdfpdf FilenaceDocument2 pagesNace Cip Level 3 Qtpcqtpcqapdfnace Cip Level 3pdfpdf FilenaceNimish Pavan100% (1)

- BGAS Level 2 3 Q A Monday To Friday PDFDocument32 pagesBGAS Level 2 3 Q A Monday To Friday PDFSathiyaseelan Sakthi Shanmugam100% (1)

- BgasDocument3 pagesBgasHari Babu100% (4)

- CIP 1,2 & 3-May 31 To 13th June 2013-Dubai - FlyerDocument1 pageCIP 1,2 & 3-May 31 To 13th June 2013-Dubai - FlyerdhanendrapardhiNo ratings yet

- CBT 31Document9 pagesCBT 31SUNIL RAJPUT50% (2)

- @coating Inspection CertificationDocument6 pages@coating Inspection CertificationAnand33% (3)

- 3855 ICorr Coating Inspector Assessment Guidelines 0821Document6 pages3855 ICorr Coating Inspector Assessment Guidelines 0821aliNo ratings yet

- Q A CoatingDocument29 pagesQ A CoatingHau Le100% (1)

- Nace-Cip2-001 V8.02Document20 pagesNace-Cip2-001 V8.02GraemeNo ratings yet

- CBT Questions 26022020Document43 pagesCBT Questions 26022020Shawn LeoNo ratings yet

- Bgas Grade 1 QuestionsDocument8 pagesBgas Grade 1 QuestionsRameshNo ratings yet

- Q A BgasDocument33 pagesQ A BgasAnonymous rpcAOp100% (2)

- CBT 8Document5 pagesCBT 8SUNIL RAJPUTNo ratings yet

- Q & A 3 BgasDocument8 pagesQ & A 3 BgasAbdulRahman Mohamed Hanifa100% (2)

- Quiz4 PDFDocument6 pagesQuiz4 PDFGilvan Silva100% (4)

- CIP Work Experience FINALDocument2 pagesCIP Work Experience FINALDeepak YadavNo ratings yet

- Model Papers PDFDocument33 pagesModel Papers PDFSeemab Malik85% (20)

- PCSDocument4 pagesPCStest1100% (2)

- Surface Preparation General Theory: Resists The Seperation of Two Surfaces in Touch)Document5 pagesSurface Preparation General Theory: Resists The Seperation of Two Surfaces in Touch)get5rajesh100% (1)

- AnswersDocument4 pagesAnswersWaseem YounisNo ratings yet

- CBT 2Document2 pagesCBT 2SUNIL RAJPUT100% (2)

- Painting and Coating Inspector Interview QuestionsDocument7 pagesPainting and Coating Inspector Interview Questionsவிஷ்ணு ராஜசெல்வன்100% (2)

- Coating Crew SupervisorDocument4 pagesCoating Crew Supervisorimtiaz100% (1)

- Bgas PaintingDocument85 pagesBgas PaintingDandaman92% (12)

- GENERAL TEST From Actual BGAS ExamsDocument8 pagesGENERAL TEST From Actual BGAS Examsmahmoud ali100% (1)

- CorrisionDocument56 pagesCorrisionUsab GamalNo ratings yet

- BGAS Short NotesDocument2 pagesBGAS Short NotesSameh Amin80% (5)

- Coating Process QuizDocument2 pagesCoating Process QuizMujjamil NakadeNo ratings yet

- Quiz1 - CIP 2Document4 pagesQuiz1 - CIP 2Gilvan Silva100% (1)

- File SSPC Pci Study Guide PDFDocument3 pagesFile SSPC Pci Study Guide PDFmicah50% (2)

- BGas Painting Multiple Choice 2Document17 pagesBGas Painting Multiple Choice 2Abdul Gafoor86% (14)

- API 510 PC 4sept04 Daily Exam 5 Closed PSJDocument12 pagesAPI 510 PC 4sept04 Daily Exam 5 Closed PSJMohammed Shakil100% (1)

- CBT Piping QuestionsDocument4 pagesCBT Piping Questionsshaijukv100% (1)

- API 653 PC 26feb05 Exam Final ClosedDocument8 pagesAPI 653 PC 26feb05 Exam Final ClosedNuwan Ranaweera100% (1)

- Coating QuestionsDocument2 pagesCoating QuestionsQaisir Mehmood100% (1)

- l6ll2l20L8: Fifth 2018Document16 pagesl6ll2l20L8: Fifth 2018dileepNo ratings yet

- PT Specfic 2Document2 pagesPT Specfic 2Yousef Adel HassanenNo ratings yet

- Saic W 2011Document3 pagesSaic W 2011munnaNo ratings yet

- Satr P 3206Document6 pagesSatr P 3206munnaNo ratings yet

- Satip X 400 01Document11 pagesSatip X 400 01munnaNo ratings yet

- Satip M 100 09Document10 pagesSatip M 100 09munnaNo ratings yet

- Satip M 100 10Document10 pagesSatip M 100 10munnaNo ratings yet

- Saic RT 2001Document24 pagesSaic RT 2001munnaNo ratings yet

- Architectural Painting Works Ins ChecklistDocument2 pagesArchitectural Painting Works Ins Checklistmunna100% (1)

- Saic RT 2007Document9 pagesSaic RT 2007munnaNo ratings yet

- Saic W 2090Document2 pagesSaic W 2090munnaNo ratings yet

- Satip M 100 07Document10 pagesSatip M 100 07munnaNo ratings yet

- Schedule C - Attachment 01Document50 pagesSchedule C - Attachment 01munnaNo ratings yet

- Satip Q 001 03Document10 pagesSatip Q 001 03munnaNo ratings yet

- Saep 397Document9 pagesSaep 397munnaNo ratings yet

- Satip Q 006 03Document10 pagesSatip Q 006 03munnaNo ratings yet

- Saep 74Document29 pagesSaep 74munna100% (2)

- Schedule FDocument5 pagesSchedule FmunnaNo ratings yet

- Saep 342Document5 pagesSaep 342munnaNo ratings yet

- Schedule B - Attachment IDocument27 pagesSchedule B - Attachment Imunna100% (2)

- Saep 42Document11 pagesSaep 42munnaNo ratings yet

- Saep 750Document19 pagesSaep 750munnaNo ratings yet

- Saic P 3105Document2 pagesSaic P 3105munnaNo ratings yet

- 01 Samss 010Document12 pages01 Samss 010Ahmed Shaban KotbNo ratings yet

- 01-SAMSS-333-HF Welded Line Pipe PDFDocument35 pages01-SAMSS-333-HF Welded Line Pipe PDFmunnaNo ratings yet

- Datasheet HCH-1000 PDFDocument4 pagesDatasheet HCH-1000 PDFJAIR ALBERTO ORTIZ AREVALONo ratings yet

- ME212Document17 pagesME212FarhanNo ratings yet

- Ppg Pmc: Khoá Huҩn Luyӌn Công Nghӌ Sơn Cơ Bҧn Phҫn 3 Thi Công SơnDocument50 pagesPpg Pmc: Khoá Huҩn Luyӌn Công Nghӌ Sơn Cơ Bҧn Phҫn 3 Thi Công SơnTrần Thái AnNo ratings yet

- Price ListDocument105 pagesPrice ListRAVI BARTIANo ratings yet

- Astm E337-2002Document25 pagesAstm E337-2002SAQUIBNo ratings yet

- CSIR Unit 10Document122 pagesCSIR Unit 10deepika100% (1)

- Atmospheric HumidityDocument19 pagesAtmospheric HumidityRicha SrivastavaNo ratings yet

- Neosensor (Two-Wire 4-20ma Output Sensor)Document16 pagesNeosensor (Two-Wire 4-20ma Output Sensor)Nguyễn Anh TuấnNo ratings yet

- Book Manual 103 BapatlaDocument80 pagesBook Manual 103 BapatlaAjay ReddyNo ratings yet

- Energy Auditing of Buildings: University of Hong Kong Ir K. K. Lam 2007Document42 pagesEnergy Auditing of Buildings: University of Hong Kong Ir K. K. Lam 2007reyhan jemekNo ratings yet

- Handbook of Humidity Measurement, Volume 1 Spect 3516704Document391 pagesHandbook of Humidity Measurement, Volume 1 Spect 3516704Hafshah DeviNo ratings yet

- Diccionario de Minería / Dictionary in Mining Minerals and Related TermsDocument656 pagesDiccionario de Minería / Dictionary in Mining Minerals and Related TermsJet Benel100% (1)

- RadioShack TERMOHIGROMETRO DatasheetDocument20 pagesRadioShack TERMOHIGROMETRO DatasheetKarlita Princesita Mala MalaNo ratings yet

- Chambers Operations+maintenance ManualDocument38 pagesChambers Operations+maintenance ManualSergio LunaNo ratings yet

- 0003Document2 pages0003mohd shafiniNo ratings yet

- Astm D4230Document6 pagesAstm D4230edcaabayNo ratings yet

- User Manual - Forma - 3029, 3039 - Countertop Incubator 10 Cu - Ft. - 7013029Document52 pagesUser Manual - Forma - 3029, 3039 - Countertop Incubator 10 Cu - Ft. - 7013029cruzrenato100% (2)

- Mechatronics Main ProjectDocument20 pagesMechatronics Main ProjectAbdi YizotawNo ratings yet

- E104 32317Document5 pagesE104 32317ImmerNo ratings yet

- NATADocument13 pagesNATADdumNo ratings yet

- SRR HPCL PGTR - 1Document188 pagesSRR HPCL PGTR - 1Siva Ram PrasadNo ratings yet

- Study of Instruments Used To Measure Microclimatic VariablesDocument6 pagesStudy of Instruments Used To Measure Microclimatic VariablesH2o100% (1)

- Chapter Two: Gas-Vapor Mixtures and Air-Conditioning ProcessDocument65 pagesChapter Two: Gas-Vapor Mixtures and Air-Conditioning ProcessMuket AgmasNo ratings yet

- Humidity & Temperature Controller Pro.Document41 pagesHumidity & Temperature Controller Pro.Amir WagdarikarNo ratings yet

- GenEcoL-Ex-1-3 8NhjNDocument13 pagesGenEcoL-Ex-1-3 8NhjNPrezyNo ratings yet

- Almemo Measuring System For Calibrating Climatic Chambers As Per Guideline Dakks-Dkd-R 5-7Document4 pagesAlmemo Measuring System For Calibrating Climatic Chambers As Per Guideline Dakks-Dkd-R 5-7kumarNo ratings yet

CIP Session I Quiz-2

CIP Session I Quiz-2

Uploaded by

munnaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CIP Session I Quiz-2

CIP Session I Quiz-2

Uploaded by

munnaCopyright:

Available Formats

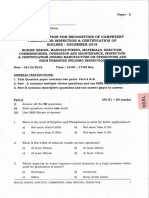

CIP Session I Quiz 2

1.

A decrease in temperature will generally cause the corrosion

rate to

I.

Increase.

II. Decrease.

III. remain constant.

A)

B)

C)

D)

2.

Dew point is the temperature at which

A)

B)

C)

D)

3.

relative humidity.

ambient temperature and wet bulb temperature.

substrate temperature and wet bulb temperature.

dew point.

Coating operations should NOT take place unless the

substrate surface temperature is at least

A)

B)

C)

D)

7.

the same as dew point temperature.

at least 5oF (about 3oC) below dew point temperature.

at least 5oF (about 3oC) above dew point temperature.

no more than 5oF (about 3oC) above dew point temperature.

A sling psychrometer directly measure

A)

B)

C)

D)

6.

steel surface thermometer.

humidity indicator stripes.

sling psychrometer.

anemometer.

Steel surface temperature during coating application should

be

A)

B)

C)

D)

5.

moisture vapour evaporates.

moisture vapour condenses

moisture vapour increases

corrosion is slowed down

Dew point is measured and calculated by using

A)

B)

C)

D)

4.

I only

II only

III only

I, II and III

40F

5oF

5oF

5oF

(20C) higher than the dew point temperature.

(3oC) higher than the dew point temperature.

(3oC) lower than the dew point temperature.

(3oC) above freezing.

Which of the following statements concerning ultra high

pressure water jetting is true?

I.

II.

III.

IV.

Production rates are cost effective.

Seldom used of for surface preparation.

Often used for surface preparation.

Lower pressure will not remove tight mill

scale.

A) III only

Page1of5

08/04

CIP Session I Quiz 2

B) I and II only

C) I and III only

D) II and IV only

8.

ISO 8503-1 comparators are available for which of the

following abrasives?

I.

Sand

II. Grit

III. Shot

A)

B)

C)

D)

9.

Workers exposed to hazardous levels of free silica dust such

as released during sand blast cleaning process, may develop

silicosis, which is a disease of the

A)

B)

C)

D)

10.

dissolves in the electrolyte.

does nothing.

has an opposite electrical polarity to anode.

is not considered to be part of the corrosion cell.

Nozzle pressure for manual blast cleaning is generally

accepted to be

A)

B)

C)

D)

13.

Visual inspection

Test papers or chemical test kits

Magnetic pull-off DFT gauge

Low voltage DC (wet sponge method)

The cathode of a corrosion cell

A)

B)

C)

D)

12.

liver.

heart.

lung.

stomach.

The presence of certain salt deposits such as ferrous

sulphate or ferrous hydroxides may be determined by which of

the following?

A)

B)

C)

D)

11.

I & II only

I & III only

II & III only

I, II and III

60 to 90 psi

90 to 100 psi

130 to 150 psi

130 psi and above

Extra-coarse Testex replica tape is used when it is expected

that the depth of the anchor pattern/surface profile to be

measured will be 3 mils (75 microns).

A) True

B) False

Page2of5

08/04

CIP Session I Quiz 2

14.

When following a specification for surface preparation

standards, the inspector should NOT

A)

B)

C)

D)

15.

ensure specified cleanliness standard is used.

ensure surface is prepared as specified.

require a cleaner surface than specified.

verify that only specified materials are used.

If the coating inspector finds that the coating was applied

thicker than specified, he/she should

A) advise contractor and owners representative immediately.

B) use good judgement in deciding whether or not deviation

from specification is allowable.

C) require that area to be blasted down to bare metal and

recoated.

D) Call the coating manufacturer to solve the problem.

16.

If the desired DFT of a coating is 100 microns (4 mils),

what wet film thickness will be required if the coating

contains 100% volume solids?

A)

A)

B)

C)

17.

50 microns (2 mils)

75 microns (3 mils)

100 microns (4 mils)

150 microns (6 mils)

A well-written coating specification should contain

information regarding

I.

surface preparation standards.

II. safety.

III. locations to be coated.

A)

B)

C)

D)

18.

The coating inspector should require white metal surface

preparation if

A)

B)

C)

D)

19.

I only

II only

III only

I, II and III

immersion surface is required.

chemical resistance is required.

the specification calls for white metal.

the manufacturers product data sheet recommends white

metal.

The requirements of a project should be defined by the

A)

B)

C)

D)

Page3of5

coating

coating

project

coating

inspector.

contractor.

engineer.

specification.

08/04

CIP Session I Quiz 2

20.

33 feet is approximately how many meters?

A)

B)

C)

D)

21.

10

15

20

30

It is the coating inspectors responsibility to

A) recommend suitable protective coating system for each

job.

B) be sure that the most economical bid for coatings is

obtained.

C) be sure that the coatings used are the specified

coatings.

D) take the pre-job meeting minutes.

22.

The coating inspectors responsibility to

A) Verify compliance with specification requirements.

B) adapt the specification to the realities of the

situation.

C) be the expert on coatings.

D) direct the contractors safety meetings.

23.

An inspectors primary duty to

I.

II.

III.

IV.

A)

B)

C)

D)

24.

I only

I and II only

I, II, III only

I, II and IV only

Inspection of mixing and thinning operations is important

A)

B)

C)

D)

25.

observe actions of the contractor.

report actions of the contractor.

document actions of the contractor.

enforce all safety rules.

only when zinc rich coatings are used.

only when inorganic zinc coatings are used.

only when a new applicator is starting work.

every time mixing and thinning is performed.

Corrosion is slower in hot environments than in cool ones.

A) True

B) False

Page4of5

08/04

CIP Session I Quiz 2

KEY

1-B, 2-B, 3-C, 4-C, 5-B, 6-B, 7-C, 8-C, 9-C, 10-B, 11-C, 12-B, 13-A,

14-C, 15-A, 16-C, 17-D, 18-C, 19-D, 20-A, 21-C, 22-A, 23-C, 24-D,

25-B.

Page5of5

08/04

You might also like

- I Corr Inspector Exam Sample Questions Level 2Document1 pageI Corr Inspector Exam Sample Questions Level 2Gabriel Pana83% (6)

- The Andhra Pradesh Factories Rules, 1950Document392 pagesThe Andhra Pradesh Factories Rules, 1950Rubal Saxena69% (29)

- SSPC PCS Exam Preparation GuideDocument4 pagesSSPC PCS Exam Preparation Guidetaimoor faisal100% (1)

- CBT CoatingDocument23 pagesCBT CoatingJagdishNo ratings yet

- I Corr Inspector Exam Sample Questions Level 3Document1 pageI Corr Inspector Exam Sample Questions Level 3Gabriel Pana67% (3)

- CBT QuestionsDocument20 pagesCBT Questionsmohammed amjad ali100% (1)

- 424QUIZ2Document6 pages424QUIZ2Magd Badr100% (1)

- CBT 12Document7 pagesCBT 12SUNIL RAJPUT100% (1)

- CIP Level 1 Quiz 4Document6 pagesCIP Level 1 Quiz 4antonioviamontNo ratings yet

- Bgas g2 QustionDocument32 pagesBgas g2 QustionMina Remon100% (1)

- CIP Session I Quiz-3Document4 pagesCIP Session I Quiz-3munna100% (6)

- CIP Session II Quiz-4Document5 pagesCIP Session II Quiz-4munna88% (8)

- CIP Session I Quiz-1Document5 pagesCIP Session I Quiz-1sahadik bahadur86% (7)

- Latihan NacecongratulationsDocument13 pagesLatihan NacecongratulationsPadma Pangreksa75% (4)

- Quiz - Quizizz 002Document6 pagesQuiz - Quizizz 002Ramon Velasco Jr.100% (3)

- BGAS Grade 2 PaintingDocument57 pagesBGAS Grade 2 PaintingNiranjan khatuaNo ratings yet

- Api 510 Preparatory ExamDocument13 pagesApi 510 Preparatory Exameldobie3100% (1)

- Pre Welding ChecklistDocument2 pagesPre Welding Checklistmunna100% (3)

- Schedule I Company Attachment IDocument1 pageSchedule I Company Attachment ImunnaNo ratings yet

- AnaJet Mpower™ Digital Apparel Printer Ver 2.5Document143 pagesAnaJet Mpower™ Digital Apparel Printer Ver 2.5JoelLeGendreNo ratings yet

- Pack House Guid Lines 8. - SopsDocument22 pagesPack House Guid Lines 8. - Sopsphase_shekhar21100% (1)

- Coating Inspection Training - Quizzes - 2Document8 pagesCoating Inspection Training - Quizzes - 2ian toro100% (2)

- CIP Session I Quiz-2Document5 pagesCIP Session I Quiz-2sahadik bahadurNo ratings yet

- CIP Session I Quiz-3Document4 pagesCIP Session I Quiz-3sahadik bahadur100% (1)

- Coating Inspector Specific Examination Candidate Name: Signature: Examinations Start Time: Signature of Authorized Evaluator 20Document8 pagesCoating Inspector Specific Examination Candidate Name: Signature: Examinations Start Time: Signature of Authorized Evaluator 20sanathNo ratings yet

- CBT 22Document16 pagesCBT 22SUNIL RAJPUTNo ratings yet

- CBT 19Document3 pagesCBT 19SUNIL RAJPUTNo ratings yet

- CIP Session I Quiz-4Document5 pagesCIP Session I Quiz-4munna100% (6)

- Nace Cip Level 3 Qtpcqtpcqapdfnace Cip Level 3pdfpdf FilenaceDocument2 pagesNace Cip Level 3 Qtpcqtpcqapdfnace Cip Level 3pdfpdf FilenaceNimish Pavan100% (1)

- BGAS Level 2 3 Q A Monday To Friday PDFDocument32 pagesBGAS Level 2 3 Q A Monday To Friday PDFSathiyaseelan Sakthi Shanmugam100% (1)

- BgasDocument3 pagesBgasHari Babu100% (4)

- CIP 1,2 & 3-May 31 To 13th June 2013-Dubai - FlyerDocument1 pageCIP 1,2 & 3-May 31 To 13th June 2013-Dubai - FlyerdhanendrapardhiNo ratings yet

- CBT 31Document9 pagesCBT 31SUNIL RAJPUT50% (2)

- @coating Inspection CertificationDocument6 pages@coating Inspection CertificationAnand33% (3)

- 3855 ICorr Coating Inspector Assessment Guidelines 0821Document6 pages3855 ICorr Coating Inspector Assessment Guidelines 0821aliNo ratings yet

- Q A CoatingDocument29 pagesQ A CoatingHau Le100% (1)

- Nace-Cip2-001 V8.02Document20 pagesNace-Cip2-001 V8.02GraemeNo ratings yet

- CBT Questions 26022020Document43 pagesCBT Questions 26022020Shawn LeoNo ratings yet

- Bgas Grade 1 QuestionsDocument8 pagesBgas Grade 1 QuestionsRameshNo ratings yet

- Q A BgasDocument33 pagesQ A BgasAnonymous rpcAOp100% (2)

- CBT 8Document5 pagesCBT 8SUNIL RAJPUTNo ratings yet

- Q & A 3 BgasDocument8 pagesQ & A 3 BgasAbdulRahman Mohamed Hanifa100% (2)

- Quiz4 PDFDocument6 pagesQuiz4 PDFGilvan Silva100% (4)

- CIP Work Experience FINALDocument2 pagesCIP Work Experience FINALDeepak YadavNo ratings yet

- Model Papers PDFDocument33 pagesModel Papers PDFSeemab Malik85% (20)

- PCSDocument4 pagesPCStest1100% (2)

- Surface Preparation General Theory: Resists The Seperation of Two Surfaces in Touch)Document5 pagesSurface Preparation General Theory: Resists The Seperation of Two Surfaces in Touch)get5rajesh100% (1)

- AnswersDocument4 pagesAnswersWaseem YounisNo ratings yet

- CBT 2Document2 pagesCBT 2SUNIL RAJPUT100% (2)

- Painting and Coating Inspector Interview QuestionsDocument7 pagesPainting and Coating Inspector Interview Questionsவிஷ்ணு ராஜசெல்வன்100% (2)

- Coating Crew SupervisorDocument4 pagesCoating Crew Supervisorimtiaz100% (1)

- Bgas PaintingDocument85 pagesBgas PaintingDandaman92% (12)

- GENERAL TEST From Actual BGAS ExamsDocument8 pagesGENERAL TEST From Actual BGAS Examsmahmoud ali100% (1)

- CorrisionDocument56 pagesCorrisionUsab GamalNo ratings yet

- BGAS Short NotesDocument2 pagesBGAS Short NotesSameh Amin80% (5)

- Coating Process QuizDocument2 pagesCoating Process QuizMujjamil NakadeNo ratings yet

- Quiz1 - CIP 2Document4 pagesQuiz1 - CIP 2Gilvan Silva100% (1)

- File SSPC Pci Study Guide PDFDocument3 pagesFile SSPC Pci Study Guide PDFmicah50% (2)

- BGas Painting Multiple Choice 2Document17 pagesBGas Painting Multiple Choice 2Abdul Gafoor86% (14)

- API 510 PC 4sept04 Daily Exam 5 Closed PSJDocument12 pagesAPI 510 PC 4sept04 Daily Exam 5 Closed PSJMohammed Shakil100% (1)

- CBT Piping QuestionsDocument4 pagesCBT Piping Questionsshaijukv100% (1)

- API 653 PC 26feb05 Exam Final ClosedDocument8 pagesAPI 653 PC 26feb05 Exam Final ClosedNuwan Ranaweera100% (1)

- Coating QuestionsDocument2 pagesCoating QuestionsQaisir Mehmood100% (1)

- l6ll2l20L8: Fifth 2018Document16 pagesl6ll2l20L8: Fifth 2018dileepNo ratings yet

- PT Specfic 2Document2 pagesPT Specfic 2Yousef Adel HassanenNo ratings yet

- Saic W 2011Document3 pagesSaic W 2011munnaNo ratings yet

- Satr P 3206Document6 pagesSatr P 3206munnaNo ratings yet

- Satip X 400 01Document11 pagesSatip X 400 01munnaNo ratings yet

- Satip M 100 09Document10 pagesSatip M 100 09munnaNo ratings yet

- Satip M 100 10Document10 pagesSatip M 100 10munnaNo ratings yet

- Saic RT 2001Document24 pagesSaic RT 2001munnaNo ratings yet

- Architectural Painting Works Ins ChecklistDocument2 pagesArchitectural Painting Works Ins Checklistmunna100% (1)

- Saic RT 2007Document9 pagesSaic RT 2007munnaNo ratings yet

- Saic W 2090Document2 pagesSaic W 2090munnaNo ratings yet

- Satip M 100 07Document10 pagesSatip M 100 07munnaNo ratings yet

- Schedule C - Attachment 01Document50 pagesSchedule C - Attachment 01munnaNo ratings yet

- Satip Q 001 03Document10 pagesSatip Q 001 03munnaNo ratings yet

- Saep 397Document9 pagesSaep 397munnaNo ratings yet

- Satip Q 006 03Document10 pagesSatip Q 006 03munnaNo ratings yet

- Saep 74Document29 pagesSaep 74munna100% (2)

- Schedule FDocument5 pagesSchedule FmunnaNo ratings yet

- Saep 342Document5 pagesSaep 342munnaNo ratings yet

- Schedule B - Attachment IDocument27 pagesSchedule B - Attachment Imunna100% (2)

- Saep 42Document11 pagesSaep 42munnaNo ratings yet

- Saep 750Document19 pagesSaep 750munnaNo ratings yet

- Saic P 3105Document2 pagesSaic P 3105munnaNo ratings yet

- 01 Samss 010Document12 pages01 Samss 010Ahmed Shaban KotbNo ratings yet

- 01-SAMSS-333-HF Welded Line Pipe PDFDocument35 pages01-SAMSS-333-HF Welded Line Pipe PDFmunnaNo ratings yet

- Datasheet HCH-1000 PDFDocument4 pagesDatasheet HCH-1000 PDFJAIR ALBERTO ORTIZ AREVALONo ratings yet

- ME212Document17 pagesME212FarhanNo ratings yet

- Ppg Pmc: Khoá Huҩn Luyӌn Công Nghӌ Sơn Cơ Bҧn Phҫn 3 Thi Công SơnDocument50 pagesPpg Pmc: Khoá Huҩn Luyӌn Công Nghӌ Sơn Cơ Bҧn Phҫn 3 Thi Công SơnTrần Thái AnNo ratings yet

- Price ListDocument105 pagesPrice ListRAVI BARTIANo ratings yet

- Astm E337-2002Document25 pagesAstm E337-2002SAQUIBNo ratings yet

- CSIR Unit 10Document122 pagesCSIR Unit 10deepika100% (1)

- Atmospheric HumidityDocument19 pagesAtmospheric HumidityRicha SrivastavaNo ratings yet

- Neosensor (Two-Wire 4-20ma Output Sensor)Document16 pagesNeosensor (Two-Wire 4-20ma Output Sensor)Nguyễn Anh TuấnNo ratings yet

- Book Manual 103 BapatlaDocument80 pagesBook Manual 103 BapatlaAjay ReddyNo ratings yet

- Energy Auditing of Buildings: University of Hong Kong Ir K. K. Lam 2007Document42 pagesEnergy Auditing of Buildings: University of Hong Kong Ir K. K. Lam 2007reyhan jemekNo ratings yet

- Handbook of Humidity Measurement, Volume 1 Spect 3516704Document391 pagesHandbook of Humidity Measurement, Volume 1 Spect 3516704Hafshah DeviNo ratings yet

- Diccionario de Minería / Dictionary in Mining Minerals and Related TermsDocument656 pagesDiccionario de Minería / Dictionary in Mining Minerals and Related TermsJet Benel100% (1)

- RadioShack TERMOHIGROMETRO DatasheetDocument20 pagesRadioShack TERMOHIGROMETRO DatasheetKarlita Princesita Mala MalaNo ratings yet

- Chambers Operations+maintenance ManualDocument38 pagesChambers Operations+maintenance ManualSergio LunaNo ratings yet

- 0003Document2 pages0003mohd shafiniNo ratings yet

- Astm D4230Document6 pagesAstm D4230edcaabayNo ratings yet

- User Manual - Forma - 3029, 3039 - Countertop Incubator 10 Cu - Ft. - 7013029Document52 pagesUser Manual - Forma - 3029, 3039 - Countertop Incubator 10 Cu - Ft. - 7013029cruzrenato100% (2)

- Mechatronics Main ProjectDocument20 pagesMechatronics Main ProjectAbdi YizotawNo ratings yet

- E104 32317Document5 pagesE104 32317ImmerNo ratings yet

- NATADocument13 pagesNATADdumNo ratings yet

- SRR HPCL PGTR - 1Document188 pagesSRR HPCL PGTR - 1Siva Ram PrasadNo ratings yet

- Study of Instruments Used To Measure Microclimatic VariablesDocument6 pagesStudy of Instruments Used To Measure Microclimatic VariablesH2o100% (1)

- Chapter Two: Gas-Vapor Mixtures and Air-Conditioning ProcessDocument65 pagesChapter Two: Gas-Vapor Mixtures and Air-Conditioning ProcessMuket AgmasNo ratings yet

- Humidity & Temperature Controller Pro.Document41 pagesHumidity & Temperature Controller Pro.Amir WagdarikarNo ratings yet

- GenEcoL-Ex-1-3 8NhjNDocument13 pagesGenEcoL-Ex-1-3 8NhjNPrezyNo ratings yet

- Almemo Measuring System For Calibrating Climatic Chambers As Per Guideline Dakks-Dkd-R 5-7Document4 pagesAlmemo Measuring System For Calibrating Climatic Chambers As Per Guideline Dakks-Dkd-R 5-7kumarNo ratings yet