Professional Documents

Culture Documents

NHMSFP As Medical Gas Pipeline System

NHMSFP As Medical Gas Pipeline System

Uploaded by

Vijayakumar MadhaiyanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NHMSFP As Medical Gas Pipeline System

NHMSFP As Medical Gas Pipeline System

Uploaded by

Vijayakumar MadhaiyanCopyright:

Available Formats

A CCRE DI TA TI ON STANDARD S

Patient Safety

MEDICAL GAS PIPELINE SYSTEM

The Canadian Standards Association (CSA) Medical gas pipeline systems Part 1: Pipelines for medical

gases, medical vacuum, medical support gases and anaesthetic gas scavenging systems (CAN/CSA

Z7396.1-12) specifies the safety requirements for medical gas pipeline systems. It applies to all facilities

providing health-care services, both public and private, regardless of type, size, location or range of

services.

Definitions

as-built drawings

Documents used and maintained by the installer on which all components of

a medical gas pipeline system are shown in the positions in which they are

installed.

maintenance

Actions performed to preserve the as-built functionality of the medical gas

pipeline system as required in the original manufacturers manual.

primary source

The portion of a supply system that is the first to be drawn on to supply the

pipeline distribution system.

secondary source

The portion of the supply system that supplies the pipeline distribution

system in the event of failure or exhaustion of the primary source of supply.

reserve source

The portion of the supply system that supplies the complete pipeline

distribution system, or a portion of it, in the event of failure or exhaustion of

both the primary and secondary sources of supply.

terminal unit

An outlet assembly in a medical gas pipeline system at which the operator

makes connections and disconnections.

zone alarm

A system used to monitor the pressure of a medical gas or vacuum

downstream of a zone valve.

zone valve

A shut-off valve in the pipeline distribution system that allows patient care

personnel and first responders to isolate a zone within a health-care facility in

the event of an emergency or for authorized maintenance within a zone.

NHMSFP College of Physicians and Surgeons of British Columbia

April 2015

Page 1 of 4

MEDICAL GAS PIPELINE SYSTEM

ACCREDITATION STANDARDS

Patient Safety

Medical gases are safely and effectively managed

INDICATORS:

Written policy and procedures are in place for:

safe use, handling and storage

medical gas supply replenishment

changing of tanks

maintenance

The medical gas supply system capacity is documented and based upon usage estimates and

frequency of gas supplier delivery

All medical gases are supplied from at least two sources, primary and secondary (reserve)

Portable cylinder supply systems consist of a primary supply of cylinders and a secondary

supply of cylinders

Liquid supply systems consist of a primary liquid vessel source of supply and a secondary

source that uses either a liquid vessel or high-pressure cylinders

Each medical gas supply cylinder are clearly labeled with the cylinders contents

Each medical gas supply cylinder are clearly marked as full, in use, or empty

Facilities that use a compressor to supply medical air have written procedures in place for response

to a carbon monoxide (CO) alarm

Medical gas supply is safely stored and secured

INDICATORS:

All cylinders are protected from sparks, flames, excessive heat, physical damage, electrical contact

or corrosion

All cylinders, either connected to the supply system or stored at the facility, are secured by a holder

or device designed to secure a cylinder to prevent falling or rolling during storage, transportation

and use

All cylinders are kept in the upright position where practicable

Cylinders not in use or empty are shut off and capped

Full and empty cylinders are kept separate

A post-valve wrench is readily available, as applicable

Medical gas supply is located in a locked room or enclosure accessible only to authorized personnel

Rooms or enclosures for supply systems are not used for any purpose other than for the placement

and storage of medical gas cylinders

NHMSFP College of Physicians and Surgeons of British Columbia

April 2015

Page 2 of 4

MEDICAL GAS PIPELINE SYSTEM

ACCREDITATION STANDARDS

Patient Safety

A no smoking sign is posted immediately outside each medical gas supply system room or

enclosure

Rooms for cylinder supply systems are built of materials having a fire rating of at least one hour and

meet building and fire code requirements

Personnel have unobstructed direct exit from supply system rooms via doors opening outward

Doors from the supply system room do not connect directly with storage locations for flammable

materials

Electrical devices in rooms for supply systems are protected from damage by positioning at least

1.5 m (5 ft.) above the floor or by guarding

Ambient temperature in medical gas supply rooms is monitored to ensure that it does not exceed

40oC for any gas and is never below 15oC for nitrous oxide and carbon dioxide

Medical gas system is safely operated and monitored

INDICATORS:

Orientation and training is provided to those who use the medical gas system to ensure safe,

consistent and accurate operation

Personnel are knowledgeable regarding the location of main and zone shut-off valves and

procedures for shutting off the medical gas system

Personnel are knowledgeable regarding the procedures for switching the supply cylinders, if needed

Line pressure is observed and recorded at least once each surgical day

Alarm panels are continuously monitored

Alarm panels can be seen (unobstructed) and accessed

Alarm panels clearly indicate the gas, zone and condition being monitored

Zone valves are installed immediately outside each anaesthetizing location

Zone valves are securely enclosed but allow for quick access in case of emergency

The medical gas pipeline system is maintained in accordance with CAN/CSA Z7396.1-12

INDICATORS:

There is a preventive maintenance plan in place

Documented preventive maintenance is performed by appropriately trained personnel in

accordance with the CSA standards

Maintenance is performed by appropriately trained personnel

The source of supply is inspected and tested, at minimum, every six months

The pressure relief valves are inspected, at minimum, every six months

NHMSFP College of Physicians and Surgeons of British Columbia

April 2015

Page 3 of 4

MEDICAL GAS PIPELINE SYSTEM

ACCREDITATION STANDARDS

Patient Safety

The pressure relief valves are replaced, at minimum, every five years

The pressure setting of the line pressure regulator is alternated, at minimum, every six months

(pipelines designed prior to 2009 may only have a single pressure regulator)

All alarms are self-tested, at minimum, monthly

Supply system alarms are inspected and tested for verification of labeling and signal operation, at

minimum, every six months

Supply system alarms are inspected and tested for activation for all field devices and verification of

set-point, at minimum, annually

Zone alarms are inspected and tested, at minimum, annually

Zone valves are tested for external leakage and control labels, at minimum, annually

Zone valves are tested for internal leakage, at minimum, annually

Terminal units are tested for function, wear and mechanical performance, at minimum, annually

Medical gas pipeline system records are appropriately maintained

INDICATORS:

Preventive maintenance and repair records are retained for the life of the system

As-built drawings of the medical gas pipeline system are retained by the facility

References

Diagnostic Accreditation Program; College of Physicians and Surgeons of British Columbia. Accreditation

standards 2010: diagnostic imaging [Internet]. Vancouver: Diagnostic Accreditation Program; 2010. DSA

1.7 Compressed gas is maintained and stored safely; [cited 2015 Feb 19]; p. 5. Available from:

http://www.dap.org/CmsFiles/file/Standards/2010%20Standards%20Updated%20to%20College%20For

mat%20October%2029%202012/Diagnostic%20Imaging%20Standards%202010%20(2)(1).pdf

Canadian Standards Association. Medical gas pipeline systems Part 1: Pipelines for medical gases,

medical vacuum, medical support gases, and anaesthetic gas scavenging systems. Mississauga, ON:

Canadian Standards Association; 2012. 140 p. CSA Standard:Z7396.1-12

Canadian Standards Association. Nonflammable medical gas piping systems. Toronto: Canadian

Standards Association; 1992. 97 p. CSA Standard No.: Z305.1-92.

WorkSafeBC. Hazardous products act (Canada) - summary [Internet]. Richmond: WorkSafeBC, 2014. Part

5 -chemical agents and biological agents. [cited 2015 Feb 19]. [about 11 screens]. Available from:

http://www2.worksafebc.com/publications/OHSRegulation/Part5.asp

NHMSFP College of Physicians and Surgeons of British Columbia

April 2015

Page 4 of 4

You might also like

- Lps 1223Document21 pagesLps 1223Rajesh khannaNo ratings yet

- Feedwater LCA Statement of ComplianceDocument5 pagesFeedwater LCA Statement of ComplianceTarundeep Singh100% (1)

- Health Care Facilities and Medical Gas and VacuumDocument27 pagesHealth Care Facilities and Medical Gas and VacuumStephen Tabiar100% (1)

- 1-Medical Gases Systems. The First Lecture.Document18 pages1-Medical Gases Systems. The First Lecture.Fireproof Sistemas Electromecánicos100% (1)

- VESDA Commissioning Forms VLP Rev01Document7 pagesVESDA Commissioning Forms VLP Rev01Femi DeleNo ratings yet

- Ilnas-En Iso 14644-4:2001Document9 pagesIlnas-En Iso 14644-4:2001Karthik JindheNo ratings yet

- CFPP 01-01 Part C Steam SterilizationDocument31 pagesCFPP 01-01 Part C Steam Sterilizationsbalu12674No ratings yet

- Quiz 2Document2 pagesQuiz 2JNo ratings yet

- Gas Systems For Laboratory Facilities - 1.12.15Document8 pagesGas Systems For Laboratory Facilities - 1.12.15Carl CrowNo ratings yet

- 0983 03 Method Statement For Installation Testing of Fire Fighting PipesDocument3 pages0983 03 Method Statement For Installation Testing of Fire Fighting PipesAnkit KumarNo ratings yet

- Complying With The 2014 FGIDocument36 pagesComplying With The 2014 FGIJihad Elias ChahlaNo ratings yet

- What Is GMP Compliant Equipment DesignDocument3 pagesWhat Is GMP Compliant Equipment DesignLaura TarazonaNo ratings yet

- Ashare Bylaws 2012Document7 pagesAshare Bylaws 2012SjeverNo ratings yet

- Air Handling UnitDocument3 pagesAir Handling UnitPrince Moni100% (2)

- British Standards Airborne Radioactivity PDFDocument3 pagesBritish Standards Airborne Radioactivity PDFJeremiah MatthewsNo ratings yet

- P-1-10 NFPA 45 - 2015 Edition Changes and Issues Related To Energy ConservationDocument27 pagesP-1-10 NFPA 45 - 2015 Edition Changes and Issues Related To Energy ConservationAnonymous 7KMe7ER100% (1)

- UL 762 Power Ventilators For Restaurant Exhaust AppliancesDocument1 pageUL 762 Power Ventilators For Restaurant Exhaust AppliancesProyectos 2 UezuNo ratings yet

- Duct Leakage TestingDocument4 pagesDuct Leakage TestingAbd Elhaleem RabeaNo ratings yet

- TSI PANDA 341 User ManualDocument38 pagesTSI PANDA 341 User ManualHernan RomeroNo ratings yet

- Tabb PDFDocument7 pagesTabb PDFFsNo ratings yet

- Maintenance Strategies and Innovative Approaches in The Pharmaceutical Industry: An Integrated Management System (IMS)Document9 pagesMaintenance Strategies and Innovative Approaches in The Pharmaceutical Industry: An Integrated Management System (IMS)Fawaz Nasser AL-HeibshyNo ratings yet

- Nadca White Paper On Chemical Applications in Hvac Systems 0Document11 pagesNadca White Paper On Chemical Applications in Hvac Systems 0Luis RodasNo ratings yet

- Iso 17873Document8 pagesIso 17873Moromete de la Bucuresti100% (1)

- PMGS Couse Note RevDocument83 pagesPMGS Couse Note RevfisplNo ratings yet

- Fire Hazard Properties of Flammable LiquidsDocument106 pagesFire Hazard Properties of Flammable Liquidsralph1949100% (1)

- Usp 797GCDocument61 pagesUsp 797GCAwni1989No ratings yet

- Delotas Cleaning Solutions: Data Centre Cleanroom Air Particle Testing & Hvac CleaningDocument28 pagesDelotas Cleaning Solutions: Data Centre Cleanroom Air Particle Testing & Hvac Cleaningzhrani100% (1)

- UL Standard 181A Standard For Closure Systems For Use With Rigid Air DuctsDocument8 pagesUL Standard 181A Standard For Closure Systems For Use With Rigid Air DuctsALI MAKRINo ratings yet

- EIGA (2008) - Comparison of EP, USP & JP For Medicinal GasDocument21 pagesEIGA (2008) - Comparison of EP, USP & JP For Medicinal GashuynhhaichauchauNo ratings yet

- Section 22 60 00 - Medical Vacuum and Gas PipingDocument14 pagesSection 22 60 00 - Medical Vacuum and Gas PipingFeroz KhanNo ratings yet

- Labdesign GuideDocument126 pagesLabdesign GuiderwbbartonNo ratings yet

- Technical Submittal 03656Document37 pagesTechnical Submittal 03656Abdel HamidNo ratings yet

- SAMMDocument14 pagesSAMMmildredeklip88No ratings yet

- Fume Hood Calibration, Face Velocity Testing: Application NoteDocument2 pagesFume Hood Calibration, Face Velocity Testing: Application NoteIván Acosta MárquezNo ratings yet

- MOH-MOWE Potable Water PDFDocument266 pagesMOH-MOWE Potable Water PDFmasoodaeNo ratings yet

- Ashrae Filtration Disinfection c19 GuidanceDocument38 pagesAshrae Filtration Disinfection c19 GuidanceVishal JainNo ratings yet

- SWOT Analysis of Pharmaceutical Industry Bangladesh HKH Ygg Iyhuih Iyhuihuih UyuhykhjDocument2 pagesSWOT Analysis of Pharmaceutical Industry Bangladesh HKH Ygg Iyhuih Iyhuihuih UyuhykhjmyhellonearthNo ratings yet

- Fgi Guidelines 2014 Hop TocDocument10 pagesFgi Guidelines 2014 Hop TocZaw Moe KhineNo ratings yet

- HTM 06-02Document114 pagesHTM 06-02mohamad5357No ratings yet

- Problem Solving FrameworkDocument2 pagesProblem Solving FrameworkGeoffNo ratings yet

- Osha 3146Document48 pagesOsha 3146s sanjaiNo ratings yet

- Centralized Medical Gas SystemDocument40 pagesCentralized Medical Gas SystemKaranbir Kaur100% (1)

- Tsi Panda 341 User ManualDocument37 pagesTsi Panda 341 User Manuala k bNo ratings yet

- Common Breathing Air Quality Standards For Scba and AirlinesDocument4 pagesCommon Breathing Air Quality Standards For Scba and AirlinesDaniel RodasNo ratings yet

- Iso 14644 2015 Pharmig XPDFDocument35 pagesIso 14644 2015 Pharmig XPDFmetrologueha1100% (1)

- PhEn602 Spring09 Notes4 PDFDocument56 pagesPhEn602 Spring09 Notes4 PDFhemantNo ratings yet

- Instructions: Installation, Operation, and Maintenance of Medium Power Substation TransformersDocument24 pagesInstructions: Installation, Operation, and Maintenance of Medium Power Substation TransformersDixie VictoriaNo ratings yet

- Engineering Manual: Air Purification Unit - ApuDocument16 pagesEngineering Manual: Air Purification Unit - ApuArdhendu ShekharNo ratings yet

- ASHRAE - The Fundamentals of Expansion Tanks PDFDocument7 pagesASHRAE - The Fundamentals of Expansion Tanks PDFAntonio LebrunNo ratings yet

- Iso14644 3Document31 pagesIso14644 3Justin Southerland100% (1)

- Oxygen USPDocument2 pagesOxygen USPMartha Lucia Roa FonsecaNo ratings yet

- Centac Centac Centac Centac: Centac Compressors 200 Hp-350 HP Cv1 CompressorsDocument2 pagesCentac Centac Centac Centac: Centac Compressors 200 Hp-350 HP Cv1 CompressorsElizabeth GamarraNo ratings yet

- Ball Valve Operation Maintenance ManualDocument7 pagesBall Valve Operation Maintenance Manualj8164322100% (1)

- Draft International Standard: ISO/DIS 14644-4Document66 pagesDraft International Standard: ISO/DIS 14644-4Ruben BoschNo ratings yet

- Medical GasesDocument6 pagesMedical GasesAtal BhowmikNo ratings yet

- 15480-H: Medical Gas Systems Guideline For Umhhc Facilities: Related SectionsDocument4 pages15480-H: Medical Gas Systems Guideline For Umhhc Facilities: Related SectionsjafarkhansfNo ratings yet

- Craftsman Snowblower ManualDocument64 pagesCraftsman Snowblower ManualKevinNo ratings yet

- Kong Long Huat Borax Decahydrate, BI GHSDocument14 pagesKong Long Huat Borax Decahydrate, BI GHSOsh 0717No ratings yet

- Cat C32 ACERT Spec Sheet - Pleasure CraftDocument8 pagesCat C32 ACERT Spec Sheet - Pleasure CraftSteven Wong100% (1)

- OISD-GDN-212-Petroleum Env AuditDocument39 pagesOISD-GDN-212-Petroleum Env AuditYani EsbeNo ratings yet

- Lab Snells Law and TIR using Phet sim-đã chuyển đổiDocument3 pagesLab Snells Law and TIR using Phet sim-đã chuyển đổiTạ Ngọc DiệpNo ratings yet

- HF Conventions: Marine VDocument21 pagesHF Conventions: Marine VHarun KınalıNo ratings yet

- 2019 Gynecomastia EAA Clinical Practice Guidelines PDFDocument16 pages2019 Gynecomastia EAA Clinical Practice Guidelines PDFRaluk BalaceanuNo ratings yet

- Theology Finals - Grade 11Document7 pagesTheology Finals - Grade 11Sophia BiancaNo ratings yet

- Bersa Arms 2011 CatalogDocument16 pagesBersa Arms 2011 CatalogAmmoLand Shooting Sports News100% (1)

- Review - 1 Faculty: Manikandan Slot: Tb1 Course: Introduction To The Innovative Physics Projects (Phy1999)Document6 pagesReview - 1 Faculty: Manikandan Slot: Tb1 Course: Introduction To The Innovative Physics Projects (Phy1999)RamNo ratings yet

- PDF A Century of Fluid Mechanics in The Netherlands Fons Alkemade Ebook Full ChapterDocument53 pagesPDF A Century of Fluid Mechanics in The Netherlands Fons Alkemade Ebook Full Chaptershelby.manns438100% (6)

- Série 400 PDFDocument526 pagesSérie 400 PDFLeonardo OliveiraNo ratings yet

- Enhanced DSL AlgorithmsDocument78 pagesEnhanced DSL AlgorithmsDaniel AlejandriNo ratings yet

- Grow As We GoDocument68 pagesGrow As We GoEg MemoriaNo ratings yet

- Executive SummaryDocument9 pagesExecutive SummaryJessNo ratings yet

- Solar Street LightDocument26 pagesSolar Street LightAr Abhinav SrivastavNo ratings yet

- Fog & MistDocument10 pagesFog & MistFahmi PrayogiNo ratings yet

- Msds Hydrogen PeroxideDocument2 pagesMsds Hydrogen PeroxideSlamet Ar100% (1)

- Fabric Test Report: Gohar TextileDocument4 pagesFabric Test Report: Gohar TextileAmir sindhuu Moon sindhuNo ratings yet

- ICT 1105 Assignment 2Document23 pagesICT 1105 Assignment 2Rachel NgNo ratings yet

- Science 7 Q4 SLM11Document15 pagesScience 7 Q4 SLM11Seen Tuna-doughNo ratings yet

- Class 10 National Genius Search Examination: Advanced: Check The Correctness of The Roll No. With The Answer SheetDocument4 pagesClass 10 National Genius Search Examination: Advanced: Check The Correctness of The Roll No. With The Answer SheetPPNo ratings yet

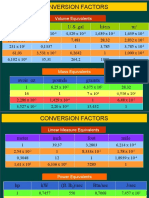

- Conversion Factors: in FT U.S. Gal Liters MDocument8 pagesConversion Factors: in FT U.S. Gal Liters MSamuel MahendraNo ratings yet

- MSDS Pentazocine Lactate Injection 101912 32-90761 1Document7 pagesMSDS Pentazocine Lactate Injection 101912 32-90761 1Andita ListyannisaNo ratings yet

- Stem 2c-Music On Plant Growth FinalDocument91 pagesStem 2c-Music On Plant Growth FinalYonaNo ratings yet

- Dental Examination Record FormDocument1 pageDental Examination Record FormDave Love NemialyNo ratings yet

- Structural Clay Loadbearing Wall Tile: Standard Specification ForDocument4 pagesStructural Clay Loadbearing Wall Tile: Standard Specification ForM RattanasakNo ratings yet

- FF-1600-EX & FF3200 Proportioning UnitDocument36 pagesFF-1600-EX & FF3200 Proportioning Unitmuhammad indra fauzi marhadinataNo ratings yet

- Annex 52A Selection of Wiring Systems: (Normative)Document10 pagesAnnex 52A Selection of Wiring Systems: (Normative)Mihaela AntonNo ratings yet