Professional Documents

Culture Documents

Gpcoewg Gecol: Document Cover Sheet

Gpcoewg Gecol: Document Cover Sheet

Uploaded by

tanmaymajhi09_796764Copyright:

Available Formats

You might also like

- API 650 Tank Design CalculationDocument8 pagesAPI 650 Tank Design Calculationmail_younes659283% (30)

- Soil Bearing Capacity Calculation Passwords RemovedDocument16 pagesSoil Bearing Capacity Calculation Passwords RemovedMaiwand Khan50% (2)

- Tank Calculation PDFDocument3 pagesTank Calculation PDFAlvin SmithNo ratings yet

- Storage Tanks CalculationsDocument21 pagesStorage Tanks Calculationsjimallen21288% (26)

- Thickness Cal. Fo DM Water Storage Tank-API 650Document15 pagesThickness Cal. Fo DM Water Storage Tank-API 650Jose Rodriguez50% (2)

- API-650 Design Procedure ExampleDocument21 pagesAPI-650 Design Procedure Examplegdwvcd93% (15)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- CalDocument19 pagesCalpandiangv100% (1)

- FinalDocument12 pagesFinalchompink6900No ratings yet

- Hfo Service Tank - ht003 Data Sheet r1 PDFDocument4 pagesHfo Service Tank - ht003 Data Sheet r1 PDFsocomenin2013No ratings yet

- 20" Mol Replacement Project: Data Sheet PipelineDocument7 pages20" Mol Replacement Project: Data Sheet PipelineAdvisNo ratings yet

- Diesel Tank TaluksangayDocument70 pagesDiesel Tank TaluksangayBert EngNo ratings yet

- Gpcoewg Gecol: Document Cover SheetDocument32 pagesGpcoewg Gecol: Document Cover Sheettanmaymajhi09_796764No ratings yet

- Design of Conical Storage TankDocument17 pagesDesign of Conical Storage TankvijaypatelnewtonNo ratings yet

- Tank Sample 최종Document34 pagesTank Sample 최종anon_548256226No ratings yet

- RCC Oht AlternateDocument50 pagesRCC Oht AlternateVarad Sonawadekar100% (1)

- Tank Calc - Api650Document90 pagesTank Calc - Api650kamleshyadavmoney100% (4)

- API 650 Tank Design CalculationsDocument8 pagesAPI 650 Tank Design Calculationsツ ツNo ratings yet

- Mill Feed Silo-10!09!08Document120 pagesMill Feed Silo-10!09!08Umer AziqNo ratings yet

- Pondasi BoilerDocument24 pagesPondasi BoilerMochammad ShokehNo ratings yet

- Design Calculation For Dirty Brackish Water Tank (129-0T2540)Document9 pagesDesign Calculation For Dirty Brackish Water Tank (129-0T2540)Dhakshina KNo ratings yet

- Supported Cone Roof (CS) Add.4Document21 pagesSupported Cone Roof (CS) Add.4skhurramq100% (2)

- RCC Bund Wall Without Shear KeyDocument21 pagesRCC Bund Wall Without Shear Keynhulugalla100% (1)

- Crane UbDocument20 pagesCrane UbBobor Emmanuel OfovweNo ratings yet

- API 650 Tank Design CalculationsDocument8 pagesAPI 650 Tank Design CalculationsVinoth Rajendra50% (4)

- Above Ground Piping Wall Thickness CalculationsDocument7 pagesAbove Ground Piping Wall Thickness Calculationslutfi awn100% (1)

- Design Calculation (CST, Unit-10)Document12 pagesDesign Calculation (CST, Unit-10)kanishkmechenggNo ratings yet

- Steel Designer's Manual, 6th Edition, 2003 R20070821FDocument5 pagesSteel Designer's Manual, 6th Edition, 2003 R20070821Fsaad7159No ratings yet

- API 620 CalculationDocument114 pagesAPI 620 Calculationvikram100% (4)

- RCC Bund Wall With Shear KeyDocument27 pagesRCC Bund Wall With Shear Keynhulugalla100% (1)

- Anchor Block Sizing: Prep. byDocument6 pagesAnchor Block Sizing: Prep. byKhan LalaNo ratings yet

- Staircase Design 01Document12 pagesStaircase Design 01MUTHUKKUMARAMNo ratings yet

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocument31 pagesStorage Tank Design Calculation - Api 650: Close Floating RoofNguyễn Duy HưngNo ratings yet

- Design Calculation For Pipe SupportsDocument200 pagesDesign Calculation For Pipe Supportssanggytha100% (1)

- PV Elite 2013 Sp3 Licensee: Isgec Filename: Pe-1668 75 - Hydro Asme Ts Calc: Case: 1 12:08P Apr 2,2014Document8 pagesPV Elite 2013 Sp3 Licensee: Isgec Filename: Pe-1668 75 - Hydro Asme Ts Calc: Case: 1 12:08P Apr 2,2014Mayank MittalNo ratings yet

- Advances in Solid Oxide Fuel Cells XFrom EverandAdvances in Solid Oxide Fuel Cells XMihails KusnezoffNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Ceramic Materials for Energy Applications IV: A Collection of Papers Presented at the 38th International Conference on Advanced Ceramics and Composites, January 27-31, 2014, Daytona Beach, FLFrom EverandCeramic Materials for Energy Applications IV: A Collection of Papers Presented at the 38th International Conference on Advanced Ceramics and Composites, January 27-31, 2014, Daytona Beach, FLHua-Tay LinNo ratings yet

- Advances in Ceramic Armor XFrom EverandAdvances in Ceramic Armor XJerry C. LaSalviaNo ratings yet

- Ceramic Materials for Energy Applications VIFrom EverandCeramic Materials for Energy Applications VIHua-Tay LinNo ratings yet

- 77th Conference on Glass Problems: A Collection of Papers Presented at the 77th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, OH, November 7-9, 2016From Everand77th Conference on Glass Problems: A Collection of Papers Presented at the 77th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, OH, November 7-9, 2016S. K. SundaramNo ratings yet

- Case Studies in Fluid Mechanics with Sensitivities to Governing VariablesFrom EverandCase Studies in Fluid Mechanics with Sensitivities to Governing VariablesNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Advances in Ceramic Armor XIFrom EverandAdvances in Ceramic Armor XIJerry C. LaSalviaNo ratings yet

- Scientific American Supplement, No. 360, November 25, 1882From EverandScientific American Supplement, No. 360, November 25, 1882No ratings yet

- FGD 001Document30 pagesFGD 001tanmaymajhi09_796764No ratings yet

- Pages From Roark's Formulas For Stress & Strain (For Deflection)Document2 pagesPages From Roark's Formulas For Stress & Strain (For Deflection)tanmaymajhi09_796764No ratings yet

- Pages From Roark's Formulas For Stress & Strain-See Case 7 (Stress in Inner Rim)Document1 pagePages From Roark's Formulas For Stress & Strain-See Case 7 (Stress in Inner Rim)tanmaymajhi09_796764No ratings yet

- Pages From Roark's Formulas For Stress & Strain-See Case 7 (Stress in Inner Rim)Document1 pagePages From Roark's Formulas For Stress & Strain-See Case 7 (Stress in Inner Rim)tanmaymajhi09_796764No ratings yet

Gpcoewg Gecol: Document Cover Sheet

Gpcoewg Gecol: Document Cover Sheet

Uploaded by

tanmaymajhi09_796764Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gpcoewg Gecol: Document Cover Sheet

Gpcoewg Gecol: Document Cover Sheet

Uploaded by

tanmaymajhi09_796764Copyright:

Available Formats

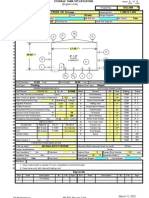

3 x 250MW Sarir Gas Turbine Project

Strength Calculation Sheet for Field Erected Tank

Rev. A

DOCUMENT COVER SHEET

Dec 01, 08

FOR APPROVAL

K.K.J

Y.K.H

S.O.C

REV.

DATE

DESCRIPTION

DGN

CHK

APP

CLIENT

GECOL

GPCOEWG

GENERAL ELECTRIC

COMPANY OF LIBYA

GENERAL PEOPLES COMMITTEE

OF ELECTRICITY, WATER AND GAS

PROJ. CONSULTANT

A R A B I A N C O N S U LT I N G A N D E N G I N E E R I N G S E RV I C E S C

O

PROJECT TITLE

SARIR 3X250MW GAS TURBINE PROJECT, LIBYA (14/2007)

CONTRACTOR

DESIGNED BY

K.K.J

Dec 01 08

GESCO

CHECKED BY

Y.K.H

APPROVED BY

S.O.C Dec 01 08

GLOBAL ELECTRICITY SERVICES CO.

Dec 01 08

TITLE

00GDF10BB001 RO PERMEATE TANK

Strength Calculation Sheet for Field Erected Tanks

SCALE

PROJ.NO.

DOCUMENT NO.

NO. OF SHT.

N/A

10026

142007-SR00-MDTA-C501

Cover Sheet +

30

REV.

A

ITEM NO. : OOGDF10BB001

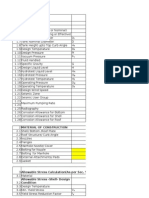

page

CONTENTS

PAGE

1 .

DESIGN DATA

----------

2 .

TANK CAPACITY

----------

3 .

WEIGHT SUMMARY

----------

4~5

4 .

DESIGN OF SHELL PLATE

----------

6~8

5 .

DESIGN OF WIND GIRDER

----------

6 .

DESIGN OF BOTTOM PLATE

----------

10

7 .

DESIGN OF ROOF

----------

11

8 .

DESIGN OF TOP ANGLE

----------

12

9 .

WIND LOAD ON TANK

----------

13 ~ 14

10 .

SEISMIC DESIGN OF TANK

----------

15 ~ 26

11 .

DESIGN OF ANCHOR

----------

17 ~ 30

of

30

ITEM NO. : OOGDF10BB001

page

of

DESIGN DATA

SERVICE

RO PERMEATE TANK

CODE

API 650 - 11th ED.

FLUID

RO PERMEATE

CAPACITY

DESIGN PRESSURE

OPERATING PRESSURE

(NOMINAL)

141

(WORKING)

120

(INTERNAL)

ATM.

(EXTERNAL)

(INTERNAL)

ATM.

(EXTERNAL)

ATM.

m3

mmH2O

mmH2O

DESIGN TEMPERATURE

60

OPERATING TEMPERATURE

50

HYDRO. TEST PRESSURE

PNEU.

TEST PRESSURE

mmH2O

mmH2O

PER CODE (PARA 8.1.2)

RADIOGRA. TEST

NO

P.W.H.T.

CORROSION ALLOWANCE

FULL WATER

(SHELL)

(ROOF)

(BOTTOM)

(STRUCTURE)

mm

mm

WIND VELOCITY

45

Km/sec.

SEISMIC FACTOR

2A (UBC)

INSULATION

30

ITEM NO. : OOGDF10BB001

page

TANK CAPACITY

1.

CAPACITY CALCULATION

NOMINAL CAPACITY

Vtotal

x Di2

Ht

141

m3

m3

141

m3

Vslope

x Ri2 x Hs

2

Vnomonal

Vtotal - Vslope

WORKING CAPACITY

Vworking

x Di2

(HLL - LLL)

120

m3

Where,

Di

INSIDE DIAMETER OF TANK

5.000

Ri

INSIDE RADIUS OF TANK

2.500

Ht

HEIGHT OF TANK

7.200

HLL

HIGH LIQUID LEVEL

6.612

LLL

LOW LIQUID LEVEL

0.500

Hc

HEIGHT OF BOTTOM CONE

0.021

of

30

ITEM NO. : OOGDF10BB001

page

of

WEIGHT SUMMARY

( 1 Kg = 9.8 N )

PART

TH'K

WIDTH

LENGTH

Q'TY

NAME

(mm)

(mm)

(mm)

(EA)

(NEW)

(CORRODED)

1513

15723.7

934

934

A240-304L

1513

15723.7

934

934

A240-304L

1513

15723.7

934

934

A240-304L

1513

15723.7

934

934

A240-304L

1148

15723.7

708

708

A240-304L

15708.0

A240-304L

15724

93

93

SS.304L

SHELL

L65x65x6

TOP ANGLE

WEIGHT (Kg)

MATERIAL

BOTTOM PLATE

1017

1017

A240-304L

ROOF PLATE

1295

1295

A240-304L

30

ITEM NO. : OOGDF10BB001

page

of

WEIGHT SUMMARY

PART

TH'K

WIDTH

LENGTH

Q'TY

WEIGHT (Kg)

NAME

(mm)

(mm)

(mm)

(EA)

(NEW)

(CORRODED)

NOZZLE

1 LOT

1000

1000

SS.304L

P/F & LADDER

1 LOT

1000

1000

CS.

OTHERS

1 LOT

442

442

SS.304L

INSULATION

1 LOT

OPERATING LIQUID

129826

129826

TEST WATER

141372

141372

ERECTION WEIGHT

9291

9291

EMPTY WEIGHT

9291

9291

OPERATING WEIGHT

139117

TEST WEIGHT

150663

MATERIAL

30

ITEM NO. : OOGDF10BB001

page

of

DESIGN OF SHELL PLATE

(FROM API 650)

PART NAME :

SHELL

1. DESIGN CONDITION

D

NOMINAL INSIDE DIAMETER OF TANK

Ht

TOTAL HEIGHT OF TANK SHELL

7.2

Hd

DESIGN LIQUID LEVEL

6.612

Hn

HIGH LIQUID LEVEL

6.612

DT

DESIGN TEMPERATURE

60

LIQUID LEVEL FOR THE DESIGN CONDITION

HT

LIQUID LEVEL FOR THE TEST CONDITION

Pi

DESIGN INTERNAL PRESSURE

mmH2O

Pe

DESIGN EXTERNAL PRESSURE

mmH2O

Gi

SPECIFIC GRAVITY OF LIQUID

DESIGN SPECIFIC GRAVITY OF LIQUID

CA

CORROSION ALLOWANCE OF SHELL

mm

CAr

CORROSION ALLOWANCE OF ROOF

mm

CAb

CORROSION ALLOWANCE OF BOTTOM

mm

trs

REQUIRED SHELL THICKNESS (LARGER OF tcs or tms)

tcs

CALCULATED SHELL THICKNESS

(LARGER OF td or tt)

td

SHELL THICKNESS FOR THE DESIGN CONDITION

tt

SHELL THICKNESS FOR THE HYDRO. TEST CONDITION

tms

MINIMUM SHELL THICKNESS

mm

Fy

MINIMUM YIELD STRENGTH

Ft

MINIMUM TENSILE STRENGTH

Sd

ALLOWABLE STRESS FOR THE DESIGN CONDITION

St

ALLOWABLE STRESS FOR THE TEST CONDITION

DESIGN WIND VELOCITY

45

m/sec.

JOINT EFFICIENCY

0.85

162.0

Km/h

30

ITEM NO. : OOGDF10BB001

page

DESIGN OF SHELL PLATE

(FROM API 650)

2. ALLOWABLE STRESS

(para 5.6.2)

Sd

FROM APPENDIX S

St

FROM APPENDIX S

COURSE

MATERIAL

Fy

Ft

Sd

St

(Mpa)

(Mpa)

(Mpa)

(Mpa)

A240-304L

170

485

139.8

155

A240-304L

170

485

139.8

155

A240-304L

170

485

139.8

155

A240-304L

170

485

139.8

155

A240-304L

170

485

139.8

155

of

30

ITEM NO. : OOGDF10BB001

page

of

DESIGN OF SHELL PLATE

(FROM API 650)

3. SHELL THICKNESS CALCULATION

(para 5.6.3.2)

DESIGN CONDITION

4.9D.(H + Pi/1000G - 0.3).G

td

CA

Sd.E

TEST CONDITION

tt

4.9D.(HT - 0.3)

St.E

COURSE

HT

td

tt

tcs

tms

trs

used

(m)

(m)

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

7.2

6.612

1.30

1.28

1.30

5.00

5.00

5.687

5.099

0.99

1.00

1.00

5.00

5.00

4.174

3.586

0.68

0.72

0.72

5.00

5.00

2.661

2.073

0.37

0.44

0.44

5.00

5.00

1.148

0.56

0.05

0.16

0.16

5.00

5.00

30

ITEM NO. : OOGDF10BB001

page

of

DESIGN OF WIND GIRDER

(FROM API 650)

PART NAME :

1ST WIND GIRDER

(para 5.9.7)

1. DESIGN CONDITION

: NOMINAL INSIDE DIAMETER OF TANK

: ORDERED THICKNESS OF TANK SHELL

ta

(UNIFORM THICKNESS)

: ORDERED THICKNESS OF TOP SHELL COURSE

H1

: MAXIMUM DISTANCE BETWEEN THE WIND GIRDER AND TOP ANGLE OR TOP WIND GIRDER

: ACTUAL WIDTH OF EACH SHELL COURSE

Wtr

: TRANSPOSED WIDTH OF EACH SHELL COURSE=

: DESIGN WIND VELOCITY

Ea

: Modulus of Elasticity at Ambient Temperature

193000 Mpa

Ed

: Modulus of Elasticity at Design Temperature

191400 Mpa

H1

9.47ta

H1

>

x

Htr

(ta/D)3

7.200

(190/V)

mm

(ta/t)5

162.0

Ed/Ea

Km/h

45

45.805 m

THEREFORE, INTERMEDIATE WIND GIRDER IS NOT REQUIRED.

t

Wtr

(mm)

(m)

(m)

1.513

1.513

Wtri

1.513

1.513

Htr

SUM OF Wtri

1.513

1.513

1.513

1.513

1.148

1.148

COURSE

7.200

(ta/t)5

m/sec.

30

ITEM NO. : OOGDF10BB001

page

10

of

DESIGN OF BOTTOM PLATE

(FROM API 650)

PART NAME :

BOTTOM

(para 5.4)

MATERIAL

A240-304L

1. DESIGN CONDITION

NOMINAL INSIDE DIAMETER OF TANK

MAXIMUM DESIGN LIQUID LEVEL

7.2

THICKNESS OF SHELL IN FIRST COURSE

DESIGN SPECIFIC GRAVITY OF LIQUID

CAb

CORROSION ALLOWANCE OF BOTTOM PLATE

2. THICKNESS OF BOTTOM PLATE

tb

tmb + CAb

tmb

mm

MINIMUM BOTTOM PLATE THICKNESS

USED :

mm

mm

mm

mm

30

ITEM NO. : OOGDF10BB001

page

11

of

DESIGN OF ROOF

(FROM API 650)

PART NAME :

ROOF

(para 5.10.4)

MATERIAL

A240-304L

1. DESIGN CONDITION

Nominal Inside Diameter

Nominal Thickness

mm

tr

Required Thickness = tm + CAr

5.00

mm

tc

Corroded Thickness

mm

CAr

Corrosion Allowance of Roof

mm

tm

Minimum Thickness of Roof

mm

Lr

Live Loads

1.2

Kpa

Ld

Dead Loads

0.65

Kpa

Ls

Snow Loads

Kpa

La

Additional Loads

0.2

Kpa

Lv

Vacuum Loads

Kpa

Sa

Allowable Stress of Roof Material

139.8

Mpa

Design Loads = The Greater of Pd1, Pd2

2.05

Kpa

Pd1

Ld + (Lr or Ls) + 0.4Lv + La

2.05

Kpa

Pd2

Ld + 0.4(Lr or Ls) + Lv + La

1.33

Kpa

0.164

9.46

sin

Roof Slope

(1 :

Angle of Cone

Em

Elastic Modulus of Rafter Material

199000 Mpa

Required Thickness

tr

D

4.8sin

T

2.2

0.5

CAr

6.11

mm

USED

mm

30

ITEM NO. : OOGDF10BB001

12

page

of

DESIGN OF TOP ANGLE

(FROM API 650)

DESIGN CONDITION

D

Nominal Inside Diameter

tc

Corroded Thickness of Shell Plate at Top Course

mm

th

Corroded Thickness of Roof Plate

mm

Rc

Inside Radius of Tank Shell

2500

mm

R2

Rc/sin

Wc

0.6(Rc.tc)0.5

67.08

mm

Wh

0.3(R2.th)0.5

97.88

mm

DESIGN OF TOP ANGLE

USE

L65x65x6

Wu : Unit Weight

57.9

N/m

Cross Sectional Area

752.7

mm2

D2/(0.432sin)

352.0

mm2

Ar

1773.3 mm2

Required Area

Ar

<

Aa

Therefore, Used Angle is

OK.

Available Area

Aa

As +Arf + Ata

1773.3 mm2

At Top Angle

Ata

752.7

mm2

At Shell

As

Wc x tc

335.4

mm2

Wh x th

685.2

mm2

At Roof

Arf

15206.9 mm

30

ITEM NO. : OOGDF10BB001

page

13

of

WIND LOAD ON TANK

(FROM API 650)

1. DESIGN CONDITION

(para 5.11)

Nominal Inside Diameter of Tank

HT

Height of Tank = Ht + Hr/2

7.356

Hr

Height of Roof

0.156

Design Liquid Level

6.612

Shell Weight less Corrosion Allowance plus Dead Weight Supported

=

57145

by the Shell

Wsc + Wrc - 0.4Fi

Wsc

Corroded Shell Weight

44457

Wrc

Corroded Roof Weight

12688

Fi

Uplift Load = .D2.Pi/4

tb

Corroded Thickness of Bottom Annular Ring

mm

Fby

Minimum Yield Strength of Annular Ring

170

Mpa

2. WIND LOAD

Fwv

860Afv

(V/190)2

Afv

Vertical Project Area

Wind Velocity

25295

40.5

=

=

162.0

Km/h

3. WIND MOMENT

Mw

Fwv.(HT/2)

93039

N-m

4. MOMENT DUE TO INTERNAL PRESSURE

Mpi

Fi.(D/2)

N-m

5. MOMENT DUE TO WEIGHT OF THE SHELL AND ROOF SUPPORTED BY THE SHELL

Mdl

W .(D/2)

142864

N-m

m2

30

ITEM NO. : OOGDF10BB001

page

14

of

WIND LOAD ON TANK

(FROM API 650)

6. MOMENT DUE TO LIQUID

Wa

59 x tb.(Fby.H)0.5

Ff

Wa..D

279644

Mf

Ff.(D/2)

699110

N-m

17803

N/m

7. OVERTURNING STABILITY

0.6Mw + Mpi =

55824

<

Mdl/1.5

95242

N-m

(UNANCHORED TANK)

Mw + 0.4Mpi =

93039

<

(Mdl + Mf)/2

420987

N-m

(UNANCHORED TANK)

30

ITEM NO. : OOGDF10BB001

page

15

of

SEISMIC DESIGN OF STORAGE TANKS

(FROM API 650 - APPENDIX E)

DESIGN DATA

I

SUG Group

D

: Tank Diamenter

5.000

: Max. Filling Height

6.612

: Design Specific Gravity

1.000

Site

: Site Class

: Importance Factor

1.25

Sds

: 5% damped, spectral response acceleration parameter

0.375

0.375

at short period (T=0.2 seconds)

Ss

2.5Q.Fa.So

: Mapped, maximum considered earthquake, 5% damped,

spectral response acceleration parameter at short period (0.2s)

(Ss = 2.5 Sp)

Sp

: Design Level Peak Accerelation

0.15

: Scaling Factor is defined as 2/3 for the ASCE 7 Methods

0.667

: Coefficient to adjust the spectral accelation from 5% - 0.5% damping

1.5

So

0.150

S1

: Mapped, maximum considered earthquake, 5% damped,

0.188

0.2

0.6

So = 0.4 Ss

spectral response acceleration parameter at one second

(S1=1.25 Sp)

: Natural period of vibration of the tank and contents

C1

: Lateral Earthquake Force Co-efficient

Fa

: Acceleration based site coeff. (from Table. E-1)

1.5

Fv

: Acceleration based site coeff. (from Table. E-2)

2.224

Rwi

: Response modification factor. (from Table. E-4)

(Impulsive)

Rwc

: Response modification factor. (from Table. E-4)

(Convective)

Tc

: The first mode sloshing wave period

2.33

0.117

Where,

Tc

Ks

1.8Ks.(D)0.5

2.33

TL

(E.4.5.2-a)

sec.

0.578 / tanh(3.6H/D)0.5

(Refer to Sds)

(E.4.5.2-c)

0.578

: Regional-dependent transition period for longer

period ground motion

(E.4.6.1 Spectral Acceleration Coefficients of API 650)

Ai

: Spectral acceleration parameter.(Impulsive)

Ai

Sds(I/Rw)

0.117

2.5Q.Fa.So(I/Rw)

(E.4.6.1-1)

sec.

sec.

30

page

ITEM NO. : OOGDF10BB001

16

SEISMIC DESIGN OF STORAGE TANKS

(FROM API 650 - APPENDIX E)

Ac

: Spectral acceleration parameter.(Convective)

When, TC < TL

Ac

=

=

2.5K.Q.Fv.So(Ts/Tc)(I/Rwc)

Ai

(E.4.6.1-4)

0.112

When, TC > TL

Ac

=

=

2.5K.Q.Fv.So(Ts.TL/Tc2)(I/Rwc)

0.117

Ts

=

=

Since :

Ac

Tc :

=

2.327

0.117

(Fv x S1)/(Fa x Ss)

0.741

>

TL

Ai

(E.4.6.1-4)

0.117

of

30

page

ITEM NO. : OOGDF10BB001

SEISMIC DESIGN OF STORAGE TANKS

(FROM API 650 - APPENDIX E)

LOADING DATA (Weight)

1) Shell & Accessories

W1s

5.758

Ton

5758

Kg

2) Bottom & Accessories

W1b

1.017

Ton

1017

Kg

3) Roof & Accessories

W1r

2.516

Ton

2516

Kg

Kg

4) Empty Weight (W1s+W1b+W1r)

W1

9.291

Ton

9291

5) Content Weight

W2

129.826

Ton

129826

Kg

6) Total Empty Weight

Wt

9.291

Ton

9291

Kg

CENTER OF GRAVITY OF SHELL

COURSE

WEIGHT

CG.

MOMENT

NO.

(N)

(m)

(N-m)

9151

0.757

6923

9151

2.270

20768

9151

3.783

34613

9151

5.296

48458

6943

6.626

46006

TOTAL

43546

3.600

156767

17

of

30

page

ITEM NO. : OOGDF10BB001

18

SEISMIC DESIGN OF STORAGE TANKS

(FROM API 650 - APPENDIX E)

BASE SHEAR FORCE

Av

Vertical acceleration parameter (impulsive)

Where, Av shall be taken as 0.14 Sds or greater for ACE 7 method unless otherwise

specified by purchaser. (refer to API 650, para E.6.1.3)

Av

0.14 x Sds

0.05250

Ws

: Total weight of tank shell

Xs

: Height from bottom of tank shell to center

56424.9796 N

6.875

of gravity of shell

27121.836 N

Wr

: Total weight of tank roof with 10% snow load

Xr

: Height from top of tank shell to roof

1.2725

Wi

: Weight of effective mass of tank content that

1062777

move in unison with the tank shell

Wf

: Weight of tank floor (Bottom Plate)

Wc

: The effective convective weight

Wc

=

=

Wp

0.230(D/H).tanh(3.67H/D) x Wp

221305

22573

Kg

(E.6.1.1-3)

{[( x D2)/4] x H} x G

129761

Kg

1272561

Effective Weight of Product

When)

Wi

D/H =

0.756

1.333

>

tanh [ 0.866D/H]

0.866D/H

1117238

113958

Kg

Wp

(E.6.1.1-1)

9969.41232 N

221305

0.053

of

30

19

page

ITEM NO. : OOGDF10BB001

of

SEISMIC DESIGN OF STORAGE TANKS

(FROM API 650 - APPENDIX E)

When)

0.756

D/H =

Wi

D/H

Wi

Xi

1.333

(1.0 - 0.218D/H) x Wp

Since,

<

1062777

108403

Kg

1.333

<

(E.6.1.1-2)

1062777.

108403

Kg

: Height from bottom of tank shell to centeriod

2.836

of lateral seismic force applied to Wi

When,

D/H

Xi

0.7562

0.375H

1.3333

(E.6.1.2.1-1)

D/H

Xi

2.480

Xc

>

: Height from bottom of tank shell to centeriod

=

Where,

1.0 -

cosh(3.67H/D) - 1

(3.67H/D)sinh(3.67H/D)

6.111

x H

2.836

6.111

(E.6.1.2.1-3)

cosh(3.67H/D) - 1

23.5826

(3.67H/D)sinh(3.67H/D)

310.9524

Total Design Base Shear

V

(Vi2 + Vc2)0.5

137962.6

Vi

Ai x (Ws+Wr+Wf+Wi)

135503.1

(E6.1-2)

Vc

Ac x Wc

25934.2

(E6.1-3)

(E6.1-1)

<

(0.5 - 0.094D/H)H

of lateral seismic force applied to Wc

Xc

0.7562

1.3333

30

page

ITEM NO. : OOGDF10BB001

20

of

30

SEISMIC DESIGN OF STORAGE TANKS

(FROM API 650 - APPENDIX E)

DYNAMIC DESIGN HOOP FORCES

Y

When,

Distance from liquid surface to analysis point (m)

0.7562

D/H =

Ni1

When,

21.4Ai.G.D.H(Y/H - 0.5(Y/H)2)tanh(0.866D/H)

0.7562

D/H =

Ni2

When,

1.333

<

1.333

>

and

13.16Ai.G.D2{Y/(0.75D) - 0.5(Y/0.75D)2}

0.7562

D/H =

1.333

>

(E-6.1.4-1a)

<

0.75d

(E-6.1.4-2a)

and

>

0.75d

6.6Ai.G.D2

(E-6.1.4-3a)

33.1Ac.G.D2cosh{3.68(H - Y)/D}

(E-6.1.4-4a)

NI3

Nc

Nh

9.8G.D.Y/2

h s

tc

cosh(3.68H/D)

Nh {Ni2 + Nc2 + (Av.Nh)2}0.5

(E-6.1.4-6)

tc

Corroded thickness of each shell course

s = 1.33S JUDGE-

tc

Ni1

Ni2

Ni3

Ni

Nc

Nh

(m)

(mm)

(N/mm)

(N/mm)

(N/mm)

(N/mm)

(N/mm)

(N/mm)

(Mpa)

or 0.9Fy

MENT

6.612

23.8

8.0

19.3

19.3

1.5

162.0

8.6

153.0

OK

5.099

22.6

16.8

19.3

22.6

2.5

124.9

9.1

153.0

OK

3.586

18.8

19.2

19.3

18.8

7.0

87.9

7.8

153.0

OK

2.073

12.6

15.4

19.3

12.6

21.1

50.8

7.4

153.0

OK

0.56

3.9

5.3

19.3

3.9

64.2

13.7

13.6

153.0

OK

COURSE

page

ITEM NO. : OOGDF10BB001

21

of

SEISMIC DESIGN OF STORAGE TANKS

(FROM API 650 - APPENDIX E)

OVERTURNING MOMENT

Mrw

: Ringwall moment - Portion of the total overturning

432769.9

N-m

517144.4

N-m

moment that acts at the base of the tank shell

perimeter

Ms

Mrw

: Slab moment (used for pile cap and pile cap design)

.

.

.

2

.

2

{Ai(Wi Xi + Ws Xs + Wr Xr)} + {Ac(Wc Xc)}

432769.9

=

Ms

517144.4

Xis

0.375 x

0.835

Xis

D/H

=

Xcs

0.866D/H

tanh(0.866D/H)

0.6549

tanh (0866 D/H)

0.5749

3.606

- 1.0

x H

(E.6.1.2.2.-1)

0.866 D/H

<

1.333

(E.6.1.2.2.-2)

1.333

<

Xis

1.0 + 1.333 x

( 0.5 + 0.06D/H) x H

=

Since,

1.333

>

0.7562

D/H =

(E.6.1.5-2)

N-m

0.7562

D/H =

When,

N-m

.

.

.

2

.

{Ai(Wi Xis + Ws Xs + Wr Xr)} + {Ac(Wc Xcs)}

When,

(E.6.1.5-1)

3.606

1.0 -

5.291

cosh(3.67H/D - 1.937)

(3.67H/D).sinh(3.67H/D)

x H

cosh((3.67 x H)/D)-1.937)

62.1423

3.67H/D x sinh(3.67H/D)

310.9524

(E.6.1.2.2.-3)

30

page

ITEM NO. : OOGDF10BB001

22

of

SEISMIC DESIGN OF STORAGE TANKS

(FROM API 650 - APPENDIX E)

STABILITY FOR SEISMIC

Resistance to Overturning (Wa)

Wa

: Resisting force of tank contents per unit length of

6343.7

N/m

shell circumference that may be used to resist the

shell overturning moment

Tb

: Thickness of tank bottom less corrosion allowance

6.5

mm

Fy

: Minimum specified yeild strength of bottom annulus

205.0

Mpa

Ge

: Effective specific gravity including vertical seismic

0.98

effects [(Ge = G(1-0.4Av)]

G

: Specific Gravity of contents

1.000

: Maximum design product level (or Tank height)

6.612

: Nominal Tank Diameter

5.000

ta

: Thickness of tank bottom plate or annular ring

6.5

24656

Wa

99ta

Fy.H.Ge

23441.4

196H.D.Gc

6343.7

mm

(E-6.2.1.1-1a)

Conditions for self-anchored (un-anchored) tank

a)

Anchorage ratio (J)

Mrw

J

(E.6.2.1.1.1-1)

2.

D (Wt(1 - 0.4Av) + Wa

Wt

1.519

: Tank and roof weight acting at base of shell

Wt

Wrs :

Ws/(.D) + Wrs/(.D)

5164.4

(E.6.2.1.1.1-2)

N/m

Roof load acting on the tank shell including 10%

of the roof design snow load

30

page

ITEM NO. : OOGDF10BB001

23

30

of

SEISMIC DESIGN OF STORAGE TANKS

(FROM API 650 - APPENDIX E)

Table E-6Anchorage Ratio Criteria (API 650)

Anchorage Ratio (J)

Criteria

No calculated uplift under the design seismic overturning

J < 0.785

moment.

The tank is self anchored.

0.785 < J <1.54

Tank is uplifting, but the tank is stable for the design

load providing the shell compression requirements are

satisfied. Tank is selfanchored.

j > 1.54

Tank is not stable and can not be self-anchored for the

design load. Modify the annular plate if L < 0.035D is

not comtrolling or add mechanical anchorage.

Where,

Anchorage ratio (J) shall be less than 0.785 in accordance with

Table E-6 of API 650, refer to above.

1.519

J=

Therefore,

1.54

<

Tank is stable, no required anchoring

Annular Plate Requirement

L

Required minimum width of the bottom annulus measured

0.175

EA

from the inside of the shell (m)

L

=

=

0.01723ta

.

Fy/(H Ge)

0.630

0.035D

0.175

Design Up-Lift Load on Anchors

W AB

=

=

1.273Mrw/D2 - Wt(1 - 0.4Av)

16980.7

(E.6.2.1.2-1)

N/m

The Anchor seismic design Load

PAB

Na

W AB(.D/Na)

33341.5

: Number of anchors

(E.6.2.1.2-2)

N

page

ITEM NO. : OOGDF10BB001

24

of

SEISMIC DESIGN OF STORAGE TANKS

(FROM API 650 - APPENDIX E)

Maximum Compression in Self-Anchored Tank

When)

0.785

<

c1

{Wt(1 + 0.4Av) + 1.273Mrw/D2}/(1000ts)

5.5

=

When)

Mpa

0.785

>

c2

(E.6.2.2.1-1a)

Wt(1 + 0.4Av) + Wa

0.607 - 0.18667(J)2/3

5.2

- Wa x

(E.6.2.2.1-2a)

1000ts

Mpa

Shell Compression in Mechanical-Anchored Tank

c3

c

ts

{Wt(1 + 0.4Av) + 1.273Mrw/D2}/(1000ts)

5.5

Mpa

5.5

Mpa

(E.6.2.2.2-1a)

: Corroded Thickness of Bottom Shell Course

Allowable Longitudinal Shell-Membrane Compression Stress

When)

G.H.D2/t2

Fc1

83ts/D

G.H.D2/t2

Fc2

>

44

(E.6.2.2.3-1a)

83.0

=

When)

6.61

6.61

Mpa

<

8ts/(2.5D) + 7.5(GH)0.5

22.5

Fc

22.5

Mpa

5.5

Mpa

44

<

0.5Fy

<

102.5

<

Fc

(E.6.2.2.3-2a)

(It's Stable.)

mm

30

page

ITEM NO. : OOGDF10BB001

SEISMIC DESIGN OF STORAGE TANKS

(FROM API 650 - APPENDIX E)

FREEBOARD

s

0.5D.Af

0.830

(E.7.2-1)

m

For SUG I and II

When)

2.327

Af1

2.5K.Q.Fv.So.I(Ts/Tc)

4

(E.7.2-2)

0.332

Ts

When)

Tc

Fv.S1/Fa.Ss

Tc

2.327

Af2

2.5K.Q.Fv.So.I(4Ts/Tc2)

>

0.741

4

(E.7.2-3)

0.571

=

For SUG III

When)

2.327

Af3

2.5K.Q.Fv.So(Ts/Tc)

TL

=

(E.7.2-4)

Tc

2.327

Af4

2.5K.Q.Fv.So(Ts.TL/Tc2) (E.7.2-5)

Af

0.457

0.332

>

TL

Minimum Required Freeboard

0.7

0.266

=

When)

Tc

0.581

(Table E-7)

25

of

30

page

ITEM NO. : OOGDF10BB001

26

SEISMIC DESIGN OF STORAGE TANKS

(FROM API 650 - APPENDIX E)

SLIDING CHECK

Sliding Resistance

Vs

(Ws + Wr + Wf + Wp)(1.0 - 0.4Av)

534955.9

=

Vs

>

(E.7.6-1)

N

137962.6

* Therefore, It's Stable.

: Friction Coefficient for tank sliding

0.4

of

30

ITEM NO. : OOGDF10BB001

page

27

of

DESIGN OF ANCHOR

1. DESIGN CONDITION

(TBL 5-21a)

Mw

Wind Moment

93039

N-m

Ms

Seismic Moment

517144

N-m

Tank Diameter

5.000

Diameter of Bolt Circle

5.200

Number of Anchors

EA.

Sa

Design Stress for Anchor

140

Mpa

W1

Dead Load of Shell minus any Corrosion Allowance and any Dead Load other

W2

than Roof plate Acting on the Shell Minus any CA.

Roof plate Acting on the Shell Minus any CA.

W3

91051

78362

57145

0.00

Kpa

Dead Load of Shell Using As-built Thickness and any Dead Load other

than Roof plate Acting on the Shell Using As-built Th'k

78362

Dead Load of Shell minus any Corrosion Allowance and any Dead Load Including

Shell Weight less Corrosion Allowance plus Dead Weight Supported

by the Shell Less 0.4 Times the Uplift From Internal Pressure

=

Wsc + Wrc - 0.4Fi

Design Pressure

Pt

Test Pressure

0.00

Kpa

Pf

Failure Pressure

-1.57

Kpa

th

Corroded Roof Plate Thickness

mm

Fy

Yield Strength of Anchor Bolt

205

Mpa

Ab

Root Area of Anchor Bolt

502.96

mm2

Db

Root Diameter of Anchor Bolt

25.31

mm

Cab

Corrosion Allowance of Anchor Bolt

3.00

mm

390.8

mm2

Abc

(M30)

4A/

Corroded Root Area of Anchor Bolt

= (Db - Cab) /4

2. UPLIFT LOAD PER ANCHOR

LOAD CASE

DESIGN PRESSURE

[(P - 0.08th) x D2 x 785} - W1] / N

REQUIRED AREA OF ANCHOR

-11169 /

-11169 N

140

-79.8 mm2

-79.8 mm2

TEST PRESSURE

[(Pt - 0.08th) x D2 x 785} - W1] / N

REQUIRED AREA OF ANCHOR

-11169 /

-11169 N

140

30

ITEM NO. : OOGDF10BB001

page

DESIGN OF ANCHOR

FAILURE PRESSURE

[(1.5Pf - 0.08th) x D2 x 785} - W3] / N

REQUIRED AREA OF ANCHOR

-16962.7 N

-16962.7 /

205

-82.7 mm2

-12.7 mm2

245.9 mm2

-13.3 mm2

247.2 mm2

(Fy)

WIND LOAD

{(4Mw/D) - W2} / N

REQUIRED AREA OF ANCHOR

-2077.39 N

-2077.39 /

164

(0.8Fy)

SEISMIC LOAD

{(4Ms/D) - W2} / N

REQUIRED AREA OF ANCHOR

40333

40333.1 /

164

(0.8Fy)

DESIGN PRESSURE + WIND

[(P - 0.08th) x D2 x 785} + 4Mw/D - W1] / N

REQUIRED AREA OF ANCHOR

-1865.09 N

-1865.09 /

140

DESIGN PRESSURE + SEISMIC

[(P - 0.08th) x D2 x 785} + 4Ms/D - W1] / N

REQUIRED AREA OF ANCHOR

40545.4 N

40545.4 /

164

(0.8Fy)

MAXIMUM REQUIRED AREA OF ANCHOR =

EFFECTIVE ARAE =

390.8 mm2

247.2 mm2

(It'S OK)

28

of

30

ITEM NO. : OOGDF10BB001

page

DESIGN OF ANCHOR

3. TENSION LOAD PER ANCHOR

(para 5.11.3)

DUE TO WIND

tBw

4Mw/(d.N) - W/N

1802.9

REQUIRED AREA

Ar

tBw/Sa

13

mm2

EFFECTIVE AREA

Ae

mm2

391

Ar

<

Ae

( It's

OK.

29

of

30

ITEM NO. : OOGDF10BB001

page

30

of

DESIGN OF ANCHOR

1. DESIGN CONDITION

Mw

Wind Moment

93039

N-m

Fw

Wind Load

25295

Fs

Seismic Load

137963

We

Empty Weight (Corroded)

91051

Wo

Operating Weight

1363349

Friction Factor

0.4

Diameter of Anchor Circle

5.200

Number of Anchors

EA.

Sa

Shear Stress of Anchor

78

Mpa

2. SLIDING CALCULATION

DUE TO WIND

FRICTION FORCE

Fr

U x We

36420

STABILITY CHECK

Fw

25295

< Fr

DUE TO SEISMIC

FRICTION FORCE

Fr

U x We

545339

STABILITY CHECK

Fs

137963

< Fr

* Therefore, Anchors are not Required.

30

You might also like

- API 650 Tank Design CalculationDocument8 pagesAPI 650 Tank Design Calculationmail_younes659283% (30)

- Soil Bearing Capacity Calculation Passwords RemovedDocument16 pagesSoil Bearing Capacity Calculation Passwords RemovedMaiwand Khan50% (2)

- Tank Calculation PDFDocument3 pagesTank Calculation PDFAlvin SmithNo ratings yet

- Storage Tanks CalculationsDocument21 pagesStorage Tanks Calculationsjimallen21288% (26)

- Thickness Cal. Fo DM Water Storage Tank-API 650Document15 pagesThickness Cal. Fo DM Water Storage Tank-API 650Jose Rodriguez50% (2)

- API-650 Design Procedure ExampleDocument21 pagesAPI-650 Design Procedure Examplegdwvcd93% (15)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- CalDocument19 pagesCalpandiangv100% (1)

- FinalDocument12 pagesFinalchompink6900No ratings yet

- Hfo Service Tank - ht003 Data Sheet r1 PDFDocument4 pagesHfo Service Tank - ht003 Data Sheet r1 PDFsocomenin2013No ratings yet

- 20" Mol Replacement Project: Data Sheet PipelineDocument7 pages20" Mol Replacement Project: Data Sheet PipelineAdvisNo ratings yet

- Diesel Tank TaluksangayDocument70 pagesDiesel Tank TaluksangayBert EngNo ratings yet

- Gpcoewg Gecol: Document Cover SheetDocument32 pagesGpcoewg Gecol: Document Cover Sheettanmaymajhi09_796764No ratings yet

- Design of Conical Storage TankDocument17 pagesDesign of Conical Storage TankvijaypatelnewtonNo ratings yet

- Tank Sample 최종Document34 pagesTank Sample 최종anon_548256226No ratings yet

- RCC Oht AlternateDocument50 pagesRCC Oht AlternateVarad Sonawadekar100% (1)

- Tank Calc - Api650Document90 pagesTank Calc - Api650kamleshyadavmoney100% (4)

- API 650 Tank Design CalculationsDocument8 pagesAPI 650 Tank Design Calculationsツ ツNo ratings yet

- Mill Feed Silo-10!09!08Document120 pagesMill Feed Silo-10!09!08Umer AziqNo ratings yet

- Pondasi BoilerDocument24 pagesPondasi BoilerMochammad ShokehNo ratings yet

- Design Calculation For Dirty Brackish Water Tank (129-0T2540)Document9 pagesDesign Calculation For Dirty Brackish Water Tank (129-0T2540)Dhakshina KNo ratings yet

- Supported Cone Roof (CS) Add.4Document21 pagesSupported Cone Roof (CS) Add.4skhurramq100% (2)

- RCC Bund Wall Without Shear KeyDocument21 pagesRCC Bund Wall Without Shear Keynhulugalla100% (1)

- Crane UbDocument20 pagesCrane UbBobor Emmanuel OfovweNo ratings yet

- API 650 Tank Design CalculationsDocument8 pagesAPI 650 Tank Design CalculationsVinoth Rajendra50% (4)

- Above Ground Piping Wall Thickness CalculationsDocument7 pagesAbove Ground Piping Wall Thickness Calculationslutfi awn100% (1)

- Design Calculation (CST, Unit-10)Document12 pagesDesign Calculation (CST, Unit-10)kanishkmechenggNo ratings yet

- Steel Designer's Manual, 6th Edition, 2003 R20070821FDocument5 pagesSteel Designer's Manual, 6th Edition, 2003 R20070821Fsaad7159No ratings yet

- API 620 CalculationDocument114 pagesAPI 620 Calculationvikram100% (4)

- RCC Bund Wall With Shear KeyDocument27 pagesRCC Bund Wall With Shear Keynhulugalla100% (1)

- Anchor Block Sizing: Prep. byDocument6 pagesAnchor Block Sizing: Prep. byKhan LalaNo ratings yet

- Staircase Design 01Document12 pagesStaircase Design 01MUTHUKKUMARAMNo ratings yet

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocument31 pagesStorage Tank Design Calculation - Api 650: Close Floating RoofNguyễn Duy HưngNo ratings yet

- Design Calculation For Pipe SupportsDocument200 pagesDesign Calculation For Pipe Supportssanggytha100% (1)

- PV Elite 2013 Sp3 Licensee: Isgec Filename: Pe-1668 75 - Hydro Asme Ts Calc: Case: 1 12:08P Apr 2,2014Document8 pagesPV Elite 2013 Sp3 Licensee: Isgec Filename: Pe-1668 75 - Hydro Asme Ts Calc: Case: 1 12:08P Apr 2,2014Mayank MittalNo ratings yet

- Advances in Solid Oxide Fuel Cells XFrom EverandAdvances in Solid Oxide Fuel Cells XMihails KusnezoffNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Ceramic Materials for Energy Applications IV: A Collection of Papers Presented at the 38th International Conference on Advanced Ceramics and Composites, January 27-31, 2014, Daytona Beach, FLFrom EverandCeramic Materials for Energy Applications IV: A Collection of Papers Presented at the 38th International Conference on Advanced Ceramics and Composites, January 27-31, 2014, Daytona Beach, FLHua-Tay LinNo ratings yet

- Advances in Ceramic Armor XFrom EverandAdvances in Ceramic Armor XJerry C. LaSalviaNo ratings yet

- Ceramic Materials for Energy Applications VIFrom EverandCeramic Materials for Energy Applications VIHua-Tay LinNo ratings yet

- 77th Conference on Glass Problems: A Collection of Papers Presented at the 77th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, OH, November 7-9, 2016From Everand77th Conference on Glass Problems: A Collection of Papers Presented at the 77th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, OH, November 7-9, 2016S. K. SundaramNo ratings yet

- Case Studies in Fluid Mechanics with Sensitivities to Governing VariablesFrom EverandCase Studies in Fluid Mechanics with Sensitivities to Governing VariablesNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Advances in Ceramic Armor XIFrom EverandAdvances in Ceramic Armor XIJerry C. LaSalviaNo ratings yet

- Scientific American Supplement, No. 360, November 25, 1882From EverandScientific American Supplement, No. 360, November 25, 1882No ratings yet

- FGD 001Document30 pagesFGD 001tanmaymajhi09_796764No ratings yet

- Pages From Roark's Formulas For Stress & Strain (For Deflection)Document2 pagesPages From Roark's Formulas For Stress & Strain (For Deflection)tanmaymajhi09_796764No ratings yet

- Pages From Roark's Formulas For Stress & Strain-See Case 7 (Stress in Inner Rim)Document1 pagePages From Roark's Formulas For Stress & Strain-See Case 7 (Stress in Inner Rim)tanmaymajhi09_796764No ratings yet

- Pages From Roark's Formulas For Stress & Strain-See Case 7 (Stress in Inner Rim)Document1 pagePages From Roark's Formulas For Stress & Strain-See Case 7 (Stress in Inner Rim)tanmaymajhi09_796764No ratings yet