Professional Documents

Culture Documents

Thickness Calculation

Thickness Calculation

Uploaded by

SyafRizalCopyright:

Available Formats

You might also like

- Thickness Calculation of Pressure Vessel ShellDocument22 pagesThickness Calculation of Pressure Vessel ShellAkshat Jain88% (26)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Retiring Wall Thickness Calculation For PipeDocument4 pagesRetiring Wall Thickness Calculation For PipeFares JawadNo ratings yet

- Astm d1785Document6 pagesAstm d1785Falak KhanNo ratings yet

- Materials Data for Cyclic Loading: Aluminium and Titanium AlloysFrom EverandMaterials Data for Cyclic Loading: Aluminium and Titanium AlloysRating: 1 out of 5 stars1/5 (1)

- Mud Gas Separator CalculationDocument16 pagesMud Gas Separator CalculationErwin Gomop-as100% (2)

- Plate CalculationDocument7 pagesPlate CalculationminhthanhmosNo ratings yet

- Pipe Thickness Calculation PDFDocument1 pagePipe Thickness Calculation PDFHeny Martha67% (3)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Asme Viii Shell & Se HeadDocument5 pagesAsme Viii Shell & Se HeadSnr George RaczNo ratings yet

- Internal CoilDocument2 pagesInternal CoilwhngomjNo ratings yet

- Epc For Tie-In Works at Se: Sample Calculation - 013842XDocument2 pagesEpc For Tie-In Works at Se: Sample Calculation - 013842Xdeua2004No ratings yet

- Super CalculationsDocument9 pagesSuper CalculationsNoé MarínNo ratings yet

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantDocument49 pagesDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536No ratings yet

- Mud Gas Separator CalculationDocument16 pagesMud Gas Separator CalculationErwin Gomop-asNo ratings yet

- Weight CalculatorDocument12 pagesWeight CalculatorShafqat AfridiNo ratings yet

- Wall THK Calculation Asme b31.4Document5 pagesWall THK Calculation Asme b31.4Dwi Hermawan100% (2)

- Stiffening Ring Cal For Exteneral Press.Document11 pagesStiffening Ring Cal For Exteneral Press.inspectormhp100% (1)

- ASME B31.3 Pipe Wall ThicknessDocument33 pagesASME B31.3 Pipe Wall Thicknessaike_5No ratings yet

- Sample4 SpreadsheetDocument21 pagesSample4 SpreadsheetTrishul Nath Pallay100% (1)

- Asme BPVC Code Viii Div. I Edition 2015, Nozzle Neck Thickness Calculation Nozzle SizeDocument2 pagesAsme BPVC Code Viii Div. I Edition 2015, Nozzle Neck Thickness Calculation Nozzle SizeAnil GhildiyalNo ratings yet

- UG 45 Sample CalculationDocument1 pageUG 45 Sample CalculationAris Purniawan100% (1)

- Total Middle East New Bitumen Terminal in TlbuDocument25 pagesTotal Middle East New Bitumen Terminal in TlbuAnupam Jana100% (2)

- 31barg CalculationDocument10 pages31barg Calculationshani5573No ratings yet

- AST Heating Coil Design Calculation Rev 0Document3 pagesAST Heating Coil Design Calculation Rev 0Pieter Grendel100% (3)

- Design Calculations For Pressure VesselsDocument32 pagesDesign Calculations For Pressure VesselsGeorge Georgian100% (3)

- Design Calculations For Pressure VesselsDocument30 pagesDesign Calculations For Pressure VesselsVinoth Rajendra100% (3)

- Engineering Design: 600 900 Flange Rating, #Document4 pagesEngineering Design: 600 900 Flange Rating, #Mayur PatelNo ratings yet

- ASME B31.3 - 2008 PipeCalculationDocument6 pagesASME B31.3 - 2008 PipeCalculationArt G. Enzi100% (8)

- Pipeline Buoyancy AnalysisDocument12 pagesPipeline Buoyancy Analysisbonnico0% (1)

- FinalDocument12 pagesFinalchompink6900No ratings yet

- SampleCalculationspipingB3132008 PDFDocument13 pagesSampleCalculationspipingB3132008 PDFsosatlantiqueNo ratings yet

- SPAN Calc.Document48 pagesSPAN Calc.yoi_123100% (1)

- L 8 IhjnmklgfDocument27 pagesL 8 IhjnmklgfbrintopvNo ratings yet

- Shell and Tube HE CalculationDocument16 pagesShell and Tube HE CalculationPradip ShindeNo ratings yet

- AD2000 (31barg) CalculationDocument10 pagesAD2000 (31barg) CalculationMagdaline Matabang100% (1)

- Design Calculations For Pressure VesselsDocument73 pagesDesign Calculations For Pressure Vesselsshani5573No ratings yet

- Nozzle THKDocument6 pagesNozzle THKabhishek198327No ratings yet

- Calculation of Pipe Reinforcement ASME B31 3Document4 pagesCalculation of Pipe Reinforcement ASME B31 3ArmandoZacariasAcosta0% (1)

- Welding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985From EverandWelding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985No ratings yet

- Mechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingFrom EverandMechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingNo ratings yet

- Pipeline and Energy Plant Piping: Design and TechnologyFrom EverandPipeline and Energy Plant Piping: Design and TechnologyRating: 5 out of 5 stars5/5 (2)

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceFrom EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Advances in Ceramic Armor XIFrom EverandAdvances in Ceramic Armor XIJerry C. LaSalviaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Absens IDocument1 pageAbsens ISyafRizalNo ratings yet

- Ins. Flow OTIDocument65 pagesIns. Flow OTISyafRizalNo ratings yet

- Fluke Calibration Temperature Measurement CalibrationDocument12 pagesFluke Calibration Temperature Measurement CalibrationSyafRizalNo ratings yet

- Electrical and Instrumentation Engineering For Oil and Gas FacilitiesDocument19 pagesElectrical and Instrumentation Engineering For Oil and Gas FacilitiesSyafRizalNo ratings yet

- 80-Budiyono, Revitalisasi Cooling Tower Rev-Yax (837-846) PDFDocument10 pages80-Budiyono, Revitalisasi Cooling Tower Rev-Yax (837-846) PDFSyafRizalNo ratings yet

- PID ControlDocument56 pagesPID ControlSyafRizal100% (1)

- Building Services ElectricalDocument27 pagesBuilding Services ElectricalSyafRizalNo ratings yet

- 37200922639NAVEED ANJUM - QA QC Inspector E&IDocument4 pages37200922639NAVEED ANJUM - QA QC Inspector E&ISyafRizalNo ratings yet

Thickness Calculation

Thickness Calculation

Uploaded by

SyafRizalOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thickness Calculation

Thickness Calculation

Uploaded by

SyafRizalCopyright:

Available Formats

2 of 4

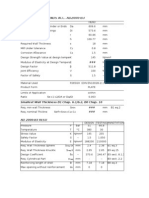

PERHITUNGAN KETEBALAN PIPA MINIMUM

t

PD

2 SE PY

tm

tm

t

c

a

m

P

D

S

E

Y

=

=

=

=

=

=

=

=

=

=

t c a

m

1

100

or

tm

t ca

0.875

Minimum required thickness, including mechanical threaded, corrosion and erosion allowances.

Pressure design thickness.

Corrosion allowance

Threaded allowance

Manufacturing tolerance (12.5)

Internal design gage pressure.

Outside diameter of pipe.

Stress value for material.

Quality factor.

Coefficient for material

PIPE MATERIAL : A 106-B

Table 1.2

P

(Psi G) 1

264.6

264.6

264.6

264.6

264.6

264.6

264.6

Recommended minimum wall thickness for seamless piping ( Class 300# )

T

t

D

S

E

Y

(Inch)

(Inch)

(Psi)

( o F) 2

122

1.315

35000

1

0.4

0.005

122

2.375

35000

1

0.4

0.009

122

3.500

35000

1

0.4

0.013

122

4.500

35000

1

0.4

0.017

122

6.625

35000

1

0.4

0.025

122

8.625

35000

1

0.4

0.033

122

10.750

35000

1

0.4

0.041

c

(Inch)

0.118

0.118

0.118

0.118

0.118

0.118

0.118

Note: 1. Max operation pressure adalah 13 barg (190 Psig), design pressure adalah 18 barg (265 Psig)

2. Max temperature adalah 50C

DTK-DOC-CAL-002-Piping Thickness Calculation

a

(Inch)

0.02

0.02

0.02

0.02

0.02

0.02

0.02

tm

(Inch)

0.163

0.168

0.173

0.177

0.186

0.195

0.204

tm

(mm)

4.150

4.266

4.389

4.498

4.731

4.949

5.182

Nearest

schedule

80

80

40

40

40

40

40

Schedule W/T

4.55

5.54

5.49

6.02

7.11

8.18

9.27

You might also like

- Thickness Calculation of Pressure Vessel ShellDocument22 pagesThickness Calculation of Pressure Vessel ShellAkshat Jain88% (26)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Retiring Wall Thickness Calculation For PipeDocument4 pagesRetiring Wall Thickness Calculation For PipeFares JawadNo ratings yet

- Astm d1785Document6 pagesAstm d1785Falak KhanNo ratings yet

- Materials Data for Cyclic Loading: Aluminium and Titanium AlloysFrom EverandMaterials Data for Cyclic Loading: Aluminium and Titanium AlloysRating: 1 out of 5 stars1/5 (1)

- Mud Gas Separator CalculationDocument16 pagesMud Gas Separator CalculationErwin Gomop-as100% (2)

- Plate CalculationDocument7 pagesPlate CalculationminhthanhmosNo ratings yet

- Pipe Thickness Calculation PDFDocument1 pagePipe Thickness Calculation PDFHeny Martha67% (3)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Asme Viii Shell & Se HeadDocument5 pagesAsme Viii Shell & Se HeadSnr George RaczNo ratings yet

- Internal CoilDocument2 pagesInternal CoilwhngomjNo ratings yet

- Epc For Tie-In Works at Se: Sample Calculation - 013842XDocument2 pagesEpc For Tie-In Works at Se: Sample Calculation - 013842Xdeua2004No ratings yet

- Super CalculationsDocument9 pagesSuper CalculationsNoé MarínNo ratings yet

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantDocument49 pagesDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536No ratings yet

- Mud Gas Separator CalculationDocument16 pagesMud Gas Separator CalculationErwin Gomop-asNo ratings yet

- Weight CalculatorDocument12 pagesWeight CalculatorShafqat AfridiNo ratings yet

- Wall THK Calculation Asme b31.4Document5 pagesWall THK Calculation Asme b31.4Dwi Hermawan100% (2)

- Stiffening Ring Cal For Exteneral Press.Document11 pagesStiffening Ring Cal For Exteneral Press.inspectormhp100% (1)

- ASME B31.3 Pipe Wall ThicknessDocument33 pagesASME B31.3 Pipe Wall Thicknessaike_5No ratings yet

- Sample4 SpreadsheetDocument21 pagesSample4 SpreadsheetTrishul Nath Pallay100% (1)

- Asme BPVC Code Viii Div. I Edition 2015, Nozzle Neck Thickness Calculation Nozzle SizeDocument2 pagesAsme BPVC Code Viii Div. I Edition 2015, Nozzle Neck Thickness Calculation Nozzle SizeAnil GhildiyalNo ratings yet

- UG 45 Sample CalculationDocument1 pageUG 45 Sample CalculationAris Purniawan100% (1)

- Total Middle East New Bitumen Terminal in TlbuDocument25 pagesTotal Middle East New Bitumen Terminal in TlbuAnupam Jana100% (2)

- 31barg CalculationDocument10 pages31barg Calculationshani5573No ratings yet

- AST Heating Coil Design Calculation Rev 0Document3 pagesAST Heating Coil Design Calculation Rev 0Pieter Grendel100% (3)

- Design Calculations For Pressure VesselsDocument32 pagesDesign Calculations For Pressure VesselsGeorge Georgian100% (3)

- Design Calculations For Pressure VesselsDocument30 pagesDesign Calculations For Pressure VesselsVinoth Rajendra100% (3)

- Engineering Design: 600 900 Flange Rating, #Document4 pagesEngineering Design: 600 900 Flange Rating, #Mayur PatelNo ratings yet

- ASME B31.3 - 2008 PipeCalculationDocument6 pagesASME B31.3 - 2008 PipeCalculationArt G. Enzi100% (8)

- Pipeline Buoyancy AnalysisDocument12 pagesPipeline Buoyancy Analysisbonnico0% (1)

- FinalDocument12 pagesFinalchompink6900No ratings yet

- SampleCalculationspipingB3132008 PDFDocument13 pagesSampleCalculationspipingB3132008 PDFsosatlantiqueNo ratings yet

- SPAN Calc.Document48 pagesSPAN Calc.yoi_123100% (1)

- L 8 IhjnmklgfDocument27 pagesL 8 IhjnmklgfbrintopvNo ratings yet

- Shell and Tube HE CalculationDocument16 pagesShell and Tube HE CalculationPradip ShindeNo ratings yet

- AD2000 (31barg) CalculationDocument10 pagesAD2000 (31barg) CalculationMagdaline Matabang100% (1)

- Design Calculations For Pressure VesselsDocument73 pagesDesign Calculations For Pressure Vesselsshani5573No ratings yet

- Nozzle THKDocument6 pagesNozzle THKabhishek198327No ratings yet

- Calculation of Pipe Reinforcement ASME B31 3Document4 pagesCalculation of Pipe Reinforcement ASME B31 3ArmandoZacariasAcosta0% (1)

- Welding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985From EverandWelding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985No ratings yet

- Mechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingFrom EverandMechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingNo ratings yet

- Pipeline and Energy Plant Piping: Design and TechnologyFrom EverandPipeline and Energy Plant Piping: Design and TechnologyRating: 5 out of 5 stars5/5 (2)

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceFrom EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Advances in Ceramic Armor XIFrom EverandAdvances in Ceramic Armor XIJerry C. LaSalviaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Absens IDocument1 pageAbsens ISyafRizalNo ratings yet

- Ins. Flow OTIDocument65 pagesIns. Flow OTISyafRizalNo ratings yet

- Fluke Calibration Temperature Measurement CalibrationDocument12 pagesFluke Calibration Temperature Measurement CalibrationSyafRizalNo ratings yet

- Electrical and Instrumentation Engineering For Oil and Gas FacilitiesDocument19 pagesElectrical and Instrumentation Engineering For Oil and Gas FacilitiesSyafRizalNo ratings yet

- 80-Budiyono, Revitalisasi Cooling Tower Rev-Yax (837-846) PDFDocument10 pages80-Budiyono, Revitalisasi Cooling Tower Rev-Yax (837-846) PDFSyafRizalNo ratings yet

- PID ControlDocument56 pagesPID ControlSyafRizal100% (1)

- Building Services ElectricalDocument27 pagesBuilding Services ElectricalSyafRizalNo ratings yet

- 37200922639NAVEED ANJUM - QA QC Inspector E&IDocument4 pages37200922639NAVEED ANJUM - QA QC Inspector E&ISyafRizalNo ratings yet