Professional Documents

Culture Documents

Pore Structure of Vuggy Carbonates and Rate Dependent Displacement in Carbonate Rocks

Pore Structure of Vuggy Carbonates and Rate Dependent Displacement in Carbonate Rocks

Uploaded by

Zao MengOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pore Structure of Vuggy Carbonates and Rate Dependent Displacement in Carbonate Rocks

Pore Structure of Vuggy Carbonates and Rate Dependent Displacement in Carbonate Rocks

Uploaded by

Zao MengCopyright:

Available Formats

SCA2011-21

1/12

PORE STRUCTURE OF VUGGY CARBONATES AND

RATE DEPENDENT DISPLACEMENT IN CARBONATE

ROCKS

Neeraj Rohilla, Dr. George J. Hirasaki

Dept. of Chemical and Biomolecular Engineering, Rice University, Houston, TX 77005

This paper was prepared for presentation at the International Symposium of the

Society of Core Analysts held in Austin, Texas, USA 18-21 September, 2011

ABSTRACT

The carbonate samples which are focus of this study are brecciated and fractured. In

order to characterize the pore size in vuggy carbonates, we use NMR along with tracer

analysis. The distribution of porosity between micro and macro-porosity can be measured

by NMR. Tracer analysis is used to characterize the pore structure by estimating flowing

fraction, dispersivity and mass transfer coefficient between flowing and stagnant streams.

For heterogeneous samples, we have found that permeability value differs by two

orders of magnitude (2 mD and 210 mD) for 1.5 inch diameter and 3.5 inch diameter

samples respectively. Flowing fraction is estimated to be 0.25-0.5. For most samples

mass transfer between flowing and stagnant streams is very poor. Tracer experiments

suggest that at moderate flow rates (1-10 ft/day) only a small fraction of matrix is

contacted by flowing stream even after five pore volumes. Based on this, the rate of

surfactant flood required for optimum contacting between flowing and stagnant streams

can be calculated for enhanced recovery of oil.

INTRODUCTION

More than 50 % of the worlds hydrocarbons are contained in carbonate reservoirs [1].

Accurate characterization of pore structure of carbonate reservoirs is essential for design

and implementation of enhanced oil recovery processes. However, characterizing pore

structure in carbonates is a complex task due to the diverse variety of pore types seen in

carbonates and extreme pore level heterogeneity.

Carbonate reservoirs have complex structures because of depositional and diagenetic

features. Carbonates may contain not only matrix and fractures but also vugs. A vug can

be defined as any pore that is significantly larger than a grain or inside of a grain. Vugs

are commonly present as leached grains, fossil chambers, fractures, and large irregular

cavities. Vugs are irregular in shape and vary in size from millimeters to centimeters.

Vuggy pore space can be divided into separate-vugs and touching-vugs, depending on

vug interconnection. Separate vugs are connected only through interparticle pore

SCA2011-21

2/12

networks and do not contribute to permeability. Touching vugs are independent of rock

fabric and form an interconnected pore system enhancing the permeability [1].

SAMPLE PREPARATION AND CHARACTERIZATION

Core samples for experiments were cleaned using a bath of Tetrahydrofuran (THF)

followed by Chloroform and Methanol. Core-plugs were dried overnight in the oven at

800C. Core-plugs were wrapped in heat shrink tubing to protect against wear and tear and

chipping away of the sharp edges. After cleaning, core-plugs were saturated with 1%

NaCl brine solution using vacuum saturation followed by pressure saturation at 1000 psi

for 24 hours. Before performing NMR experiment, core-plug was wrapped in paraffin

film to avoid the gravity drainage of brine solution from big vugs.

NMR Results: NMR experiments were performed on 100% brine saturated core-plugs

on 2 MHz Maran-SS. Only 1.5 inch diameter plugs were used in the experiments because

the NMR instrument cannot accommodate 3.5 inch diameter plugs. For experiments,

half-echo spacing of 200 s was used and signal to noise ratio of 100 was used.

Figure 1. T2 relaxation time spectrum of 100% brine saturated rock sample for core sample: 3V

Figure 2. T2 relaxation time spectrum of 100% brine saturated rock sample for core sample: 2V

SCA2011-21

3/12

Figures 1-5 show T2 relaxation time spectrum for various core plugs taken from different

source rocks. Black solid vertical line corresponds to the traditional cutoff value of 90 ms

for carbonate rocks. The dashed vertical line separates the relaxation spectrum into nonvuggy and vuggy porosity by assuming that T2 values of 750 ms and higher correspond to

vugs [2]. The permeability values for the majority of the core plugs are within the range

of 0.5-6 mD. Figure 1 shows that for core plug 3V majority of the porosity resides in

these large vugs and contribution of small pore sizes to porosity is very small. NMR

response for core plug 2V (Figure 2) shows the peak at relaxation time of about 90 ms.

Using the traditional cut off formula would classify 2V sample as non-pay. The low value

of permeability suggests that the vugs do not form an interconnected pore network.

Figure 3. T2 relaxation time spectrum of 100% brine saturated rock sample for core sample: 2VA

Figure 3 shows the T2 relaxation time spectrum for a core plug 2VA. Although, this plug

was drilled from the same source rock as the previous sample (Figure 2), NMR response

shows a large contribution from vugs and relatively smaller contribution from small sized

pores. Figure 4 and 5 show the T2 relaxation time spectrum for core plugs 1H and 1HA.

In both cases, we observe that relaxation time has contributions from small sized micropores, vugs and some intermediate size pores. The low value of permeability suggests

that vugs are isolated vugs and do not create any interconnected flow channels.

Figure 4. T2 relaxation time spectrum of 100% brine saturated rock sample for core sample: 1H

SCA2011-21

4/12

Figure 5. T2 relaxation time spectrum of 100% brine saturated rock sample for core sample: 1HA

Table 1 summarizes T2 log mean and measured values of permeability for various core

plugs. NMR results suggest that these carbonate rocks are very heterogeneous. In some

cases, vugs contribute most to the porosity while in other smaller pores are dominant.

Samples taken within the proximity of 3 inches exhibit very different T2 relaxation time

spectrum. Most of the samples show small value of permeability and there is no obvious

correlation with the value of T2 Log mean.

Table 1. T2 Log mean versus permeability for various core plugs

S. No.

Core ID

1

2

3

4

5

6

7

8

9

3V

2V

2VA

1H

1HA

6H

6HA

8V

9V

T2 Log Mean

(ms)

1180

81

637

79

112

436

247

140

Permeability (mD)

6

2

4

4

1.7

45

510

3

2

TRACER ANALYSIS

In this section, we describe methods to characterize the key features of pore structure

such as fraction of dead-end pores and dispersion and capacitance effects. We use the

modified version of differential capacitance model of Coats and Smith [3] and a solution

procedure developed by Baker [4] to study dispersion and capacitance effects in cores.

Brigham [5] showed that differential capacitance model can be written for either flowing

(effluent) concentration or in-situ concentration. During tracer experiments, flowing

concentrations are measured hence in the following formulation we work with flowing

(effluent) concentrations. The differential capacitance model assumes:

1. The fluid flow is one dimensional

2. The fluid flow is single phase flow

SCA2011-21

5/12

3. The fluid and porous media are incompressible

4. The fluid density is constant

5. The porosity is constant throughout the system

The model can be described by the following set of differential equations:

(1)

(2)

The domain of interest is: x > 0

Where, K is dispersion coefficient, (1-f) is the fraction of dead end pores, is the

porosity, M is the mass transfer coefficient, C is tracer concentration in flowing stream,

C* is the tracer concentration in stagnant volume and u is the superficial velocity.

Interstitial velocity v can be defined as, v = .

The boundary and initial conditions are:

(3)

cBC is injected concentration at the inlet (x=0) and cIC is the initial concentration in the

system at the start of the experiment (t=0). The governing and boundary and initial

conditions are made dimensionless as follows:

; where v is the

interstitial velocity (v =

and L is system length. Dimensionless concentrations are

defined as:

Using the above mentioned dimensionless variables the system is characterized by three

dimensionless groups which are defined as follows.

f is the flowing fraction,

is similar to the inverse of macroscopic Peclet number and

is the ratio of dispersivity to system length.

defines the ratio of the rate of mass

transfer to the rate of convection. The above set of differential equations with gives

SCA2011-21

6/12

boundary and initial conditions can be solved using Laplace transform. The solution can

be expressed in terms of dimensionless Laplace variable as follows:

(4)

The resulting solution can be numerically inverted into time domain using the computer

program of Hollenbeck [6] which is based on the algorithm of De Hoog, Knight and

Stokes [7]. Baker [4] and Salter et. al [8] suggested that rather than transforming equation

4 into time domain for the purpose of parameter estimation, the experimental data should

be transformed into the Laplace domain for obtaining fitted parameters using least square

curve fitting. The fitted parameters correspond to a set which minimizes the error.

Parameter estimation is done by using Lavenberg-Marquardt algorithm [9]. When the

value of NM is large, the fitted parameters may not be correct due to non-uniqueness of

the solution. This happens because large value of mass transfer coefficient allows of

exchange between stagnant and flowing stream and resulting fitted parameters show

apparent higher value of flowing fraction. To obtain unique set of parameters, we use

experimental data of effluent concentration at two different flow rates. We further assume

that mass transfer between stagnant and flowing streams is dominated by diffusion

coefficient and mass transfer coefficient does not depend on the flow rate. The dispersion

coefficient (K) varies linearly with interstitial velocity (v). We use these additional

constraints in the cost function of parameter estimation algorithm and obtain fitted model

parameters for two cases simultaneously.

The rock samples subject of this study are heterogeneous in nature and some of the

assumptions of Coats and Smith model (constant porosity and one dimensional flow) may

not be completely satisfied.

Recovery Efficiency and Transfer Between Flowing And Stagnant Streams

Tracer flow analysis described in previous section can be complimented with the help of

recovery efficiency calculations. Recovery efficiency is defined as the fraction of initial

fluid in place displaced with injected tracer fluid.

tmax

Recovery Efficiency =

(1 C )dt

0

Hence, recovery efficiency can be plotted as a function of pore volume throughput. When

all of the initial fluid in place is displaced by injected tracer fluid, the recovery efficiency

approaches unity. Two sets of synthetic datasets shown in figure 6 have same value of

flowing fraction and dispersivity () but different values of mass transfer group (NM). In

first case even though the effluent concentration approaches unity after 1.5 pore volumes,

SCA2011-21

7/12

the recovery efficiency is only 0.4 and hence most of initial fluid in place has not been

replaced by injected tracer fluid. Larger value of NM in second case results in significant

mass transfer between flowing and stagnant streams and recovery efficiency approaches

unity after about 2 pore volumes. Hence, recovery efficiency is an excellent measure of

the fraction of dead end pores contacted by displacing tracer fluid.

Figure 6. Plots of effluent concentration and recovery efficiency as a function of pore volume throughput

illustrating importance of mass transfer between flowing and stagnant streams

Setup For Tracer Experiments

The core holder for 1.5 inch diameter samples is Hassler type core holder. We have

adopted similar design for fabricating flow setup for 3.5 inch diameter core samples.

Based on NMR results and permeability measurements, we believe that larger diameter

samples are better candidates to study the connectivity of vugs and to accurately

characterize the pore structure.

Sodium bromide is used as tracer in the experiments. For experiments, the initial tracer

concentration is 100 ppm and injected tracer boundary condition is 10,000 ppm To

measure the tracer concentration at outlet, a bromide ion sensitive electrode is used in

combination with a flow cell. Bromide electrode and flow cell enable us to measure

tracer concentration continuously without collecting multiple effluent samples and

analyze them separately.

TRACER FLOW EXPERIMENTS

Validation with Sandpack Systems: Two types of sandpack systems are used in tracer

experiments. The length of sandpack systems is about one feet. Homogeneous sandpack

is prepared by using a single sand layer which has fairly uniform particle size

distribution. Heterogeneous sandpack consists of two layers of sand. The top layer sand is

of low permeability and the bottom layer sand has a permeability value which is 19 times

that of the top layer. Each sand layer occupies half of the volume in the sand pack. This

system represents a case where the flowing fraction would be less than one and there will

SCA2011-21

8/12

be significant mass transfer between stagnant and flowing streams. Figure 12 shows the

plot of effluent concentration versus pore volume throughput for both homogeneous and

heterogeneous sandpacks. Figure 7 shows early breakthrough of tracer which is a

measure of smaller flowing fraction. We also notice that effluent concentration increases

slowly after an early breakthrough. The flowing fraction for this case was interpreted to

be about 0.65 from effluent concentration data.

Figure 7. Effluent concentration versus pore volume throughput for homogeneous and heterogeneous

sandpacks

Rock Samples: Tracer flow experiments were conducted on core plugs of 1.5 inch

diameter and core samples of 3.5 inch diameter sample. First we described two of the

experiments conducted on 1.5 inch diameter samples. Figure 8 and 9 show the effluent

concentration and recovery efficiency plots for core samples 3V and 1H. The estimated

value of flowing fraction for 3V sample is 0.5 and that for 1H sample is 0.2.

Figure 8. Effluent concentration and recovery efficiency for core plug 3V (diameter = 1.5 inch, length =

1.25 inch)

SCA2011-21

9/12

The estimated value of dispersivity for samples 3V and 1H is 1 cm and 0.8 cm

respectively. However, the estimated value of mass transfer coefficient for both samples

differs by one order of magnitude. To make better sense of the value of mass transfer

coefficient, we express inverse of mass transfer coefficient in days. As seen from table 2,

1/M is 0.17 days for sample 3V while 0.02 days for sample 1H. We recall that T2

relaxation spectrum for sample 1H has a continuous pore sizes distribution having vugs,

small and intermediate size pores as shown in figure 4. Sample 3V on the other hand had

did not have a continuous relaxation spectrum covering three orders of pore sizes. This

could be the reason that sample 1H can have much higher value of mass transfer

coefficient in comparison to sample 3V.

Figure 9. Effluent concentration and recovery efficiency for core plug 1H (diameter = 1.5 inch, length =

2.25 inch)

C^ , Recovery E ciency

0.9

0.8

0.7

0.6

0.5

Case 1: C^ versus P V (21 ft/ day)

Case 1: Recovery E ciency

Case 2: C^ versus P V (1.8 ft/ day)

0.4

0.3

0.2

Case 2: Recovery E ciency

Case 3: C^ versus P V (0.36 ft/ day)

0.1

Case 3: Recovery E ciency

0

0

0.5

1.5

2.5

3.5

PV

Figure 10. Effluent concentration and recovery efficiency for core plug 3.5 B (diameter 3.5 inch, length =

3.75 inch) at three different flowrates

SCA2011-21

10/12

Figure 10 shows the effect of displacement rates (interstitial velocity) on mass transfer

between flowing and stagnant streams. Experiments were conducted for three different

interstitial velocities (21 ft/day, 1.8 ft/day and 0.36 ft/day). As we reduced the interstitial

velocity less than 1 ft/day, we begin to see significant mass transfer between flowing and

stagnant streams as evidenced by enhanced recovery efficiency shown in figure 10.

After estimating unique model parameters from tracer flow experiments for a known

sample, recovery efficiency can be calculated as a function of pore volume throughput for

various displacement rates as shown in figure 11. We find that at high displacements

rates only fraction of dead end pores is contacted and recovery is poor. As displacement

rates are decreased we find the optimum rate at which recovery efficiency is significantly

improved and reducing the displacement rates further are not useful. Experiments to

characterize the pore structure in the laboratories should be conducted at flowrates which

corresponds to NM value of 1 or higher to ensure enough exchange between flowing and

stagnant streams.

1

0.9

Recovery Efficiency

0.8

0.7

0.6

0.5

0.4

Q = 0.004 ft/day, N = 35

0.3

Q = 0.04 ft/day, N = 3.5

0.2

Q = 0.4 ft/day, N = 0.35

0.1

Q = 21 ft/day, N = 0.006

0

0

0.5

1.5

2.5

3.5

PV

Figure 11. Estimated recovery efficient for various interstitial velocities using parameters estimated from

tracer flow experiments.

DISCUSSION AND CONCLUSIONS

Calculated permeability for 3.5 inch diameter samples is in the range of 200-300 mD

which is about two orders of magnitude higher than that for 1.5 inch diameter samples

(0.5-6 mD). This proves our hypothesis that for such heterogeneous samples small

diameter plugs of about 1 inch diameter are not suitable to study pore structure as the

scale of heterogeneity is roughly the same order as the diameter of the plugs. Currently

full sized cores are available only in 3.5 inch and 4.0 inch diameter sizes. Additional

experiments will be conducted on 4.0 inch diameter samples to find out if 3.5 inch

diameter samples are representative candidates for stydying connectivity of the vug

systems.

SCA2011-21

11/12

Some inferences on the connectivity of the vugs can be made from NMR specturm alone.

Spectrums such as in figure 4, showing overlap of different relaxation times with that for

vugs may indicate possibility of the presence of connected pore network channels than

the case when the different relaxation time peaks are well seperated. However such

inferences should always be confirmed with other independent analysis such as Tracer

flow experiments and thin section SEM images/CT scan micrographs.

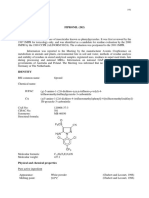

Table 2 summarizes estimated values of flowing fraction, dispersivity and mass transfer

coefficient for various core samples. For core samples of 1.5 inch diameter, we observe

that flowing fraction is about 0.2-0.5. Flowing fraction is estimated to be 0.4 or higher for

3.5 inch diameter samples. In almost all samples, the value of dimensionless group for

mass transfer (NM) is much smaller than 1. However for one 1.5 inch diameter core

sample (1H) the estimated value of NM is 5.3. The NMR T2 relaxation time spectrum

corresponding to this core sample is shown in figure 4. We observe that for this particular

core sample NMR response shows a wide distribution of different pore sizes. Due to

overlap of several pore sizes this core sample shows significantly higher value of mass

transfer group (NM) than other core samples.

Table 2. Summary of estimated model parameters from various tracer flow experiments

Sample

Diameter

(ID)

(inch)

3V

1H

3.5_A

3.5_B

3.5_C

1.5

1.5

3.5

3.5

3.5

f

0.5

0.2

0.39

0.47

0.71

0.01 0.31

5.3 0.14

0.05 0.23

0.34 0.183

0.13 0.19

=K/v

1/M

(ft/day)

(cm)

(day)

15

1.7

3.1

0.36

0.4

1.0

0.8

2.2

1.7

1.8

0.17

0.02

2.54

2.45

6.03

Figure 12. Bar charts showing flowing fraction and inverse of mass transfer coefficient estimated from

tracer flow experiments

SCA2011-21

12/12

Estimated model parameters from tracer flow experiments are used to analyze different

regimes of mass transfer. The regime of small mass transfer corresponds to the case when

the value of dimensionless group for mass transfer is much smaller than unity (NM<1). In

this regime effluent concentration/recovery efficiency versus pore volume throughput

curves are strongly dependent on interstitial velocity. The regime of strong mass transfer

corresponds to the case when the value of dimensionless group for mass transfer is much

greater than unity (NM > 1). In the regime of strong mass transfer there is no dependence

of insterstitial velocity on effluent concentration/recovery efficiency curve.

ACKNOWLEDGEMENTS

We acknowledge Petrleos Mexicanos (PEMEX) and Rice Consortium for processes in

porous media for funding support.

REFERENCES

1. Palaz, I and Marfurt, K. 1997 Carbonate seismology. Society of Exploration

Geophysicists

2. Chang, D., Vinegar, H., Morris, C. and Straley, C., Effective Porosity,

Producible Fluid, and Permeability in Carbonates from NMR Logging, The

Log Analyst, 38, 1997, 60-72

3. Coats, K. H. and Smith, B. D. Dead-End Pore Volume and Dispersion in

Porous Media, Soc. Pet. Eng. J., Trans., AIME, (1964), 231, 73-84

4. Baker, L.E., Effects of dispersion and dead-end pore volume in miscible

flooding. Soc. Pet. Eng. J., Trans. AIME, (1975), 263, 219-227

5. Brigham, W. Mixing equations in short laboratory cores Soc. Pet. Eng.

1974, J 14 91-99

6. Hollenbeck, K. INVLAP.m: A matlab function for numerical inversion of

Laplace transforms by the de Hoog algorithm [Online; accessed 05July-2009]. URL: http://www.isva.dtu.dk/staff/karl/invlap.m

7. Salter, S. J. and Mohanty, K. K. Multiphase flow in porous media: I.

Macroscopic observations and modeling, Paper SPE 11017 presented at 57th

SPE Annual Technical Conference and Exhibition, New Orleans, LA, 1982

8. De Hoog, F., Knight, J. and Stokes, A. An improved method for numerical

inversion of Laplace transforms, SIAM Journal on Scientific and Statistical

Computing 1975 3 357.

9. Marquardt, D. W. An Algorithm for Least-Squares Estimation of Nonlinear

Parameters, Journal of the Society for Industrial and Applied Mathematics

1963 11 [No. 2] 31441.

10. Zakaria, A. S., Nasr-El-Din, H. A., and Ziauddin, M. 2015. Predicting the

Performance of the Acid-Stimulation Treatments in Carbonate Reservoirs

with Nondestructive Tracer Tests. SPE J. Preprint. SPE-174084-PA. http://

dx.doi.org/10.2118/174084-PA

You might also like

- Tracer Technology-To ResmanDocument41 pagesTracer Technology-To ResmanLuciano FucelloNo ratings yet

- E741 - 11Document17 pagesE741 - 11cremsky100% (1)

- Petrophysics PcRI Journal (2014)Document7 pagesPetrophysics PcRI Journal (2014)Moustafader DernaikaNo ratings yet

- A Numerical Study On Concentration Polarization and System Zhou2006Document9 pagesA Numerical Study On Concentration Polarization and System Zhou2006inara2160No ratings yet

- Permeability NMRDocument5 pagesPermeability NMRFarid Hendra Pradana100% (1)

- Permeability Estimation in Tight Gas Sands and Shales Using NMR - A New Interpretive MethodologyDocument9 pagesPermeability Estimation in Tight Gas Sands and Shales Using NMR - A New Interpretive MethodologyabdounouNo ratings yet

- Das 2016Document8 pagesDas 2016Jose SilvaNo ratings yet

- Advances in SCAL Data Interpretations OnDocument10 pagesAdvances in SCAL Data Interpretations Onreza hasanebrahimiNo ratings yet

- Relative Permeabilities and Transport System in Mixed Wetted Carbonate RocksDocument7 pagesRelative Permeabilities and Transport System in Mixed Wetted Carbonate RocksRosa K Chang HNo ratings yet

- Making Sense of Carbonate Pore SystemsDocument25 pagesMaking Sense of Carbonate Pore SystemsRosa K Chang HNo ratings yet

- How To Integrate Wireline Formation Tester, Logs, Core and Well Test Data To Get Hydraulic Flow Unit Permeabilitys - Application To Algeria Gas FieldDocument13 pagesHow To Integrate Wireline Formation Tester, Logs, Core and Well Test Data To Get Hydraulic Flow Unit Permeabilitys - Application To Algeria Gas FieldJamalNo ratings yet

- Integrating Log and Core Data 111Document3 pagesIntegrating Log and Core Data 111GHIFFARI PARAMANTA ELBEESNo ratings yet

- Whiten 1993Document8 pagesWhiten 1993sandileNo ratings yet

- SaturationModelling MyersDocument16 pagesSaturationModelling MyersLouis PlumNo ratings yet

- SPE 56417 Effect of A Wetting Immobile Phase On Diffusion and Macroscopic Dispersion in Unconsolidated Porous MediaDocument13 pagesSPE 56417 Effect of A Wetting Immobile Phase On Diffusion and Macroscopic Dispersion in Unconsolidated Porous MediaDaniel Camilo BustosNo ratings yet

- Drop Size Distribution in Highly Concentrated Liquid-Liquid Dispersions Using A Light Back Scattering MethodDocument8 pagesDrop Size Distribution in Highly Concentrated Liquid-Liquid Dispersions Using A Light Back Scattering MethodDouglas SansaoNo ratings yet

- 1 s2.0 S0009250906005604 MainDocument17 pages1 s2.0 S0009250906005604 MainSuhas Koushik S DNo ratings yet

- Low-Field Nuclear Magnetic Resonance Characterization of Organic Content in ShalesDocument12 pagesLow-Field Nuclear Magnetic Resonance Characterization of Organic Content in ShalesRosa K Chang HNo ratings yet

- Use of The NMR and Resistivity Logs To Quantify Movable Hydrocarbon Solution For The Tight and Low-Resistivity Carbonate ReservoirsDocument17 pagesUse of The NMR and Resistivity Logs To Quantify Movable Hydrocarbon Solution For The Tight and Low-Resistivity Carbonate ReservoirsRohit BindalNo ratings yet

- LV 2013Document10 pagesLV 2013Chingiz QarayevNo ratings yet

- Reservoir Rock PorosityDocument106 pagesReservoir Rock PorosityAnna AroraNo ratings yet

- Performance of Hollow Fiber Membrane Gas-Liquid Contactors To Absorb Co UsingDocument13 pagesPerformance of Hollow Fiber Membrane Gas-Liquid Contactors To Absorb Co UsingPitri YantiNo ratings yet

- Chemical Engineering ScienceDocument9 pagesChemical Engineering ScienceAlessandro PosillicoNo ratings yet

- Modeling Concentration Polarization in Reverse Osmosis Processes PDFDocument18 pagesModeling Concentration Polarization in Reverse Osmosis Processes PDFIbrahim Al-MutazNo ratings yet

- Determination of Duvernay Formation Reservoir PropertiesDocument8 pagesDetermination of Duvernay Formation Reservoir Propertiesgeoahamza85No ratings yet

- 2005 205 NTG - DeterminationDocument13 pages2005 205 NTG - Determinationالبروفيسور الليبيNo ratings yet

- Flow Distribution in Different Microreactor Scale-Out Geometries and The Effect of Manufacturing Tolerances and Channel BlockageDocument12 pagesFlow Distribution in Different Microreactor Scale-Out Geometries and The Effect of Manufacturing Tolerances and Channel Blockagejoy ravalNo ratings yet

- Research ArticleDocument25 pagesResearch ArticleMahmoud HefnyNo ratings yet

- Wadsworth-2017-Topological Inversions in CoaleDocument6 pagesWadsworth-2017-Topological Inversions in Coale旭康 鲁No ratings yet

- Relative Permeability Assessment in A Giant Carbonate Reservoir Using Digital Rock PhysicsDocument12 pagesRelative Permeability Assessment in A Giant Carbonate Reservoir Using Digital Rock PhysicsRosa K Chang HNo ratings yet

- Marchisio D.L.,Rivautella L.,Gavi E.,Vanni M. - Design of Chemical Reactors For Nano-ParticleDocument8 pagesMarchisio D.L.,Rivautella L.,Gavi E.,Vanni M. - Design of Chemical Reactors For Nano-ParticleJordy CanalesNo ratings yet

- Chapter 14Document19 pagesChapter 14Fahmi BajryNo ratings yet

- Rheological and Depositional Characterisation of Paste-Like Tailings SlurriesDocument10 pagesRheological and Depositional Characterisation of Paste-Like Tailings SlurriesWilder Atalaya ChavezNo ratings yet

- Micron Particle Deposition in The Nasal Cavity Using The V - F ModelDocument6 pagesMicron Particle Deposition in The Nasal Cavity Using The V - F ModelkinthavongNo ratings yet

- Epe 2013112114121806Document4 pagesEpe 2013112114121806Roland Rawlins IgaborNo ratings yet

- Well CorrealtionDocument9 pagesWell CorrealtionHarith NordinNo ratings yet

- SPE 123703 Reservoir Rock Typing in A Carbonate Reservoir-Cooperation of Core and Log Data: Case StudyDocument22 pagesSPE 123703 Reservoir Rock Typing in A Carbonate Reservoir-Cooperation of Core and Log Data: Case Studygeoahamza85No ratings yet

- Synthesis and Properties of Microporous Sol Gel Silica MembranesDocument6 pagesSynthesis and Properties of Microporous Sol Gel Silica MembranesCaro CuadrasNo ratings yet

- Mechanical Behavior of An Altered Reservoir Limestone: Multi-Scale and Core Analysis ApproachesDocument12 pagesMechanical Behavior of An Altered Reservoir Limestone: Multi-Scale and Core Analysis ApproachesRosa K Chang HNo ratings yet

- PETROPHYSICS Combined Rock and Fluid CharacterDocument19 pagesPETROPHYSICS Combined Rock and Fluid CharacterstephenNo ratings yet

- 1 s2.0 S0008884605002760 MainDocument9 pages1 s2.0 S0008884605002760 MainHocine HocineNo ratings yet

- Chemical Engineering Journal: Dimitrios Tsaoulidis, Panagiota AngeliDocument9 pagesChemical Engineering Journal: Dimitrios Tsaoulidis, Panagiota AngeliMarcosNo ratings yet

- A Microreactor For The Nitration of Benzene and TolueneDocument19 pagesA Microreactor For The Nitration of Benzene and TolueneAnna YagodnitsinaNo ratings yet

- Comparison of The Extensional and Shear Viscosity Characteristics Aqueous Hydroxyethylcellulose SolutionsDocument10 pagesComparison of The Extensional and Shear Viscosity Characteristics Aqueous Hydroxyethylcellulose Solutionsmarcela_baquero_3No ratings yet

- GGGGGGDocument154 pagesGGGGGGMohamed KamalNo ratings yet

- Cement and Concrete Research 30Document10 pagesCement and Concrete Research 30Acraz Muhammad BahrumNo ratings yet

- Novel Approach To Quantifying Deepwater Laminated Sequences Using Integrated Evaluation of LWD Real-Time Shear, Porosity, Azimuthal Density and High-Resolution Propagation ResistivityDocument16 pagesNovel Approach To Quantifying Deepwater Laminated Sequences Using Integrated Evaluation of LWD Real-Time Shear, Porosity, Azimuthal Density and High-Resolution Propagation ResistivityshantanurilNo ratings yet

- Liquid ExtractionDocument7 pagesLiquid Extractionhande_kmrlNo ratings yet

- Spe 174968 MS PDFDocument11 pagesSpe 174968 MS PDFmejiasidNo ratings yet

- Chemical Engineering Science: Pawe" Sobieszuk, Ryszard Pohorecki, Pawe" Cygan Ski, Jacek GrzelkaDocument9 pagesChemical Engineering Science: Pawe" Sobieszuk, Ryszard Pohorecki, Pawe" Cygan Ski, Jacek GrzelkajayashriNo ratings yet

- Rock Physics and Reservoir Characteristic of A Calcitic-Dolomitic Sandstone ReserviorDocument14 pagesRock Physics and Reservoir Characteristic of A Calcitic-Dolomitic Sandstone ReserviordelacourNo ratings yet

- 53 3Huphdelolw/3Uhglfwlrqviurp$Frxvwlf&Ruh 0hdvxuhphqwv: $'udhjh 6wdwrloDocument6 pages53 3Huphdelolw/3Uhglfwlrqviurp$Frxvwlf&Ruh 0hdvxuhphqwv: $'udhjh 6wdwrlomythygpbhuNo ratings yet

- Measuring Lipid Membrane Viscosity Using Rotational and Translational Probe DiffusionDocument5 pagesMeasuring Lipid Membrane Viscosity Using Rotational and Translational Probe Diffusionpegah89No ratings yet

- Quasi-3D Modelling of Two-Phase Slug Flow in PipesDocument12 pagesQuasi-3D Modelling of Two-Phase Slug Flow in PipeskumarNo ratings yet

- 3-Graded-Viscosity-Bank Design With Pseudoplastic Fluids (1988)Document13 pages3-Graded-Viscosity-Bank Design With Pseudoplastic Fluids (1988)Lara SchimithNo ratings yet

- IJMF Paper 43Document16 pagesIJMF Paper 43Prantik DasNo ratings yet

- Lake and Hirasaki (1981) (SPE-8436-PA)Document10 pagesLake and Hirasaki (1981) (SPE-8436-PA)Anonymous PO7VwbBnNo ratings yet

- Reservoir Rock PorosityDocument106 pagesReservoir Rock PorosityRajat WadhwaniNo ratings yet

- Sca2010 17Document12 pagesSca2010 17Rosa K Chang HNo ratings yet

- Fluid Dynamics in Complex Fractured-Porous SystemsFrom EverandFluid Dynamics in Complex Fractured-Porous SystemsBoris FaybishenkoNo ratings yet

- Geological Carbon Storage: Subsurface Seals and Caprock IntegrityFrom EverandGeological Carbon Storage: Subsurface Seals and Caprock IntegrityStéphanie VialleNo ratings yet

- Lapworth Et Al. 2021Document14 pagesLapworth Et Al. 2021Sayantan GangulyNo ratings yet

- Water Into Lake Mass BalanceDocument34 pagesWater Into Lake Mass BalancebrahmishtanNo ratings yet

- R0478 PDFDocument6 pagesR0478 PDFSoniaNo ratings yet

- 2-2014 9.03biological and Microbiological Evaluation of Aquafeeds and feedstuffs-MBT PDFDocument96 pages2-2014 9.03biological and Microbiological Evaluation of Aquafeeds and feedstuffs-MBT PDFGail AidNo ratings yet

- Glycerol AnalysisDocument4 pagesGlycerol AnalysisrinifiahNo ratings yet

- By: Prabhat Khare: Asst. ProfessorDocument25 pagesBy: Prabhat Khare: Asst. ProfessorSUMIT KUMAR PANDITNo ratings yet

- Proposed Revisions To Usp Sterile Product - Package Integrity EvaluationDocument56 pagesProposed Revisions To Usp Sterile Product - Package Integrity EvaluationDarla Bala KishorNo ratings yet

- Páginas Desde LibroDocument54 pagesPáginas Desde LibromanuelNo ratings yet

- Ahu CisbatDocument7 pagesAhu CisbatDewa ayu putu laksmi putri wijayaNo ratings yet

- Assessing GW and SW InteractionDocument133 pagesAssessing GW and SW InteractionDang AnNo ratings yet

- Methods in Karst HydrogeologyDocument279 pagesMethods in Karst HydrogeologyAbdalle SahalNo ratings yet

- I) Using Isolated Organ / Tissues:: Ex.: Roots and Leaves For Study of Nicotiana and Datura, Petal Disc For StudyDocument22 pagesI) Using Isolated Organ / Tissues:: Ex.: Roots and Leaves For Study of Nicotiana and Datura, Petal Disc For Studypreetisingh17No ratings yet

- FipronilDocument175 pagesFipronilMa.Paula SicbaldiNo ratings yet

- BioRxn Eng PDFDocument638 pagesBioRxn Eng PDFalabastrinoNo ratings yet

- La Respuesta Anabólica A La Ingesta de Proteínas Durante La Recuperación Post-EjercicioDocument22 pagesLa Respuesta Anabólica A La Ingesta de Proteínas Durante La Recuperación Post-EjercicioMANUEL ESTUARDO BRAVO CALDERONNo ratings yet

- Hssaisoune 2019Document13 pagesHssaisoune 2019rohith babuNo ratings yet

- The Noble Gases As Geochemical TracersDocument390 pagesThe Noble Gases As Geochemical TracersAmat SapriNo ratings yet

- Technique Used For Study of Bio Synthetic PathwayDocument9 pagesTechnique Used For Study of Bio Synthetic Pathwayshankul kumar95% (19)

- 1950, Von Bertalanffy, The Theory of Open Systems in Physics and BiologyDocument7 pages1950, Von Bertalanffy, The Theory of Open Systems in Physics and BiologyPancho MainländerNo ratings yet

- ISOTEC® Stable Isotopes - Resonating With The Advancing Field of Biomolecular NMRDocument11 pagesISOTEC® Stable Isotopes - Resonating With The Advancing Field of Biomolecular NMRSigma-AldrichNo ratings yet

- Tech Pres 20Document10 pagesTech Pres 20Mirza Mohammed Yousuf BaigNo ratings yet

- Principles of Stable Isotope Research - With Special - 2021 - Clinical NutritionDocument15 pagesPrinciples of Stable Isotope Research - With Special - 2021 - Clinical NutritionErick Mosquera LópezNo ratings yet

- Apha 1020QCDocument10 pagesApha 1020QCErick Leonardo Valle MendozaNo ratings yet

- Nguyet, Vu T. M. - Hydrogeological Characterisation and Groundwater Protection of Tropical Mountainous Karst Areas in NW VietnamDocument152 pagesNguyet, Vu T. M. - Hydrogeological Characterisation and Groundwater Protection of Tropical Mountainous Karst Areas in NW VietnamCae Martins100% (1)

- Mark R. Schoeberl Et Al - Estimation of Stratospheric Age Spectrum From Chemical TracersDocument18 pagesMark R. Schoeberl Et Al - Estimation of Stratospheric Age Spectrum From Chemical TracersRemazzzNo ratings yet

- Gravity Circuit PerformanceDocument19 pagesGravity Circuit Performanceprimo_tech100% (1)

- Abstract Book ENVIRA 2017Document248 pagesAbstract Book ENVIRA 2017Anonymous SjEVReExNo ratings yet

- Simulation of Atomic Diffusion in The FCC Nial System: A Kinetic Monte Carlo StudyDocument33 pagesSimulation of Atomic Diffusion in The FCC Nial System: A Kinetic Monte Carlo StudyajeykrishnaNo ratings yet