Professional Documents

Culture Documents

Core Tools (APQP, PPAP, FMEA, MSA, SPC and Problem Solving)

Core Tools (APQP, PPAP, FMEA, MSA, SPC and Problem Solving)

Uploaded by

Rob WillestoneOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Core Tools (APQP, PPAP, FMEA, MSA, SPC and Problem Solving)

Core Tools (APQP, PPAP, FMEA, MSA, SPC and Problem Solving)

Uploaded by

Rob WillestoneCopyright:

Available Formats

Core Tools (APQP, PPAP, FMEA, MSA, SPC and Problem Solving)

about:reader?url=http://www.mmtc.org/what-we-do/quality-manageme...

mmtc.org

K. Seman

Advanced Product Quality Planning (APQP)

Production Part Approval Process (PPAP)

Failure Mode Effects Analysis (FMEA)

Measurement Systems Analysis (MSA)

Statistical Process Control (SPC) and

Root Cause Analysis and Reporting Methods

2-Day Risk Management using FMEA

MMTC trainers strive to stay on top of the latest versions of the

Core Tools and interpret the requirements for practical deployment.

Training sessions are offered in open enrollment format or on-site

for employees. Each attendee receives a copy of the latest reference

manual issued by AIAG. MMTC offers Core Tools training in APQP,

FMEA and PPAP combination, SPC, MSA, Root Cause Analysis and

Reporting Methods.

Core Tools: APQP, FMEA and PPAP (2-Day

Training) CEU Credits: 1.4

1 of 6

8/2/2016 10:36 AM

Core Tools (APQP, PPAP, FMEA, MSA, SPC and Problem Solving)

about:reader?url=http://www.mmtc.org/what-we-do/quality-manageme...

(Outline)

MMTC offers this combination class to train companies in the

planning, launch and validation of a new automotive product or

process. The course blends three powerful tools to guide

participants through all steps of the launch process. With an

emphasis on contextual learning, attendees will use actual

production parts in all phases of training.

Advanced Product Quality Planning (APQP) is applied to our

injection molding process, which produces several different

components that are assembled later. Participants use blueprint

drawings for the parts as they learn project management skills in

planning the sequence, selecting the gages, inspection points in the

process, floor layout, and generating the control plan. Content

includes:

TS 16949 requirements

Product design and development

Planning and defining the program

Validation of product and process

APQP team dynamics

Control plan methodology

Failure Mode Effects Analysis (FMEA) During day two of the

training, participants apply the latest version of FMEA to the plastic

parts to determine what can go wrong with the parts and the

process. Content includes:

What is FMEA; how does it fit into APQP

Robust design concepts (DFMEA)

2 of 6

8/2/2016 10:36 AM

Core Tools (APQP, PPAP, FMEA, MSA, SPC and Problem Solving)

about:reader?url=http://www.mmtc.org/what-we-do/quality-manageme...

Quality system requirements

Design and process FMEA objectives

Recommended FMEA process sequence

Production Part Approval Process (PPAP) As the PPAP

process is introduced; it is applied to the parts produced. Actual

measurements are taken and are used to complete the various test

sheets of PPAP. Content includes:

When is PPAP required (applicability)

Dimensional, material and test results

Process requirements

Floor layout (single process flow)

Offered on-site or in an open enrollment format the remaining Core

Tools are delivered in one day sessions.

Statistical Process Control (SPC) (1-day class)

CEU Credits: 0.7

(Outline)

Basic SPC is applied using the parts produced in the MMTC factory.

Participants run a group of sequentially produced parts and then

measure them to determine average, range and sigma. Control

limits are calculated using these same parts and additional samples

are measured and plotted to determine where the process is going

and why. Interpretations of results are part of this course as well as

capability study exercises.

Concepts of SPC detection vs. prevention

3 of 6

8/2/2016 10:36 AM

Core Tools (APQP, PPAP, FMEA, MSA, SPC and Problem Solving)

about:reader?url=http://www.mmtc.org/what-we-do/quality-manageme...

Basic fundamentals

Improving the process (attacking waste)

Gathering data and preparing charts

The 7 statistical tools

X bar and R charts (setting control limits)

Measurement System Analysis (MSA) (1-day

class) CEU Credits: 0.7

(Outline)

If measurements are used to guide decisions, then it follows

logically that the more error there is in the measurements, the more

error there will be in the decisions based on those measurements.

The purpose of Measurement System Analysis is to qualify a

measurement system for use by quantifying its accuracy, precision,

and stability. Content includes:

Over-correction/tampering

Understanding your measurement system

Basic concepts of gage analysis

Problem Solving, Root Cause Analysis and

Reporting Methods (1-day class) CEU Credits:

0.7

(Outline)

Root cause analysis and problem-solving tools are presented and

demonstrated in this session. Both internal (yield issues) and

external (warranty, field failure, customer complaint) problems are

introduced in the manner they are typically encountered. Teams use

4 of 6

8/2/2016 10:36 AM

Core Tools (APQP, PPAP, FMEA, MSA, SPC and Problem Solving)

about:reader?url=http://www.mmtc.org/what-we-do/quality-manageme...

these tools to identify, analyze and solve the issues and determine

root cause. Understanding is gained through practical hands-on

exercises using the tools listed below. Problems are introduced to

demonstrate the typical formats for reporting the findings, applying

solutions and corrections such as Global 8-D. Tools covered

include:

5-Whys

Brainstorming

Cause and effect

Process mapping and analysis

Scatter diagram

Risk Management Using FMEA (2-day class)

CEU Credits: 1.4

(Outline)

This training will orient participants to the steps of Risk

Management using the tool of Failure Mode Effects Analysis

(FMEA) to define, manage, and reduce risks. Processes also used in

this training include brainstorming, creating SIPOCs, and creating

Process Flowcharts to help in the understanding, and analasys of

the process. The training addresses each step of doing a FMEA,

with exercises designed to ensure maximum understanding of both

Design FMEA and Process FMEA. The first day of this program

includes training on tools used when doing an FMEA, how to do an

FMEA, and exercises to re-inforce understanding. Day two involves

having each company select a process to do a PFMEA on with

instructed guidance. The processes selected are taken through the

process taught, beginning with SIPOC and flowchart, sharing each

phase with the group. In this environment, each companys FMEA is

partially finished by the end of the second day.

5 of 6

8/2/2016 10:36 AM

Core Tools (APQP, PPAP, FMEA, MSA, SPC and Problem Solving)

about:reader?url=http://www.mmtc.org/what-we-do/quality-manageme...

An updated class listing can be found HERE.

For more information on MMTC's Core Tools program, contact

us at 888-414-6682 or via email at inquiry@mmtc.org.

6 of 6

8/2/2016 10:36 AM

You might also like

- Volkswagen Selfcheck ListDocument104 pagesVolkswagen Selfcheck ListМиша Макух100% (1)

- Ppap - Aiag ManualDocument102 pagesPpap - Aiag Manualquintozh100% (1)

- Appendix 25 VDA 6 3 Process AuditDocument12 pagesAppendix 25 VDA 6 3 Process AuditSeda De Drasnia100% (2)

- APQP OverviewDocument86 pagesAPQP OverviewLuis Lujano100% (3)

- VDA 6.3 Standard Questionnaire enDocument19 pagesVDA 6.3 Standard Questionnaire enFlorida Elena MitroiNo ratings yet

- Formel Q Capability V8 Appendix enDocument8 pagesFormel Q Capability V8 Appendix enSlavomír LukáčNo ratings yet

- Quality Core ToolsDocument14 pagesQuality Core Toolsالعاب الاطفال- jeux enfantsNo ratings yet

- Manual - APQP 20121017 PDFDocument135 pagesManual - APQP 20121017 PDFBerk NoyanNo ratings yet

- CQI Wessex ISO-TS CORE TOOLS Presentation John Skinner 11dec12Document54 pagesCQI Wessex ISO-TS CORE TOOLS Presentation John Skinner 11dec12Gabryel BogdanNo ratings yet

- Core Tools Forms V5dDocument119 pagesCore Tools Forms V5dIng. Alberto AguilarNo ratings yet

- BS 534 PDFDocument26 pagesBS 534 PDFRob Willestone50% (2)

- 2012 CQT BokDocument12 pages2012 CQT BokRob WillestoneNo ratings yet

- Software ReliabilityDocument211 pagesSoftware Reliabilityapi-3775463100% (1)

- Apqp PlanDocument3 pagesApqp Plananon-448387100% (1)

- Aiag Ppap4Document75 pagesAiag Ppap4tamtom75No ratings yet

- 1 ApqpDocument30 pages1 ApqpVIPIN YADAVNo ratings yet

- APQP TrainingDocument22 pagesAPQP TrainingSandeep Malik100% (1)

- APQP Manual VolvoDocument30 pagesAPQP Manual VolvoVictor Hugo50% (2)

- VDA Flyer - 6 5 Product AuditDocument2 pagesVDA Flyer - 6 5 Product AuditEdwin Osogo100% (1)

- IATF 16949 Awareness Training-Terms OnlyDocument18 pagesIATF 16949 Awareness Training-Terms Onlysuresh kumar67% (3)

- Volvo ApqpDocument30 pagesVolvo ApqpAmolPagdalNo ratings yet

- Register Forum Home Page Post Attachment Files All Help Lost PasswordDocument3 pagesRegister Forum Home Page Post Attachment Files All Help Lost PasswordKirthivasanNo ratings yet

- Design Verification Process Project III Samudra Indonesia 20/11/2019 Samudra Indonesia 21/12/2019 See Project III R1 ReportDocument6 pagesDesign Verification Process Project III Samudra Indonesia 20/11/2019 Samudra Indonesia 21/12/2019 See Project III R1 ReportAufa Jaya Perkasa LegalityNo ratings yet

- APQPDocument2 pagesAPQPjitenderbawalia0% (1)

- Form Sheet AIAG VDA Design U Process-FMEA enDocument2 pagesForm Sheet AIAG VDA Design U Process-FMEA en57641100% (1)

- Ppap-Template 4th EditionDocument23 pagesPpap-Template 4th EditionAshutosh SinghNo ratings yet

- GM Customer Specifics - Rev 05-07-15Document34 pagesGM Customer Specifics - Rev 05-07-15hugocronyNo ratings yet

- Advanced Product Quality Planning (APQP) and Production Part Approval Process (PPAP) Training MaterialDocument29 pagesAdvanced Product Quality Planning (APQP) and Production Part Approval Process (PPAP) Training MaterialxiwaxeNo ratings yet

- PPAP FundamentalsDocument21 pagesPPAP FundamentalsRajdeep SinghNo ratings yet

- GP-12 Check SheetsDocument2 pagesGP-12 Check SheetsLam Nguyen100% (4)

- APQP ENG SiemensDocument12 pagesAPQP ENG SiemensVikash KumarNo ratings yet

- PAPP Checklists and FormsDocument4 pagesPAPP Checklists and FormsA M100% (1)

- Checklist Audit ISO TS 16949Document14 pagesChecklist Audit ISO TS 16949Demi RamaNo ratings yet

- Six Sigma ToolsDocument92 pagesSix Sigma ToolsjoseggNo ratings yet

- IATF Auditor Guide First Ed April 2009 Final PDFDocument32 pagesIATF Auditor Guide First Ed April 2009 Final PDFkarthikkanda100% (7)

- FMEA Errata Sheet ENG AIAG VDA FMEA Handbook 202000602 PDFDocument10 pagesFMEA Errata Sheet ENG AIAG VDA FMEA Handbook 202000602 PDFBonny BonitoNo ratings yet

- Iso IATF 16949 Upgrade Planner and Delta ChecklistDocument14 pagesIso IATF 16949 Upgrade Planner and Delta ChecklistHomero Januncio100% (1)

- Cover Sheet: Attachements / Items For Inspection Product / ProcessDocument6 pagesCover Sheet: Attachements / Items For Inspection Product / ProcessSeval GünaltayNo ratings yet

- IATF 16949 2016 Gap Tool InstructionsDocument11 pagesIATF 16949 2016 Gap Tool InstructionsJosé María Moreno63% (8)

- Apqp PpapDocument50 pagesApqp PpapEvandro Ribeiro50% (2)

- VDA 6.3 Process Audit and Checklist For The Car Industry - NimonikAppDocument6 pagesVDA 6.3 Process Audit and Checklist For The Car Industry - NimonikApprodolfo barbosaNo ratings yet

- AIAG - Production Part Approval Process (PPAP) 4th EditionDocument74 pagesAIAG - Production Part Approval Process (PPAP) 4th EditionIvan Bolivar Barraza100% (1)

- APQP - QuestionnaireDocument2 pagesAPQP - QuestionnaireLOGANATHAN V100% (1)

- Printout Final IATF 16949 2016 - Key ChangesDocument89 pagesPrintout Final IATF 16949 2016 - Key ChangesSudhagar100% (3)

- APQPDocument25 pagesAPQPHeera Singh100% (3)

- Risk Management Using Failure Mode and Effect Analysis (FMEA)From EverandRisk Management Using Failure Mode and Effect Analysis (FMEA)No ratings yet

- APQPDocument4 pagesAPQPAmit Kumar SharmaNo ratings yet

- Core Tools (APQP, PPAP, FMEA, MSA, SPC and Problem Solving)Document2 pagesCore Tools (APQP, PPAP, FMEA, MSA, SPC and Problem Solving)skluxNo ratings yet

- APQP Core ToolsDocument5 pagesAPQP Core ToolsbbaskaranNo ratings yet

- Core ToolsDocument4 pagesCore Toolsraghusanth007No ratings yet

- Experiment No 7 MEMDocument11 pagesExperiment No 7 MEMImdad JalaliNo ratings yet

- Advanced Product Quality Planning PDFDocument35 pagesAdvanced Product Quality Planning PDFThuận HoàngNo ratings yet

- React (Web Framework) - WikipediaDocument15 pagesReact (Web Framework) - WikipediaRob WillestoneNo ratings yet

- Sales and Marketing Risks To Consider Yes No N/A Comments / Action RequiredDocument2 pagesSales and Marketing Risks To Consider Yes No N/A Comments / Action RequiredRob WillestoneNo ratings yet

- Cqe Sample ExamDocument1 pageCqe Sample ExamRob WillestoneNo ratings yet

- Pie Field Indicator Product Data Sheet EnglishDocument1 pagePie Field Indicator Product Data Sheet EnglishDarwin Zuni RosadoNo ratings yet

- Magnetic Flux Indicators Product Data Sheet EnglishDocument1 pageMagnetic Flux Indicators Product Data Sheet EnglishRob WillestoneNo ratings yet

- Best Practice Quality Policy StatementsDocument3 pagesBest Practice Quality Policy StatementsRob WillestoneNo ratings yet

- Welcome: at TheDocument32 pagesWelcome: at TheRob WillestoneNo ratings yet

- Cqe Sample ExamDocument1 pageCqe Sample ExamRob WillestoneNo ratings yet

- QEHS ManualDocument100 pagesQEHS ManualRob WillestoneNo ratings yet

- How To Apply Risk-Based Thinking To Quality ProcessesDocument58 pagesHow To Apply Risk-Based Thinking To Quality Processesnorlie100% (5)

- Ts 16949 Proc Forms MatrixDocument1 pageTs 16949 Proc Forms MatrixRob WillestoneNo ratings yet

- KPI Assessment FormDocument2 pagesKPI Assessment FormRob Willestone100% (1)

- 9.14.1. Determined by Equation For Mass Per Unit Length According To API 5LDocument2 pages9.14.1. Determined by Equation For Mass Per Unit Length According To API 5LRob WillestoneNo ratings yet

- Management Vs Non Management GuidelinesDocument1 pageManagement Vs Non Management GuidelinesRob WillestoneNo ratings yet

- Asnt Level II RT InterpretationDocument43 pagesAsnt Level II RT InterpretationRob Willestone100% (13)

- Audit ChecklistDocument21 pagesAudit ChecklistRob WillestoneNo ratings yet

- E2 - Equipment Operators Daily ChecklistDocument1 pageE2 - Equipment Operators Daily ChecklistRob WillestoneNo ratings yet

- Comansa 5 LC 4010: Flat Top Tower CraneDocument4 pagesComansa 5 LC 4010: Flat Top Tower CranedamindaNo ratings yet

- Ukmt 2009 Junior Math OlympiadDocument4 pagesUkmt 2009 Junior Math OlympiadSadi SnmzNo ratings yet

- Catalogo de CouplingsDocument32 pagesCatalogo de CouplingsjoravicaNo ratings yet

- AsdxxxxDocument2 pagesAsdxxxxalexyno8No ratings yet

- 06-06-1986 at 5-30 AmDocument67 pages06-06-1986 at 5-30 Amrahul106No ratings yet

- Sensores 3500B EUIDocument32 pagesSensores 3500B EUICesar Ego-Aguirre Calderon100% (3)

- Electrical M04 ECUs enDocument13 pagesElectrical M04 ECUs enAimet TraslaviñaNo ratings yet

- 2016 Catalogue-SpanishDocument101 pages2016 Catalogue-SpanishwgonzalesmNo ratings yet

- Determinants+ (Properties+,+Mulitplication+of+Determinants+) JEE+2021Document44 pagesDeterminants+ (Properties+,+Mulitplication+of+Determinants+) JEE+2021BrucleeNo ratings yet

- It8501 Web Technology SyllabusDocument3 pagesIt8501 Web Technology SyllabusJaya Lakshmi0% (2)

- Special Kind of FunctionsDocument14 pagesSpecial Kind of FunctionsRon Francis Reguero CababatNo ratings yet

- ABB PV ReferencesDocument48 pagesABB PV Referencesahmetgumus1902No ratings yet

- Electricity I 1Document9 pagesElectricity I 1Charles Daniel Torre MalolesNo ratings yet

- Science Interactive TextDocument112 pagesScience Interactive Textaapirzado100% (12)

- Visual Inspection of Crimped ConnectionsDocument1 pageVisual Inspection of Crimped Connectionsvinay gayateNo ratings yet

- NG300 ESales Spec SheetDocument2 pagesNG300 ESales Spec SheetSamrandNo ratings yet

- Maths Class X Sample Paper Test 05 For Board Exam 2024Document6 pagesMaths Class X Sample Paper Test 05 For Board Exam 2024suiiironaldo255No ratings yet

- Rasi Chart (Nirayan) : TransitDocument4 pagesRasi Chart (Nirayan) : TransittajkhanNo ratings yet

- Using and Interpreting CronbachDocument5 pagesUsing and Interpreting CronbachMay Angelica TenezaNo ratings yet

- Application of Rate of Reaction in Daily LifeDocument2 pagesApplication of Rate of Reaction in Daily LifeZhi Xian PoahNo ratings yet

- DsssssDocument2 pagesDssssssuhasNo ratings yet

- Goldengate12 2 X Cert Matrix 2769360Document18 pagesGoldengate12 2 X Cert Matrix 2769360repakulakishoreNo ratings yet

- Gen Math Module 1Document15 pagesGen Math Module 1Bernard Dale B. RocientoNo ratings yet

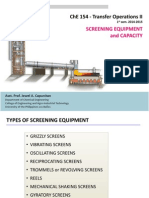

- Che 154 Lecture 3b Screening EquipmentDocument34 pagesChe 154 Lecture 3b Screening EquipmentAiza CabolesNo ratings yet

- Two Pass SWRO Tender Technical SpecificationDocument369 pagesTwo Pass SWRO Tender Technical Specificationmarksion exchangeNo ratings yet

- Intro Emb SysDocument294 pagesIntro Emb SysSanjay YadavNo ratings yet

- 81221H Pressure ENGDocument11 pages81221H Pressure ENGGopal HegdeNo ratings yet

- Digitax ST User Guide Issue 6 (0475-0001-06) - Approved PDFDocument210 pagesDigitax ST User Guide Issue 6 (0475-0001-06) - Approved PDFMazarel AurelNo ratings yet

- OIR Test Part 1Document25 pagesOIR Test Part 1Avanindra Nayak100% (1)