Professional Documents

Culture Documents

Conduit - Electrical Design Guide

Conduit - Electrical Design Guide

Uploaded by

zeliteCopyright:

Available Formats

You might also like

- Items - HabytDocument5 pagesItems - HabytHarsh VardhanNo ratings yet

- Trenwa Trench Catalog PDFDocument56 pagesTrenwa Trench Catalog PDFizallesNo ratings yet

- BMS WiringDocument2 pagesBMS WiringJaved BhattiNo ratings yet

- TP21 - BEC - DT - 0402 MAS For 11 KV Chiller Starter Panel Rev - 3 PDFDocument127 pagesTP21 - BEC - DT - 0402 MAS For 11 KV Chiller Starter Panel Rev - 3 PDFzeliteNo ratings yet

- Underground Duct Banks and Raceways - Electrical Design GuideDocument2 pagesUnderground Duct Banks and Raceways - Electrical Design GuideDaniel BolivarNo ratings yet

- 26 05 43 Underground Ducts and Raceways For Electrical SystemsDocument7 pages26 05 43 Underground Ducts and Raceways For Electrical SystemsjopaypagasNo ratings yet

- Overhead Conductor Installation Guide: Recommended PracticesDocument20 pagesOverhead Conductor Installation Guide: Recommended PracticesCarlos PlaceresNo ratings yet

- Guys and AnchorsDocument34 pagesGuys and AnchorsVijay Kumar0% (1)

- Hubbell Pole Line Hardware PDFDocument50 pagesHubbell Pole Line Hardware PDFGary LewisNo ratings yet

- Neutral Grounding Resistors: Installation and Maintenance InstructionsDocument7 pagesNeutral Grounding Resistors: Installation and Maintenance Instructionsks_ramachandra7017No ratings yet

- Conduit SpecificationDocument22 pagesConduit Specificationamijetomar08No ratings yet

- Mechanical Design of Overhead Lines PDFDocument70 pagesMechanical Design of Overhead Lines PDFEng-Ahmad Abo-AledousNo ratings yet

- Figure 1 - Motor Control CabinetDocument6 pagesFigure 1 - Motor Control CabinetJosé Vicente González VivasNo ratings yet

- Technical Manual 1Document118 pagesTechnical Manual 1Homero Silva100% (14)

- Types of Insulators: Pin Type InsulatorDocument11 pagesTypes of Insulators: Pin Type InsulatorGary M TrajanoNo ratings yet

- Checklist For 33kV DP Structure Design & DrawingDocument4 pagesChecklist For 33kV DP Structure Design & DrawingRupesh KhandekarNo ratings yet

- Transformer Bushings PDFDocument36 pagesTransformer Bushings PDFhashamNo ratings yet

- Practices For Grounding and Bonding of Cable Trays - EEPDocument5 pagesPractices For Grounding and Bonding of Cable Trays - EEPSaraswatapalitNo ratings yet

- 500KV CT Ca550 3000a PDFDocument3 pages500KV CT Ca550 3000a PDFHafiz Bilal AhmadNo ratings yet

- Line ErectionDocument14 pagesLine ErectionPrashant Trivedi100% (1)

- Insulators & TypesDocument48 pagesInsulators & Typesdilleh50% (2)

- Pole Design by PLS-POLE ProgramDocument5 pagesPole Design by PLS-POLE ProgramMohammed K. HayderNo ratings yet

- Engineered Wood ProductsDocument21 pagesEngineered Wood Productspppppp5No ratings yet

- CatalogDocument48 pagesCatalogAhmad AshrafNo ratings yet

- Desingconstructionof33kv11kvlines 150329033645 Conversion Gate01Document167 pagesDesingconstructionof33kv11kvlines 150329033645 Conversion Gate01Akshaya AroraNo ratings yet

- Simple Calculations For Pulling CableDocument6 pagesSimple Calculations For Pulling CableKatherine SalazarNo ratings yet

- Load Tables ASD K-SeriesDocument77 pagesLoad Tables ASD K-SeriesEnrique Olvera LaraNo ratings yet

- Anchor Bolt Tolerances PDFDocument1 pageAnchor Bolt Tolerances PDFwokeoooNo ratings yet

- Techinical Specifications Welcome To NescoDocument54 pagesTechinical Specifications Welcome To NescotejzabNo ratings yet

- Ingal Eps Utility Poles Brochure PDFDocument16 pagesIngal Eps Utility Poles Brochure PDFJosue HasbunNo ratings yet

- Airport Underground Electrical Duct Banks and ConduitsDocument8 pagesAirport Underground Electrical Duct Banks and ConduitsDevrim Gürsel0% (1)

- 4.0M Crusher Run Road: (200mm THK.) FFL +0.000mDocument1 page4.0M Crusher Run Road: (200mm THK.) FFL +0.000mAzree Mohd NoorNo ratings yet

- NPD 350 SQM Home Building PackageDocument10 pagesNPD 350 SQM Home Building Packageallenbc4512No ratings yet

- DG BusductDocument16 pagesDG BusductanandpurushothamanNo ratings yet

- BUILDING SERVICES IIQuestion BankDocument37 pagesBUILDING SERVICES IIQuestion BankSiva RamanNo ratings yet

- PLP - Dogbone Vibration DamperDocument5 pagesPLP - Dogbone Vibration DamperHFandino1100% (1)

- Buried Ring EarthingDocument2 pagesBuried Ring EarthingAshish KumarNo ratings yet

- Long-Life Xlpe Insulated Power Cable PDFDocument6 pagesLong-Life Xlpe Insulated Power Cable PDFbitconceptsNo ratings yet

- Vibration Dampers: Subject To Change Without NoticeDocument8 pagesVibration Dampers: Subject To Change Without NoticeWeber HahnNo ratings yet

- 16126Document13 pages16126uddinnadeemNo ratings yet

- High Mast Catalogue-CU PhoscoDocument44 pagesHigh Mast Catalogue-CU PhoscoGuha Arnab100% (3)

- CIVI 6051: Design of Industrial StructureDocument38 pagesCIVI 6051: Design of Industrial StructureZia MccollinNo ratings yet

- Electrical Canle Trench SpecificationDocument12 pagesElectrical Canle Trench SpecificationSumit Kumar DattaNo ratings yet

- High Mast CatalogueDocument16 pagesHigh Mast CatalogueAliz BnNo ratings yet

- Transmission LinesDocument18 pagesTransmission LinesfrimpongeNo ratings yet

- Dynamic Engineering Consultant Mina Al Arab Precinct - 5 MEP SpecificationDocument8 pagesDynamic Engineering Consultant Mina Al Arab Precinct - 5 MEP SpecificationBala Krishna GallaNo ratings yet

- Underground Duct Banks and Raceways - Electrical Design GuideDocument3 pagesUnderground Duct Banks and Raceways - Electrical Design GuideabhijitdadNo ratings yet

- 16110s01 Conduit and RacewayDocument3 pages16110s01 Conduit and RacewayVICTOR JOSE VILORIANo ratings yet

- Facility ManagementDocument7 pagesFacility ManagementTajudeen IbrahimNo ratings yet

- SEWA Regulations For Electrical ConnectionDocument5 pagesSEWA Regulations For Electrical Connectionkidscv10No ratings yet

- Electrical Work Procedure Manual: A Novoue Solutions Inc. PropertyDocument20 pagesElectrical Work Procedure Manual: A Novoue Solutions Inc. Propertyeric maestroNo ratings yet

- RC SpecDocument1 pageRC SpecPraveenNo ratings yet

- Scope: Lectrical Aterials and EthodsDocument9 pagesScope: Lectrical Aterials and EthodsAnonymous uXEdLjNo ratings yet

- Section 260526 - Grounding and Bonding For Electrical SystemsDocument6 pagesSection 260526 - Grounding and Bonding For Electrical SystemsVCNo ratings yet

- DG260543Document7 pagesDG260543Ahmed OsamaNo ratings yet

- LV Cable InstallationDocument20 pagesLV Cable Installationkailasamvv100% (1)

- TESP11920R0 LV Raceways & Cable InstallationDocument20 pagesTESP11920R0 LV Raceways & Cable InstallationPERVEZ AHMAD KHANNo ratings yet

- U W Electrical Raceways: Engineering Services Facility Design InformationDocument4 pagesU W Electrical Raceways: Engineering Services Facility Design InformationAhmed EzzatNo ratings yet

- 26 05 26 User-Grounding and BondingDocument5 pages26 05 26 User-Grounding and BondingFaheem PP13No ratings yet

- Design Condition For Earthing SystemDocument4 pagesDesign Condition For Earthing SystemRashad SarwarNo ratings yet

- Duct BankDocument7 pagesDuct BankAwotiku AbimbolaNo ratings yet

- Wiring Methods and Materials - Engr. MahusayDocument77 pagesWiring Methods and Materials - Engr. Mahusayron villanuevaNo ratings yet

- !-Bab 02 Moulded Case Circuit Breaker (MCCB)Document38 pages!-Bab 02 Moulded Case Circuit Breaker (MCCB)zeliteNo ratings yet

- Rowan University Design Guide 2013Document4 pagesRowan University Design Guide 2013zeliteNo ratings yet

- Wearing of BSP Uniform and Office Attire PDFDocument1 pageWearing of BSP Uniform and Office Attire PDFzeliteNo ratings yet

- Rowan University Design Guide 2013Document3 pagesRowan University Design Guide 2013zeliteNo ratings yet

- Rowan University Design Guide 2013Document10 pagesRowan University Design Guide 2013zeliteNo ratings yet

- Rowan University Design Guide 2013Document2 pagesRowan University Design Guide 2013zeliteNo ratings yet

- Rowan University Design Guide 2013Document1 pageRowan University Design Guide 2013zeliteNo ratings yet

- Le-Corbusier (Chandigarh and Radiant City) : Presented byDocument72 pagesLe-Corbusier (Chandigarh and Radiant City) : Presented byABHISHEK MAHARJANNo ratings yet

- Concrete Sheet Pile Drawing PDFDocument4 pagesConcrete Sheet Pile Drawing PDFsurangaNo ratings yet

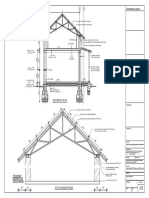

- Metal Truss With AtticDocument2 pagesMetal Truss With AtticManojNo ratings yet

- StructuralDocument14 pagesStructuralGigi YouNo ratings yet

- Japanese Urban Artificial Islands An Overview of Projects and Schemes For Marine Cities During 1960-1990sDocument10 pagesJapanese Urban Artificial Islands An Overview of Projects and Schemes For Marine Cities During 1960-1990sAnkita Roy ChowdhuryNo ratings yet

- Roof ArchitionalDocument124 pagesRoof ArchitionalRusscel MarquesesNo ratings yet

- Pds Honel Brochure 2022Document5 pagesPds Honel Brochure 2022aj.chat.gpt.coderNo ratings yet

- Renfrew Renfrew Floor PlanDocument1 pageRenfrew Renfrew Floor PlanLauraNo ratings yet

- Viktor Kovcic - Planning Kaptol Area, 1908, Zlatko JuricDocument18 pagesViktor Kovcic - Planning Kaptol Area, 1908, Zlatko JuricDorian VujnovićNo ratings yet

- Foreword: GP1 Principles of Measurement GP2 Bills of QuantitiesDocument8 pagesForeword: GP1 Principles of Measurement GP2 Bills of QuantitiesEren ArslanNo ratings yet

- WS TDG 08 Stairs Balustrades Handrails 11-20Document56 pagesWS TDG 08 Stairs Balustrades Handrails 11-20ifc saigon oneNo ratings yet

- RUET Architecture BuildingDocument26 pagesRUET Architecture BuildingNamrata Sarkar Tapti100% (1)

- Master List of Codes / Standards: Sr. No. Code/ Standards Year of Revision / EditionDocument20 pagesMaster List of Codes / Standards: Sr. No. Code/ Standards Year of Revision / Editionpiyu114No ratings yet

- Edoc - Pub - en Code 203 en PDFDocument375 pagesEdoc - Pub - en Code 203 en PDFAbishek NagarajNo ratings yet

- Group 3 - Review of PlanningDocument96 pagesGroup 3 - Review of PlanningAngela LeonardoNo ratings yet

- The Unexpectedly Tropical History of Brutalism PDFDocument14 pagesThe Unexpectedly Tropical History of Brutalism PDFakshayNo ratings yet

- G.A, Foundation & Assembly Drawing - CPS R0-13.06.23Document6 pagesG.A, Foundation & Assembly Drawing - CPS R0-13.06.23newattelectricNo ratings yet

- Sample Drawings 5Document9 pagesSample Drawings 5Sherwin DominguezNo ratings yet

- Allowable VOC Content For LEEDDocument5 pagesAllowable VOC Content For LEEDreemadeponNo ratings yet

- Layan Adoul - Compressed PortfolioDocument17 pagesLayan Adoul - Compressed Portfoliocw2tpvngg9No ratings yet

- Laurie Baker: - The Hassan Fathy of India'Document14 pagesLaurie Baker: - The Hassan Fathy of India'Arnav DasaurNo ratings yet

- DBM OfficeDocument76 pagesDBM OfficeSrija RoyNo ratings yet

- RFI, Pour Cards DataDocument58 pagesRFI, Pour Cards DataSandip PaulNo ratings yet

- Policarpio - BGT 5 - Research No.2Document21 pagesPolicarpio - BGT 5 - Research No.2Tracy PolicarpioNo ratings yet

- P5 Final Report Margarita Gancayco Barcia 5064902Document131 pagesP5 Final Report Margarita Gancayco Barcia 5064902James Edward DonguyaNo ratings yet

- Civil Guruji EstimationDocument122 pagesCivil Guruji EstimationEshwar Prasad100% (2)

- E-Book On Jain ArchitectureDocument13 pagesE-Book On Jain ArchitectureChaarvee BevaraNo ratings yet

- 2017.07.28 - R1 - Technical Specification Accept - Ver.1.7 Clean - Ok ASD, VOL 3 PDFDocument211 pages2017.07.28 - R1 - Technical Specification Accept - Ver.1.7 Clean - Ok ASD, VOL 3 PDFVitali MihalachiNo ratings yet

- Annexes PDFDocument89 pagesAnnexes PDFnathNo ratings yet

Conduit - Electrical Design Guide

Conduit - Electrical Design Guide

Uploaded by

zeliteOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Conduit - Electrical Design Guide

Conduit - Electrical Design Guide

Uploaded by

zeliteCopyright:

Available Formats

ROWAN UNIVERSITY

Design Guide

FINAL 2013

SECTION 260533 CONDUIT

This section is intended to define the general installation requirements for the conduit systems installed at

the Rowan University.

For underground conduits, refer to section 260502 for excavation and backfill requirements.

The National Electrical Code shall govern the actual sizing of conduit during the design process. Minimum

design conduit sizing shall accommodate type XHHW insulated wire.

1.0

Conduit shall be identified in accordance with Section 260553 Electrical Identification.

2.0

Each electrical system, such as lighting (480/277 volt), receptacle (208/120 volt), emergency

lighting, fire alarm system, telephone/data system, Building Automation System, security system,

and CCTV system, shall be routed in a dedicated conduit system.

3.0

Conduits shall be designed to run parallel with the lines of the building. Electrical conduits shall

not be supported on hangers with any other services, pipes, ducts, or other mechanical systems

and shall be supported independently of any ceiling support systems. Related conduits shall be

grouped together and supported from a conduit rack; provide space on rack for 25 percent

additional conduits.

4.0

Rigid steel conduit fittings shall be of the threaded type or compression only. Zinc based cast

fittings are not permitted use cast iron or cast steel.

5.0

EMT conduit fittings shall be:

a. compression type for sizes 2 1/2 inches and below.

b. set screws for all conduit sizes above 2 1/2 inches.

6.0

Fittings for non-metallic conduit systems shall be compatible with the conduit material and type

and shall be suitable for use with the required adhesives.

7.0

Exposed conduit (or other raceways) shall be installed above water and steam piping. Maintain a

minimum 12 inches clearance between conduit and all piping systems with fluid temperatures

exceeding 104 degree F.

A.

Maintain a minimum clearance of at least 6 inches between power conduits and

telecommunications conduits and at least 12 inches between power conduits and

unshielded twisted-pair telecommunications cables or as required by EIA/TIA Standard

569.

8.0

Conduit (or other raceways) shall be designed and installed with expansion joints to allow for

thermal expansion of conduit system and movement of the building (at expansion joints) and

keep stresses within the allowable limits of the conduit. Expansion joints shall be located as per

NEC requirements and, as a minimum, at all building expansion joints. Expansion joints shall

allow for the required amount of movement in order to prevent buckling of conduit or pullout at

fittings.

9.0

Junction/pull boxes (or suitable conduit fittings) shall be located to facilitate installation of cables

and insure that the pulling tension of cables is not exceeded. However, install no more than the

equivalent of (3) 90-degree bends between pull boxes or fittings. Junction/pull boxes and conduit

CONDUIT

260533 - 1

ROWAN UNIVERSITY

Design Guide

FINAL 2013

fittings shall be located so that the capability for future access is maintained. Junction/pull boxes

shall not be located on building expansion joints.

10.0

Conduit shall be installed so that access to equipment, systems, piping, etc. is not blocked by the

conduit.

11.0

Conduit and support systems shall be designed to meet applicable seismic codes.

12.0

Lateral installation of conduit on rooftops is not permitted except as required to serve rooftop

equipment.

13.0

In general, conduit sizes and types shall be suitable for the applications. The following is a

summary of minimum conduit requirements.

A.

All conduits shall be a minimum 3/4 inch.

B.

Underground Installations:

1.

2.

3.

4.

5.

6.

C.

Concrete encased ductbanks under roadways, parking lots, or other areas

subject to vehicular traffic and all medium voltage work: Use schedule 40 rigid

PVC conduit; ductbank shall be steel reinforced. The minimum burial depth for

all medium voltage duct banks is 3 feet below grade.

Concrete encased ductbanks in all other areas:

a.

Use schedule 40 rigid PVC.

b.

Where elbows are required to transition from horizontal to vertical, use

rigid steel conduit sweep elbows.

c.

Reinforcement of concrete is not required.

Direct burial of branch circuit wiring for lighting, pumps, receptacles, etc.: Use

Schedule 40 PVC conduit.

Installation of conduits under building slabs and foundations is strictly prohibited.

The only exception allowed is service entrance feeders which shall be permitted

to be installed under slab, although horizontal entry through the foundation wall is

preferred. Service entrance feeder conduits shall terminate in a pull box located

on the inside of the foundation wall. Entrance pull boxes shall be have a drain

line to building sump. Service entrance feeders shall continue via exposed

conduit run from the entrance pull box to the service equipment.

All wiring to devices located within the building will be installed in raceway

systems located within the structure.

Underground duct banks and conduit shall be located above water lines and

below steam piping. Maintain a minimum 6-foot clearance between underground

conduit or duct banks and any parallel steam lines. Underground crossings

above and below steam lines shall maintain a minimum 24-inch clearance and

the space between shall be filled with foam glass insulation.

In slab, above grade:

1.

The installation of conduit in above grade concrete slabs is prohibited.

D.

Outdoor Locations, Above Grade: In corrosive environments, use schedule rigid 80 PVC

and compatible fittings. In non-corrosive environments, use rigid steel conduit.

CONDUIT

260533 - 2

ROWAN UNIVERSITY

Design Guide

FINAL 2013

E.

Wet and Damp Locations: In corrosive environments, use schedule rigid 80 PVC and

compatible fittings. in non-corrosive environments, use rigid steel conduit. All roof conduit

penetrations shall use rigid steel conduit.

F.

Dry Locations:

A.

Switchboard and panelboard feeders: EMT or RGS.

Feeders or branch circuits 100 amps and larger: EMT.

Circuits operating above 600V: Rigid steel conduit.

Exposed conduit in finished areas: Coordinate with Architect.

Equipment Rooms: Install IMC or RGS conduit in rough-use areas like mechanical and

electrical equipment rooms, janitor's closets, etc.

B.

C.

D.

E.

F.

Conduit in Walls: EMT.

G.

Above Ceiling:

H.

conductor.

Rooftop locations where exposed: RGS

G.

Hazardous Locations: RGS.

H.

Metal Clad (MC) Cable Installations

1.

2.

3.

4.

5.

6.

I.

Type MC cable installation shall be in accordance with the following:

No more than nine (9) total current-carrying conductors in multiple MC cable runs

shall be bundled together into a single MC cable hanger. Wireway or ladder type

tray with dual supports may also be used to support MC cable with fill as allowed

by the NEC. Neutrals shall be counted as current-carrying conductors. (Not

necessary in three phase feeders)

MC cable shall be run parallel or perpendicular to walls. No diagonal runs shall

be permitted.

Maintain a clearance of at least 6 inches from hot water and other hightemperature pipes and telecommunications conduits, and at least 12 inches from

unshielded twisted-pair telecommunications cables.

The arrangement of MC cables and fastening methods shall be subject to the

approval of the University Engineering Department. Securely support all MC

cable with cable hangers, individual spring steel support clips, steel trapeze

hangers, threaded rods or dedicated No. 8 AWG drop wires. Cable supports

shall be fastened to concrete slabs, beams, joists or other structural members of

the building. Do not support MC cable on hung ceilings or on ceiling support

wires, or on HVAC ducts, piping, etc. The use of cable ties to support MC cable

is prohibited.

Support MC cable every 6 feet and within 1 foot of every box, panelboard, fitting,

or cable termination.

All MC cables passing through fire-rated walls or electrical/telecommunications

room walls shall be provided with a UL-listed, fire-rated penetration assembly.

Flexible Metal Conduit:

1.

CONDUIT

EMT or MC cable with insulated ground

Provide flexible metallic conduits for connections to motors, transformers, and

other electrical equipment when it is subject to movement, vibration,

misalignment, cramped quarters or where noise transmission is to be eliminated

or reduced. Do not use flexible non-metallic conduit. Flexible metallic conduit

shall be of the liquid-tight type when installed under any of the following

conditions:

260533 - 3

ROWAN UNIVERSITY

Design Guide

FINAL 2013

a.

b.

c.

d.

e.

f.

g.

h.

Exterior locations.

Moisture or humidity-laden atmospheres where it is possible for

condensation to accumulate.

Corrosive atmospheres.

Where water or spray due to wash-operations is frequent or possible.

Wherever there is a possibility of seepage or dripping of oil, grease or

water.

Connections to pumps.

Maximum allowable length is 6 feet.

Minimum allowable length for vibrating equipment is 18 inches.

J.

All other applications not specified herein, use RGS conduit.

K.

Paint all medium voltage conduit and junction boxes red and identify with voltage label.

CONDUIT

260533 - 4

You might also like

- Items - HabytDocument5 pagesItems - HabytHarsh VardhanNo ratings yet

- Trenwa Trench Catalog PDFDocument56 pagesTrenwa Trench Catalog PDFizallesNo ratings yet

- BMS WiringDocument2 pagesBMS WiringJaved BhattiNo ratings yet

- TP21 - BEC - DT - 0402 MAS For 11 KV Chiller Starter Panel Rev - 3 PDFDocument127 pagesTP21 - BEC - DT - 0402 MAS For 11 KV Chiller Starter Panel Rev - 3 PDFzeliteNo ratings yet

- Underground Duct Banks and Raceways - Electrical Design GuideDocument2 pagesUnderground Duct Banks and Raceways - Electrical Design GuideDaniel BolivarNo ratings yet

- 26 05 43 Underground Ducts and Raceways For Electrical SystemsDocument7 pages26 05 43 Underground Ducts and Raceways For Electrical SystemsjopaypagasNo ratings yet

- Overhead Conductor Installation Guide: Recommended PracticesDocument20 pagesOverhead Conductor Installation Guide: Recommended PracticesCarlos PlaceresNo ratings yet

- Guys and AnchorsDocument34 pagesGuys and AnchorsVijay Kumar0% (1)

- Hubbell Pole Line Hardware PDFDocument50 pagesHubbell Pole Line Hardware PDFGary LewisNo ratings yet

- Neutral Grounding Resistors: Installation and Maintenance InstructionsDocument7 pagesNeutral Grounding Resistors: Installation and Maintenance Instructionsks_ramachandra7017No ratings yet

- Conduit SpecificationDocument22 pagesConduit Specificationamijetomar08No ratings yet

- Mechanical Design of Overhead Lines PDFDocument70 pagesMechanical Design of Overhead Lines PDFEng-Ahmad Abo-AledousNo ratings yet

- Figure 1 - Motor Control CabinetDocument6 pagesFigure 1 - Motor Control CabinetJosé Vicente González VivasNo ratings yet

- Technical Manual 1Document118 pagesTechnical Manual 1Homero Silva100% (14)

- Types of Insulators: Pin Type InsulatorDocument11 pagesTypes of Insulators: Pin Type InsulatorGary M TrajanoNo ratings yet

- Checklist For 33kV DP Structure Design & DrawingDocument4 pagesChecklist For 33kV DP Structure Design & DrawingRupesh KhandekarNo ratings yet

- Transformer Bushings PDFDocument36 pagesTransformer Bushings PDFhashamNo ratings yet

- Practices For Grounding and Bonding of Cable Trays - EEPDocument5 pagesPractices For Grounding and Bonding of Cable Trays - EEPSaraswatapalitNo ratings yet

- 500KV CT Ca550 3000a PDFDocument3 pages500KV CT Ca550 3000a PDFHafiz Bilal AhmadNo ratings yet

- Line ErectionDocument14 pagesLine ErectionPrashant Trivedi100% (1)

- Insulators & TypesDocument48 pagesInsulators & Typesdilleh50% (2)

- Pole Design by PLS-POLE ProgramDocument5 pagesPole Design by PLS-POLE ProgramMohammed K. HayderNo ratings yet

- Engineered Wood ProductsDocument21 pagesEngineered Wood Productspppppp5No ratings yet

- CatalogDocument48 pagesCatalogAhmad AshrafNo ratings yet

- Desingconstructionof33kv11kvlines 150329033645 Conversion Gate01Document167 pagesDesingconstructionof33kv11kvlines 150329033645 Conversion Gate01Akshaya AroraNo ratings yet

- Simple Calculations For Pulling CableDocument6 pagesSimple Calculations For Pulling CableKatherine SalazarNo ratings yet

- Load Tables ASD K-SeriesDocument77 pagesLoad Tables ASD K-SeriesEnrique Olvera LaraNo ratings yet

- Anchor Bolt Tolerances PDFDocument1 pageAnchor Bolt Tolerances PDFwokeoooNo ratings yet

- Techinical Specifications Welcome To NescoDocument54 pagesTechinical Specifications Welcome To NescotejzabNo ratings yet

- Ingal Eps Utility Poles Brochure PDFDocument16 pagesIngal Eps Utility Poles Brochure PDFJosue HasbunNo ratings yet

- Airport Underground Electrical Duct Banks and ConduitsDocument8 pagesAirport Underground Electrical Duct Banks and ConduitsDevrim Gürsel0% (1)

- 4.0M Crusher Run Road: (200mm THK.) FFL +0.000mDocument1 page4.0M Crusher Run Road: (200mm THK.) FFL +0.000mAzree Mohd NoorNo ratings yet

- NPD 350 SQM Home Building PackageDocument10 pagesNPD 350 SQM Home Building Packageallenbc4512No ratings yet

- DG BusductDocument16 pagesDG BusductanandpurushothamanNo ratings yet

- BUILDING SERVICES IIQuestion BankDocument37 pagesBUILDING SERVICES IIQuestion BankSiva RamanNo ratings yet

- PLP - Dogbone Vibration DamperDocument5 pagesPLP - Dogbone Vibration DamperHFandino1100% (1)

- Buried Ring EarthingDocument2 pagesBuried Ring EarthingAshish KumarNo ratings yet

- Long-Life Xlpe Insulated Power Cable PDFDocument6 pagesLong-Life Xlpe Insulated Power Cable PDFbitconceptsNo ratings yet

- Vibration Dampers: Subject To Change Without NoticeDocument8 pagesVibration Dampers: Subject To Change Without NoticeWeber HahnNo ratings yet

- 16126Document13 pages16126uddinnadeemNo ratings yet

- High Mast Catalogue-CU PhoscoDocument44 pagesHigh Mast Catalogue-CU PhoscoGuha Arnab100% (3)

- CIVI 6051: Design of Industrial StructureDocument38 pagesCIVI 6051: Design of Industrial StructureZia MccollinNo ratings yet

- Electrical Canle Trench SpecificationDocument12 pagesElectrical Canle Trench SpecificationSumit Kumar DattaNo ratings yet

- High Mast CatalogueDocument16 pagesHigh Mast CatalogueAliz BnNo ratings yet

- Transmission LinesDocument18 pagesTransmission LinesfrimpongeNo ratings yet

- Dynamic Engineering Consultant Mina Al Arab Precinct - 5 MEP SpecificationDocument8 pagesDynamic Engineering Consultant Mina Al Arab Precinct - 5 MEP SpecificationBala Krishna GallaNo ratings yet

- Underground Duct Banks and Raceways - Electrical Design GuideDocument3 pagesUnderground Duct Banks and Raceways - Electrical Design GuideabhijitdadNo ratings yet

- 16110s01 Conduit and RacewayDocument3 pages16110s01 Conduit and RacewayVICTOR JOSE VILORIANo ratings yet

- Facility ManagementDocument7 pagesFacility ManagementTajudeen IbrahimNo ratings yet

- SEWA Regulations For Electrical ConnectionDocument5 pagesSEWA Regulations For Electrical Connectionkidscv10No ratings yet

- Electrical Work Procedure Manual: A Novoue Solutions Inc. PropertyDocument20 pagesElectrical Work Procedure Manual: A Novoue Solutions Inc. Propertyeric maestroNo ratings yet

- RC SpecDocument1 pageRC SpecPraveenNo ratings yet

- Scope: Lectrical Aterials and EthodsDocument9 pagesScope: Lectrical Aterials and EthodsAnonymous uXEdLjNo ratings yet

- Section 260526 - Grounding and Bonding For Electrical SystemsDocument6 pagesSection 260526 - Grounding and Bonding For Electrical SystemsVCNo ratings yet

- DG260543Document7 pagesDG260543Ahmed OsamaNo ratings yet

- LV Cable InstallationDocument20 pagesLV Cable Installationkailasamvv100% (1)

- TESP11920R0 LV Raceways & Cable InstallationDocument20 pagesTESP11920R0 LV Raceways & Cable InstallationPERVEZ AHMAD KHANNo ratings yet

- U W Electrical Raceways: Engineering Services Facility Design InformationDocument4 pagesU W Electrical Raceways: Engineering Services Facility Design InformationAhmed EzzatNo ratings yet

- 26 05 26 User-Grounding and BondingDocument5 pages26 05 26 User-Grounding and BondingFaheem PP13No ratings yet

- Design Condition For Earthing SystemDocument4 pagesDesign Condition For Earthing SystemRashad SarwarNo ratings yet

- Duct BankDocument7 pagesDuct BankAwotiku AbimbolaNo ratings yet

- Wiring Methods and Materials - Engr. MahusayDocument77 pagesWiring Methods and Materials - Engr. Mahusayron villanuevaNo ratings yet

- !-Bab 02 Moulded Case Circuit Breaker (MCCB)Document38 pages!-Bab 02 Moulded Case Circuit Breaker (MCCB)zeliteNo ratings yet

- Rowan University Design Guide 2013Document4 pagesRowan University Design Guide 2013zeliteNo ratings yet

- Wearing of BSP Uniform and Office Attire PDFDocument1 pageWearing of BSP Uniform and Office Attire PDFzeliteNo ratings yet

- Rowan University Design Guide 2013Document3 pagesRowan University Design Guide 2013zeliteNo ratings yet

- Rowan University Design Guide 2013Document10 pagesRowan University Design Guide 2013zeliteNo ratings yet

- Rowan University Design Guide 2013Document2 pagesRowan University Design Guide 2013zeliteNo ratings yet

- Rowan University Design Guide 2013Document1 pageRowan University Design Guide 2013zeliteNo ratings yet

- Le-Corbusier (Chandigarh and Radiant City) : Presented byDocument72 pagesLe-Corbusier (Chandigarh and Radiant City) : Presented byABHISHEK MAHARJANNo ratings yet

- Concrete Sheet Pile Drawing PDFDocument4 pagesConcrete Sheet Pile Drawing PDFsurangaNo ratings yet

- Metal Truss With AtticDocument2 pagesMetal Truss With AtticManojNo ratings yet

- StructuralDocument14 pagesStructuralGigi YouNo ratings yet

- Japanese Urban Artificial Islands An Overview of Projects and Schemes For Marine Cities During 1960-1990sDocument10 pagesJapanese Urban Artificial Islands An Overview of Projects and Schemes For Marine Cities During 1960-1990sAnkita Roy ChowdhuryNo ratings yet

- Roof ArchitionalDocument124 pagesRoof ArchitionalRusscel MarquesesNo ratings yet

- Pds Honel Brochure 2022Document5 pagesPds Honel Brochure 2022aj.chat.gpt.coderNo ratings yet

- Renfrew Renfrew Floor PlanDocument1 pageRenfrew Renfrew Floor PlanLauraNo ratings yet

- Viktor Kovcic - Planning Kaptol Area, 1908, Zlatko JuricDocument18 pagesViktor Kovcic - Planning Kaptol Area, 1908, Zlatko JuricDorian VujnovićNo ratings yet

- Foreword: GP1 Principles of Measurement GP2 Bills of QuantitiesDocument8 pagesForeword: GP1 Principles of Measurement GP2 Bills of QuantitiesEren ArslanNo ratings yet

- WS TDG 08 Stairs Balustrades Handrails 11-20Document56 pagesWS TDG 08 Stairs Balustrades Handrails 11-20ifc saigon oneNo ratings yet

- RUET Architecture BuildingDocument26 pagesRUET Architecture BuildingNamrata Sarkar Tapti100% (1)

- Master List of Codes / Standards: Sr. No. Code/ Standards Year of Revision / EditionDocument20 pagesMaster List of Codes / Standards: Sr. No. Code/ Standards Year of Revision / Editionpiyu114No ratings yet

- Edoc - Pub - en Code 203 en PDFDocument375 pagesEdoc - Pub - en Code 203 en PDFAbishek NagarajNo ratings yet

- Group 3 - Review of PlanningDocument96 pagesGroup 3 - Review of PlanningAngela LeonardoNo ratings yet

- The Unexpectedly Tropical History of Brutalism PDFDocument14 pagesThe Unexpectedly Tropical History of Brutalism PDFakshayNo ratings yet

- G.A, Foundation & Assembly Drawing - CPS R0-13.06.23Document6 pagesG.A, Foundation & Assembly Drawing - CPS R0-13.06.23newattelectricNo ratings yet

- Sample Drawings 5Document9 pagesSample Drawings 5Sherwin DominguezNo ratings yet

- Allowable VOC Content For LEEDDocument5 pagesAllowable VOC Content For LEEDreemadeponNo ratings yet

- Layan Adoul - Compressed PortfolioDocument17 pagesLayan Adoul - Compressed Portfoliocw2tpvngg9No ratings yet

- Laurie Baker: - The Hassan Fathy of India'Document14 pagesLaurie Baker: - The Hassan Fathy of India'Arnav DasaurNo ratings yet

- DBM OfficeDocument76 pagesDBM OfficeSrija RoyNo ratings yet

- RFI, Pour Cards DataDocument58 pagesRFI, Pour Cards DataSandip PaulNo ratings yet

- Policarpio - BGT 5 - Research No.2Document21 pagesPolicarpio - BGT 5 - Research No.2Tracy PolicarpioNo ratings yet

- P5 Final Report Margarita Gancayco Barcia 5064902Document131 pagesP5 Final Report Margarita Gancayco Barcia 5064902James Edward DonguyaNo ratings yet

- Civil Guruji EstimationDocument122 pagesCivil Guruji EstimationEshwar Prasad100% (2)

- E-Book On Jain ArchitectureDocument13 pagesE-Book On Jain ArchitectureChaarvee BevaraNo ratings yet

- 2017.07.28 - R1 - Technical Specification Accept - Ver.1.7 Clean - Ok ASD, VOL 3 PDFDocument211 pages2017.07.28 - R1 - Technical Specification Accept - Ver.1.7 Clean - Ok ASD, VOL 3 PDFVitali MihalachiNo ratings yet

- Annexes PDFDocument89 pagesAnnexes PDFnathNo ratings yet