Professional Documents

Culture Documents

Kelly Spinner

Kelly Spinner

Uploaded by

ardserOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kelly Spinner

Kelly Spinner

Uploaded by

ardserCopyright:

Available Formats

OIL WORKS, INC.

P.O. BOX 69170

2416 FM 1936

ODESSA, TEXAS 79769

TEL (800) 531-3273

FAX (432) 381-7526

WWW.OILWORKSINC.COM

OILWORKSINC@OILWORKSINC.COM

Model OWI 1500

Kelly Spinner

z

z

z

z

Variable Speed Control

Tapered Roller Bearing

Set In Upper Bearing

Carrier

Radial Bearing In Lower

Bearing Carrier

OWI Turbine Air Motors

Solid Steel Machined

Housing

Replaceable Seal

Sleeves

Totally Sealed Capsule

PATENT #6,619,389 B1

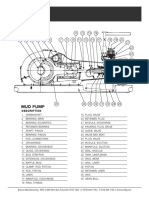

OWI 1500 KELLY SPINNER

PARTS LIST

ITEM #

1

2a

2b

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

50

51

52

53

54

56

61

62

63

64

65

66

68

71

73

77

78

79

81

83

84

85

86

STOCK #

1KS0001

1KS0920

1KS0917

1KS0901

1KS0003

1KS0903

1KS0004

1KS0017

1KS0006

1KS0007

1KS0008

1KS0009

1KS0010

1KS0011

1KS0904

1KS0012

1KS0905

1KS0013

1KS0906

1KS0014

1KS0907

1KS0015

1KS0957

1KS0958

1KS0931

1KS0909

1KS0932

1KS0933

1KS0933

1KS0933

1KS0932

1KS0934

1KS0934

1KS0910

1KS0911

1KS0912

1KS0914

1KS0937

1KS0939

1KS0938

1KS0952

1KS0953

1KS0944

1KS0948

1KS0950

1KS0956

1KS0949

1KS0955

1KS0954

1KS0915

1KS0946

1KS0941

1KS0947

1KS0945

1KS0016

1KS0018

1KS0019

1KS0951

1KS0951

1KS0908

1KS0935

1KS0936

1KS0021

1KS0981

1KS0943

1KS0980

1KS0978

1KS0913

1KS0902

1KS0940

1KS0942

1KS0985

DESCRIPTION

STEM, 46"

STARTER, RH183

STARTER, LH73

NEOPRENE SHEILD

CAP, TOP BRG

RACE, TOP CARRIER BRG

CARRIER, TOP BRG

SLEEVE, SEAL (LAB SEAL TO GREASE SEAL

SEAL, LAB SLEEVE

HOUSING, TOP

HOUSING, LOWER

GEAR, RING

GEAR, HUB

CARRIER, LOWER BRG

BRG, LOWER CARRIER RADIAL

CAP, LOWER BRG

SEAL, LOWER OIL

SLEEVE, LOWER SEAL

SEAL, MIDDLE OIL

SLEEVE, MIDDLE SEAL

SEAL, TOP OIL

SLEEVE, TOP SEAL

ZERK, 1/8" GREASE

ZERK, 1/8" RELIEF

SHIM SET

RING, SPIROLOX SNAP

BOLT, TOP BRG CAP

BOLT, TOP BRG CARRIER

BOLT, HOUSING

BOLT, LOWER BRG CARRIER

BOLT, LOWER BRG CAP

BOLT, RING GEAR

BOLT, TURBINE MOTOR

VALVE, RELAY

VALVE, PILOT

BRACKET, PILOT VALVE

THROTTLE, CONTROL VALVE

AIR LINE, THROTTLE

AIR LINE, BREAK-OUT

AIR LINE, MAKE-UP

HOSE, AIR SUPPLY

HOSE, LH73 MOTOR SUPPLY

ADAPTER, 90 DEGREE

ADAPTER, STRAIGHT

HOSE, LH73 AIR SUPPLY BENDIX

TEE

ELL, 90 DEGREE

NIPPLE, CLOSE

NIPPLE, 2"

STRAINER, "Y"

ADAPTER, RELAY HOSE

ADAPTER, AIR LINE

ADAPTER, RELAY VALVE

ADAPTER, PILOT HOSE

LUG, TOP HOUSING

KEY,SHAFT

BRACKET, GREASE HOSE

HOSE, RH183 AIR SUPPLY BENDIX

HOSE, GREASE

SEAL, LAB REPLACEMENT OIL

BOLT, LUG

WASHER, LUG BOLT

TAG,KELLY SPINNER

RING,TOP BEARING RETAINING

ADAPTER, 45 DEGREE

BOLT, LUG

BOLT, LUG

SCREW, PILOT VALVE BRACKET

BRG, TOP CARRIER, SET

EYE, LIFTING

ADAPTER, AIR LINE

HOSE, RH183 MOTOR SUPPLY

PART #

QTY

15011

15012-183

15012-73L

15013

15014

SEE #83

15016

15069

15018

15019

15020

15021

15022

15023

15024

15025

15026

15027

15028

15029

15030

15031

15032

15033

15034

15035

15036

15037

15038

15039

15040

15041

15042

15043

15044

15045

15046

15047

15049

15048

15050

15051

15052

15053

15054

15055

15056

15057

15058

15060

15061

15062

15063

15064

15066

15071

15072

15073

15073

15074

15075-3 1/2

15076

15079

15081

15087

15075-1 1/4

15075-3

15086

15015-A

15077

15088

15085

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

1

1

8

6

8

8

8

6

6

2

1

2

1

1

1

1

1

2

1

2

1

1

2

2

4

1

2

2

2

1

2

1

1

1

1

1

4

4

1

1

2

4

4

4

2

2

1

1

AIR SUPPLY FOR KELLY SPINNER

A MINIMUM 2 AIR SUPPLY LINE SHOULD BE INSTALLED ALONG SIDE THE MUD

STANDPIPE. AT THE TOP OF THE STANDPIPE THE 2 NEEDS TO BE REDUCED TO 1.

THE 1 HOSE IS RUN DOWN THE ROTARY HOSE TO THE KELLY SPINNER Y

STRAINER.

INSTALLATION OF THE HAND THROTTLE CONTROL VALVE AND

PILOT AIR LINES

THE CONTROL VALVE SHOULD BE MOUNTED IN THE DRILLERS CONSOLE AND A

LUBRICATOR INSTALLED IN THE SUPPLY LINE OF THE VALVE. THE THREE

CONTROL LINES SHOULD BE FASTENED TO THE 2 STANDPIPE AND RUN UP THE

DERRICK AND DOWN THE ROTARY HOSE THEN CONNECTED TO THE KELLY

SPINNER. IF HARD LINES ARE USED TO RUN THE CONTROL LINES UP THE

DERRICK, 1/8 OR PIPE SHOULD BE USED. THE SMALLER THE LINES THE

BETTER CONTROL YOU WILL HAVE OF THE KELLY SPINNER.

INSTALLATION OF THE KELLY SPINNER

THE KELLY SPINNER IS MADE UP BETWEEN THE SWIVEL STEM AND THE KELLY

VALVE. THE TURNBUCKLES ARE ATTACHED TO THE SWIVEL ACCORDING TO

THE DRAWING FURNISHED. THE TURNBUCKLES SHOULD BE CROSSED, NEVER

STRAIGHT UP AND DOWN.

NOTE: BEFORE CONNECTING THE AIR LINES AND CONTROL LINES TO THE KELLY

SPINNER, BLOW SUFFICIENT AIR THROUGH THEM TO REMOVE ANY FOREIGN

MATTER THAT COULD GET INTO THE KELLY SPINNER.

UPON INSTALLATION OF THE KELLY SPINNER, GREASE THE TOP AND BOTTOM

BEARING HOUSINGS WITH ALL-PURPOSE WATER REPELLENT GREASE. GREASE

ZERK FITTINGS ARE LOCATED ON THE TOP AND BOTTOM SEAL RETAINERS.

THERE ARE GREASE RELIEFS OPPOSITE THE GREASE ZERKS (AT THE BOTTOM OF

THE TOP BEARING CARRIER ON LATER MODELS). IT IS BEST TO TURN THE

ROTARY TABLE WHILE GREASING THE KELLY SPINNER. SOME LATER MODELS

HAVE A GREASE HOSE INSTALLED ON THE TOP SEAL RETAINER. THIS HOSE

LEADS DOWN TO THE BOTTOM OF THE KELLY SPINNER AND IS ATTACHED TO A

LOWER HOUSING BOLT. THIS HOSE MAKES IT EASIER TO GREASE THE TOP

BEARING WHILE DRILLING. DO NOT EVER REMOVE OR PLUG ANY GREASE

RELIEFS. THIS WILL PRESSURIZE THE BEARING CAVITY AND CAUSE

INTERNAL SEAL DAMAGE.

AIR PRESSURE ADJUSTMENTS CAN BE MADE AT THE HAND THROTTLE CONTROL

VALVE TO LIMIT THE MAXIMUM TORQUE OUTPUT OF THE KELLY SPINNER TO

THE DESIRED LEVEL. THE RECOMMEMDED PRESSURE FOR THE GEAR REDUCED

MOTOR IS 80 PSI.

TROUBLE SHOOTING GUIDE

IN CASES WHERE THE KELLY SPINNER MOTOR DOES NOT WORK OR STAYS ON,

THE MOST COMMON PROBLEM IS THE RELAY VALVE. THE MOST FREQUENT

CAUSE IS FOREIGN MATTER COMING THROUGH THE CONTROL LINE.

DISASSEMBLE THE RELAY VALVE AND CLEAN IT OF ANY FOREIGN MATTER AND

REASSEMBLE. DISCONNECT THE AIR LINES AND BLOW AIR THROUGH THEM AND

REATTACH.

IF THE KELLY SPINNER SEEMS TO LOSE POWER OR BECOME WEAK, DISASSEMBLE

AND CLEAN THE Y STRAINER. THIS Y STRAINER SHOULD BE CLEANED

PERIODICALLY FOR PREVENTATIVE MAINTENANCE. IF THE RING GEAR HAS

BEEN DAMAGED IT CAN BE REPLACED BY TURNING THE SPINNER OVER AND

REMOVING THE CAP SCREWS FROM THE LOWER PLATE. LIFT THE LOWER

PLATE AND BEARING CARRIER OVER THE PIN END OF THE SUB. REMOVE THE 5/8

CAP SCREWS HOLDING THE RING GEAR ON TO THE STEM. THERE ARE THREADED

HOLES IN THE RING GEAR TO USE AS PUSHER HOLES. TAKE THE TWO CAP

SCREWS THAT HOLD THE RING GEAR ON, PUT THEM IN THE THREADED HOLES

AND PUSH THE RING GEAR OFF. IT WILL TAKE A SMALL AMOUNT OF HEAT ON

THE NEW RING GEAR TO BE ABLE TO INSTALL IT ON THE STEM. REINSTALL THE

5/8 CAP SCREWS IN THE RING GEAR THEN INSTALL THE LOWER BEARING

HOUSING AND PLATE OVER THE PIN OF THE SPINNER. REINSTALL THE CAP

SCREWS IN THE LOWER HOUSING. NOTE: RE TIE-WIRE ALL CAP SCREWS ON

THE SPINNER. NO BEARING ADJUSTMENT IS NEEDED.

OPERATION OF THE KELLY SPINNER

THE OWI 1500 KELLY SPINNER IS DESIGNED TO OPERATE AT VARIABLE SPEEDS.

WHEN YOU ENGAGE THE THROTTLE IN THE FORWARD POSITION DO NOT

RETURN TO NEUTRAL UNTIL THE KELLY IS MADE UP TO THE DESIRED

POSITION. YOU CAN REDUCE OR INCREASE SPEED WITH THE THROTTLE BUT

ONCE THE THROTTLE VALVE IS RETURNED TO THE NEUTRAL POSITION DO NOT

RE-ENGAGE THE THROTTLE VALVE FOR 20 TO 30 SECONDS. THE TURBINE AIR

MOTOR TURNS IN EXCESS OF 20,000 RPM AND MUST BE GIVEN AMPLE TIME TO

STOP BEFORE RE-ENGAGING, OR PINION AND MOTOR DAMAGE CAN OCCUR.

You might also like

- Swivel Tool CatalogDocument16 pagesSwivel Tool CatalogVishal RamsookNo ratings yet

- Manual F 1300 1600Document71 pagesManual F 1300 1600Camilo Sanchez VanegasNo ratings yet

- SOP 829-009 Nipple Up BOPs.Document2 pagesSOP 829-009 Nipple Up BOPs.Anonymous XbmoAFtINo ratings yet

- 1625 de Das 001Document7 pages1625 de Das 001Leonardo Alvarez100% (1)

- B+V ELEVATOR Slip Type BVT Tubing VS11 A4Document2 pagesB+V ELEVATOR Slip Type BVT Tubing VS11 A4AhmedNo ratings yet

- HH-Rotary Table ZP175 - ZP205 PDFDocument3 pagesHH-Rotary Table ZP175 - ZP205 PDFYosed L SantosNo ratings yet

- Parts List EMI 450Document185 pagesParts List EMI 450Mauricio Garcia100% (1)

- Manual Spider Varco 750Document38 pagesManual Spider Varco 750JAVIER EDUARDO MANTILLA BUITRAGONo ratings yet

- Drillmec Hydraulic Drilling Rig Package Model Hh300: Price: Please Contact Mr. Tommaso BrovelliDocument2 pagesDrillmec Hydraulic Drilling Rig Package Model Hh300: Price: Please Contact Mr. Tommaso Brovellidave_88140% (1)

- USS Flat Washer Size ChartDocument1 pageUSS Flat Washer Size ChartardserNo ratings yet

- Eastar SpecificationsDocument2 pagesEastar SpecificationsUmar ShamsudinNo ratings yet

- Sintef A17034 Organisational Accidents and Resilience Organisations Six Perspectives. Revision 2 PDFDocument143 pagesSintef A17034 Organisational Accidents and Resilience Organisations Six Perspectives. Revision 2 PDFAparupa KarNo ratings yet

- DG450 HOOK 大钩: Parts List 5-B)Document8 pagesDG450 HOOK 大钩: Parts List 5-B)waleed100% (1)

- M3036 Block 5861Document21 pagesM3036 Block 5861Gregory StewartNo ratings yet

- Bha HandlingDocument7 pagesBha HandlingAbdul Hameed OmarNo ratings yet

- Canrig TM80/120 SpecsDocument16 pagesCanrig TM80/120 Specsaris4silveyraNo ratings yet

- Doc. 20-1715 Rev D (9/12/1005) Pneumatic Spider Operating Procedure ManualDocument12 pagesDoc. 20-1715 Rev D (9/12/1005) Pneumatic Spider Operating Procedure ManualGregory StewartNo ratings yet

- SEC5 (1) WashpipeDocument22 pagesSEC5 (1) WashpipeCarlos Alberto PerdomoNo ratings yet

- Deadline Anchors BrochureDocument3 pagesDeadline Anchors Brochurejlmunozv100% (3)

- DG450 Hook Operation ManualDocument11 pagesDG450 Hook Operation ManualHala Dawod100% (3)

- 7.6 SingleDocument226 pages7.6 Singlewuillian barretoNo ratings yet

- Mud Gas Separator Poor Boy Degasser - Well Control - Netwas Group OilDocument6 pagesMud Gas Separator Poor Boy Degasser - Well Control - Netwas Group OilJUAN JOSE VESGA RUEDANo ratings yet

- D-GASSERS Orizontal + Vertical PDFDocument2 pagesD-GASSERS Orizontal + Vertical PDFciucalata880% (1)

- Swaco' Style Drilling Choke PartsDocument1 pageSwaco' Style Drilling Choke PartsBodega 3001No ratings yet

- Cameron EB 555 D Rev U2 - VBR Engineering InfoDocument6 pagesCameron EB 555 D Rev U2 - VBR Engineering InfoCanrig Ramde100% (1)

- Ym16-Ii-00 Hydraulic Cathead 液压猫头: Parts List (4-C)Document7 pagesYm16-Ii-00 Hydraulic Cathead 液压猫头: Parts List (4-C)waleedNo ratings yet

- Series 5000B4 Manual - Revision D 12 30 2010Document16 pagesSeries 5000B4 Manual - Revision D 12 30 2010mektroNo ratings yet

- TDS-11SA Rig Up ChecklistDocument2 pagesTDS-11SA Rig Up Checklistluis lopezNo ratings yet

- Nexans - TDS Service LoopsDocument4 pagesNexans - TDS Service LoopsPrejit Radhakrishna100% (1)

- CLE14000DPcerev9 09 PDFDocument139 pagesCLE14000DPcerev9 09 PDFAdhie WaelacxhNo ratings yet

- Cameron Type Choke ManualDocument12 pagesCameron Type Choke ManualParag Padole100% (1)

- Drilling Tools PDFDocument76 pagesDrilling Tools PDFIssamNo ratings yet

- 06b AppendixB2 (1000HPRig) 1582535891879Document103 pages06b AppendixB2 (1000HPRig) 1582535891879Harsh TiwariNo ratings yet

- Cobra Kcobra MCDocument2 pagesCobra Kcobra MCEd CalheNo ratings yet

- Mast and Dwks Raising ChecklistDocument4 pagesMast and Dwks Raising Checklistjinyuan74No ratings yet

- Koomy UnitDocument2 pagesKoomy UnitBeni N SoloNo ratings yet

- FKDQ8007 User ManualDocument24 pagesFKDQ8007 User ManualbrasgNo ratings yet

- Dies & Inserts Catalog 2018 PDFDocument35 pagesDies & Inserts Catalog 2018 PDFJuan David Fuentes100% (1)

- List Sparepart MI-SWACO Shale ShakerDocument23 pagesList Sparepart MI-SWACO Shale ShakerahnafNo ratings yet

- DG450 Hook Parts ListDocument8 pagesDG450 Hook Parts ListHala Dawod50% (2)

- HH-Travling BlockDocument3 pagesHH-Travling Blockabdi rachman100% (2)

- 980 Catwalk Broch 2014 v10 FINALDocument6 pages980 Catwalk Broch 2014 v10 FINALtictacalNo ratings yet

- Den Con 2009 2010 CatalogDocument36 pagesDen Con 2009 2010 CatalogAdrian Cantaragiu100% (1)

- Baker SPDDocument49 pagesBaker SPDWilliamNo ratings yet

- Bentec Mud Pump T-1600-Ac - 130209Document2 pagesBentec Mud Pump T-1600-Ac - 130209leo100% (2)

- Instructions For The Safe Use of P-Quip Liner Retention Systems - Pt. No. 80000111 Revision Date August 9, 2006Document7 pagesInstructions For The Safe Use of P-Quip Liner Retention Systems - Pt. No. 80000111 Revision Date August 9, 2006Heri VillaNo ratings yet

- 11"-5000psi Double Ram BOP ManualDocument64 pages11"-5000psi Double Ram BOP ManualDavid EskarousNo ratings yet

- Contitech HP HosesDocument65 pagesContitech HP HosesRobert FlateråsNo ratings yet

- F-1600 Triplex Pump 泥浆泵: Parts List 6-A)Document27 pagesF-1600 Triplex Pump 泥浆泵: Parts List 6-A)waleedNo ratings yet

- No. JJ450/45-K Mast Parts List JJ745406-00 Item No. Description Qu. RemarkDocument3 pagesNo. JJ450/45-K Mast Parts List JJ745406-00 Item No. Description Qu. RemarkShaikh Sabir HussainNo ratings yet

- Cameron Manual Type F FCDocument7 pagesCameron Manual Type F FCEnrique HortaNo ratings yet

- SJ Petro-ZJ40 Truck-Mounted Drilling RigDocument58 pagesSJ Petro-ZJ40 Truck-Mounted Drilling Rigchtoil2020No ratings yet

- NOV Elevator Link CompatibilityDocument2 pagesNOV Elevator Link CompatibilityisamelgqNo ratings yet

- Horizontal Vacuum D-GasserDocument2 pagesHorizontal Vacuum D-Gasseremiliano100% (1)

- Ton Torque ManometrosDocument16 pagesTon Torque ManometrosEliecer DiazNo ratings yet

- Sub-X: Wellhead & BOP GasketsDocument2 pagesSub-X: Wellhead & BOP GasketsEugene EvgerNo ratings yet

- Valve Seat Inspection and LappingDocument3 pagesValve Seat Inspection and LappingCristian BoselliNo ratings yet

- 801 I.1.3 Man Rider Winch Product Maintenance InformationDocument14 pages801 I.1.3 Man Rider Winch Product Maintenance InformationPedro SanchezNo ratings yet

- Catalogo Ramde ColombiaDocument16 pagesCatalogo Ramde ColombiaSharay Villanova100% (1)

- Access - Air Kelly Spinner Manual PDFDocument9 pagesAccess - Air Kelly Spinner Manual PDFadjoudj100% (1)

- Series 600: Globe Style Sizes 3 Through 42 InchesDocument8 pagesSeries 600: Globe Style Sizes 3 Through 42 Inchesrizviabbas2012No ratings yet

- 2009 BBM Service ManualDocument43 pages2009 BBM Service ManualjgokeyNo ratings yet

- 7-11 Endurance Racer-Cycleworld Dec 88Document11 pages7-11 Endurance Racer-Cycleworld Dec 88Matheus Zambon MenezesNo ratings yet

- Bronco Schematic Mud PumpsDocument1 pageBronco Schematic Mud PumpsardserNo ratings yet

- Bronco Schematic Drawworks PDFDocument1 pageBronco Schematic Drawworks PDFardserNo ratings yet

- Bronco Schematic Brake Systems PDFDocument1 pageBronco Schematic Brake Systems PDFardserNo ratings yet

- Us4696377 PDFDocument9 pagesUs4696377 PDFardserNo ratings yet

- Bronco Schematic DrawworksDocument1 pageBronco Schematic DrawworksardserNo ratings yet

- Instruction Manual Safety Principles, Operation and Maintenance For Travelling Chain BlocksDocument26 pagesInstruction Manual Safety Principles, Operation and Maintenance For Travelling Chain BlocksardserNo ratings yet

- 2008 NHSTES Program WebDocument6 pages2008 NHSTES Program WebardserNo ratings yet

- InfoMant ProductSheet enDocument1 pageInfoMant ProductSheet enardserNo ratings yet

- Measurement and Analysis in The Well: Logging, Permits Real-Time Detection of The Presence ofDocument18 pagesMeasurement and Analysis in The Well: Logging, Permits Real-Time Detection of The Presence ofardserNo ratings yet

- 5708ac8a280ba67b8efedbe40b7217fbDocument424 pages5708ac8a280ba67b8efedbe40b7217fbardserNo ratings yet

- Drilling Rig Components Illustration - Komponen Utama PemboranDocument86 pagesDrilling Rig Components Illustration - Komponen Utama PemboranPuji LestariNo ratings yet

- Welcome To The VHDL LanguageDocument399 pagesWelcome To The VHDL LanguageardserNo ratings yet

- VHDL CompDocument46 pagesVHDL CompardserNo ratings yet

- E4nb71 PDFDocument99 pagesE4nb71 PDFtambache69100% (1)

- 4 Quarter Performance Task in Statistics and ProbabilityDocument5 pages4 Quarter Performance Task in Statistics and ProbabilitySHS Panaguiton Emma Marimel HUMSS12-ANo ratings yet

- Item Wise Rate TenderDocument5 pagesItem Wise Rate TenderB-05 ISHA PATELNo ratings yet

- Lesson Plan in Science 1.3Document38 pagesLesson Plan in Science 1.3Heidi Dalyagan DulnagonNo ratings yet

- Process Flow ChartDocument22 pagesProcess Flow ChartKumar Ashutosh100% (1)

- Verizon Wiretapping - Comments in Support of MR Cowie's ComplaintDocument8 pagesVerizon Wiretapping - Comments in Support of MR Cowie's ComplaintireportNo ratings yet

- StaircasesDocument11 pagesStaircasesatiNo ratings yet

- Razones de CambioDocument1 pageRazones de CambioCarlos FloresNo ratings yet

- Parts List: JTR-MOL254/LBADocument74 pagesParts List: JTR-MOL254/LBAJoseNo ratings yet

- Iso 7966 1993Document11 pagesIso 7966 1993Sci KelayNo ratings yet

- Grade 7 Quizzes q1w7Document2 pagesGrade 7 Quizzes q1w7api-251197253No ratings yet

- UPS Technical Data Sheet (MS-DD-SAP01-ELE-DS-0015 - Rev2)Document6 pagesUPS Technical Data Sheet (MS-DD-SAP01-ELE-DS-0015 - Rev2)Muhammad YusufNo ratings yet

- Soal Uas Ganjil SMK XiDocument2 pagesSoal Uas Ganjil SMK Xibondan iskandarNo ratings yet

- DMA Actuator Drives For - Motorised Butterfly Valve DMK - Motorised Throttle DMLDocument8 pagesDMA Actuator Drives For - Motorised Butterfly Valve DMK - Motorised Throttle DMLemil_88No ratings yet

- Linear Programming TheoryDocument104 pagesLinear Programming Theorykostas_ntougias5453No ratings yet

- 6501i-8001i Manual de Servicio r5Document1,126 pages6501i-8001i Manual de Servicio r5marco102167% (3)

- Risk Assessment On Temperature and Relative Humidity Deviation During On-Going Stability StudiesDocument2 pagesRisk Assessment On Temperature and Relative Humidity Deviation During On-Going Stability StudiesAAAAAAAAAAAAAAAAAAAA ANo ratings yet

- Manual de Partes-HISTER 9 Ton.Document556 pagesManual de Partes-HISTER 9 Ton.Juan PabloNo ratings yet

- William James - PsychologistDocument5 pagesWilliam James - PsychologistCecilia SusaiNo ratings yet

- The Spirit of Jugaad / Bricolage For Enhanced Corporate EntrepreneurshipDocument20 pagesThe Spirit of Jugaad / Bricolage For Enhanced Corporate EntrepreneurshippanditpreachesNo ratings yet

- AMRITA EXAM DatesheetDocument9 pagesAMRITA EXAM DatesheetSARRALLE EQUIPMENT INDIA PVT LTDNo ratings yet

- Internship Report - AmtechDocument31 pagesInternship Report - AmtechRahil ShahNo ratings yet

- Module 5 in Eed 114: ReviewDocument6 pagesModule 5 in Eed 114: ReviewYvi BenrayNo ratings yet

- On Arushi Murder CaseDocument8 pagesOn Arushi Murder Case0000No ratings yet

- Exercise Oracle Forms 6i TrainingDocument5 pagesExercise Oracle Forms 6i TrainingFarooq Shahid100% (1)

- Fire and Gas PhilosophyDocument19 pagesFire and Gas PhilosophyOmar TocmoNo ratings yet

- 13.4.2 WBS 6.6 Cerberus Corperation Case Study Managing Stakeholder ConflictDocument7 pages13.4.2 WBS 6.6 Cerberus Corperation Case Study Managing Stakeholder ConflictJorge Alejandro Betancur JaramilloNo ratings yet

- Analiza C. Cortes 20 ItemsDocument6 pagesAnaliza C. Cortes 20 ItemsEngel AlardeNo ratings yet