Professional Documents

Culture Documents

Early Thermal Cracking

Early Thermal Cracking

Uploaded by

sudhir12345Copyright:

Available Formats

You might also like

- API 571 SummaryDocument7 pagesAPI 571 Summaryzackyat7976100% (1)

- Three Point Bending Test: Experiment No 1Document9 pagesThree Point Bending Test: Experiment No 1Manjunatha Babu N.sNo ratings yet

- Ruj.: Kod: Subjek: No Helaian: Ruj. Lukisan: Disemak Tarikh: Direkabentuk Oleh: ProjekDocument5 pagesRuj.: Kod: Subjek: No Helaian: Ruj. Lukisan: Disemak Tarikh: Direkabentuk Oleh: ProjekHafiz Budean RahmanNo ratings yet

- Design Example 5 - Pad Base - Axial Load Plus Bending Moment (Small Eccentricity)Document5 pagesDesign Example 5 - Pad Base - Axial Load Plus Bending Moment (Small Eccentricity)nuwan010% (1)

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- ES - Crack Width CalculationDocument2 pagesES - Crack Width CalculationprabhuNo ratings yet

- Irrigation Division Chunar, Mirzapur: Design of Parapet Wall at Top of Jirgo DamDocument4 pagesIrrigation Division Chunar, Mirzapur: Design of Parapet Wall at Top of Jirgo Damgovind narayan ShuklaNo ratings yet

- Concrete Filled Steel Pipe DesignDocument23 pagesConcrete Filled Steel Pipe DesignahsanmohNo ratings yet

- 3 EC4-2 Background Gerhard HanswilleDocument67 pages3 EC4-2 Background Gerhard Hanswilleantonio111aNo ratings yet

- LECTURE2 Shear ConnectionDocument36 pagesLECTURE2 Shear ConnectionMahmoud A SalamaNo ratings yet

- Lecture 7ADocument32 pagesLecture 7AAnonymous 37iyUV5No ratings yet

- Design of Column BasesDocument9 pagesDesign of Column Basesdarshanakp100% (1)

- RCC Beam With Different Choice of Design WSD For Singly & Doubly ReinforcementDocument5 pagesRCC Beam With Different Choice of Design WSD For Singly & Doubly ReinforcementdsanandaNo ratings yet

- Module 6 Bridge Engineering BatchDocument120 pagesModule 6 Bridge Engineering BatchKrish Chand100% (3)

- Prestress End Block Design To CIRIADocument3 pagesPrestress End Block Design To CIRIAbalamurugan25011990100% (1)

- Bridge Design v1.1 enDocument186 pagesBridge Design v1.1 enGaurav GhaiNo ratings yet

- Typical Wall ReinforcementDocument3 pagesTypical Wall ReinforcementMichelle TaiNo ratings yet

- Piling Practices Under Eurocode 7 (Contractor Point of View) PDFDocument42 pagesPiling Practices Under Eurocode 7 (Contractor Point of View) PDFBatu GajahNo ratings yet

- Sample of Design BriefDocument17 pagesSample of Design BriefshingkeongNo ratings yet

- Dynamic Calculation For Retaining WallDocument6 pagesDynamic Calculation For Retaining WallSabrina ImloulNo ratings yet

- Ramset Specifiers Anchoring Resource Book ANZ - TruBolt Mechanical AnchoringDocument10 pagesRamset Specifiers Anchoring Resource Book ANZ - TruBolt Mechanical AnchoringjlolhnpNo ratings yet

- Eurocode - Load Combinations For Steel Structures - R1Document26 pagesEurocode - Load Combinations For Steel Structures - R1anil97232No ratings yet

- Grillage AnalysisDocument9 pagesGrillage Analysismonika chauhanNo ratings yet

- INFASO 9.4 Example FinalDocument28 pagesINFASO 9.4 Example Finalpperic13No ratings yet

- Design of Cantilever WallDocument11 pagesDesign of Cantilever WallMF YousufNo ratings yet

- Column Pad DesignDocument1 pageColumn Pad DesignMunene NdumiaNo ratings yet

- International Lateral LoadsDocument38 pagesInternational Lateral LoadsRamilArtates100% (1)

- Spreadsheets To BS 8110Document10 pagesSpreadsheets To BS 8110Alma M. LaraNo ratings yet

- European Design Guide For Footbridge Vibration: ArticleDocument15 pagesEuropean Design Guide For Footbridge Vibration: ArticleAndoNo ratings yet

- ERSS Design in SingaporeDocument89 pagesERSS Design in SingaporecienconsultantsNo ratings yet

- Slab With and Without OpeningDocument17 pagesSlab With and Without Openingstructure123No ratings yet

- EN1994 4 HanswilleDocument73 pagesEN1994 4 Hanswilleoluomo1No ratings yet

- Capping Beam Design 1Document8 pagesCapping Beam Design 1massive85No ratings yet

- Design of Purlin No:: 1.geometry Data 1.1 Material PropertiesDocument7 pagesDesign of Purlin No:: 1.geometry Data 1.1 Material PropertiesFakhira Alya SabrinaMzNo ratings yet

- End Plates - Worked Examples With Partial Depth End Plate - Example 5Document1 pageEnd Plates - Worked Examples With Partial Depth End Plate - Example 5Kimutai Kirui AlphonceNo ratings yet

- Design of Composite Columns v3 - Ver1 (KJ) AMDDocument104 pagesDesign of Composite Columns v3 - Ver1 (KJ) AMDImran SaikatNo ratings yet

- 09 Strut DesignDocument1 page09 Strut DesignThaungMyintNo ratings yet

- Flexure and Shear Design of Corbel BracketDocument12 pagesFlexure and Shear Design of Corbel BracketaquibzafarNo ratings yet

- Bursting Reinforcement Design LatestDocument7 pagesBursting Reinforcement Design LatestVenkat PalliNo ratings yet

- Gravity Wall DesignDocument28 pagesGravity Wall Designකණිෂ්ක ගුණසේකරNo ratings yet

- RCC Footing Design As Per BS CodeDocument50 pagesRCC Footing Design As Per BS CodeREENA VINODNo ratings yet

- Curved Prestressed BeamDocument5 pagesCurved Prestressed Beama96lhfNo ratings yet

- Retaining Wall Analysis & Design (BS8002 - 1994)Document10 pagesRetaining Wall Analysis & Design (BS8002 - 1994)IKNo ratings yet

- Lap-Length As Per 1992Document6 pagesLap-Length As Per 1992RahulNo ratings yet

- Anchorage in Concrete Structures: Doctoral ThesisDocument352 pagesAnchorage in Concrete Structures: Doctoral Thesiskeithth12322No ratings yet

- Pile Capacity NewDocument1 pagePile Capacity NewChowdhury PriodeepNo ratings yet

- Hyperstatic PDFDocument5 pagesHyperstatic PDFAmbrishNo ratings yet

- Gustave Magnel LectureDocument4 pagesGustave Magnel LectureRachel BushNo ratings yet

- Chapter 7: Box Girder BridgesDocument26 pagesChapter 7: Box Girder BridgesPacha Khan KhogyaniNo ratings yet

- BoltDocument23 pagesBoltMohamad Syahmi0% (1)

- MEGA Metro Columns Design As Per IRSDocument40 pagesMEGA Metro Columns Design As Per IRSAnonymous cYcLLOmmk8No ratings yet

- Wind Loading On Lighting Steel Column - en 40-3-1:2013 AssumptionsDocument12 pagesWind Loading On Lighting Steel Column - en 40-3-1:2013 Assumptions6BisnagaNo ratings yet

- Design and Construction B1 - Steel Beam: LoadingDocument20 pagesDesign and Construction B1 - Steel Beam: LoadingEllie MarshNo ratings yet

- RC Detailing To EC2Document69 pagesRC Detailing To EC2Ahmed Nurul100% (1)

- Finite Element Analysis of Structures through Unified FormulationFrom EverandFinite Element Analysis of Structures through Unified FormulationNo ratings yet

- Cable Supported Bridges: Concept and DesignFrom EverandCable Supported Bridges: Concept and DesignRating: 5 out of 5 stars5/5 (1)

- Pier & Footing For Canal TroughDocument18 pagesPier & Footing For Canal TroughjaffnaNo ratings yet

- Project: Matrade Exhibition Center-Main Roof: Calculation For Steel Column Base PlateDocument10 pagesProject: Matrade Exhibition Center-Main Roof: Calculation For Steel Column Base PlateYANIshaNo ratings yet

- Travel Tips For Drivers - Milford Road2Document2 pagesTravel Tips For Drivers - Milford Road2sudhir12345No ratings yet

- DBR - Rev GDocument51 pagesDBR - Rev Gsudhir12345No ratings yet

- Team League Table: Enginuity 2020 CompetitionDocument5 pagesTeam League Table: Enginuity 2020 Competitionsudhir12345No ratings yet

- Team League Table: Enginuity 2020 CompetitionDocument5 pagesTeam League Table: Enginuity 2020 Competitionsudhir12345No ratings yet

- Analysis Report - Element Comparison Report-126989Document11 pagesAnalysis Report - Element Comparison Report-126989sudhir12345No ratings yet

- Walkers Joggers Runners Elite Wheelchair Seeds: Quay STDocument1 pageWalkers Joggers Runners Elite Wheelchair Seeds: Quay STsudhir12345No ratings yet

- RTB20 Course Overview MapDocument1 pageRTB20 Course Overview Mapsudhir12345No ratings yet

- Enginuity2020 Basic League Table End of Period 8Document5 pagesEnginuity2020 Basic League Table End of Period 8sudhir12345No ratings yet

- Team League Table: Enginuity 2020 CompetitionDocument5 pagesTeam League Table: Enginuity 2020 Competitionsudhir12345No ratings yet

- Team League Table: Enginuity 2020 CompetitionDocument5 pagesTeam League Table: Enginuity 2020 Competitionsudhir12345No ratings yet

- Assessment Policy Table A - University Grade Descriptors 2019Document1 pageAssessment Policy Table A - University Grade Descriptors 2019sudhir12345No ratings yet

- 2 Cheap Cars Claim Form: Please Fill in This Form, and Send It To Claims@2cheapcars - Co.nzDocument2 pages2 Cheap Cars Claim Form: Please Fill in This Form, and Send It To Claims@2cheapcars - Co.nzsudhir12345No ratings yet

- Consent Form 2020 - Filled PDFDocument1 pageConsent Form 2020 - Filled PDFsudhir12345No ratings yet

- Country Specific Guidelines: Country Min Pass Max Pass Minimum A Grade Range Equivalent Minimum B Grade Range EquivalentDocument3 pagesCountry Specific Guidelines: Country Min Pass Max Pass Minimum A Grade Range Equivalent Minimum B Grade Range Equivalentsudhir12345No ratings yet

- Influence - of - Strain - Rate - On - Ductile - Versus - Brittle For GJS 500-14 VolvoDocument8 pagesInfluence - of - Strain - Rate - On - Ductile - Versus - Brittle For GJS 500-14 VolvoJason WuNo ratings yet

- Defectos de Los Rieles en ExplotacionDocument6 pagesDefectos de Los Rieles en ExplotacionMiguel OvandoNo ratings yet

- Black Line Breaker ToolsDocument16 pagesBlack Line Breaker ToolsDeno Manuel LudzanNo ratings yet

- 02 PDFDocument39 pages02 PDFShishir Kumar NayakNo ratings yet

- Nickel and Nickel AlloysDocument0 pagesNickel and Nickel Alloysidien100% (1)

- Astm D 2412-2021Document7 pagesAstm D 2412-2021Mohammed Ali100% (1)

- Dire Dawa Intitute of Technology: Department of Mechanical EngineeringDocument39 pagesDire Dawa Intitute of Technology: Department of Mechanical EngineeringaberNo ratings yet

- 2 3A Lecture Fatigue PDFDocument39 pages2 3A Lecture Fatigue PDFKamel FedaouiNo ratings yet

- Introduction To MineralogyDocument16 pagesIntroduction To MineralogyEmily Faith BelcenaNo ratings yet

- (p645-652) Metals Handbook. Volume 1, Properties and Selection Irons, Steels, and High-Performance Alloys PDFDocument8 pages(p645-652) Metals Handbook. Volume 1, Properties and Selection Irons, Steels, and High-Performance Alloys PDFSethGraceNo ratings yet

- Hydrogen Cracking in Specialty Steels: Knolls Atomic Power Laboratory Schenectady, New YorkDocument23 pagesHydrogen Cracking in Specialty Steels: Knolls Atomic Power Laboratory Schenectady, New YorkNattapong PongbootNo ratings yet

- Astm D 5147 d5147m 18 Sampling and Testing Modified Bituminous Sheet MaterialpdfDocument11 pagesAstm D 5147 d5147m 18 Sampling and Testing Modified Bituminous Sheet MaterialpdfQazeem IsmailNo ratings yet

- Tire Cord Review-ZhangDocument12 pagesTire Cord Review-Zhangmanish pande100% (1)

- 093977366XStrength of ShipsDocument250 pages093977366XStrength of Shipsrafael100% (3)

- M03 Properties of MaterialsDocument82 pagesM03 Properties of MaterialsSolomonNo ratings yet

- Engineering Failure Analysis: Adam Adamkowski, Adam Henke, Mariusz LewandowskiDocument17 pagesEngineering Failure Analysis: Adam Adamkowski, Adam Henke, Mariusz LewandowskiTeja InkuluNo ratings yet

- Fatigue Crack-Scatter FactorDocument8 pagesFatigue Crack-Scatter Factorabhi024No ratings yet

- Life Extension Methods in Aero-Engines OMMI (Vol.3, Issue 1) April 2004Document15 pagesLife Extension Methods in Aero-Engines OMMI (Vol.3, Issue 1) April 2004D ARUL KUMARESANNo ratings yet

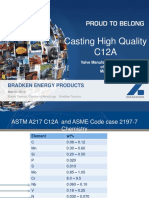

- Casting High Quality C12A: Bradken Energy ProductsDocument37 pagesCasting High Quality C12A: Bradken Energy Productsdelta lab sangliNo ratings yet

- A CASE STUDY 1 LeeDocument5 pagesA CASE STUDY 1 Leealdrin77No ratings yet

- FuselagesDocument14 pagesFuselagesBechir FoudhailiNo ratings yet

- Environment Hydrogen Embrittlement of Pipeline Steel X70Document15 pagesEnvironment Hydrogen Embrittlement of Pipeline Steel X70Metrach AbdrazakNo ratings yet

- TWI 581-CTOD Testing Update (1996)Document25 pagesTWI 581-CTOD Testing Update (1996)Mansour TavakoliNo ratings yet

- ASTM D 5628-96 (2001) Impact Resistance of Flat, Rigid Plastic Specimens by Means of A Falling Dart (Tup or Falling Mass)Document10 pagesASTM D 5628-96 (2001) Impact Resistance of Flat, Rigid Plastic Specimens by Means of A Falling Dart (Tup or Falling Mass)Thomas JangisNo ratings yet

- Characteristics of Carbon Fiber Phenolic CompositeDocument8 pagesCharacteristics of Carbon Fiber Phenolic CompositeEduardo Fernandez SanchezNo ratings yet

- Structure of Hydrated Cement PasteDocument11 pagesStructure of Hydrated Cement PasteAli Ismael100% (1)

- An Investigation of The Fatigue and Fretting PerformanceDocument19 pagesAn Investigation of The Fatigue and Fretting PerformanceKrishna PrasadNo ratings yet

Early Thermal Cracking

Early Thermal Cracking

Uploaded by

sudhir12345Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Early Thermal Cracking

Early Thermal Cracking

Uploaded by

sudhir12345Copyright:

Available Formats

3)

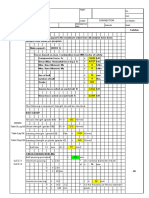

Early thermal Cracking Check in wall

1 Control of crack spacing

Minimum reinforcement area As

Ac . (fct*/fy)

Ac = Area of effective concrete

b

1000 mm

500 mm

Take d as

250 mm

Hence, Ac

250000 sq.mm

Tensile strength of immature concrete fct = 0.12(fcu)^0.7

fcu

Cube Strength

fct

40 N/sq.mm

1.59 N/sq.mm

fy

500 N/sq.mm

hence, min. As

794 sq.mm

2 Control of Crack Width

As = (fct*/fb) . Ac . /2w . [ r( sh + th) - 0.5 ult ]

fct*/fb

Ac

0.67 For Type 2 deformed

250000 sq.mm

Bar size

16 mm

Crack width, w

0.200 mm

Shrinkage strain sh

1.00E-04

Thermal strain th

4.13E-04 (refer calculations below)

Ult. Tensile strain Capacity

2.00E-04

ult

Restraint Factor R

0.50 (refer table below)

Calculation of Thermal Strain

th

= 0.8

(T1 + T2)

Coeff. Of thermal exp. of concrete

0

1.20E-05 / C

T1 = Short term fall in temperature from hydration peak to ambient conditions

Steel formwork

Cement

Content

300

Winter

0

18mm plywood formwork

Summer

0

12

Winter

0

18

20

Summer

0

28

350

15

23

27

35

400

17

27

32

43

Choose T1 as

Is section thicker than 500mm

=

(Y/N)

0

43 C

(Y = Yes = increase value by 10 deg. ; N = No = no change)

Hence T1

(from table 1 BS5400 - severe expos,)

0

43 C

Is sulphate resisting portland cement used? (Y/N)

(Used 60% GGBS)

(Y = Yes = decrease value by 20% ; N = No = no change)

Hence T1

0

43 C

T2 = Long term fall in temperature from ambient to the seasonal minimum

Summer

0

Winter

0

20

10

Choose T2 as

Are full movement joints provided <= 15m

0

20 C

(Y = Yes = T2=0 ; N = No = Use T2)

0

20 C

Hence T2

Is restraint subjected to same climatic exposure?

0

0 C

(Y = Yes = T2=0 ; N = No = Use T2)

Hence T2

Hence, Thermal strain

th = 0.8

(T1 + T2)

4.13E-04

Restraint Factor

Factor

Restraint Condition

External

Base on blinding

0.20

Edge restraint in box type deck

cast in stages

0.50

Wall cast onto base

0.60

Edge element cast onto slab

0.80

Infill bays

1.00

Internal

0.50

Choose R as

0.50

Area of steel required

1048 sq.mm

Area of steel required per face

1048 sq.mm

For a width

Provide bars of dia

1000 mm

16 mm

Spacing

191.875 mm / face

No. of bars

5.212 Nos.

Area provided

1048 sq.mm

OK

You might also like

- API 571 SummaryDocument7 pagesAPI 571 Summaryzackyat7976100% (1)

- Three Point Bending Test: Experiment No 1Document9 pagesThree Point Bending Test: Experiment No 1Manjunatha Babu N.sNo ratings yet

- Ruj.: Kod: Subjek: No Helaian: Ruj. Lukisan: Disemak Tarikh: Direkabentuk Oleh: ProjekDocument5 pagesRuj.: Kod: Subjek: No Helaian: Ruj. Lukisan: Disemak Tarikh: Direkabentuk Oleh: ProjekHafiz Budean RahmanNo ratings yet

- Design Example 5 - Pad Base - Axial Load Plus Bending Moment (Small Eccentricity)Document5 pagesDesign Example 5 - Pad Base - Axial Load Plus Bending Moment (Small Eccentricity)nuwan010% (1)

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- ES - Crack Width CalculationDocument2 pagesES - Crack Width CalculationprabhuNo ratings yet

- Irrigation Division Chunar, Mirzapur: Design of Parapet Wall at Top of Jirgo DamDocument4 pagesIrrigation Division Chunar, Mirzapur: Design of Parapet Wall at Top of Jirgo Damgovind narayan ShuklaNo ratings yet

- Concrete Filled Steel Pipe DesignDocument23 pagesConcrete Filled Steel Pipe DesignahsanmohNo ratings yet

- 3 EC4-2 Background Gerhard HanswilleDocument67 pages3 EC4-2 Background Gerhard Hanswilleantonio111aNo ratings yet

- LECTURE2 Shear ConnectionDocument36 pagesLECTURE2 Shear ConnectionMahmoud A SalamaNo ratings yet

- Lecture 7ADocument32 pagesLecture 7AAnonymous 37iyUV5No ratings yet

- Design of Column BasesDocument9 pagesDesign of Column Basesdarshanakp100% (1)

- RCC Beam With Different Choice of Design WSD For Singly & Doubly ReinforcementDocument5 pagesRCC Beam With Different Choice of Design WSD For Singly & Doubly ReinforcementdsanandaNo ratings yet

- Module 6 Bridge Engineering BatchDocument120 pagesModule 6 Bridge Engineering BatchKrish Chand100% (3)

- Prestress End Block Design To CIRIADocument3 pagesPrestress End Block Design To CIRIAbalamurugan25011990100% (1)

- Bridge Design v1.1 enDocument186 pagesBridge Design v1.1 enGaurav GhaiNo ratings yet

- Typical Wall ReinforcementDocument3 pagesTypical Wall ReinforcementMichelle TaiNo ratings yet

- Piling Practices Under Eurocode 7 (Contractor Point of View) PDFDocument42 pagesPiling Practices Under Eurocode 7 (Contractor Point of View) PDFBatu GajahNo ratings yet

- Sample of Design BriefDocument17 pagesSample of Design BriefshingkeongNo ratings yet

- Dynamic Calculation For Retaining WallDocument6 pagesDynamic Calculation For Retaining WallSabrina ImloulNo ratings yet

- Ramset Specifiers Anchoring Resource Book ANZ - TruBolt Mechanical AnchoringDocument10 pagesRamset Specifiers Anchoring Resource Book ANZ - TruBolt Mechanical AnchoringjlolhnpNo ratings yet

- Eurocode - Load Combinations For Steel Structures - R1Document26 pagesEurocode - Load Combinations For Steel Structures - R1anil97232No ratings yet

- Grillage AnalysisDocument9 pagesGrillage Analysismonika chauhanNo ratings yet

- INFASO 9.4 Example FinalDocument28 pagesINFASO 9.4 Example Finalpperic13No ratings yet

- Design of Cantilever WallDocument11 pagesDesign of Cantilever WallMF YousufNo ratings yet

- Column Pad DesignDocument1 pageColumn Pad DesignMunene NdumiaNo ratings yet

- International Lateral LoadsDocument38 pagesInternational Lateral LoadsRamilArtates100% (1)

- Spreadsheets To BS 8110Document10 pagesSpreadsheets To BS 8110Alma M. LaraNo ratings yet

- European Design Guide For Footbridge Vibration: ArticleDocument15 pagesEuropean Design Guide For Footbridge Vibration: ArticleAndoNo ratings yet

- ERSS Design in SingaporeDocument89 pagesERSS Design in SingaporecienconsultantsNo ratings yet

- Slab With and Without OpeningDocument17 pagesSlab With and Without Openingstructure123No ratings yet

- EN1994 4 HanswilleDocument73 pagesEN1994 4 Hanswilleoluomo1No ratings yet

- Capping Beam Design 1Document8 pagesCapping Beam Design 1massive85No ratings yet

- Design of Purlin No:: 1.geometry Data 1.1 Material PropertiesDocument7 pagesDesign of Purlin No:: 1.geometry Data 1.1 Material PropertiesFakhira Alya SabrinaMzNo ratings yet

- End Plates - Worked Examples With Partial Depth End Plate - Example 5Document1 pageEnd Plates - Worked Examples With Partial Depth End Plate - Example 5Kimutai Kirui AlphonceNo ratings yet

- Design of Composite Columns v3 - Ver1 (KJ) AMDDocument104 pagesDesign of Composite Columns v3 - Ver1 (KJ) AMDImran SaikatNo ratings yet

- 09 Strut DesignDocument1 page09 Strut DesignThaungMyintNo ratings yet

- Flexure and Shear Design of Corbel BracketDocument12 pagesFlexure and Shear Design of Corbel BracketaquibzafarNo ratings yet

- Bursting Reinforcement Design LatestDocument7 pagesBursting Reinforcement Design LatestVenkat PalliNo ratings yet

- Gravity Wall DesignDocument28 pagesGravity Wall Designකණිෂ්ක ගුණසේකරNo ratings yet

- RCC Footing Design As Per BS CodeDocument50 pagesRCC Footing Design As Per BS CodeREENA VINODNo ratings yet

- Curved Prestressed BeamDocument5 pagesCurved Prestressed Beama96lhfNo ratings yet

- Retaining Wall Analysis & Design (BS8002 - 1994)Document10 pagesRetaining Wall Analysis & Design (BS8002 - 1994)IKNo ratings yet

- Lap-Length As Per 1992Document6 pagesLap-Length As Per 1992RahulNo ratings yet

- Anchorage in Concrete Structures: Doctoral ThesisDocument352 pagesAnchorage in Concrete Structures: Doctoral Thesiskeithth12322No ratings yet

- Pile Capacity NewDocument1 pagePile Capacity NewChowdhury PriodeepNo ratings yet

- Hyperstatic PDFDocument5 pagesHyperstatic PDFAmbrishNo ratings yet

- Gustave Magnel LectureDocument4 pagesGustave Magnel LectureRachel BushNo ratings yet

- Chapter 7: Box Girder BridgesDocument26 pagesChapter 7: Box Girder BridgesPacha Khan KhogyaniNo ratings yet

- BoltDocument23 pagesBoltMohamad Syahmi0% (1)

- MEGA Metro Columns Design As Per IRSDocument40 pagesMEGA Metro Columns Design As Per IRSAnonymous cYcLLOmmk8No ratings yet

- Wind Loading On Lighting Steel Column - en 40-3-1:2013 AssumptionsDocument12 pagesWind Loading On Lighting Steel Column - en 40-3-1:2013 Assumptions6BisnagaNo ratings yet

- Design and Construction B1 - Steel Beam: LoadingDocument20 pagesDesign and Construction B1 - Steel Beam: LoadingEllie MarshNo ratings yet

- RC Detailing To EC2Document69 pagesRC Detailing To EC2Ahmed Nurul100% (1)

- Finite Element Analysis of Structures through Unified FormulationFrom EverandFinite Element Analysis of Structures through Unified FormulationNo ratings yet

- Cable Supported Bridges: Concept and DesignFrom EverandCable Supported Bridges: Concept and DesignRating: 5 out of 5 stars5/5 (1)

- Pier & Footing For Canal TroughDocument18 pagesPier & Footing For Canal TroughjaffnaNo ratings yet

- Project: Matrade Exhibition Center-Main Roof: Calculation For Steel Column Base PlateDocument10 pagesProject: Matrade Exhibition Center-Main Roof: Calculation For Steel Column Base PlateYANIshaNo ratings yet

- Travel Tips For Drivers - Milford Road2Document2 pagesTravel Tips For Drivers - Milford Road2sudhir12345No ratings yet

- DBR - Rev GDocument51 pagesDBR - Rev Gsudhir12345No ratings yet

- Team League Table: Enginuity 2020 CompetitionDocument5 pagesTeam League Table: Enginuity 2020 Competitionsudhir12345No ratings yet

- Team League Table: Enginuity 2020 CompetitionDocument5 pagesTeam League Table: Enginuity 2020 Competitionsudhir12345No ratings yet

- Analysis Report - Element Comparison Report-126989Document11 pagesAnalysis Report - Element Comparison Report-126989sudhir12345No ratings yet

- Walkers Joggers Runners Elite Wheelchair Seeds: Quay STDocument1 pageWalkers Joggers Runners Elite Wheelchair Seeds: Quay STsudhir12345No ratings yet

- RTB20 Course Overview MapDocument1 pageRTB20 Course Overview Mapsudhir12345No ratings yet

- Enginuity2020 Basic League Table End of Period 8Document5 pagesEnginuity2020 Basic League Table End of Period 8sudhir12345No ratings yet

- Team League Table: Enginuity 2020 CompetitionDocument5 pagesTeam League Table: Enginuity 2020 Competitionsudhir12345No ratings yet

- Team League Table: Enginuity 2020 CompetitionDocument5 pagesTeam League Table: Enginuity 2020 Competitionsudhir12345No ratings yet

- Assessment Policy Table A - University Grade Descriptors 2019Document1 pageAssessment Policy Table A - University Grade Descriptors 2019sudhir12345No ratings yet

- 2 Cheap Cars Claim Form: Please Fill in This Form, and Send It To Claims@2cheapcars - Co.nzDocument2 pages2 Cheap Cars Claim Form: Please Fill in This Form, and Send It To Claims@2cheapcars - Co.nzsudhir12345No ratings yet

- Consent Form 2020 - Filled PDFDocument1 pageConsent Form 2020 - Filled PDFsudhir12345No ratings yet

- Country Specific Guidelines: Country Min Pass Max Pass Minimum A Grade Range Equivalent Minimum B Grade Range EquivalentDocument3 pagesCountry Specific Guidelines: Country Min Pass Max Pass Minimum A Grade Range Equivalent Minimum B Grade Range Equivalentsudhir12345No ratings yet

- Influence - of - Strain - Rate - On - Ductile - Versus - Brittle For GJS 500-14 VolvoDocument8 pagesInfluence - of - Strain - Rate - On - Ductile - Versus - Brittle For GJS 500-14 VolvoJason WuNo ratings yet

- Defectos de Los Rieles en ExplotacionDocument6 pagesDefectos de Los Rieles en ExplotacionMiguel OvandoNo ratings yet

- Black Line Breaker ToolsDocument16 pagesBlack Line Breaker ToolsDeno Manuel LudzanNo ratings yet

- 02 PDFDocument39 pages02 PDFShishir Kumar NayakNo ratings yet

- Nickel and Nickel AlloysDocument0 pagesNickel and Nickel Alloysidien100% (1)

- Astm D 2412-2021Document7 pagesAstm D 2412-2021Mohammed Ali100% (1)

- Dire Dawa Intitute of Technology: Department of Mechanical EngineeringDocument39 pagesDire Dawa Intitute of Technology: Department of Mechanical EngineeringaberNo ratings yet

- 2 3A Lecture Fatigue PDFDocument39 pages2 3A Lecture Fatigue PDFKamel FedaouiNo ratings yet

- Introduction To MineralogyDocument16 pagesIntroduction To MineralogyEmily Faith BelcenaNo ratings yet

- (p645-652) Metals Handbook. Volume 1, Properties and Selection Irons, Steels, and High-Performance Alloys PDFDocument8 pages(p645-652) Metals Handbook. Volume 1, Properties and Selection Irons, Steels, and High-Performance Alloys PDFSethGraceNo ratings yet

- Hydrogen Cracking in Specialty Steels: Knolls Atomic Power Laboratory Schenectady, New YorkDocument23 pagesHydrogen Cracking in Specialty Steels: Knolls Atomic Power Laboratory Schenectady, New YorkNattapong PongbootNo ratings yet

- Astm D 5147 d5147m 18 Sampling and Testing Modified Bituminous Sheet MaterialpdfDocument11 pagesAstm D 5147 d5147m 18 Sampling and Testing Modified Bituminous Sheet MaterialpdfQazeem IsmailNo ratings yet

- Tire Cord Review-ZhangDocument12 pagesTire Cord Review-Zhangmanish pande100% (1)

- 093977366XStrength of ShipsDocument250 pages093977366XStrength of Shipsrafael100% (3)

- M03 Properties of MaterialsDocument82 pagesM03 Properties of MaterialsSolomonNo ratings yet

- Engineering Failure Analysis: Adam Adamkowski, Adam Henke, Mariusz LewandowskiDocument17 pagesEngineering Failure Analysis: Adam Adamkowski, Adam Henke, Mariusz LewandowskiTeja InkuluNo ratings yet

- Fatigue Crack-Scatter FactorDocument8 pagesFatigue Crack-Scatter Factorabhi024No ratings yet

- Life Extension Methods in Aero-Engines OMMI (Vol.3, Issue 1) April 2004Document15 pagesLife Extension Methods in Aero-Engines OMMI (Vol.3, Issue 1) April 2004D ARUL KUMARESANNo ratings yet

- Casting High Quality C12A: Bradken Energy ProductsDocument37 pagesCasting High Quality C12A: Bradken Energy Productsdelta lab sangliNo ratings yet

- A CASE STUDY 1 LeeDocument5 pagesA CASE STUDY 1 Leealdrin77No ratings yet

- FuselagesDocument14 pagesFuselagesBechir FoudhailiNo ratings yet

- Environment Hydrogen Embrittlement of Pipeline Steel X70Document15 pagesEnvironment Hydrogen Embrittlement of Pipeline Steel X70Metrach AbdrazakNo ratings yet

- TWI 581-CTOD Testing Update (1996)Document25 pagesTWI 581-CTOD Testing Update (1996)Mansour TavakoliNo ratings yet

- ASTM D 5628-96 (2001) Impact Resistance of Flat, Rigid Plastic Specimens by Means of A Falling Dart (Tup or Falling Mass)Document10 pagesASTM D 5628-96 (2001) Impact Resistance of Flat, Rigid Plastic Specimens by Means of A Falling Dart (Tup or Falling Mass)Thomas JangisNo ratings yet

- Characteristics of Carbon Fiber Phenolic CompositeDocument8 pagesCharacteristics of Carbon Fiber Phenolic CompositeEduardo Fernandez SanchezNo ratings yet

- Structure of Hydrated Cement PasteDocument11 pagesStructure of Hydrated Cement PasteAli Ismael100% (1)

- An Investigation of The Fatigue and Fretting PerformanceDocument19 pagesAn Investigation of The Fatigue and Fretting PerformanceKrishna PrasadNo ratings yet