Professional Documents

Culture Documents

Work Instruction For Marking of Plates, Pipes For Cutting and Forgings For Identification

Work Instruction For Marking of Plates, Pipes For Cutting and Forgings For Identification

Uploaded by

Mohit TyagiCopyright:

Available Formats

You might also like

- MAN L32/40DF (Technical Documentation - Engine Operating Instructions)Document264 pagesMAN L32/40DF (Technical Documentation - Engine Operating Instructions)aveselov8850% (6)

- Example MDR ProcedureDocument8 pagesExample MDR ProcedureOkas Paskal100% (1)

- QC WELDING WORKS CHECKLIST Rev.0Document2 pagesQC WELDING WORKS CHECKLIST Rev.0Rajesh Kumar Ravi100% (2)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Piping Specialty Item Design GuideDocument3 pagesPiping Specialty Item Design GuideCivil Friend67% (3)

- Scope of Work For Metering SkidDocument5 pagesScope of Work For Metering SkidmusaveerNo ratings yet

- Inspection & Test PlanDocument19 pagesInspection & Test Planaszliza100% (1)

- Application DIN 2303Document8 pagesApplication DIN 2303Marcelle Poll100% (1)

- Welding Grooving ProcedureDocument19 pagesWelding Grooving ProcedureAzhar Ali67% (3)

- Indian Oil Corporation Limited: CIN - L23201MH1959GOI011388Document10 pagesIndian Oil Corporation Limited: CIN - L23201MH1959GOI011388Yatendra TyagiNo ratings yet

- Technical Specification - LPG HeaterDocument94 pagesTechnical Specification - LPG Heaterhbsheen100% (1)

- Std. PR For LT Isolating SwitchDocument10 pagesStd. PR For LT Isolating SwitchJigyesh SharmaNo ratings yet

- Recovered Energy, Inc. Quality Control ManualDocument16 pagesRecovered Energy, Inc. Quality Control ManualpeymanNo ratings yet

- Questionnaire Manufacturer AssessmentDocument27 pagesQuestionnaire Manufacturer AssessmentKrunoslav Duga100% (1)

- Index of Revisions: Material RequisitionDocument23 pagesIndex of Revisions: Material RequisitionLANKAPALLISURINo ratings yet

- Supplier Data Requirements - Furnace Pressure PartsDocument5 pagesSupplier Data Requirements - Furnace Pressure PartsAleem QureshiNo ratings yet

- FABRICATION PROCEDURS For DuctingDocument5 pagesFABRICATION PROCEDURS For Ductingsafaruddin KSNo ratings yet

- Work Method Statement For Piping PrefabricationDocument11 pagesWork Method Statement For Piping Prefabricationsoumaya yahyaoui100% (3)

- A096 2441 2118 MR 0 PDFDocument119 pagesA096 2441 2118 MR 0 PDFMohsen Halweni100% (1)

- New Bios 2G Hydrotreatment Unit-Cartagena, Spain Supply and Fabrication of Reformer Steel Casing, Structures and StackDocument2 pagesNew Bios 2G Hydrotreatment Unit-Cartagena, Spain Supply and Fabrication of Reformer Steel Casing, Structures and StackAHMED KHAMISNo ratings yet

- ACdxgeneral 2011Document6 pagesACdxgeneral 2011Anonymous dEg1HtoNo ratings yet

- Passivation Criteria For NadCAPDocument49 pagesPassivation Criteria For NadCAPSounak BanerjeeNo ratings yet

- Bakhrabad Siddhirganj Pipeline Project Piping / Equipment Specifications For Launcher and ReceiverDocument8 pagesBakhrabad Siddhirganj Pipeline Project Piping / Equipment Specifications For Launcher and ReceiverIbad AlamNo ratings yet

- Shop Fabrication ProcedureDocument6 pagesShop Fabrication ProcedureAdrian IrawanNo ratings yet

- Antrag 15085 Engl KoA RichtlinieDocument9 pagesAntrag 15085 Engl KoA RichtlinieCarlos Nombela PalaciosNo ratings yet

- Inspection Record For Grouting: Items To InspectDocument1 pageInspection Record For Grouting: Items To InspectJoseph PeterNo ratings yet

- BS en 15085 - 2quality Requirements For ManufcturersDocument48 pagesBS en 15085 - 2quality Requirements For ManufcturersSubramanian R0% (1)

- Product Trace AbilityDocument2 pagesProduct Trace AbilitysvmadhavaramNo ratings yet

- Indian Oil Corporation Limited: Vendor Code:........................Document72 pagesIndian Oil Corporation Limited: Vendor Code:........................ANIMESH JAINNo ratings yet

- Tech Spec Flow OrificeDocument63 pagesTech Spec Flow OrificeSHIVAJI CHOUDHURY100% (1)

- Laporan AHU 031940042Document17 pagesLaporan AHU 031940042Aji NurmandwiNo ratings yet

- TRHT Ae GN 00 Oo 205 - 1Document27 pagesTRHT Ae GN 00 Oo 205 - 1kerkar mohammedNo ratings yet

- PMI Procedure Tracebilty MatrialDocument11 pagesPMI Procedure Tracebilty MatrialIksan Adityo Mulyo100% (2)

- Spare Parts and Special Tools - Procedure & Instructions To VendorsDocument10 pagesSpare Parts and Special Tools - Procedure & Instructions To Vendorsph0inix100% (1)

- 07.0 Job Specification For WeldersDocument5 pages07.0 Job Specification For WeldersrodwellbNo ratings yet

- MS For Welding Consumable ControlDocument10 pagesMS For Welding Consumable Controlmansih457100% (1)

- Questionnaire Manufacturer Assessment PDFDocument27 pagesQuestionnaire Manufacturer Assessment PDFulasNo ratings yet

- Basic Engineering Data SheetsDocument59 pagesBasic Engineering Data SheetsDave CNo ratings yet

- Specification 103 Rev. 8 - Supplier Document RequirementsDocument16 pagesSpecification 103 Rev. 8 - Supplier Document RequirementsTadaya KasaharaNo ratings yet

- STD PD R 01 Product Development ReportDocument6 pagesSTD PD R 01 Product Development ReportsamcbsivNo ratings yet

- Anubar SpecDocument8 pagesAnubar SpecSHIVAJI CHOUDHURYNo ratings yet

- C08-016-000J-TS155 - 0 Presion DiferencialDocument11 pagesC08-016-000J-TS155 - 0 Presion DiferencialCristian RománNo ratings yet

- I08-028-000J-TS072 - 0 Sonar Flow MetersDocument8 pagesI08-028-000J-TS072 - 0 Sonar Flow MetersCristian RománNo ratings yet

- Sample MRB Index For ENIDocument1 pageSample MRB Index For ENIAnanthu Krishnan100% (1)

- Inspection and Test ProcedureDocument8 pagesInspection and Test Proceduregaehdd1100% (1)

- 2 Lesson Notes Instrument DatasheetDocument5 pages2 Lesson Notes Instrument Datasheetmubanga20000804100% (1)

- Slides Plant Description (From PFD & P&IDs) E.HDocument47 pagesSlides Plant Description (From PFD & P&IDs) E.HRobert Waters100% (1)

- DIN 18800-7 Antrag EnglDocument9 pagesDIN 18800-7 Antrag Englgorgika papandNo ratings yet

- Instru SpecsDocument23 pagesInstru SpecsSanjay SharmaNo ratings yet

- Technical Spec - Station Lighting-BanharpallifinalDocument166 pagesTechnical Spec - Station Lighting-BanharpallifinalSreenubabu KandruNo ratings yet

- Part-2 (A) Scope of WorksDocument249 pagesPart-2 (A) Scope of Worksjai karanNo ratings yet

- LS 164-04 - 6 Identification Traceability of Piping Material On Construction Site (EN)Document6 pagesLS 164-04 - 6 Identification Traceability of Piping Material On Construction Site (EN)Kreshna Wisnu BrataNo ratings yet

- Method Statement-Ext Pipe FittingsDocument13 pagesMethod Statement-Ext Pipe FittingsSam JoseNo ratings yet

- Specifications Durayappah StadiumDocument64 pagesSpecifications Durayappah StadiumAhamed Manazir Hazzaan0% (1)

- A 02Document30 pagesA 02senioor2004No ratings yet

- 3623-DAL-F-J-112-R1 DP Txs (Flow)Document6 pages3623-DAL-F-J-112-R1 DP Txs (Flow)Roshin99No ratings yet

- CHW2204 00 EL CAL 7302 Rev1 Ilumination Level CalculationDocument5 pagesCHW2204 00 EL CAL 7302 Rev1 Ilumination Level CalculationphongtttNo ratings yet

- Process Steam Traps Design GuideDocument8 pagesProcess Steam Traps Design GuideCivil FriendNo ratings yet

- Our Calculated Weight Is 163.24 MT. We Have Added Weight of Items Whose Weights Were Not Given in The BOQ-Rev-BDocument1 pageOur Calculated Weight Is 163.24 MT. We Have Added Weight of Items Whose Weights Were Not Given in The BOQ-Rev-BMohit TyagiNo ratings yet

- HydroponicsDocument16 pagesHydroponicsMohit TyagiNo ratings yet

- S.no Item Description Quantity Required in NosDocument1 pageS.no Item Description Quantity Required in NosMohit TyagiNo ratings yet

- Binder1 PDFDocument8 pagesBinder1 PDFMohit TyagiNo ratings yet

- Gasket InquiryDocument9 pagesGasket InquiryMohit TyagiNo ratings yet

- Open Tender EnquiryDocument3 pagesOpen Tender EnquiryMohit TyagiNo ratings yet

- HRSGDocument13 pagesHRSGMohit Tyagi100% (2)

- Training & Development Dept.: To Be Filled by WorkmenDocument1 pageTraining & Development Dept.: To Be Filled by WorkmenMohit TyagiNo ratings yet

- HTTP WWW - Bebonchina.com Steel Steel-Plate DIN 15MO3Document2 pagesHTTP WWW - Bebonchina.com Steel Steel-Plate DIN 15MO3Mohit TyagiNo ratings yet

- Power CompaniesDocument1 pagePower CompaniesMohit TyagiNo ratings yet

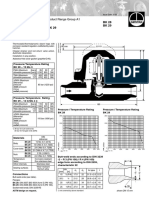

- BK 28 BK 29 Duo Steam Traps BK 28, BK 29 PN 100, PN 160 DN 15 - 25 MM ( " - 1")Document2 pagesBK 28 BK 29 Duo Steam Traps BK 28, BK 29 PN 100, PN 160 DN 15 - 25 MM ( " - 1")Mohit TyagiNo ratings yet

- Fitting OfferDocument3 pagesFitting OfferMohit TyagiNo ratings yet

- 2014 Israel-Gaza Con Ict: 1 BackgroundDocument1 page2014 Israel-Gaza Con Ict: 1 BackgroundMohit TyagiNo ratings yet

- List of PipingDocument1 pageList of PipingMohit TyagiNo ratings yet

- Clad and Dissimilar MetalsDocument57 pagesClad and Dissimilar MetalsMohit TyagiNo ratings yet

Work Instruction For Marking of Plates, Pipes For Cutting and Forgings For Identification

Work Instruction For Marking of Plates, Pipes For Cutting and Forgings For Identification

Uploaded by

Mohit TyagiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Work Instruction For Marking of Plates, Pipes For Cutting and Forgings For Identification

Work Instruction For Marking of Plates, Pipes For Cutting and Forgings For Identification

Uploaded by

Mohit TyagiCopyright:

Available Formats

SL No.

Issued to:

DOC. NO

TMD

WORK INSTRUCTION FOR MARKING OF

PLATES, PIPES FOR CUTTING AND

FORGINGS FOR IDENTIFICATION

:QIT 4.5.02.01

REVISION :R 0

PAGE

:1 OF 2

DATE

: 23.11.2013

1. Scope of work

1.1Material identification for feeding to the shops.

2. Equipment

2.1Calibrated measuring instruments.

3. Reference documents

3.1Drawing

3.2I.T.P/Traveler

3.3Cutting diagram/ sketch

4. Method

Activity

Prepare material feeding request (format No.4522) based on

applicable reference documents and send to stores.

Responsibility

Planning engineer

4.2

Receive the required material for marking from respective store

incharge.

Planning engineer

4.3

Get the parts marked & transfer on them the identification details

as per guide lines given below:

Planning engineer/

Concerned shop

supervisor

4.3.1

FOR PRESSURE PARTS:

Job No., Mark No., Heat No. & Grade shall be marked on each

part.

Planning engineer/

Concerned shop

supervisor

4.3.2

FOR NON-PRESSURE PARTS:

Job No., Mark No. shall be marked on each part.

Planning engineer/

Concerned shop

supervisor

4.3.3

Ready to use items (like forgings) which are supplied directly to

the shops shall be got identified in the shop/ yard.

Planning engineer

4.3.4

For bulk quantities to be used in running lengths (Rods, fins,

tubes etc.) identification will be maintained in shop by suitable

means like tags, physical location, color coding etc.

Shop Incharge

4.4

In case the material is to be used after check testing, identify the

same with its check test No.

Planning engineer

4.5

Offer the marked parts for inspection and identification through

Inspection Request cum Report format no.4506

Planning engineer

4.6

Inspect and identify the marked parts as per relevant inspection

procedures.

Head Inspection

4.7

Ensure transfer of appropriate marking and identification stamp

an all balance/ unused material also.

Head Inspection

4.8

Coordinate with Preparation/ Production shops (as applicable)

for cutting of the identified parts after inspection clearance.

Planning engineer

4.9

Coordinate for handling over the inward challan to Shipping and

Transport deptt. for transportation of cut parts to the shop.

Planning engineer

4.1

DOC. NO

:QIT 4.5.02.01

You might also like

- MAN L32/40DF (Technical Documentation - Engine Operating Instructions)Document264 pagesMAN L32/40DF (Technical Documentation - Engine Operating Instructions)aveselov8850% (6)

- Example MDR ProcedureDocument8 pagesExample MDR ProcedureOkas Paskal100% (1)

- QC WELDING WORKS CHECKLIST Rev.0Document2 pagesQC WELDING WORKS CHECKLIST Rev.0Rajesh Kumar Ravi100% (2)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Piping Specialty Item Design GuideDocument3 pagesPiping Specialty Item Design GuideCivil Friend67% (3)

- Scope of Work For Metering SkidDocument5 pagesScope of Work For Metering SkidmusaveerNo ratings yet

- Inspection & Test PlanDocument19 pagesInspection & Test Planaszliza100% (1)

- Application DIN 2303Document8 pagesApplication DIN 2303Marcelle Poll100% (1)

- Welding Grooving ProcedureDocument19 pagesWelding Grooving ProcedureAzhar Ali67% (3)

- Indian Oil Corporation Limited: CIN - L23201MH1959GOI011388Document10 pagesIndian Oil Corporation Limited: CIN - L23201MH1959GOI011388Yatendra TyagiNo ratings yet

- Technical Specification - LPG HeaterDocument94 pagesTechnical Specification - LPG Heaterhbsheen100% (1)

- Std. PR For LT Isolating SwitchDocument10 pagesStd. PR For LT Isolating SwitchJigyesh SharmaNo ratings yet

- Recovered Energy, Inc. Quality Control ManualDocument16 pagesRecovered Energy, Inc. Quality Control ManualpeymanNo ratings yet

- Questionnaire Manufacturer AssessmentDocument27 pagesQuestionnaire Manufacturer AssessmentKrunoslav Duga100% (1)

- Index of Revisions: Material RequisitionDocument23 pagesIndex of Revisions: Material RequisitionLANKAPALLISURINo ratings yet

- Supplier Data Requirements - Furnace Pressure PartsDocument5 pagesSupplier Data Requirements - Furnace Pressure PartsAleem QureshiNo ratings yet

- FABRICATION PROCEDURS For DuctingDocument5 pagesFABRICATION PROCEDURS For Ductingsafaruddin KSNo ratings yet

- Work Method Statement For Piping PrefabricationDocument11 pagesWork Method Statement For Piping Prefabricationsoumaya yahyaoui100% (3)

- A096 2441 2118 MR 0 PDFDocument119 pagesA096 2441 2118 MR 0 PDFMohsen Halweni100% (1)

- New Bios 2G Hydrotreatment Unit-Cartagena, Spain Supply and Fabrication of Reformer Steel Casing, Structures and StackDocument2 pagesNew Bios 2G Hydrotreatment Unit-Cartagena, Spain Supply and Fabrication of Reformer Steel Casing, Structures and StackAHMED KHAMISNo ratings yet

- ACdxgeneral 2011Document6 pagesACdxgeneral 2011Anonymous dEg1HtoNo ratings yet

- Passivation Criteria For NadCAPDocument49 pagesPassivation Criteria For NadCAPSounak BanerjeeNo ratings yet

- Bakhrabad Siddhirganj Pipeline Project Piping / Equipment Specifications For Launcher and ReceiverDocument8 pagesBakhrabad Siddhirganj Pipeline Project Piping / Equipment Specifications For Launcher and ReceiverIbad AlamNo ratings yet

- Shop Fabrication ProcedureDocument6 pagesShop Fabrication ProcedureAdrian IrawanNo ratings yet

- Antrag 15085 Engl KoA RichtlinieDocument9 pagesAntrag 15085 Engl KoA RichtlinieCarlos Nombela PalaciosNo ratings yet

- Inspection Record For Grouting: Items To InspectDocument1 pageInspection Record For Grouting: Items To InspectJoseph PeterNo ratings yet

- BS en 15085 - 2quality Requirements For ManufcturersDocument48 pagesBS en 15085 - 2quality Requirements For ManufcturersSubramanian R0% (1)

- Product Trace AbilityDocument2 pagesProduct Trace AbilitysvmadhavaramNo ratings yet

- Indian Oil Corporation Limited: Vendor Code:........................Document72 pagesIndian Oil Corporation Limited: Vendor Code:........................ANIMESH JAINNo ratings yet

- Tech Spec Flow OrificeDocument63 pagesTech Spec Flow OrificeSHIVAJI CHOUDHURY100% (1)

- Laporan AHU 031940042Document17 pagesLaporan AHU 031940042Aji NurmandwiNo ratings yet

- TRHT Ae GN 00 Oo 205 - 1Document27 pagesTRHT Ae GN 00 Oo 205 - 1kerkar mohammedNo ratings yet

- PMI Procedure Tracebilty MatrialDocument11 pagesPMI Procedure Tracebilty MatrialIksan Adityo Mulyo100% (2)

- Spare Parts and Special Tools - Procedure & Instructions To VendorsDocument10 pagesSpare Parts and Special Tools - Procedure & Instructions To Vendorsph0inix100% (1)

- 07.0 Job Specification For WeldersDocument5 pages07.0 Job Specification For WeldersrodwellbNo ratings yet

- MS For Welding Consumable ControlDocument10 pagesMS For Welding Consumable Controlmansih457100% (1)

- Questionnaire Manufacturer Assessment PDFDocument27 pagesQuestionnaire Manufacturer Assessment PDFulasNo ratings yet

- Basic Engineering Data SheetsDocument59 pagesBasic Engineering Data SheetsDave CNo ratings yet

- Specification 103 Rev. 8 - Supplier Document RequirementsDocument16 pagesSpecification 103 Rev. 8 - Supplier Document RequirementsTadaya KasaharaNo ratings yet

- STD PD R 01 Product Development ReportDocument6 pagesSTD PD R 01 Product Development ReportsamcbsivNo ratings yet

- Anubar SpecDocument8 pagesAnubar SpecSHIVAJI CHOUDHURYNo ratings yet

- C08-016-000J-TS155 - 0 Presion DiferencialDocument11 pagesC08-016-000J-TS155 - 0 Presion DiferencialCristian RománNo ratings yet

- I08-028-000J-TS072 - 0 Sonar Flow MetersDocument8 pagesI08-028-000J-TS072 - 0 Sonar Flow MetersCristian RománNo ratings yet

- Sample MRB Index For ENIDocument1 pageSample MRB Index For ENIAnanthu Krishnan100% (1)

- Inspection and Test ProcedureDocument8 pagesInspection and Test Proceduregaehdd1100% (1)

- 2 Lesson Notes Instrument DatasheetDocument5 pages2 Lesson Notes Instrument Datasheetmubanga20000804100% (1)

- Slides Plant Description (From PFD & P&IDs) E.HDocument47 pagesSlides Plant Description (From PFD & P&IDs) E.HRobert Waters100% (1)

- DIN 18800-7 Antrag EnglDocument9 pagesDIN 18800-7 Antrag Englgorgika papandNo ratings yet

- Instru SpecsDocument23 pagesInstru SpecsSanjay SharmaNo ratings yet

- Technical Spec - Station Lighting-BanharpallifinalDocument166 pagesTechnical Spec - Station Lighting-BanharpallifinalSreenubabu KandruNo ratings yet

- Part-2 (A) Scope of WorksDocument249 pagesPart-2 (A) Scope of Worksjai karanNo ratings yet

- LS 164-04 - 6 Identification Traceability of Piping Material On Construction Site (EN)Document6 pagesLS 164-04 - 6 Identification Traceability of Piping Material On Construction Site (EN)Kreshna Wisnu BrataNo ratings yet

- Method Statement-Ext Pipe FittingsDocument13 pagesMethod Statement-Ext Pipe FittingsSam JoseNo ratings yet

- Specifications Durayappah StadiumDocument64 pagesSpecifications Durayappah StadiumAhamed Manazir Hazzaan0% (1)

- A 02Document30 pagesA 02senioor2004No ratings yet

- 3623-DAL-F-J-112-R1 DP Txs (Flow)Document6 pages3623-DAL-F-J-112-R1 DP Txs (Flow)Roshin99No ratings yet

- CHW2204 00 EL CAL 7302 Rev1 Ilumination Level CalculationDocument5 pagesCHW2204 00 EL CAL 7302 Rev1 Ilumination Level CalculationphongtttNo ratings yet

- Process Steam Traps Design GuideDocument8 pagesProcess Steam Traps Design GuideCivil FriendNo ratings yet

- Our Calculated Weight Is 163.24 MT. We Have Added Weight of Items Whose Weights Were Not Given in The BOQ-Rev-BDocument1 pageOur Calculated Weight Is 163.24 MT. We Have Added Weight of Items Whose Weights Were Not Given in The BOQ-Rev-BMohit TyagiNo ratings yet

- HydroponicsDocument16 pagesHydroponicsMohit TyagiNo ratings yet

- S.no Item Description Quantity Required in NosDocument1 pageS.no Item Description Quantity Required in NosMohit TyagiNo ratings yet

- Binder1 PDFDocument8 pagesBinder1 PDFMohit TyagiNo ratings yet

- Gasket InquiryDocument9 pagesGasket InquiryMohit TyagiNo ratings yet

- Open Tender EnquiryDocument3 pagesOpen Tender EnquiryMohit TyagiNo ratings yet

- HRSGDocument13 pagesHRSGMohit Tyagi100% (2)

- Training & Development Dept.: To Be Filled by WorkmenDocument1 pageTraining & Development Dept.: To Be Filled by WorkmenMohit TyagiNo ratings yet

- HTTP WWW - Bebonchina.com Steel Steel-Plate DIN 15MO3Document2 pagesHTTP WWW - Bebonchina.com Steel Steel-Plate DIN 15MO3Mohit TyagiNo ratings yet

- Power CompaniesDocument1 pagePower CompaniesMohit TyagiNo ratings yet

- BK 28 BK 29 Duo Steam Traps BK 28, BK 29 PN 100, PN 160 DN 15 - 25 MM ( " - 1")Document2 pagesBK 28 BK 29 Duo Steam Traps BK 28, BK 29 PN 100, PN 160 DN 15 - 25 MM ( " - 1")Mohit TyagiNo ratings yet

- Fitting OfferDocument3 pagesFitting OfferMohit TyagiNo ratings yet

- 2014 Israel-Gaza Con Ict: 1 BackgroundDocument1 page2014 Israel-Gaza Con Ict: 1 BackgroundMohit TyagiNo ratings yet

- List of PipingDocument1 pageList of PipingMohit TyagiNo ratings yet

- Clad and Dissimilar MetalsDocument57 pagesClad and Dissimilar MetalsMohit TyagiNo ratings yet