Professional Documents

Culture Documents

Effectively Using Pressure Sensors With Today's Data Acquisition Systems

Effectively Using Pressure Sensors With Today's Data Acquisition Systems

Uploaded by

noneOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effectively Using Pressure Sensors With Today's Data Acquisition Systems

Effectively Using Pressure Sensors With Today's Data Acquisition Systems

Uploaded by

noneCopyright:

Available Formats

Automotive Testing Expo Europe 2011

Effectively Using Pressure

Sensors with Todays Data

Acquisition Systems

Chris Novak

Global Application Engineer

Honeywell Sensing and Control

Copyright 2011 Honeywell International Inc. All rights reserved.

Honeywell.com

Electromechanical Transducer

Mechanical Input ( Force )

Wheatstone Bridge

Structure (L/L)

Electrical Output (Vout)

Strain Gage / Piezo Resistors

------------------Amplifier

Electrical Output (R/R)

Display / Output

Basic Theory

Honeywell Confidential

Honeywell.com

Understanding Pressure Sensors

Pressure is defined as force per unit area

All pressure sensors use a force-summing device to convert the pressure into

a stress or displacement proportional to the pressure

The stress or displacement is then applied to an electrical transduction

element to generate the required signal

Below examples are generally related to Silicon Piezo Resistive Pressure

Pressure

(Force/Area)

Deformation of

Sense Element

Change in

Electrical

Properties

Change in

Output

Examples

RB-R

RB+R

RB+R

RB-R

Honeywell Confidential

Honeywell.com

Understanding Piezo Resistive-Type Pressure

In Piezo Resistive Pressure Sensors, the transduction elements which convert

the stress from the diaphragm deflection into an electrical signal are Piezo

Resistors

Piezo Resistance = changing electrical resistance due to mechanical stress

As shown here, typically 4 Piezo Resistors are used - connected in a

Wheatstone bridge circuit - to provide an output which changes primarily with

pressure.

Honeywell Confidential

Honeywell.com

Understanding Foil-Based Pressure Sensors

Two basic types of Foil-based Pressure sensors

Diaphragm

Force Sensor-based

Mechanical

Transmitter

Strain Gages

Strain Gages

Single Diaphragm

Gaged

Element

Single Diaphragm

Pressure Port

Pipe

Fluid Under Pressure

Fluid Under Pressure

Gaged Diaphragm

Gaged Force Sensor with Mechanical Transmitter

Honeywell Confidential

Honeywell.com

Understanding Load Measurement

As Applied to Pressure Sensors

Load Cells Measure Direct Force

Strain Gage Technology a Key Function of Load Cells

The Structure (Spring Element) is the Most Critical Component

Multiple-bending Beam Design

Multiple-Bending Beam

Shear-Web Design

Shear Web

Strain Gage

(Wheatstone Bridge or Electrical Circuits)

Low capacity: 20 20K N

p

Capacity:

2K 1M N

p

y

P

C

T

T

C

T

C

C

T

Vout

C

T

Vin

4 active arms with pairs

subjected to equal and

opposite strains.

4 active arms with pairs

subjected to equal and

opposite strains.

A Direct Measurement of Force

Honeywell Confidential

Honeywell.com

Wheatstone Bridge (Electrical Circuits)

Resistan

where

Ohms

The gage measures resistance (i.e. Ohms), which is converted to strain

when a Force is applied.

L R

Strain

R

L

Gage Factor is the ratio of resistance change to strain change. A

specific R in the gage = specific L on the base material.

+ increased resistance = increased output

R R

Gage _ Factor F R R

R RF

L

L

Vout

Vin

Vout VB VD

- Decreased resistance = increased output

Mechanical Meets Electrical

Honeywell Confidential

Honeywell.com

Types of Pressure Sensors

Pressure Measurement Types

Barometric

Inches Water

Psi of Vacuum

Todays Atmospheric Pressure

Atmospheric Pressure on

day gage was sealed

Applied

Pressure

Differential

Applied

Pressure

P1

Silicon

Examples

Sealed

Reference

Applied

Pressure

Reference

Pressure

Applied

Pressure

Vacuum

True Gage

Gage

Absolute

Pressure

Gauge

(gage)

Ambient

Pressure

Differential

Pressure

Absolute

Applied

Pressure

P2

Front/Topside sensing

Absolute Vacuum

Back-side

sensing

Honeywell Confidential

Honeywell.com

Typical Applications For Automotive Pressure

Assembly &

Testing

Component

Testing

Powertrain

Testing

Automated paint

system pressure

Automated sealant

dispensing systems

End of line leak testing

Oil pump testing

Cold engine testing

Fuel injection system

pressure

Vehicle fluid fill control

pressures

Fluid pump pressure

Brake system &

assembly testing

Tire manufacturing

mold pressure control

Air bag system

Suspension pressure

Hydraulic pressure

Dynamometer hot

engine testing

Oil pressure

Coolant pressure

Fuel flow,

consumption, flow &

pressure

Intake air flow

Manifold vacuum

testing

Transmission pressure

testing

Emissions testing

Cylinder compression

(cold test)

Vehicle &

Proving

Ground Testing

Road handling

(steering system

pressures)

Brake testing

(pressure)

Ride

Motorsports

Applications

Brake system status

Fuel line pressure

Aero-dynamics testing

Tire pressure

Engine diagnostics

Vacuum pressure

Fuel-air ratio

Honeywell Confidential

Honeywell.com

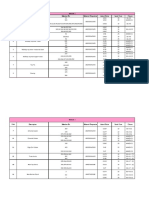

Pressure Case Studies

PRESSURE Application 1:

Component leak test stations

End of Line stations that monitor

pressure drops on brake

cylinders, after system has been

pressurized

Model/Models:

Model Z, TJE & STJE pressure

sensor family

Accuracy & Repeatability: 0.25%,

0.1% & 0.05%

Why Use Honeywell?

Foil based sensing technology,

along with beam element design,

provides a superior temperature

performance

Hermetically sealed sensor

Flexibility of standard outputs

Compound range availability

PRESSURE Application 2:

On-board testing of transmission

fluid pressure

Pressure sensors are installed

directly on the transmission of a

test vehicle to capture actual road

performance

Model/Models:

Model S, A-105, A-205

Subminiature pressure sensors

Accuracy: 0.5% FS

Why Use Honeywell?

Foil based sensing technology

provides a superior temperature

performance

High performance with dynamically

changing temperature

On-board vehicle testing demands

small sensor package

40 years of Pedigree reliable,

stable & robust product

PRESSURE Application 3:

Automotive Brake component cycle life

testing

Monitoring brake pressure during cycle

testing to ensure accurate control

Model/Models:

Model Z, TJE & STJE pressure sensor

family

Accuracy & Repeatability: 0.25%, 0.1%

& 0.05%

Why Use Honeywell?

Better accuracy

Hermetically sealed sensor

Customizable to facilitate a bleed screw

on the pressure port, ensuring safe

return of brake fluid to reservoir

Honeywell Confidential

Honeywell.com

Working with Instrumentation

Honeywell Sensors

Instrumentation

SW

1.

Sensor

mV/V

SC + A/D

D*

Bridge-based

Pressure

sensors

SW

2.

Sensor + SC

A* = 5 VDC, 10 VDC, 4-20mA

D* = Digital signal

A*

A/D

D*

SC = Signal Conditioning

A/D = Analog to Digital Conversion

SW = Software Including PC

Honeywell Confidential

Honeywell.com

Plug and Play

Transducer Electronic Data Sheet (TEDS):

IEEE 1451.4 covers communication protocol

Data stored in EPROM on Sensor

Standard Templates

Accuracy options look up tables, curve fitting, etc.

Honeywell Confidential

Honeywell.com

For More Information

If you would like more information on any of Honeywells

pressure transducers or other products for test &

measurement applications, please contact us:

Ph: (800) 848-6564 (U.S.) or +1 614-850-5000

Fax: +1 614-850-1111

Email: info.tm@honeywell.com

Visit Us Online: http://measurementsensors.honeywell.com

Honeywell Confidential

Thank you.

You might also like

- Evpn in The Data CenterDocument106 pagesEvpn in The Data CenterankitNo ratings yet

- Ga 216 07 PDFDocument24 pagesGa 216 07 PDFabudabeejajaNo ratings yet

- A100 - FOUNDATION PLAN Layout1Document1 pageA100 - FOUNDATION PLAN Layout1avdesh7777No ratings yet

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialFrom EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialRating: 3.5 out of 5 stars3.5/5 (3)

- Transformer TestingDocument24 pagesTransformer Testingmuaz_aminu142269% (16)

- Testing of Transformer: Vijai Electricals LTDDocument57 pagesTesting of Transformer: Vijai Electricals LTDPhani KumarNo ratings yet

- SIKA Product OverviewDocument8 pagesSIKA Product OverviewamirriyyahNo ratings yet

- TettexGeneralCatalog PDFDocument127 pagesTettexGeneralCatalog PDFvictorNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Prestressed Concrete Example ProblemDocument76 pagesPrestressed Concrete Example ProblemXiaoman Tu90% (63)

- Retaining Wall CalculationDocument9 pagesRetaining Wall CalculationAlexPakNo ratings yet

- Bolting Technology Catalogue Echnology CatalogueDocument56 pagesBolting Technology Catalogue Echnology CatalogueHarold AnilloNo ratings yet

- Study of A Refrigeration Unit (R633)Document52 pagesStudy of A Refrigeration Unit (R633)mahbub133294% (17)

- PVEP Electrohydraulic Actuator TN 11022662 Rev-AA Apr-2007Document9 pagesPVEP Electrohydraulic Actuator TN 11022662 Rev-AA Apr-2007Sasko DimitrovNo ratings yet

- HoneyWell Model G SubminaturePressureTransducerDatasheetDocument4 pagesHoneyWell Model G SubminaturePressureTransducerDatasheetDizzixxNo ratings yet

- Instrumentation Is A Collective Term For Measuring Instruments That Are Used For IndicatingDocument12 pagesInstrumentation Is A Collective Term For Measuring Instruments That Are Used For IndicatingVincentNo ratings yet

- TF TestingDocument25 pagesTF Testingask4vinod100% (2)

- Kulite Pressure Transducer HandbookDocument76 pagesKulite Pressure Transducer Handbookpmud123No ratings yet

- Company Profile PT. Inako PersadaDocument22 pagesCompany Profile PT. Inako PersadaTiar_Rahman_9553No ratings yet

- Module 3Document219 pagesModule 3Sourav PoddarNo ratings yet

- ELE Product Catalogue 50-51Document2 pagesELE Product Catalogue 50-51casanovavnNo ratings yet

- Catalog Basic Vario GBDocument140 pagesCatalog Basic Vario GBOpscenar_Pandora100% (1)

- Pressure Sensor: Class: III B.SC (Electronics) Subject: Sensor TechnologyDocument16 pagesPressure Sensor: Class: III B.SC (Electronics) Subject: Sensor TechnologyThilaga KaviNo ratings yet

- SC-600 - Electro-Pneumatic - Devices - Pressure Control Valves REXROTHDocument60 pagesSC-600 - Electro-Pneumatic - Devices - Pressure Control Valves REXROTHadrianahoukiNo ratings yet

- 02 Yokogawa Vigilant-Catalogue PDFDocument4 pages02 Yokogawa Vigilant-Catalogue PDFm33mNo ratings yet

- BIPM Dynamic WS 2012 Talk 03 RipperDocument100 pagesBIPM Dynamic WS 2012 Talk 03 Ripperjrlr65No ratings yet

- Construction: Our AC & DC Portable Type Ammeter & Voltmeter Are Manufactured by The BestDocument2 pagesConstruction: Our AC & DC Portable Type Ammeter & Voltmeter Are Manufactured by The BestKaran JadavNo ratings yet

- UK HO1 Speed Range DSDocument6 pagesUK HO1 Speed Range DSIsabelaSandovalNo ratings yet

- Transducers AND: Static CharactersticsDocument44 pagesTransducers AND: Static CharactersticsAbhinav RathoreNo ratings yet

- P 40.2 Pressure CalibratorsDocument24 pagesP 40.2 Pressure CalibratorsHamza EttalebNo ratings yet

- BM235-Manual-EEVblog Revision 18 August 2017Document33 pagesBM235-Manual-EEVblog Revision 18 August 2017Sergio austraNo ratings yet

- ERT 321 Process Control & DynamicsDocument49 pagesERT 321 Process Control & Dynamicshakita86No ratings yet

- Machine Conditionvibration MonitoringDocument32 pagesMachine Conditionvibration Monitoringmohamed abourayaNo ratings yet

- Process Control and InstrumentationDocument46 pagesProcess Control and InstrumentationLeonardo ImmoNo ratings yet

- Transmitters: Instrumentation & ControlDocument42 pagesTransmitters: Instrumentation & ControlJohnNo ratings yet

- Measurement PressureDocument20 pagesMeasurement Pressurelp mishraNo ratings yet

- Fenwal Smoke Detectors: Advantages/BenefitsDocument2 pagesFenwal Smoke Detectors: Advantages/Benefitsosvi009No ratings yet

- Industrial Instrumentation Ch.E-401: Kashif IqbalDocument29 pagesIndustrial Instrumentation Ch.E-401: Kashif Iqbaljesustavares100% (1)

- Testing ToolsDocument5 pagesTesting ToolsbhpNo ratings yet

- Industry Current & Voltage TransducersDocument51 pagesIndustry Current & Voltage TransducersZohaib SiddiqueNo ratings yet

- TAS For Loading TruckDocument74 pagesTAS For Loading Truckjittshong8072No ratings yet

- Industrial Instrumentation Ch.E-401: Kashif IqbalDocument25 pagesIndustrial Instrumentation Ch.E-401: Kashif IqbalBilal AkbarNo ratings yet

- Chapter 3 - 23 06 19Document18 pagesChapter 3 - 23 06 19Sazzad HossainNo ratings yet

- Flow Angle Probe Miniature Is Pressure TransducerDocument2 pagesFlow Angle Probe Miniature Is Pressure TransducerD ARUL KUMARESANNo ratings yet

- PIBC VPI Series Technical Manual DN50-250Document14 pagesPIBC VPI Series Technical Manual DN50-250mohammed rameesNo ratings yet

- K & T Style Hydraulic System Test Analysers - ManualDocument16 pagesK & T Style Hydraulic System Test Analysers - Manualpravesh bhartiNo ratings yet

- Presentation On Electrical Equipments: Presented By: Purvi Chauhan B.Tech. 4 Year (EEE)Document18 pagesPresentation On Electrical Equipments: Presented By: Purvi Chauhan B.Tech. 4 Year (EEE)Vaishali SharmaNo ratings yet

- Mec 220T - Quality Inspection & Product Validation: Module 5: ComparatorsDocument20 pagesMec 220T - Quality Inspection & Product Validation: Module 5: ComparatorsMPD19I004 MADDUKURI SRINo ratings yet

- Hamdon Echometer Model E Well Analyzer BrochureDocument4 pagesHamdon Echometer Model E Well Analyzer BrochurearispriyatmonoNo ratings yet

- Pneumatics and Electro PneumaticsDocument56 pagesPneumatics and Electro PneumaticsobnamiajuliusNo ratings yet

- Omicron CP Line CatalogueDocument32 pagesOmicron CP Line CatalogueShirosh AyeshmanthaNo ratings yet

- CombinePDF 1714017507069Document67 pagesCombinePDF 1714017507069Debu JanaNo ratings yet

- H Series 4 Installation Checklist: Read This Document Thoroughly and CarefullyDocument7 pagesH Series 4 Installation Checklist: Read This Document Thoroughly and Carefullyanwar sadatNo ratings yet

- Process Control PPT 1901Document39 pagesProcess Control PPT 1901Ashish DhimanNo ratings yet

- Cummins QSB6.7 and QSB4.5 With CM850 ECM - Sensor & Actuator LocationDocument30 pagesCummins QSB6.7 and QSB4.5 With CM850 ECM - Sensor & Actuator LocationAnders Hedlöf100% (4)

- Transmitter e Htj-E002Document5 pagesTransmitter e Htj-E002masatusNo ratings yet

- Paper100 td013 - en PDocument146 pagesPaper100 td013 - en PPabloNo ratings yet

- Bolt Mike IIIDocument2 pagesBolt Mike IIIvrapciudorianNo ratings yet

- Enyecontrols System Info UpdatedDocument116 pagesEnyecontrols System Info UpdatedJon Elmer DelgadoNo ratings yet

- Testing: Valvetrain Systems For Combustion EnginesDocument48 pagesTesting: Valvetrain Systems For Combustion EnginesJose Luis RattiaNo ratings yet

- Utility and Substation Testing AGDocument8 pagesUtility and Substation Testing AGgusNo ratings yet

- GE Bolt Mike III User Manual2016051922133 PDFDocument2 pagesGE Bolt Mike III User Manual2016051922133 PDFBrenno GonçalvesNo ratings yet

- DV Power Catalogue - EngDocument16 pagesDV Power Catalogue - EngcvevasNo ratings yet

- Zimco LinecardDocument4 pagesZimco LinecardJitendra BhosaleNo ratings yet

- Catalog UKDocument140 pagesCatalog UKcarniz8912No ratings yet

- Handbook of Microwave Component Measurements: with Advanced VNA TechniquesFrom EverandHandbook of Microwave Component Measurements: with Advanced VNA TechniquesRating: 4 out of 5 stars4/5 (1)

- Legal Requirements: 2.2 Laws, Practices and Parties InvolvedDocument10 pagesLegal Requirements: 2.2 Laws, Practices and Parties InvolvednoneNo ratings yet

- Appendix F: Emergency Preparedness ................................................. 303Document10 pagesAppendix F: Emergency Preparedness ................................................. 303noneNo ratings yet

- 6 Construction and Commissioning ............................................ 63Document10 pages6 Construction and Commissioning ............................................ 63noneNo ratings yet

- IS - Steel Strengthening 8M20 I Profile - Aug 4, 2020Document7 pagesIS - Steel Strengthening 8M20 I Profile - Aug 4, 2020noneNo ratings yet

- Malaysia Dam Safety Management Guidelines (Mydams)Document10 pagesMalaysia Dam Safety Management Guidelines (Mydams)noneNo ratings yet

- Electronic Copy: X Malaysia Dam Safety Management GuidelinesDocument10 pagesElectronic Copy: X Malaysia Dam Safety Management GuidelinesnoneNo ratings yet

- Description Member No. Material Properties Actual Ratio Load Case ClauseDocument2 pagesDescription Member No. Material Properties Actual Ratio Load Case ClausenoneNo ratings yet

- JKR Ibs Score Ver 2 2016Document73 pagesJKR Ibs Score Ver 2 2016noneNo ratings yet

- Strip Footing DWG PDFDocument1 pageStrip Footing DWG PDFnoneNo ratings yet

- PIER ForceDocument1 pagePIER ForcenoneNo ratings yet

- Hilti HIT-RE 500V3 Injection Adhesive With Rebar ApplicationDocument1 pageHilti HIT-RE 500V3 Injection Adhesive With Rebar ApplicationnoneNo ratings yet

- Roof SlabDocument2 pagesRoof SlabnoneNo ratings yet

- Preliminary Work: The SiteDocument56 pagesPreliminary Work: The Sitenone100% (1)

- Bridge 1 OptimisedDocument1 pageBridge 1 OptimisednoneNo ratings yet

- VSL Post Tensioning SolutionsDocument28 pagesVSL Post Tensioning SolutionsDea NurahmanNo ratings yet

- Bridge 10B 1. Modelling: Figure 1:node DetailsDocument7 pagesBridge 10B 1. Modelling: Figure 1:node DetailsnoneNo ratings yet

- Design Formula For EC2 Version 06.15Document1 pageDesign Formula For EC2 Version 06.15noneNo ratings yet

- Example Max - Rxn&hor - Movexp.Document1 pageExample Max - Rxn&hor - Movexp.noneNo ratings yet

- Sulphuric Acid PlantsDocument16 pagesSulphuric Acid PlantsSekar.SNo ratings yet

- Ethics Design BriefDocument5 pagesEthics Design Briefapi-2345832450% (1)

- Flexabrasion of HairDocument10 pagesFlexabrasion of Hairilu_007_in6535No ratings yet

- Candy Chocolate MachinesDocument12 pagesCandy Chocolate MachinesAbigail PanjaitanNo ratings yet

- Mautic Developer GuideDocument222 pagesMautic Developer GuideMorph DiainNo ratings yet

- GC Tips Tricks-Agilent (Compatibility Mode)Document43 pagesGC Tips Tricks-Agilent (Compatibility Mode)Sneha PatelNo ratings yet

- Corporatestandard: 1.0 SCOPEDocument31 pagesCorporatestandard: 1.0 SCOPESamNo ratings yet

- E. ValvesDocument19 pagesE. Valveshermano balbonNo ratings yet

- SwitzerDocument4 pagesSwitzerJove MultisystemsNo ratings yet

- SM MultiV 5 OutdoorUnits PDFDocument235 pagesSM MultiV 5 OutdoorUnits PDFRizky Febrinaldi100% (1)

- Silk Touch EmulsionDocument1 pageSilk Touch EmulsionHooriaNo ratings yet

- Dynacoll® 7150-EnDocument2 pagesDynacoll® 7150-EnLU CHUNHUINo ratings yet

- CSC248 Julai 22 QuizDocument9 pagesCSC248 Julai 22 QuizAdib AfhamNo ratings yet

- Curriculum Vitae: Rajnish Kumar S/O Sh. Madan Lal C/O Accounts Branch NIT Hamirpur H.P-177005 E-Mail Id: Mob. No.Document3 pagesCurriculum Vitae: Rajnish Kumar S/O Sh. Madan Lal C/O Accounts Branch NIT Hamirpur H.P-177005 E-Mail Id: Mob. No.Rajnish KumarNo ratings yet

- ELD Catálogo Hook PDFDocument34 pagesELD Catálogo Hook PDFCristian Alonso Gonzalez MolinaNo ratings yet

- Book Nelems Bookdetails: Import Public Class Public Private IntDocument3 pagesBook Nelems Bookdetails: Import Public Class Public Private IntUSAMA SARWARNo ratings yet

- M01 Getting Started StudentDocument24 pagesM01 Getting Started StudentArturo AdunaNo ratings yet

- File 20210119 102344 Ketcau Han 3.06Document66 pagesFile 20210119 102344 Ketcau Han 3.06Nguyễn Văn NguyệnNo ratings yet

- Part ListDocument183 pagesPart Listamat doankNo ratings yet

- Method of Statement For Hydraulic Jack TestingDocument5 pagesMethod of Statement For Hydraulic Jack TestingAs-Syaff ResourcesNo ratings yet

- Online Reservation SystemDocument12 pagesOnline Reservation SystemBaloy N. Da Haus20% (5)

- Mix Design For Concrete Grade M 25Document3 pagesMix Design For Concrete Grade M 25Omar Marghani SalmaNo ratings yet

- DC System Technical Data SheetDocument4 pagesDC System Technical Data SheetArnold Steven0% (1)

- Student Solutions Manual (International Edition) Digital & Analog Comm. Systems 7th Edition, L.W. Couch, IIDocument28 pagesStudent Solutions Manual (International Edition) Digital & Analog Comm. Systems 7th Edition, L.W. Couch, IILieselotte DessersNo ratings yet

- Jointing Manual For DI PipeDocument16 pagesJointing Manual For DI PipeSaifur RahmanNo ratings yet