Professional Documents

Culture Documents

United States Patent 1191: Davies Et A1

United States Patent 1191: Davies Et A1

Uploaded by

cvkkkk1Copyright:

Available Formats

You might also like

- The Fabric Formwork Book PDFDocument318 pagesThe Fabric Formwork Book PDFtoth_daniel75% (4)

- A Method of Measuring Earth Resistivity by Frank Wenner PDFDocument14 pagesA Method of Measuring Earth Resistivity by Frank Wenner PDFArogya Raju Pudhota50% (2)

- U.S. Patent 2,683,388, Entitled "Pickup Device For Stringed Instruments" To Keller, Issued 1954.Document4 pagesU.S. Patent 2,683,388, Entitled "Pickup Device For Stringed Instruments" To Keller, Issued 1954.Anonymous a7S1qyXNo ratings yet

- Solved Problems in Electromagnetics by Syed A NasarDocument444 pagesSolved Problems in Electromagnetics by Syed A NasarOnur Çakıroğlu80% (10)

- 5 Development and Operating Experience PDFDocument10 pages5 Development and Operating Experience PDFVijaya100% (4)

- Oct. 18, 1966 G. H. Lagher 3,279,229: Roller-Bending Machine For Rounding Sheet MetalDocument3 pagesOct. 18, 1966 G. H. Lagher 3,279,229: Roller-Bending Machine For Rounding Sheet Metalxuanphuong2710No ratings yet

- United States PatentDocument6 pagesUnited States Patentaless2056No ratings yet

- Classification and Function of RelaysDocument7 pagesClassification and Function of RelaysVasu BagganNo ratings yet

- Unit 3 Tension Members: StructureDocument28 pagesUnit 3 Tension Members: StructureRaj BakhtaniNo ratings yet

- J. W. Mayo Etal Electrical-Connector: Filed June 1965Document3 pagesJ. W. Mayo Etal Electrical-Connector: Filed June 1965Kevin CooperNo ratings yet

- Unit 3 (C) Pressure MeasurementDocument17 pagesUnit 3 (C) Pressure MeasurementFuzail AhmadNo ratings yet

- July 3T,"Í962 A. B. Swallcsw Etal 3,047,860: Two-Fly Electromagnetic Energy Reflecting FabricDocument4 pagesJuly 3T,"Í962 A. B. Swallcsw Etal 3,047,860: Two-Fly Electromagnetic Energy Reflecting Fabricdavid19775891No ratings yet

- TRANSFLUXORS and Their Application in Automation and Remote Control 1964Document59 pagesTRANSFLUXORS and Their Application in Automation and Remote Control 1964JonNo ratings yet

- AC Windings StudentsDocument17 pagesAC Windings StudentsSisira JayamannaNo ratings yet

- DC Machine NotesDocument41 pagesDC Machine NotesEric GithinjiNo ratings yet

- (12 Ulllted States Patent (10) Patent N0.: US 6,901,818 B1Document15 pages(12 Ulllted States Patent (10) Patent N0.: US 6,901,818 B1brig1960No ratings yet

- Three Phase Stator Windings: Types of A-C WindingsDocument10 pagesThree Phase Stator Windings: Types of A-C WindingsNiño John JaymeNo ratings yet

- Power Transformer Basic DesignDocument31 pagesPower Transformer Basic DesigntajakaNo ratings yet

- Us 5360355Document6 pagesUs 5360355kimscribd66No ratings yet

- Three-Phase A.C. CircuitsDocument32 pagesThree-Phase A.C. CircuitsĐỗ ĐứcNo ratings yet

- PDFDocument32 pagesPDFUnknownNo ratings yet

- Tangential DriveDocument5 pagesTangential Drivecopkutusu2012No ratings yet

- H. A. Enge 3,071,702: High-Voltage Generator With'Solid Insulation Filed Dec. 3, 1958Document3 pagesH. A. Enge 3,071,702: High-Voltage Generator With'Solid Insulation Filed Dec. 3, 1958Victor Von DoomNo ratings yet

- Three Phase Stator Windings: Types of A-C WindingsDocument10 pagesThree Phase Stator Windings: Types of A-C Windingsvaraprasad93No ratings yet

- Dren Ker 1956Document8 pagesDren Ker 1956Pulkit BimalNo ratings yet

- Transformer Trouble, Test, Drying, Parallel OperationDocument35 pagesTransformer Trouble, Test, Drying, Parallel OperationMohammad Ibnul Hossain100% (1)

- US2574551 (Electronic Tachometer)Document7 pagesUS2574551 (Electronic Tachometer)Aaron Choco De GuzmanNo ratings yet

- 3 Phase Transformer - Phasor RepresentationDocument37 pages3 Phase Transformer - Phasor RepresentationnooralhudNo ratings yet

- EEPC108 Module 1Document52 pagesEEPC108 Module 1Elizabeth GomezNo ratings yet

- Dobby ControlDocument14 pagesDobby ControlPradip GuptaNo ratings yet

- Principles and Construction of TransformerDocument5 pagesPrinciples and Construction of TransformerJohn Kenneth ArellonNo ratings yet

- Strain Gauges NptelDocument15 pagesStrain Gauges Nptelsushant271992No ratings yet

- New Microsoft Word DocumentDocument17 pagesNew Microsoft Word Documentyousfe0% (1)

- May 29, 1945-L. H. B. Beer 2,377,175Document11 pagesMay 29, 1945-L. H. B. Beer 2,377,175Victor Von DoomNo ratings yet

- (54 Ion Cluster Acceleratio: Other Publications: United States Patent (191Document9 pages(54 Ion Cluster Acceleratio: Other Publications: United States Patent (191Victor Von DoomNo ratings yet

- Over Head LinesDocument8 pagesOver Head LinesDdumbaNo ratings yet

- Speed of Sound in Water by A Direct MethodDocument6 pagesSpeed of Sound in Water by A Direct MethodTony GeorgeNo ratings yet

- Insulators: Desirable Properties of InsulatorsDocument10 pagesInsulators: Desirable Properties of InsulatorsethanNo ratings yet

- US1170811Document4 pagesUS1170811George AcostaNo ratings yet

- 1 - Insulators String Efficiency ProblemDocument71 pages1 - Insulators String Efficiency ProblemVeera Vamsi Yejju100% (1)

- Transient Eddy 06Document1 pageTransient Eddy 06Constantin DorinelNo ratings yet

- MVMK Mm. .: File?d Jan. 29, 1944Document4 pagesMVMK Mm. .: File?d Jan. 29, 1944Syed Umair RizviNo ratings yet

- Lecture 7Document11 pagesLecture 7yoziscijuniorNo ratings yet

- Power Transformer Construction WindingsDocument5 pagesPower Transformer Construction WindingsRobert GalarzaNo ratings yet

- Description of Sample Problems: Ls-DynaDocument29 pagesDescription of Sample Problems: Ls-DynaraviNo ratings yet

- WA ER: March 15, 1966 H. P. RaabeDocument9 pagesWA ER: March 15, 1966 H. P. Raabedavid19775891No ratings yet

- Size, Shape, and Low Energy Electronic Structure of Carbon NanotubesDocument4 pagesSize, Shape, and Low Energy Electronic Structure of Carbon Nanotubesteju1996coolNo ratings yet

- Design and Power Conditioning For The Coil GunDocument5 pagesDesign and Power Conditioning For The Coil GunkomuncuNo ratings yet

- Three-Winding Transformer MODEL and TESTSDocument4 pagesThree-Winding Transformer MODEL and TESTSdaovantutudvhtd100% (1)

- Sheath CurrentsDocument5 pagesSheath Currentsscribdkkk100% (1)

- 2-1-Elements of Electrical EngineeringDocument164 pages2-1-Elements of Electrical EngineeringPrachi PolNo ratings yet

- LecherrrrDocument18 pagesLecherrrrChristian Amenofis MarinoNo ratings yet

- Electrodynamic Shaker Fundamentals PDFDocument8 pagesElectrodynamic Shaker Fundamentals PDFJorge Luis Ardila MatajiraNo ratings yet

- Electrical Power Transmission and DistributionDocument29 pagesElectrical Power Transmission and DistributionEngrAneelKumarAkhaniNo ratings yet

- Nbsbulletinv4n1p141 A2bDocument8 pagesNbsbulletinv4n1p141 A2bDiegoNo ratings yet

- US5186686Document11 pagesUS5186686雷黎明No ratings yet

- Experiment No.7 Transformers: Engr. Conrado QuinalayoDocument9 pagesExperiment No.7 Transformers: Engr. Conrado QuinalayoJaloyd MacalalagNo ratings yet

- LRL Accelerators, The 184-Inch SynchrocyclotronFrom EverandLRL Accelerators, The 184-Inch SynchrocyclotronNo ratings yet

- Experiments on the Absence of Mechanical Connexion between Ether and MatterFrom EverandExperiments on the Absence of Mechanical Connexion between Ether and MatterNo ratings yet

- Feb. 8, 1966 L.. H. Smith 3,233,345: Filed July Lí 1964 2 Sheets-Sheet LDocument6 pagesFeb. 8, 1966 L.. H. Smith 3,233,345: Filed July Lí 1964 2 Sheets-Sheet Lcvkkkk1No ratings yet

- Sept. 4 - , 1956 A. Cherkin 2,761,445: Filed May 3, 1952 2 Sheets-Sheet 1Document5 pagesSept. 4 - , 1956 A. Cherkin 2,761,445: Filed May 3, 1952 2 Sheets-Sheet 1cvkkkk1No ratings yet

- Predictive Astro M N KedarDocument388 pagesPredictive Astro M N KedarPrasan Nanda71% (7)

- Gli55 User ManualDocument126 pagesGli55 User Manualcvkkkk1No ratings yet

- John Nash Thesis LengthDocument4 pagesJohn Nash Thesis Lengthmaureennonweilertulsa100% (2)

- A Finite Element Study of The Onset of Vortex Shedding in Flow Past Variously Shaped BodiesDocument23 pagesA Finite Element Study of The Onset of Vortex Shedding in Flow Past Variously Shaped BodiesAshish PawarNo ratings yet

- CBSE Class 12 Chemistry Board Question Paper Solved 2018 Set 1Document21 pagesCBSE Class 12 Chemistry Board Question Paper Solved 2018 Set 1Sumit ChauhanNo ratings yet

- Lecture-5 - Miller Indices of Cubic SystemDocument23 pagesLecture-5 - Miller Indices of Cubic SystemSibasish RoutNo ratings yet

- HT Rate Calculations - Helical CoilsDocument4 pagesHT Rate Calculations - Helical CoilssandeshNo ratings yet

- Epoxy HandbookDocument277 pagesEpoxy HandbookTan Soh Huen100% (3)

- Produktkatalog 2012-2013Document228 pagesProduktkatalog 2012-2013Dominique RogalskiNo ratings yet

- WS 050 1001 C Thermoshield Model 883BDocument6 pagesWS 050 1001 C Thermoshield Model 883Bcandra trisilawatiNo ratings yet

- Biochemistry Lab NotesDocument2 pagesBiochemistry Lab NotesEppNo ratings yet

- Introduction To Steel Reinforcement WorkDocument12 pagesIntroduction To Steel Reinforcement Workalmond2008No ratings yet

- Moe - Nonlinear PerspectiveDocument7 pagesMoe - Nonlinear PerspectiveAya GlidaNo ratings yet

- Gilson - Catalogo 2019 - Horno BO-60Document1 pageGilson - Catalogo 2019 - Horno BO-60ELVIsNo ratings yet

- SPE 39895 Improved Selection of Candidates For StimulationDocument9 pagesSPE 39895 Improved Selection of Candidates For StimulationJesus Ponce GNo ratings yet

- Trilon® M GranulesDocument4 pagesTrilon® M GranulesMuhammad SalehNo ratings yet

- Rocker Bogie MechanismDocument6 pagesRocker Bogie MechanismKool GalzNo ratings yet

- AC CircuitsDocument12 pagesAC CircuitsLights Camera, ActionNo ratings yet

- Iq Test1Document9 pagesIq Test1ALJa bherNo ratings yet

- Computers and Chemical EngineeringDocument13 pagesComputers and Chemical EngineeringAndreea IoanaNo ratings yet

- Mathgen 339996123Document10 pagesMathgen 339996123Olivier GouveiaNo ratings yet

- State of Practice in Soil Liquefaction MitigationDocument29 pagesState of Practice in Soil Liquefaction MitigationAndreas Erdian WijayaNo ratings yet

- 2011 EU RAC Installer - WWW - Kib.bgDocument31 pages2011 EU RAC Installer - WWW - Kib.bgk_chavdarovNo ratings yet

- IC Fabrication TechnologyDocument5 pagesIC Fabrication TechnologyEldo N BabyNo ratings yet

- WTG 3 4 Psse ModelDocument20 pagesWTG 3 4 Psse ModelErsiAgo100% (1)

- Penurunan Persamaan BETDocument7 pagesPenurunan Persamaan BETDyah Ayu Pramoda WardaniNo ratings yet

- Introduction To Robotics: Sandesh R S RvceDocument11 pagesIntroduction To Robotics: Sandesh R S RvceSandesh RSNo ratings yet

- The CubliDocument20 pagesThe CubliLin Lina0% (1)

- Velocity Severity Velocity Range Limits and Machine Classes ISO Standard 10816-1Document1 pageVelocity Severity Velocity Range Limits and Machine Classes ISO Standard 10816-1Karthik VkNo ratings yet

United States Patent 1191: Davies Et A1

United States Patent 1191: Davies Et A1

Uploaded by

cvkkkk1Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

United States Patent 1191: Davies Et A1

United States Patent 1191: Davies Et A1

Uploaded by

cvkkkk1Copyright:

Available Formats

United States Patent 1191

[11]

4,444,445

Davies et a1.

[451

Apr. 24, 1984

[54] APPARATUS INCLUDING ELECTRIC

CURRENT TRANSFER

2,236,707

4/1941

Damer et a1. ..................... .1310/239

3,324,445

6/1967

Miller ............................. .. 339/61 M

FOREIGN PATENT DOCUMENTS

[75] Inventors: Evan J. Davies; Alec G. Allen, both of

Sutton Cold?eld, England

513269

2/1955

Italy ............................... .. 339/9 RY

[73] Assignee: National Research Development

Corporation, London, England

Assistant Examiner-David L. Pirlot

[21] App]. No.: 341,183

Attorney, Agent, or Firm-Cushman, Darby & Cushman

[22] Filed:

[57]

[30]

Jan. 20, 1982

Foreign Application Priority Data

Jan. 26, 1981 [GB]

Jun. 29, 1981 [GB]

Primary Examiner-Joseph H. McGlynn

'

ABSTRACT

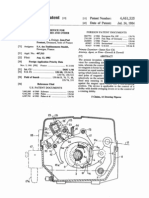

Apparatus consuming heavy electric current, such as an

arc furnace, has concentric members (1) vand (3) be

United Kingdom ............... .. 8102313

United Kingdom ............... .. 8119930

tween which the current has to be transferred. The

member (3) can rotate around, and/or move axially

[51]

Int. Cl.3 ........................................... .. H01R 39/00

[52]

[58]

U.S. Cl. .............................. .. 339/5 M; 339/9 RY

Field of Search .................... .. 339/5, 7, 6 R, 6 A,

with respect to, member (1). Interposed, an annular

member (2) has helically twisted tufts (11) of copper

wire slidably retained by bushes (12) in a hole (10). The

[56]

339/6 RL, 8 R, 8 A, 8 P, 8 L, 8 PB, 8 PS, 8 RL,

copper wires are compressed to ?t between the mem

9 RY, 61 M; 310/219, 231, 239, 248

References Cited

bers (1) and (3), and the compression is stored as elastic

helical twisting energy, ensuring good contact pressure

to transfer current between the members (1) and (3).

U.S. PATENT DOCUMENTS

1,908,764 5/1933 Kruger .............................. .. 339/8 R

1 Claim, 3 Drawing Figures

US. Patent -

Apr. 24, 1984

4,444,445

ft

APPARATUS INCLUDING ELECTRIC CURRENT

TRANSFER

This invention relates to apparatus having two rela

tively movable conductive members between which

electric current is to be transferrediExamples of types

of apparatus which are envisaged are electrochemical

plant, are furnaces and induction heaters, where very

heavy currents are handled and where a certain free

dom of movement of current-carrying members during

>

straints, not shown, arranged so that the member 2 does

not protrude out of the space between the ?rst and third

members.

As shown in more detail in FIG. 2, the second mem

ber 2 is an annulus having numerous radial bushed holes

10 in a regular array. In each hole 10, a bristle in the

form of a tuft 11 of springy copper wire is held. The tuft

11 is square-cut at each end and slightly longer (when

unstressed) than the distance from the outer surface of

the first member 1 to the inner surface of the third mem

ber 3.

able or axiallydisplaceable or both). In the invention,

It will be appreciated that, if the member 3 were

absent, the holes 10 need be only blindtholes facing the

?rst member 1, and the tufts slightly longerthan the

holes were deep plus the spacing between themembers

1 and 2. In any case, the tufts could be conductively

bonded in position, and each tuft could consist of a

single wire only. An alternative material to copper

the surface of one of the members is characterized by a

would be, for example, phosphor bronze for its springi

plurality of spaced resilient conductive bristles (e.g. of 20

wire, or of tufts of wire) under pressure brushing the

ness.

use is needed.

In apparatus according to the invention, the members

have surfaces facing each other, their relative motion

being such that the distance apart of the surfaces re

mains substantially the same (e.g. they are parallel

plates, or they may be concentric and mutually rotat

surface of the other member to effect the current trans

FIG. 3 shows the three members in their relative

operative positions, and one of the holes 10 in more

detail. A bush 12 is force-?tted one at each end of the

fer. The pressure is preferably accommodated elasti

hole 10, flush with the body sides of the member 2.

cally, preferably as a helical twist imparted to the tufts.

25 (Instead of one bush 12, the hole 10 could have been

The tufts may be rooted in holes in the member.

counterbored). The tuft 11, which is twisted elastically

The apparatus may consist of three concentric mem

to form a long pitch helix or any other con?guration

bers. In this case, the middle one may be annular and

giving axial springiness, is ?tted to the illustrated pos

bristled, further having spaced conductive bristles di

tion by presenting it through both bushes 12. The tufts

rected outwardly to brush an outermost (third) concen

are a somewhat loose fit through the bushes. When the

tric conductive member mutually rotatable or axially

apparatus is assembled, the tufts 11 are necessarily com

displaceable or both with respect to the innermost (?rst)

pressed axially and relax partly by adjusting the pitch of

member, for current transfer between the ?rst and the

their helix and partly by bowing-out in the central part

third members. The outwardly directed bristles may be

of the hole 10 between the bushes 12; the helical form

rooted in through-holes and may be long enough to

protrude such as simultaneously to serve as inwardly 35 prevents excessive bowing-out.

When the apparatus is assembled, the numerous tufts

directed bristles.

11 are held in position by compression between the

The invention will now be described by way of exam

members 1 and 3, while the member 2 is free to slide

ple with reference to the accompanying drawings, in

(either axially, subject to the limit restraints, or rotation

which

FIG. 1 shows schematically part of an apparatus 40 ally) relatively to either of those members.

Grooves 2a (inner) and 2b (outer) in the member 2

according to the invention

retain the previously mentioned guide blocks, shown as

21 and 22, for preserving the spacing between the mem

bers 1 and 2, and 2 and 3.

FIG. 3 is a section (to a still larger scale) taken in the

vertical plane including the line IIIIII shown in FIG. 45 In use, heavy electric current (kiloamps or more) is to

be transferred from the power supply to the arm 3a,

2, and showing the other members in position.

FIG. 2 shows one member of the apparatus to a larger

scale and

Turning to FIG. 1, a ?rst member 1 is a copper col

umn having a rigid radial arm 1a leading to a fixed

supply of electricity.

A second member 2 is a non-magnetic annulus

mounted concentrically on the column 1 with clearance

and able to move axially and rotationally with respect

to the ?rst member 1. Preferably the annular gap be

tween the members 1 and 2 is determined by non-con

ductive guide blocks (e. g. of nylon or PTFE) in the gap. 55

A third conductive member 3 has a concentric space

which may have to move during passage of the current.

(The expedient of water-cooled flexible cables to do this

job is cumbersome and expensive). Current passes from

the member 1 into the member 3 through the numerous

tufts 11, such that any given wire is carrying only a

modest current; should any wire be carrying excessive

current, it will heat up and thus become more resistive,

automatically forcing the total current to balance itself

out better amongst all the wires.

The axial compression of the tufts 11, stored largely

accommodating the second member 2 with clearance

as a helix-twisting force, provides the contact pressure,

and has a rigid arm 30 leading to a moveable electrode

arm of an arc furnace (not shown). When the electrode

and each individual wire can move along its own axis,

even within a tuft, to adopt an equilibrium position to

arm is moved, the third member 3 is thus forced to slide 60 bear against both the members 1 and 3; of course the tuft

as a whole can also move to adopt such an equilibrium

over and/or rotate about the second member 2. Move

ments of the electrode arm which cannot be accommo

dated by such sliding and rotation are not permitted.

position.

As the member 3 is moved, the tufts 11 (under their

propensity to untwist and hence to lengthen) wipe the

The return to the electricity supply would run to a ?xed

counter-electrode of the arc furnance. The second 65 surface of the member 1 or of the member 3 or both,

thus providing a self-cleaning action and automatically

member 2 is not positively driven to move in any direc

taking up slight wear or surface irregularities. Accord

tion, but is freely left to take up inertly any position as

ingly, no special conditions should be needed in the way

the third member 3 is moved, subject to axial limit re

4,444,445

of cooling gas or inert gas, except preferably for some

1L Apparatus including ?rst, second and third mem

bers, said ?rst and third members being two mutually

rotatable and axially displaceable concentric conduc

rudimentary protection against gros dirt.

Which of the members 1 and 3 is moveable and which

of them is connected to the power supply can be re

tive members between which electric current is to be

versed compared with the illustrated example.

transferred, said ?rst and said third members having

When the device is used as a connector, for example

when the member 1 can be withdrawn completely and

replaced as in the connections to an induction heater

coil, it may be desirable to restrain the tufts 11 from

excessive protrusion into the gap vacated by the mem

ber 1 but without interfering with their pressure func

surfaces facing each other and their relative motion

being such that the distance apart of the surfaces re

mains substantially the same, said second member being

diate member having a plurality of spaced resilient tufts

tion. A simple annular clip in association with the

of wire disposed in substantially radially extending

an intermediate annular member which is concentric

with said ?rst and third members, said second, interme

bushes 12 would suffice, such as a clip about the tuft 11

throughholes in said second member, said tufts being

within the hole 10 and abutting the bush 12 nearer to the

long enough to protrude both inwardly and outwardly

member 1, and there are many other ways of doing it. 15 thereof and the ends of said tufts thereby being under

Still when the device is used as a connector, a long

lead chamfer can be provided on the member 1, so that

pressure and simultaneously brushing the facing sur

on its reinsertion, it smoothly recompresses the tufts 11

which might otherwise obstruct it.

We claim:

rent transfer, the pressure being accommodated elasti

faces of said ?rst and third members to effect the cur

cally as a helical twist imparted to said tufts.

i

25

35

45

50

55

65

You might also like

- The Fabric Formwork Book PDFDocument318 pagesThe Fabric Formwork Book PDFtoth_daniel75% (4)

- A Method of Measuring Earth Resistivity by Frank Wenner PDFDocument14 pagesA Method of Measuring Earth Resistivity by Frank Wenner PDFArogya Raju Pudhota50% (2)

- U.S. Patent 2,683,388, Entitled "Pickup Device For Stringed Instruments" To Keller, Issued 1954.Document4 pagesU.S. Patent 2,683,388, Entitled "Pickup Device For Stringed Instruments" To Keller, Issued 1954.Anonymous a7S1qyXNo ratings yet

- Solved Problems in Electromagnetics by Syed A NasarDocument444 pagesSolved Problems in Electromagnetics by Syed A NasarOnur Çakıroğlu80% (10)

- 5 Development and Operating Experience PDFDocument10 pages5 Development and Operating Experience PDFVijaya100% (4)

- Oct. 18, 1966 G. H. Lagher 3,279,229: Roller-Bending Machine For Rounding Sheet MetalDocument3 pagesOct. 18, 1966 G. H. Lagher 3,279,229: Roller-Bending Machine For Rounding Sheet Metalxuanphuong2710No ratings yet

- United States PatentDocument6 pagesUnited States Patentaless2056No ratings yet

- Classification and Function of RelaysDocument7 pagesClassification and Function of RelaysVasu BagganNo ratings yet

- Unit 3 Tension Members: StructureDocument28 pagesUnit 3 Tension Members: StructureRaj BakhtaniNo ratings yet

- J. W. Mayo Etal Electrical-Connector: Filed June 1965Document3 pagesJ. W. Mayo Etal Electrical-Connector: Filed June 1965Kevin CooperNo ratings yet

- Unit 3 (C) Pressure MeasurementDocument17 pagesUnit 3 (C) Pressure MeasurementFuzail AhmadNo ratings yet

- July 3T,"Í962 A. B. Swallcsw Etal 3,047,860: Two-Fly Electromagnetic Energy Reflecting FabricDocument4 pagesJuly 3T,"Í962 A. B. Swallcsw Etal 3,047,860: Two-Fly Electromagnetic Energy Reflecting Fabricdavid19775891No ratings yet

- TRANSFLUXORS and Their Application in Automation and Remote Control 1964Document59 pagesTRANSFLUXORS and Their Application in Automation and Remote Control 1964JonNo ratings yet

- AC Windings StudentsDocument17 pagesAC Windings StudentsSisira JayamannaNo ratings yet

- DC Machine NotesDocument41 pagesDC Machine NotesEric GithinjiNo ratings yet

- (12 Ulllted States Patent (10) Patent N0.: US 6,901,818 B1Document15 pages(12 Ulllted States Patent (10) Patent N0.: US 6,901,818 B1brig1960No ratings yet

- Three Phase Stator Windings: Types of A-C WindingsDocument10 pagesThree Phase Stator Windings: Types of A-C WindingsNiño John JaymeNo ratings yet

- Power Transformer Basic DesignDocument31 pagesPower Transformer Basic DesigntajakaNo ratings yet

- Us 5360355Document6 pagesUs 5360355kimscribd66No ratings yet

- Three-Phase A.C. CircuitsDocument32 pagesThree-Phase A.C. CircuitsĐỗ ĐứcNo ratings yet

- PDFDocument32 pagesPDFUnknownNo ratings yet

- Tangential DriveDocument5 pagesTangential Drivecopkutusu2012No ratings yet

- H. A. Enge 3,071,702: High-Voltage Generator With'Solid Insulation Filed Dec. 3, 1958Document3 pagesH. A. Enge 3,071,702: High-Voltage Generator With'Solid Insulation Filed Dec. 3, 1958Victor Von DoomNo ratings yet

- Three Phase Stator Windings: Types of A-C WindingsDocument10 pagesThree Phase Stator Windings: Types of A-C Windingsvaraprasad93No ratings yet

- Dren Ker 1956Document8 pagesDren Ker 1956Pulkit BimalNo ratings yet

- Transformer Trouble, Test, Drying, Parallel OperationDocument35 pagesTransformer Trouble, Test, Drying, Parallel OperationMohammad Ibnul Hossain100% (1)

- US2574551 (Electronic Tachometer)Document7 pagesUS2574551 (Electronic Tachometer)Aaron Choco De GuzmanNo ratings yet

- 3 Phase Transformer - Phasor RepresentationDocument37 pages3 Phase Transformer - Phasor RepresentationnooralhudNo ratings yet

- EEPC108 Module 1Document52 pagesEEPC108 Module 1Elizabeth GomezNo ratings yet

- Dobby ControlDocument14 pagesDobby ControlPradip GuptaNo ratings yet

- Principles and Construction of TransformerDocument5 pagesPrinciples and Construction of TransformerJohn Kenneth ArellonNo ratings yet

- Strain Gauges NptelDocument15 pagesStrain Gauges Nptelsushant271992No ratings yet

- New Microsoft Word DocumentDocument17 pagesNew Microsoft Word Documentyousfe0% (1)

- May 29, 1945-L. H. B. Beer 2,377,175Document11 pagesMay 29, 1945-L. H. B. Beer 2,377,175Victor Von DoomNo ratings yet

- (54 Ion Cluster Acceleratio: Other Publications: United States Patent (191Document9 pages(54 Ion Cluster Acceleratio: Other Publications: United States Patent (191Victor Von DoomNo ratings yet

- Over Head LinesDocument8 pagesOver Head LinesDdumbaNo ratings yet

- Speed of Sound in Water by A Direct MethodDocument6 pagesSpeed of Sound in Water by A Direct MethodTony GeorgeNo ratings yet

- Insulators: Desirable Properties of InsulatorsDocument10 pagesInsulators: Desirable Properties of InsulatorsethanNo ratings yet

- US1170811Document4 pagesUS1170811George AcostaNo ratings yet

- 1 - Insulators String Efficiency ProblemDocument71 pages1 - Insulators String Efficiency ProblemVeera Vamsi Yejju100% (1)

- Transient Eddy 06Document1 pageTransient Eddy 06Constantin DorinelNo ratings yet

- MVMK Mm. .: File?d Jan. 29, 1944Document4 pagesMVMK Mm. .: File?d Jan. 29, 1944Syed Umair RizviNo ratings yet

- Lecture 7Document11 pagesLecture 7yoziscijuniorNo ratings yet

- Power Transformer Construction WindingsDocument5 pagesPower Transformer Construction WindingsRobert GalarzaNo ratings yet

- Description of Sample Problems: Ls-DynaDocument29 pagesDescription of Sample Problems: Ls-DynaraviNo ratings yet

- WA ER: March 15, 1966 H. P. RaabeDocument9 pagesWA ER: March 15, 1966 H. P. Raabedavid19775891No ratings yet

- Size, Shape, and Low Energy Electronic Structure of Carbon NanotubesDocument4 pagesSize, Shape, and Low Energy Electronic Structure of Carbon Nanotubesteju1996coolNo ratings yet

- Design and Power Conditioning For The Coil GunDocument5 pagesDesign and Power Conditioning For The Coil GunkomuncuNo ratings yet

- Three-Winding Transformer MODEL and TESTSDocument4 pagesThree-Winding Transformer MODEL and TESTSdaovantutudvhtd100% (1)

- Sheath CurrentsDocument5 pagesSheath Currentsscribdkkk100% (1)

- 2-1-Elements of Electrical EngineeringDocument164 pages2-1-Elements of Electrical EngineeringPrachi PolNo ratings yet

- LecherrrrDocument18 pagesLecherrrrChristian Amenofis MarinoNo ratings yet

- Electrodynamic Shaker Fundamentals PDFDocument8 pagesElectrodynamic Shaker Fundamentals PDFJorge Luis Ardila MatajiraNo ratings yet

- Electrical Power Transmission and DistributionDocument29 pagesElectrical Power Transmission and DistributionEngrAneelKumarAkhaniNo ratings yet

- Nbsbulletinv4n1p141 A2bDocument8 pagesNbsbulletinv4n1p141 A2bDiegoNo ratings yet

- US5186686Document11 pagesUS5186686雷黎明No ratings yet

- Experiment No.7 Transformers: Engr. Conrado QuinalayoDocument9 pagesExperiment No.7 Transformers: Engr. Conrado QuinalayoJaloyd MacalalagNo ratings yet

- LRL Accelerators, The 184-Inch SynchrocyclotronFrom EverandLRL Accelerators, The 184-Inch SynchrocyclotronNo ratings yet

- Experiments on the Absence of Mechanical Connexion between Ether and MatterFrom EverandExperiments on the Absence of Mechanical Connexion between Ether and MatterNo ratings yet

- Feb. 8, 1966 L.. H. Smith 3,233,345: Filed July Lí 1964 2 Sheets-Sheet LDocument6 pagesFeb. 8, 1966 L.. H. Smith 3,233,345: Filed July Lí 1964 2 Sheets-Sheet Lcvkkkk1No ratings yet

- Sept. 4 - , 1956 A. Cherkin 2,761,445: Filed May 3, 1952 2 Sheets-Sheet 1Document5 pagesSept. 4 - , 1956 A. Cherkin 2,761,445: Filed May 3, 1952 2 Sheets-Sheet 1cvkkkk1No ratings yet

- Predictive Astro M N KedarDocument388 pagesPredictive Astro M N KedarPrasan Nanda71% (7)

- Gli55 User ManualDocument126 pagesGli55 User Manualcvkkkk1No ratings yet

- John Nash Thesis LengthDocument4 pagesJohn Nash Thesis Lengthmaureennonweilertulsa100% (2)

- A Finite Element Study of The Onset of Vortex Shedding in Flow Past Variously Shaped BodiesDocument23 pagesA Finite Element Study of The Onset of Vortex Shedding in Flow Past Variously Shaped BodiesAshish PawarNo ratings yet

- CBSE Class 12 Chemistry Board Question Paper Solved 2018 Set 1Document21 pagesCBSE Class 12 Chemistry Board Question Paper Solved 2018 Set 1Sumit ChauhanNo ratings yet

- Lecture-5 - Miller Indices of Cubic SystemDocument23 pagesLecture-5 - Miller Indices of Cubic SystemSibasish RoutNo ratings yet

- HT Rate Calculations - Helical CoilsDocument4 pagesHT Rate Calculations - Helical CoilssandeshNo ratings yet

- Epoxy HandbookDocument277 pagesEpoxy HandbookTan Soh Huen100% (3)

- Produktkatalog 2012-2013Document228 pagesProduktkatalog 2012-2013Dominique RogalskiNo ratings yet

- WS 050 1001 C Thermoshield Model 883BDocument6 pagesWS 050 1001 C Thermoshield Model 883Bcandra trisilawatiNo ratings yet

- Biochemistry Lab NotesDocument2 pagesBiochemistry Lab NotesEppNo ratings yet

- Introduction To Steel Reinforcement WorkDocument12 pagesIntroduction To Steel Reinforcement Workalmond2008No ratings yet

- Moe - Nonlinear PerspectiveDocument7 pagesMoe - Nonlinear PerspectiveAya GlidaNo ratings yet

- Gilson - Catalogo 2019 - Horno BO-60Document1 pageGilson - Catalogo 2019 - Horno BO-60ELVIsNo ratings yet

- SPE 39895 Improved Selection of Candidates For StimulationDocument9 pagesSPE 39895 Improved Selection of Candidates For StimulationJesus Ponce GNo ratings yet

- Trilon® M GranulesDocument4 pagesTrilon® M GranulesMuhammad SalehNo ratings yet

- Rocker Bogie MechanismDocument6 pagesRocker Bogie MechanismKool GalzNo ratings yet

- AC CircuitsDocument12 pagesAC CircuitsLights Camera, ActionNo ratings yet

- Iq Test1Document9 pagesIq Test1ALJa bherNo ratings yet

- Computers and Chemical EngineeringDocument13 pagesComputers and Chemical EngineeringAndreea IoanaNo ratings yet

- Mathgen 339996123Document10 pagesMathgen 339996123Olivier GouveiaNo ratings yet

- State of Practice in Soil Liquefaction MitigationDocument29 pagesState of Practice in Soil Liquefaction MitigationAndreas Erdian WijayaNo ratings yet

- 2011 EU RAC Installer - WWW - Kib.bgDocument31 pages2011 EU RAC Installer - WWW - Kib.bgk_chavdarovNo ratings yet

- IC Fabrication TechnologyDocument5 pagesIC Fabrication TechnologyEldo N BabyNo ratings yet

- WTG 3 4 Psse ModelDocument20 pagesWTG 3 4 Psse ModelErsiAgo100% (1)

- Penurunan Persamaan BETDocument7 pagesPenurunan Persamaan BETDyah Ayu Pramoda WardaniNo ratings yet

- Introduction To Robotics: Sandesh R S RvceDocument11 pagesIntroduction To Robotics: Sandesh R S RvceSandesh RSNo ratings yet

- The CubliDocument20 pagesThe CubliLin Lina0% (1)

- Velocity Severity Velocity Range Limits and Machine Classes ISO Standard 10816-1Document1 pageVelocity Severity Velocity Range Limits and Machine Classes ISO Standard 10816-1Karthik VkNo ratings yet