Professional Documents

Culture Documents

SMEDA Seed Processing Unit (Wheat & Rice) PDF

SMEDA Seed Processing Unit (Wheat & Rice) PDF

Uploaded by

pradip_kumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SMEDA Seed Processing Unit (Wheat & Rice) PDF

SMEDA Seed Processing Unit (Wheat & Rice) PDF

Uploaded by

pradip_kumarCopyright:

Available Formats

Pre-Feasibility Study

SEED PROCESSING UNIT

(Wheat & Rice)

Small and Medium Enterprise Development Authority

Government of Pakistan

www.smeda.org.pk

HEAD OFFICE

6th Floor LDA Plaza Egerton Road, Lahore

Tel 111 111 456, Fax: 6304926-7 Website www.smeda.org.pk

Helpdesk@smeda.org.pk

REGIONAL OFFICE

PUNJAB

REGIONAL OFFICE

SINDH

REGIONAL OFFICE

NWFP

REGIONAL OFFICE

BALOCHISTAN

8th Floor LDA Plaza Egerton

Road, Lahore

Tel 111 111 456, Fax:

6304926-7 Website

www.smeda.org.pk

5TH Floor, Bahria

Complex II, M.T. Khan Road,

Karachi.

Tel: (021) 111-111-456

Fax: (021) 5610572

Helpdesk-khi@smeda.org.pk

Ground Floor

State Life Building

The Mall, Peshawar.

Tel: (091) 9213046-47

Fax: (091) 286908

helpdesk-pew@smeda.org.pk

Bungalow No. 15-A

Chaman Housing Scheme

Airport Road, Quetta.

Tel: (081) 831623, 831702

Fax: (081) 831922

helpdesk-qta@smeda.org.pk

helpdesk@smeda.org.pk

April, 2008

Pre-Feasibility Study

Seed Processing Unit (Wheat & Rice)

DISCLAIMER

The purpose and scope of this information memorandum is to introduce the subject

matter and provide a general idea and information on the said area. All the material

included in this document is based on data/information gathered from various sources and

is based on certain assumptions. Although, due care and diligence has been taken to

compile this document, the contained information may vary due to any change in any of

the concerned factors, and the actual results may differ substantially from the presented

information. SMEDA does not assume any liability for any financial or other loss

resulting from this memorandum in consequence of undertaking this activity. Therefore,

the content of this memorandum should not be relied upon for making any decision,

investment or otherwise. The prospective user of this memorandum is encouraged to

carry out his/her own due diligence and gather any information he/she considers

necessary for making an informed decision.

The content of the information memorandum does not bind SMEDA in any legal or other

form.

DOCUMENT CONTROL

Document No.

PREF-44

Revision

Prepared by

SMEDA-Punjab

Approved by

GM Punjab

Issue Date

June 20, 2002

Issued by

Library Officer

1

PREF-44/April, 2008/2

Pre-Feasibility Study

Seed Processing Unit (Wheat & Rice)

INTRODUCTION

1.1

Project Brief

1.2

The Main Components of Undesirable Materials in Seed Lots

1.3

Types of Seed Processing Plants

1.3.1 Mobile.

1.3.2 Fixed

4

4

5

1.4

Opportunity Rationale

1.5

Proposed Capacity

1.6

2

3

4

Total Project Cost

CURRENT INDUSTRY STRUCTURE

MARKETING

RAW MATERIAL/MODUS OPERANDI

6

7

8

4.1

Raw Material

4.2

Process Flow

4.3

Modus Operandi/Seed Processing

4.3.1 Drying

4.3.2 Cleaning

4.3.3 Grading

5

6

7

8

8.1

8.2

9

9

9

9

HUMAN RESOURCE REQUIREMENTS

MACHINERY & EQUIPMENT DETAILS

OFFICE EQUIPMENT

LAND & BUILDING

Recommended Mode for Acquiring Land

9

10

10

11

11

Infrastructure Requirements

11

PROJECT ECONOMICS

12

9.1

Project Cost

12

9.2

Project Return

12

9.3

Financing Plan

12

9.4

Estimated Time Frame for Project Completion

12

10 KEY SUCCESS FACTORS

11 THREATS FOR THE BUSINESS

12

13

11.1

Government Regulations

13

11.2

Inadequate supply of other agriculture inputs

13

11.3

Mis-leading Research

13

2

PREF-44/April, 2008/2

Pre-Feasibility Study

Seed Processing Unit (Wheat & Rice)

11.4

Intrusion in Production Chain

14

11.5

Weak Marketing

14

12 REGULATIONS

14

12.1

Mandatory Registration of Seed Processing Units, Dealers: Higher Fines for Substandard

Sale Proposed

14

13 FINANCIAL ANALYSIS

16

13.1

Projected Income Statement

16

13.2

Projected Cash flow Statement

17

13.3

Projected Balance Sheet

18

14 KEY ASSUMPTIONS

20

3

PREF-44/April, 2008/2

Pre-Feasibility Study

Seed Processing Unit (Wheat & Rice)

INTRODUCTION

1.1 Project Brief

Seed processing unit is a project in agriculture sector in which Approved/Certified seeds

of wheat and rice will be produced through the multiplication1 of Basic Seed (Breeder

seed), which will be acquired from seed research institutes & Seed Corporations. This

business can be started in the rural and peri-urban areas. Under the proposed project, the

approved seed will be processed and marketed in the local market. The processing of the

seed involves cleaning, grading, treating, packing, and storing operations.

Currently, there is a shortage of the approved seed, due to which its price has spiraled up.

Hence, it has become difficult for a farmer to purchase seed at a higher price. The

proposed project will facilitate in fulfilling this gap and will provide wheat and rice seed

suitable for sowing. Moreover, this project in the long-run can be considered as a

lucrative investment because the potential for quality seed is quite high in the agriculture

market.

Processing is a value addition activity which improves the physical purity and health of

seed stock by removing various contaminants including undersized and shriveled grains,

inert matter and seeds of other crops.

1.2 The Main Components of Undesirable Materials in Seed Lots

The harvested seeds from a Sheller or thresher or a combine harvester machine contain

many types of undesirable materials.

a) Plant parts and inert matter (stem, leave, stone, soil etc.)

b) Weed seeds (Noxious and obnoxious).

c) Other crop seeds (other cultivars).

d) Seeds of the variety which are immature, broken, damaged and deteriorated.

Therefore, uncleaned seed has to be processed to remove the above mentioned

contaminants to upgrade the quality of seed and to apply seed treatment with chemicals.

1.3 Types of Seed Processing Plants

There are two types of seed processing plants.

1.3.1 Mobile.

It consists of one or two combined machines. Generally, it is an air screen cleaner above

or combined with an indented cylinder. A separate treater may accompany the processing

machine.

Multiplication is the growth of certified seeds through supplying basic seed to the selected registered

growers, from whom the output of their crops of wheat and rice will be purchased.

4

PREF-44/April, 2008/2

Pre-Feasibility Study

Seed Processing Unit (Wheat & Rice)

1.3.2 Fixed

It has two types of layout which are used for processing of large quantity of seed:

a) Vertical-Processing machines are put in different floors in a multistoried building. The

incoming seeds are first elevated to bins from machine on one floor to the other machine

for the next operation. The ground floor is used for seed packaging and storage.

b) Horizontal-In this type of lay out, seeds are elevated in to surge bins and pass on

through machine by gravity and then re-elevated for the next cleaning operation. The

construction and supervision of this type of arrangement is economical than fixed type of

lay out.

1.4 Opportunity Rationale

Seeds are the foundation of human and animal life on earth-the foods we eat, the fiber we

wear, and most of the products we use in our daily life, are created from a seed. There is

no substitute for a quality seed as quality seed is essential for growing quality crops,

which ultimately results in a better quality of life.

Since the evolution of civilization, mankind has been involved in a plethora of agriculture

activities but this practice has reduced with the passage of time. Today, approximately

three percent of the worlds population is engaged in crop production in most of the

industrialized countries, yet more food is produced now than ever in history of mankind.

Agriculture sector contributes 24% of the total GDP for Pakistan. However, the massive

population influx in Pakistan, has greatly burdened the agriculture sector as its

productivity is not able to meet the current food requirements. Furthermore, the lands are

underutilized, due to conventional farming practices i.e. use of conventional seeds,

improper usage of fertilizer and pesticides, etc. One can say that the current agricultural

production system has reached the point of diminishing returns. Further infusion of

physical inputs without basic structural and technological reforms is not going to bring a

response from the agricultural sector. If the current trend is allowed to persist, not only

will it put severe strain on food supplies with unimaginable social and political

ramifications, but bring down the whole edifice of national economic viability because

agricultural production forms the bedrock of Pakistans industrial production.

The solution lies in concurrent and integrated approach towards re-planning the

agricultural production systems in Pakistan, a part of which is also the development of

better seed. The idea revolves around increasing the crop yield by developing high

yielding crop seeds having disease resistance and high germination percentage.

The Government of Pakistan has also declared this sector as an industry, to meet the

rising demand in the agriculture sector, especially in wheat and rice, as these two crops

are considered to be the staple crops. Wheat fulfils the basic need of food of majority of

the populace, whereas the rice is capable of generating great profits as it has a huge

export potential.

In this context, Small & Medium Enterprise Development Authority (SMEDA) has

commissioned to undertake a Pre-Feasibility study for finding the underlying potential in

the seed processing industry.

5

PREF-44/April, 2008/2

Pre-Feasibility Study

Seed Processing Unit (Wheat & Rice)

1.5 Proposed Capacity

The proposed Seed Processing Unit has a maximum capacity of processing 3 tons of seed

per hour. This production capacity is estimated to be economically viable and justifies the

capital as well as operational costs of the project.

Table 1-1Plant Capacity

Description

Input

(Tons)

Wheat

3

Rice

3

Total

Production

Per hour(tons)

3

3

Table 1-2 Product mix

Products

Percentage of

products

Out put (%)

86%

90.00%

Production per

hour

Production

2.58

2.7

5.28

Production per

year

(in tons)

Wheat Seed

Processing

Season

Wheat Seed

Small Seed

wastages

Total

Rice Seed

Processing

Season

Paddy

Animal Seed

Wastages

Total

1 August ----- 30th November

85%

2.55

612

14%

1%

100%

0.42

0.03

3

100.8

7.2

720

1st February --- 30th April

90%

9%

1%

100%

2.7

0.27

0.03

3

486

48.6

5.4

540

1.6 Total Project Cost

The proposed Seed Processing Unit needs a capital investment of about Rs.12.840

million which includes machinery and equipment. In addition to this, a sum of Rs.0.901

million is required as working capital, which will be used for purchasing raw seeds as

well as for meeting the initial expenses of the first year.

CURRENT INDUSTRY STRUCTURE

Till the seventies, there was no proper mechanism for the seed processing in Pakistan. In

1976, the Government established Provincial Seed Corporations; Punjab Seed

Corporation & Sindh Seed Corporation. Currently, these two Corporations are supplying

6

PREF-44/April, 2008/2

Pre-Feasibility Study

Seed Processing Unit (Wheat & Rice)

only ten percent of the cereal seeds and 30% of the cotton seed of the countrys

requirement. Apart from this, a few multinationals and some local processing concerns

have embarked on the opportunity of realizing the potential existent in this market.

However, the practice currently in vogue among the general farming community is that

they still are using the part of their crop produce as seed instead of using the quality seed.

The reason for the low adoption rate of the quality seed is that the corporations and

agencies are supplying only 19% of the wheat seeds requirement and 7.8 % of the rice

seeds requirement. The seed market in Pakistan values to approximately US$ 468

million. The average seed requirement in Pakistan of wheat is 846,000 tons and that of

rice is 625,000 tons. Currently, the availability of certified seeds is very low i.e. 19%

availability against the total demand for wheat, and 7.8% availability against the total

demand for rice. Furthermore, there is a vast network of seed distributors consisting of

nearly 1,200 seed dealers across the country. There are approximately 300 seed

companies registered with the Government, out of which nearly ten percent are active.

Table 2-1Distribution of Improved Seed (Tons)2

Province/crop 2000-01

2001-02

2002-03

2003-04

2004-05

2005-06

Punjab

Wheat

139.96

122.53

105.02

103.87

128.59

116.75

Paddy

1.88

4.13

4.04

6.85

8.47

8.82

Wheat

7.85

13.40

14.98

20.43

25.00

35.37

Paddy

0.32

0.38

0.19

0.48

1.08

1.74

Wheat

6.91

6.77

8.53

10.25

15.01

12.36

Paddy

0.01

0.27

0.19

0.17

0.17

0.00

Wheat

4.50

0.55

0.88

0.96

2.60

1.87

Paddy

0.06

0.08

0.04

0.05

0.00

0.00

Sindh

N.W.F.P

Balochistan

MARKETING

The marketing of approved seed will follow the existing distribution network of the seed

dealers, along with the dealers of the agriculture inputs. Furthermore, the farming

community has to be sensitized about the usage of the approved seed, which will not only

result in enhanced productivity of crop but also lead to increased revenues for the

industry. The sensitization can be achieved through a tailored campaign for achieving the

2

Federal Seed Certification &Registration Department, Islamabad

7

PREF-44/April, 2008/2

Pre-Feasibility Study

Seed Processing Unit (Wheat & Rice)

desired objective- to increase the sales of the seed. The success of the industry is

dependent on the timely availability of the quality seeds at the appropriate places at

competitive prices and in proper packaging.

Moreover, due to a massive demand of the quality seeds in the reconstruction and

development of the agriculture sector of Afghanistan, this project also has the export

potential, if able to meet the international standards required for seed production.

RAW MATERIAL/MODUS OPERANDI

4.1 Raw Material

The raw-material for the said project will follow the following mode:

Basic Seed: The Basic Seed which is the basic raw material for the production of

approved seed, can be obtained from the seed corporations.

Approved Seed: The Basic seed will be cultivated under the controlled environment at

various seed farms, which will result in multiplying it and producing approved seed

through processing. The approved seed is the final product of the project, which will then

be distributed and sold through marketing for growing crops with higher yields.

4.2 Process Flow

RECEPTION

HOLDING

CONDITIONING

PRECLEANING

STORAGE

BASIC CLEANING

SECONDARY SEPARATION

SEED TREATMENT

PAKAGING

DISPATCH

8

PREF-44/April, 2008/2

STORAGE

Pre-Feasibility Study

Seed Processing Unit (Wheat & Rice)

4.3 Modus Operandi/Seed Processing

In the process of seed processing for wheat and rice, Basic Seed will be acquired by the

entrepreneur from the seed corporations like Punjab Seed Corporation. This Basic Seed,

will then be distributed among the selected growers/farmers, who will sow this seed and

grow it in a controlled environment. Subsequently, the output produce from these farms

of wheat and rice i.e. their crop, will be purchased by the entrepreneur for further

processing. After purchasing, the processing of wheat and rice seed will be as follows:

4.3.1 Drying

At the time of harvest, the seed normally contains very high moisture content i.e. above

16% on average. In order to avoid any negative effects of high moisture, the seed has to

be dried and the moisture content has to be reduced to 8-12%. If the seed is stored at high

moisture content, it loses germination quickly and is infested with pest and diseases.

4.3.2 Cleaning

In order to make the seed suitable for cultivation, impurities like weeds, immature seeds,

inert matters, infected seeds, other crop seeds have to be removed.

4.3.3 Grading

After cleaning, the seed requires grading. The grading is of the following types:

Length grading

The clean seed is further graded in this process from the point of view of its

length and the immature/infected seeds or any foreign matter that may not have

been removed in the cleaning process are removed in the length grading process.

Gravity Separating

Gravity separating is followed after length grading and is helpful in removing

light and immature seeds having low germination.

Treating

This process is followed after gravity separating. In the process, a suitable

fungicide and color is used to protect the seed from fungus and various soil

related diseases. The color also gives a suitable appearance to the seed and

proving that a check has been performed, confirming that all seeds have been

uniformly treated.

Packing

To avoid any moisture contents the processed seed is stored in bags which are stored

properly.

HUMAN RESOURCE REQUIREMENTS

The proposed Seed Processing Unit requires the following human resources/staff:

9

PREF-44/April, 2008/2

Pre-Feasibility Study

Seed Processing Unit (Wheat & Rice)

Table 5-1

Positions

Chief executive

General Manager

Agronomist

Researcher

Field Assistants

Plant operators

Plant Supervisor

Sales officers

Accounts Assistant

Store Keeper

Guard

peon/sweeper

Total

Required Salary per Month Salary per Annum

1

75,000

900,000

1

60,000

720,000

1

25,000

300,000

1

18,000

216,000

2

8,000

192,000

4

6,500

312,000

1

12,000

144,000

2

12,000

288,000

1

12,000

144,000

1

6,500

78,000

2

6,000

144,000

2

5,000

120,000

19

3,558,000

MACHINERY & EQUIPMENT DETAILS

The type of equipment needed for the Seed Processing Unit is as under:

Table 6-1 Plant and Machinery3

Description

Pre Cleaning System

Gravity Separating System

Length Grader

Elevator

Rotary Dryer Plant

Treater Plant Iron

Generator

Total

Unit Cost

1

1

1

4

1

1

1

Total Cost

1,150,000

1,150,000

700,000

400,000

100,000

700,000

400,000

100,000

2,350,000

OFFICE EQUIPMENT

Following equipment will be required to cater the needs of administrative block.

Table 7-1 Required Office equipment

Description

Computers

Computer printer (s)

Telephones

3

Quantity

Cost / Rate

Amount

1

1

2

25,000

12,000

3,500

25,000

12,000

7,000

Alhamra Mechenical Works,Bhawalnagar Road Kabula Sharif.Tel # 0457-851110,852430

10

PREF-44/April, 2008/2

Pre-Feasibility Study

Seed Processing Unit (Wheat & Rice)

Fans

Total

1,850

9,250

53,250

Table 7-2 Furniture and Fixtures

Furniture &

Fixtures

chairs

tables

stools

Lighting

Total

Price per unit

Quantity

3,500

6,000

500

10,000

10

5

4

Total cost

35,000

30,000

2,000

10,000

77,000

L AND & B UI L DI NG

8.1 Recommended Mode for Acquiring Land

It is recommended that the proposed project should be started in an acquired land, which

is approximately 8 kanals (one acre). The land should be somewhere near the major cities

of Punjab in a rural or a peri-urban location, preferably near Lahore, but outside the

municipal limits.

Table 8-1 Land Requirement

Required Land (in sq. ft)

36,000

In kanals

8

Per Marla Cost

150,000

Total Cost

1,200,000

8.2 Infrastructure Requirements

The project will have the following infrastructure components:

Table 8-2 Construction Cost

Space requirement

Production Hall

Stores

Office

Security Room

Total Covered Area

Open Space

Total

In sq.ft

3,200

4,800

360

80

8,440

27,560

36,000

11

PREF-44/April, 2008/2

Cost per sq. Ft Construction Cost

650

2,080,000

650

3,120,000

850

306,000

850

68,000

100

2,756,000

8,330,000

Pre-Feasibility Study

Seed Processing Unit (Wheat & Rice)

PROJECT ECONOMICS

9.1 Project Cost

The cost of the project will be as follows:

Head

Land

Building

Furniture

Office equipment

Plant & Machinery:

Preliminary Expenses4

Office vehicle 5

Sub total

Total working capital

Total Project Cost

Cost (Rs.)

1,200,000

8,330,000

77,000

53,250

2,350,000

180,000

650,000

12,840,250

901,733

13,741,983

9.2 Project Return

38%

3.68

12,256,164

Projects Internal Rate of Return (IRR)

Payback Period (Years)

Net Present Value (NPV) (Rs)

9.3 Financing Plan

Financing

Sponsors Equity

Bank Finance

Share

50%

50%

Rs

6,870,991

6,870,991

9.4 Estimated Time Frame for Project Completion

The estimated time frame for the completion of the project will be one year.

10 KEY SUCCESS FACTORS

There are a number of factors which contribute towards the success of a project. In case

of the project of Seed Processing Unit, some of the Key Success Factors are as follows:

The seed must be free from inert material, weed seed and seed of other varieties and

crops; have safe moisture content; have high germination and vigor; and be relatively

free of damage and disease. The seed must also be treated, bagged and labeled

properly.

Includes ,utility connection charges, salaries of administrative staff and expense related to companys

incorporation

5

Price of Suzuki Shehzore

12

PREF-44/April, 2008/2

Pre-Feasibility Study

Seed Processing Unit (Wheat & Rice)

The harvested seed must be dried to the level of safe moisture content. This is to

reduce physiological activity and damage from storage fungi and insects.

Generally, seed has contaminants of various kinds when it comes into the processing

plant, especially if it has been harvested with an improperly adjusted combine or

thresher or threshed directly on the ground. Cleaning can be done because seeds differ

in length, width, thickness, density, shape, surface texture, color, affinity for liquids,

and electrical conductivity, but the most commonly used characteristics are seed size

and density. Cleaning increases the seed quality by improving physical purity and

germination. That means that inert matter must be removed.

After the seeds are treated, they are bagged, labeled and stored. Bagging and labeling

should be done so that the content of the bag can be guaranteed to farmers purchasing

the seed.

Seeds should be stored under conditions, which maintain seed quality. The ambient

conditions and the storage period will determine the type of storage that is required.

Relative humidity and temperature are very important. High relative humidity and

high temperature reduce the viability of seed.

All inside parts of cleaning machines should be accessible so that hidden seeds can be

removed.

All seed plants should have an internal seed-quality control system. Laboratories to

assess quality before and after processing and to monitor the efficiency of the

different processing machines are essential.

While planning and purchasing seed plants, it is important to include sufficient spare

parts. Proper maintenance is essential.

Only properly-trained seed staff should operate plants. A comprehensive training

program needs to go hand in hand with the establishment of new seed plants.

11 THREATS FOR THE BUSINESS

11.1 Government Regulations

Various government regulations such as price regulations and red-tapism in the process

of seed certification can result in delaying the intended project plan.

11.2 Inadequate supply of other agriculture inputs

Inadequate supply of agriculture inputs such as fertilizer, irrigation water, pesticides, etc.

can result in hampering the intended project benefits.

11.3 Mis-leading Research

Improper identification of varieties, which are not suitable for the Pakistani climatic and

agriculture conditions, or varieties prone to diseases, or requiring high inputs (having low

returns on investment) can be a major threat to the project.

13

PREF-44/April, 2008/2

Pre-Feasibility Study

Seed Processing Unit (Wheat & Rice)

11.4 Intrusion in Production Chain

Since this project is dependent on the contract growers, therefore, if the entrepreneur is

not able to maintain a controlled environment through constant monitoring mechanism, it

may result in the altered seed variety, hence resulting in disturbing the production chain.

11.5 Weak Marketing

Weak or improper marketing strategies can result in failure of the project.

12 REGULATIONS

12.1 Mandatory Registration of Seed Processing Units, Dealers: Higher Fines fo r

Substandard Sale Proposed

ISLAMABAD (August 01 2007): The government is making registration of private

sector companies, seed dealers and seed processing units mandatory, to settle legal

disputes, and enhance penalties on sale of substandard seed, official sources told Business

Recorder.

These measures would be taken through amendments in the `ineffective` Seed Act 1976,

to be placed before the Cabinet in its meeting on Wednesday. The Ministry of Food,

Agriculture and Livestock (Minfal) is of the view that the existing Seed Act is unable to

meet the changing scenario of the emerging seed industry and the requirements of private

sector.

Moreover, the definitions given in the Act are not compatible with the advancement in

the field of seed technology and trade. The penalties given in the Seed Act are not

deterrent to curb the sale of substandard seed in the market, which is one of the reasons to

propose amendments in the Act, sources said

Minfal, after detailed consultations with the stakeholder, has proposed following

amendments in the Seed Act, 1976.

a) Renaming the department to meet legal proceedings in the court and addition of

more compatible definitions of various terms.

b) Registration of private sector companies, seed dealers and seed processing units to

settle the arising legal disputes.

c) Access to pre-basic seed to the private sector, provision for which did not exist

before.

d) Training of private seed sector personnel, especially to work under WTO regime.

e) Enhancement of penalties/fines for effective seed enforcement.

f) Promotion of research in seed science and technology to strengthen seed industry

and the research-based regulatory mechanism.

g) Restriction on sale of unapproved/banned varieties and effectively control various

cheating practices through the provision of misbranding clause.

14

PREF-44/April, 2008/2

Pre-Feasibility Study

Seed Processing Unit (Wheat & Rice)

h) Registration of plant variety and horticulture nurseries; and

i) Establishment of accredited seed testing laboratories in public as well as in private

sector.

j) Establishment of federal seed and variety evaluation committee

The Federal Seed Certification & Registration Department controls the quality of seeds.

This department has the following functions:

Registration of the Growers

Field inspection of the Crops

Sampling and testing of seeds

Control of the quality of seeds

Certification of Seeds

Issuance of the quality certificate

This department, for achieving the quality standards and for insuring genetic

identity/purity of seeds, adopts the following modus operandi for seed certification;

Field Inspections

Field Inspections are carried out for determining the crops in which seed development is

necessary. Furthermore, the origin and history as well as the progress of various seeds is

also determined during these inspections.

Seed Tests

The department also carries out various laboratory tests, which includes germination,

purity analysis, moisture analysis, seed diseases, seed pests, seed health.

15

PREF-44/April, 2008/2

Pre-Feasibility Study

Seed Processing Unit (Wheat & Rice)

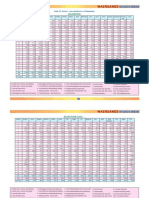

13 FINANCIAL ANALYSIS

13.1 Projected Income Statement

Rs(000)

Year - I

Year - II

Year - III

Year - IV

Year - V

11,856

13,715

15,860

18,213

20,790

23,612

26,697

Cost of Sales

Gross Profit

Operating Expenses:

Electricity

Administrative Salaries

Printing & Stationary

Entertainment

Marketing

Telephone Fax and Postage

Administrative Expenses

Consultants share

2,464

9,392

2,424

11,292

2,401

13,459

2,392

15,820

2,398

18,393

2,430

21,182

144

2,394

24

48

119

48

2,777

2,371

145

4,215

24

48

107

48

4,588

2,743

147

4,425

24

49

96

49

4,791

3,172

148

4,647

25

49

86

49

5,005

3,643

150

4,879

25

50

78

50

5,232

4,158

Operating Profit

4,244

3,960

5,497

7,173

9,003

914

721

529

337

144

3,330

416

3,239

405

4,968

621

6,836

855

2,914

2,834

4,347

2,914

2,914

5,748

Sales/Revenue

Financial Charges

Profit before Taxation

Taxation

13%

Profit after Taxation

Acc. Profit b/f

Accumulated Profit c/f

Year - IX

Year - X

30,068

33,747

37,759

2,462

24,235

2,507

27,561

2,564

31,183

2,632

35,126

151

5,123

25

50

70

50

5,470

4,722

153

5,677

25

51

63

51

6,020

5,339

154

5,960

26

51

57

51

6,300

6,014

156

6,259

26

52

51

52

6,595

6,749

157

6,571

26

52

46

52

6,906

7,552

10,989

12,876

15,247

17,838

20,669

8,859

1,107

10,989

1,374

12,876

1,609

15,247

1,906

17,838

2,230

20,669

2,584

5,982

7,751

9,616

11,266

13,341

15,609

18,085

5,748

10,095

16,076

23,828

33,444

44,710

58,052

73,660

10,095

16,076

23,828

33,444

44,710

58,052

73,660

91,745

16

PREF-44April, 2008/2

Year - VI Year - VII Year - VIII

Pre-Feasibility Study

Seed Processing Unit (Wheat & Rice)

13.2 Projected Cash flow Statement

(000)

Year 1

Year 2

Year 3

Year 4

Year 5

Profit before Financial

Charges & Taxation

Amortization

Depreciation

1,076

968

871

783

705

Working Capital Change

5,347

(367)

4,951

(58)

6,387

(68)

7,973

(74)

9,722

(81)

Cash from other Sources

Owners

Bank Finance

Total Sources

Applications:

Fixed Assets

Preliminary Expenses

Re -Payment of Loan

L C Charges

Tax

Cash Increase/(Decrease)

Opening Balance

Closing Balance

4,244

27

6,871

6,871

13,742

18,722

11,933

180

2,288

416

14,818

3,904

3,904

3,960

23

4,893

5,497

20

7,173

17

6,319

7,899

9,641

10,989

12

634

Year 7

12,876

10

571

Year 8

15,247

9

513

Year 9

17,838

7

462

Year 10

20,669

6

416

11,636

(89)

13,457

(98)

15,769

(107)

18,308

(117)

21,090

(127)

11,546

13,359

15,663

18,191

20,963

2,096

405

2,501

1,903

621

2,524

1,711

855

2,565

1,518

1,107

2,626

1,374

1,374

1,609

1,609

1,906

1,906

2,230

2,230

2,584

2,584

2,392

3,795

5,333

7,015

10,173

11,750

13,757

15,961

18,380

3,904

6,297

10,092

15,425

22,440

32,613

44,362

58,119

74,080

6,297

10,092

15,425

22,440

32,613

44,362

58,119

74,080

92,460

17

PREF-44April, 2008/2

9,003

14

Year 6

Pre-Feasibility Study

Seed Processing Unit (Wheat & Rice)

13.3 Projected Balance Sheet

Year - I

Fixed Assets

Land

Buildings

Office Equipment

Plant & Machinery

Total Fixed Assets

Preliminary Expenses

Current Assets:

Accounts Receivable

Cash in Hand / Bank

1,200

7,497

45

2,115

Year - II

1,200

6,747

38

1,904

Year - III

1,200

6,073

33

1,713

Year - IV

Year - V

1,200

5,465

28

1,542

1,200

4,919

24

1,388

Year - VI

1,200

4,427

20

1,249

Year - VII

1,200

3,984

17

1,124

Year - VIII

1,200

3,586

15

910

Year - IX

1,200

3,227

12

910

Rs(000)

Year - X

1,200

2,904

10

819

10,857

153

9,889

130

9,018

111

8,235

94

7,530

80

6,896

68

6,325

58

5,812

49

5,350

42

4,934

35

395

3,904

457

6,297

529

10,092

607

15,425

693

22,440

787

32,613

890

44,362

1,002

58,119

1,125

74,080

1,259

92,460

15,310

16,773

19,749

24,361

30,743

40,363

51,635

64,982

80,597

98,688

Owners Equity:

Capital

Accumulated Profit

6,871

2,914

6,871

5,748

6,871

10,095

6,871

16,076

6,871

23,828

6,871

33,444

6,871

44,710

6,871

58,052

6,871

73,660

6,871

91,745

Long Term Loan

5,497

4,123

2,748

1,374

28

31

35

39

44

49

54

60

66

72

15,310

16,773

19,749

24,361

30,743

40,363

51,635

64,982

80,597

98,688

Current Liabilities:

Current Portion

of Long Term Loan

Accounts Payable

18

PREF-44April, 2008/2

Pre-Feasibility Study

Seed Processing Unit (Wheat & Rice)

14 KEY ASSUMPTIONS

Table 14-1 Production Assumptions

10

3 ton per hour

Number of Machines

Seasonal Production Capacity (tons)

Table 14-2 Operating Assumptions

Hours operational per day

Shifts Per Day

Days operational for Wheat

Days operational for Rice

Days operational per Year (factory)

1 August - 30November

1 February 30 April

Table 14-3 Economy/Agriculture Related Assumptions

10 %

6.5 %

5%

6.5%

Electricity consumption growth rate

Electricity price growth rate

Wage growth rate

Inflation

Table 14-4 Cash flow Assumptions

30

15

Account receivable cycle (days)

Account payable cycle (days)

Table 14-5 Revenue Assumptions

18

10

26

4

10% per annum

6.5% per annum

Wheat

Small Seed

Rice

Animal Seed

Sales growth rate

Sales price growth rate

Table 14-6 Expense Assumptions

Purchase price per kg (wheat) from the farmer

Purchase price per kg (rice) from the farmer

Promotional expenses (%age of expected sales)

Machine maintenance per annum

Raw material price growth rate

Depreciation method

20

PREF-44April,, 2008/2

Rs.15.6

Rs.16.275

1%

1% of project cost

6.5%

Straight Line

8

2

120

90

300

Pre-Feasibility Study

Seed Processing Unit (Wheat & Rice)

Table 14-7 Financial Assumptions

Project life

Debt: equity

Interest rate on debt

Debt tenure

Debt payment per year

10 Years

50:50

14%

5 years

2

21

PREF-44April,, 2008/2

You might also like

- Seed Processing Plant Project ReportDocument36 pagesSeed Processing Plant Project ReportPrashant Naikwadi92% (12)

- Company Profile Raya FoodsDocument16 pagesCompany Profile Raya FoodsIMRAN TAHASILDARNo ratings yet

- Project Report On Whipping CreamDocument5 pagesProject Report On Whipping CreamEIRI Board of Consultants and PublishersNo ratings yet

- Business PlanDocument11 pagesBusiness PlanKashif razaNo ratings yet

- KGN OLK 84 2013 Tender For Supply of Cutlery & Crockery For Olkaria Geothermal Health Spa ProjectDocument79 pagesKGN OLK 84 2013 Tender For Supply of Cutlery & Crockery For Olkaria Geothermal Health Spa ProjectMoses Karanja MungaiNo ratings yet

- BT LetterDocument1 pageBT LetterSayani SahaNo ratings yet

- Hybrid Maize Seed Production ManualDocument129 pagesHybrid Maize Seed Production ManualSarthluz VanohNo ratings yet

- Jain - Hi - Tech - Nursery DetailsDocument12 pagesJain - Hi - Tech - Nursery DetailsVsa KitchenNo ratings yet

- LUMS Paper On The Seed IndustryDocument33 pagesLUMS Paper On The Seed IndustryAbdul Moiz MehmoodNo ratings yet

- 1.principle of Quality Seed ProductionDocument6 pages1.principle of Quality Seed ProductionJx NxnNo ratings yet

- Standard DOA (JV) Draft - 26.10Document14 pagesStandard DOA (JV) Draft - 26.10moulishabujNo ratings yet

- Family RestaurantDocument26 pagesFamily RestaurantGOLLAVILLI GANESHNo ratings yet

- 05 - Madinah Hotel Auditing Procedures - Rajhi - 2012 - 2013Document19 pages05 - Madinah Hotel Auditing Procedures - Rajhi - 2012 - 2013Santo Mulyono100% (1)

- Code of Ethics and Business Conduct 2004Document11 pagesCode of Ethics and Business Conduct 2004petervangeersomNo ratings yet

- Agri & Food Processing - IQF and Frozen Food Processing ProjectDocument7 pagesAgri & Food Processing - IQF and Frozen Food Processing ProjectSunil K GuptaNo ratings yet

- A Banquet Hall Is Used For Many Different Types of Functions Including Wedding ReceptionsDocument12 pagesA Banquet Hall Is Used For Many Different Types of Functions Including Wedding ReceptionsmadddiuNo ratings yet

- Job Specification - Technical ManagerDocument3 pagesJob Specification - Technical ManagerMian ZainNo ratings yet

- Catering ProposalDocument13 pagesCatering ProposalOKOTHNo ratings yet

- The Seed Industry in Pakistan - Regulation, Politics and EntrepreneurshipDocument35 pagesThe Seed Industry in Pakistan - Regulation, Politics and EntrepreneurshipAhsan 11No ratings yet

- Pany ProfileDocument3 pagesPany ProfileAbhilash DwivedyNo ratings yet

- Report On Pharmaceutical Industry in BangladeshDocument76 pagesReport On Pharmaceutical Industry in BangladeshShamsuddin AhmedNo ratings yet

- Ethical Trading PolicyDocument3 pagesEthical Trading PolicyPaul SuciuNo ratings yet

- Procedure For Exports of Peanuts and Peanut Products2018Document49 pagesProcedure For Exports of Peanuts and Peanut Products2018alohasabariNo ratings yet

- Overview of MARKETING PLANDocument27 pagesOverview of MARKETING PLANjoanne riveraNo ratings yet

- Tier 1 Business Plan SampleDocument14 pagesTier 1 Business Plan SamplejacksonwitterNo ratings yet

- Poultry Busniess PlanDocument32 pagesPoultry Busniess Plandaniyal ahmadNo ratings yet

- SSG Agro: Dry Fish Market AssessmentDocument26 pagesSSG Agro: Dry Fish Market AssessmentmasudNo ratings yet

- Broker User Manual PDFDocument181 pagesBroker User Manual PDFrahulag03No ratings yet

- Thailand Food Processing Industry March 2014Document86 pagesThailand Food Processing Industry March 2014nils2484No ratings yet

- EMZ Standard Operating ProceduresDocument16 pagesEMZ Standard Operating ProceduresEmz Pengosro MarianoNo ratings yet

- Summer Training At: Swot Analysis OnDocument99 pagesSummer Training At: Swot Analysis OnVivek KumarNo ratings yet

- Allahdin Group of CompaniesDocument18 pagesAllahdin Group of CompaniesMuhammad Fahad100% (1)

- High School Franchise Rs. 5.8 Million Aug 2015Document18 pagesHigh School Franchise Rs. 5.8 Million Aug 2015RajaNo ratings yet

- 2Document6 pages2Zohair SheikhNo ratings yet

- Concept Paper Govt Seed Farm HanguDocument12 pagesConcept Paper Govt Seed Farm HanguFarhat DurraniNo ratings yet

- "On The Water" Business PlanDocument22 pages"On The Water" Business Planmohammad10000100% (2)

- FoSCoS - FSSAI - ProductsDocument42 pagesFoSCoS - FSSAI - ProductsSameer NaikNo ratings yet

- Postharvest Diseases Root and Tuber CropsDocument43 pagesPostharvest Diseases Root and Tuber CropsApocalypto Statum100% (1)

- Answer To Assignment 2 Porter's 5 Forces ModelDocument7 pagesAnswer To Assignment 2 Porter's 5 Forces ModelYmyvballYusupNo ratings yet

- SMEDA Cut Flower Farm (Rose) 4Document14 pagesSMEDA Cut Flower Farm (Rose) 4AliAslamTurkNo ratings yet

- Integrated Fish N Pultry FirmDocument8 pagesIntegrated Fish N Pultry FirmArghya NeelNo ratings yet

- Summer Internship ReportDocument52 pagesSummer Internship ReportAman HamzaNo ratings yet

- Model Detailed Project Report: Mixed Vegetable Pickle UnitDocument18 pagesModel Detailed Project Report: Mixed Vegetable Pickle UnitAnabNo ratings yet

- Title of Business Plan Food Industry Business PlanDocument26 pagesTitle of Business Plan Food Industry Business PlanIsmail AzhariNo ratings yet

- You Are Given USD 10000 To Start A Business. Explain Any Agricultural Business That You Would Start and Why You Choose That Line of AgribusinessDocument5 pagesYou Are Given USD 10000 To Start A Business. Explain Any Agricultural Business That You Would Start and Why You Choose That Line of AgribusinessLawrence Nyamunderu100% (1)

- LPG Market Prospects IndiaDocument22 pagesLPG Market Prospects IndiaHHO MartNo ratings yet

- Project Report On Pharmaceutical Unit (Tablet, Capsules, Syrups, Ointments, Lotion, Nebulizer)Document16 pagesProject Report On Pharmaceutical Unit (Tablet, Capsules, Syrups, Ointments, Lotion, Nebulizer)EIRI Board of Consultants and PublishersNo ratings yet

- Canteen Store DepartmentDocument5 pagesCanteen Store DepartmentZamina RiXviNo ratings yet

- 001 Businessplan-Rubberplantation FinalDocument29 pages001 Businessplan-Rubberplantation FinalAung Naing SoeNo ratings yet

- HVAP VCA-Reports GingerDocument81 pagesHVAP VCA-Reports GingerChandeswori KojuNo ratings yet

- Sop - 1Document2 pagesSop - 1syful islamNo ratings yet

- Schedule III of Companies Act 2013 in Excel Format-2Document48 pagesSchedule III of Companies Act 2013 in Excel Format-2divya shindeNo ratings yet

- High GrowthDocument88 pagesHigh GrowthPrakash Kc0% (1)

- Akkufinal - Peanut ButterDocument9 pagesAkkufinal - Peanut ButteradarshNo ratings yet

- Ready To Eat VegetablesDocument7 pagesReady To Eat VegetablesMita TannaNo ratings yet

- Baseline Survey On Competition and Markets in EthiopiaDocument112 pagesBaseline Survey On Competition and Markets in Ethiopiaasfawm3No ratings yet

- Project Report: M/S Siva Sai Seeds Prop: Mrs. MAMATHA, W/O Sri ChandrasekharDocument41 pagesProject Report: M/S Siva Sai Seeds Prop: Mrs. MAMATHA, W/O Sri ChandrasekharRamakrishna NaiduNo ratings yet

- Chapter 1Document36 pagesChapter 1Amit Kumar0% (1)

- Project Proposal On Establishment of Seed Processing Infrastructure Facilities For Vegetable CropsDocument6 pagesProject Proposal On Establishment of Seed Processing Infrastructure Facilities For Vegetable CropsVikas KumarNo ratings yet

- Pulses Processing Unit: 1.1 Current ScenarioDocument12 pagesPulses Processing Unit: 1.1 Current ScenarioMANOJ JAINNo ratings yet

- Kingdom Valley RawalpindiDocument1 pageKingdom Valley RawalpindiYasir MukhtarNo ratings yet

- Skyline (FGEHA) Islamabad Feb-2022 FinalDocument16 pagesSkyline (FGEHA) Islamabad Feb-2022 FinalYasir MukhtarNo ratings yet

- Poultry Brochure 3Document8 pagesPoultry Brochure 3Yasir MukhtarNo ratings yet

- Chemical Industries Part 2 1Document23 pagesChemical Industries Part 2 1Yasir MukhtarNo ratings yet

- Chemical IndustriesDocument13 pagesChemical IndustriesYasir MukhtarNo ratings yet

- VM0006 Methodology For Carbon Accounting For Mosaic and Landscape Scale REDD Projects Version 2.1Document166 pagesVM0006 Methodology For Carbon Accounting For Mosaic and Landscape Scale REDD Projects Version 2.1Yasir MukhtarNo ratings yet

- VMR0006 Methodology For Installation of High Efficiency Firewood Cookstoves v1.1Document33 pagesVMR0006 Methodology For Installation of High Efficiency Firewood Cookstoves v1.1Yasir MukhtarNo ratings yet

- YarrowayFarm SowingCalendarDocument3 pagesYarrowayFarm SowingCalendarYasir MukhtarNo ratings yet

- Oshan X7 BrochureDocument31 pagesOshan X7 BrochureYasir MukhtarNo ratings yet

- PoultryDocument1 pagePoultryYasir MukhtarNo ratings yet

- IBA Training CalenderDocument1 pageIBA Training CalenderYasir MukhtarNo ratings yet

- Pamphlet For Gulayan Sa TahananDocument3 pagesPamphlet For Gulayan Sa TahananLily cathylene estoriaNo ratings yet

- NotesDocument36 pagesNotesSumit KumarNo ratings yet

- Rice and Wheat-GEODocument16 pagesRice and Wheat-GEORishab Shetty100% (1)

- Floristic Inventory of Pir Mehr Ali Shah Arid Agriculture University PDFDocument6 pagesFloristic Inventory of Pir Mehr Ali Shah Arid Agriculture University PDFWaqar GhoryNo ratings yet

- Hawaiian Noni Seed Processing and Germination: Snelson@hawaii - EduDocument8 pagesHawaiian Noni Seed Processing and Germination: Snelson@hawaii - EduSadDecemberNo ratings yet

- Annual Report CPIN 2017Document6 pagesAnnual Report CPIN 2017Ahmad ZakiNo ratings yet

- Case Study On GMOsDocument11 pagesCase Study On GMOsroselle azucena100% (1)

- The Rediscovery of AmaranthDocument24 pagesThe Rediscovery of AmaranthCalujnaiNo ratings yet

- I Am Not Ashamed For The GospelDocument6 pagesI Am Not Ashamed For The GospelJohn BawNo ratings yet

- Course Details: Course Details:: AEM 509 Agricultural Development and Policy 3 Units Three Hours Per WeekDocument2 pagesCourse Details: Course Details:: AEM 509 Agricultural Development and Policy 3 Units Three Hours Per WeekmustafaNo ratings yet

- Foreign Marketing SelectionDocument9 pagesForeign Marketing SelectionSammir MalhotraNo ratings yet

- #14 Lampiran 14 HSS US SCS Distribusi Hujan 12 JamDocument11 pages#14 Lampiran 14 HSS US SCS Distribusi Hujan 12 Jamchandra adriawanNo ratings yet

- Lancrop Laboratories Soil TypesDocument2 pagesLancrop Laboratories Soil TypesHernando MontenegroNo ratings yet

- Introduction To Furrow IrrigationDocument10 pagesIntroduction To Furrow Irrigationrujinakhatun2006No ratings yet

- Wheat: Global Scenario (2013-14) Country Area Production Yield % To World (Mha) (MT) (T/ha) ProductionDocument8 pagesWheat: Global Scenario (2013-14) Country Area Production Yield % To World (Mha) (MT) (T/ha) ProductionGanpat Lal SharmaNo ratings yet

- MPRA Paper 76213 PDFDocument26 pagesMPRA Paper 76213 PDFMon GatarinNo ratings yet

- Survey Information and Respondent Consent FormDocument32 pagesSurvey Information and Respondent Consent FormKimberly IsmaelNo ratings yet

- 2022 GKS-G Available Departments For University Track (Regional, Natural Science and Engineering) (English)Document56 pages2022 GKS-G Available Departments For University Track (Regional, Natural Science and Engineering) (English)Anita CortézNo ratings yet

- Vat Liability Guide - 2012Document29 pagesVat Liability Guide - 2012Dobu KolobingoNo ratings yet

- PCIP Tarlac Sweetpotato 20150522Document54 pagesPCIP Tarlac Sweetpotato 20150522Alen YbanezNo ratings yet

- Capsicum Production Module PDFDocument34 pagesCapsicum Production Module PDFalka khugshalNo ratings yet

- Marketing Plan PDFDocument11 pagesMarketing Plan PDFsetuNo ratings yet

- AbstractBoo-10thACPP en AmatDocument186 pagesAbstractBoo-10thACPP en AmatFahriadi PakayaNo ratings yet

- Rajasthan: Table 52: District - Wise Distribution of WastelandsDocument4 pagesRajasthan: Table 52: District - Wise Distribution of WastelandsVivek KodoorNo ratings yet

- Bar & Lunch Menu InfusinDocument5 pagesBar & Lunch Menu InfusinmalawianboiNo ratings yet

- Part 2 Punjab Univeristy Syllabus Course OutlineDocument16 pagesPart 2 Punjab Univeristy Syllabus Course OutlineWasim JamaliNo ratings yet

- Soal Braja 4.5. Dimas.Document2 pagesSoal Braja 4.5. Dimas.Fikri DzikrillahNo ratings yet

- Marketingof Agricultural ProductsDocument45 pagesMarketingof Agricultural ProductsGodugu SandeepNo ratings yet

- Weather Prediction Based On Fuzzy Logic AlgorithmDocument6 pagesWeather Prediction Based On Fuzzy Logic AlgorithmHadi JameelNo ratings yet

- Dai2018 PDFDocument79 pagesDai2018 PDFkhalid bouitiNo ratings yet