Professional Documents

Culture Documents

QAP For PQR'S - For Impact Testing

QAP For PQR'S - For Impact Testing

Uploaded by

Dries VandezandeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QAP For PQR'S - For Impact Testing

QAP For PQR'S - For Impact Testing

Uploaded by

Dries VandezandeCopyright:

Available Formats

Company Pty (Ltd)

QUALITY PLAN / JOB INSTRUCTION

EQUIPMENT DESCRIPTION:

CUSTOMER:

Done By: J.Venter

WELD PROCEDURE QUALIFICATION

JOB No. A7892

Page 1 of 3

Rev: 0

Approved:

Date : 14 AUG 08

Date :

XXXXXXXXXXX

Op.

No.

Work Description

1.

QAP WH02.12.0808.07.G

(AISI8630-85K to API 5L X80)

Procedure / Work

Instruction

Report /

Docmt

Artisan

Sign-off

Rev

Intervention

1 2 3 4

PREPARE AISI8630 Gr 85K TEST COUPON.

NK TO IDENTIFY PIPE TO BE USED.

DO NOT FLAME CUT EDGE TO BE WELDED >>> SAW CUT.

2.

M/C WELD BEVEL (DO NOT FLAME CUT)

IMIR#7981-1

COUPON LENGTH:

100mm MIN

LOG#: M200062M

COUPON LENGTH:

100mm MIN

TRANSFER IMIR & HEAT & PIECE NUMBER TO TEST COUPON BY

HARD STAMPING >>> LLOYDS TO WITNESS

MARK THE LEFT OVER PIECE AND RESERVE FOR FUTURE USE >>>

STORE IN WELDING ENGINEERs STORE>>>JV TO ADVISE

PREPARE API 5L X80 TEST COUPON >>> OD & ID TO MATCH ABOVE

AISI8630 TEST COUPON EXACTLY.

DO NOT FLAME CUT.

3.

TRANSFER IMIR & HEAT NUMBER TO TEST COUPON BY HARD

STAMPING >>> LLOYDS TO WITNESS

MARK THE LEFT OVER PIECE AND RESERVE FOR FUTURE USE >>>

STORE IN WELDING ENGINEERs STORE>>>JV TO ADVISE

4.

MPI WELD BEVEL ON BOTH TEST COUPONS

NT11.02

INTERVENTION:

H = HOLD ( Process MAY NOT continue prior to sign-off)

W = Witness ( Process MAY proceed if Insp. Auth. not present)

1 = Subcontractor(s)

2 = Algoa Insp. / Witness -

REPORT

R

R = Review of Documents Only

3 = Customer

4 = Third Party :

Approval

2 3 4

DB THERMAL (PTY) LTD

QUALITY PLAN / JOB INSTRUCTION

Rev.

JOB No. A7892

Page 2 of 3

( Continuation )

Op.

No.

Work Description

5.

SETUP TEST COUPONS FOR WELDING >>> JV AND LLOYDS TO

WITNESS

QAP WH02.12.0808.07.G

Procedure / Work

Instruction

Report /

Docmt

WHO1.12.0808.07.G

Artisan

Sign-off

Rev

Intervention

1 2 3 4

W

WELD JOINT COMPLETE >>> JV AND LLOYDS TO WITNESS.

WELD BUILD SECTION FOR ALL WELD TENSILE TEST >>> JV TO

ADVISE.

6.

ALL WELDING PARAMETERS TO BE RECORDED.

WHO1.12.0808.07.G

PQR

REPORT

ALL WELD CONSUMABLE BATCH NUMBERS TO BE RECORDED AND

TRACEABLE TO CERTIFICATE.

WELDER ID STAMP ADJACENT TO WELD.

7.

YELLOW PAINT MARK TEST COUPON WITH PQR NUMBER

WHO1.12.0808.07.G

8.

VISUAL INSP 100% WELD BSR

NT51.01

REPORT

9.

MPI 100% WELD BSR

NT11.02

REPORT

10.

RT 100% WELD BSR

NT31.01

REPORT

TRANSFER / HARD STAMP THE FOLLOWING:

11.

12.

1.

2.

3.

4.

JOB NUMBER

PQR NUMBER >>> WHO2.12.0808.07.G

WELDER ID STAMP ADJACENT TO WELD

IMIR & HEAT & PIECE NUMBER & MATERIAL TYPE ONTO EACH

PIECE.

PWHT >>> JV TO ADVISE

ENG001 (G) 11/2006

WHO1.12.0808.07.G

Approval

2 3 4

DB THERMAL (PTY) LTD

QUALITY PLAN / JOB INSTRUCTION

Op.

No.

Work Description

13.

Rev.

JOB No. A7892

Page 3 of 3

( Continuation )

Procedure / Work

Instruction

Report /

Docmt

MPI 100% WELD ASR

NT11.02

REPORT

14.

RT 100% WELD ASR

NT31.01

REPORT

15.

QC VERIFY ALL ABOVE OPERATIONS AND DOCUMENTATION ARE

COMPLETE

SIGN

OFF

16.

SEND PWHTd TEST PIECE TO STORES FOR TRANSPORT TO VML

17.

SEND TO VML >>> JV TO ADVISE

QAP WH02.12.0808.07.G

Artisan

Sign-off

Rev

Intervention

1 2 3 4

IMPACT TESTING TESTING AT METLAB >>> JV TO ADVISE

18.

19.

ALL MECHANICAL TEST SPECIMENS AND LEFT OVER TEST COUPON

MATERIAL TO BE RETURNED TO XXXXX FOR FUTURE REFERENCE

>>> NK TO STORE

RECEIVE TEST RESULTS AND FINALIZE PQR DOCUMETS THEN SEND

TO CUSTOMER FOR APPROVAL.

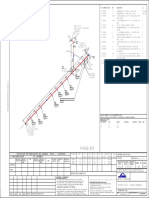

Weld Prep.

ENG001 (G) 11/2006

Approval

2 3 4

You might also like

- PQR 014 (Qualified Sa 106 GR BDocument5 pagesPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- Specification For Bare Stainless Steel Welding Electrodes andDocument33 pagesSpecification For Bare Stainless Steel Welding Electrodes andpurnawanNo ratings yet

- Chapter 8 Cladding and External FinishingDocument66 pagesChapter 8 Cladding and External Finishingnabin prasaiNo ratings yet

- AB-036386 Hardness Testing For Welding Procedure QualificationDocument1 pageAB-036386 Hardness Testing For Welding Procedure QualificationAmr MahmoudNo ratings yet

- Welding Parameters Control PipelineDocument1 pageWelding Parameters Control PipelinemusheerNo ratings yet

- Roundness Before Weld TK012-strike 1Document2 pagesRoundness Before Weld TK012-strike 1yuwantoniNo ratings yet

- Pt. Astar Testing & InspectionDocument2 pagesPt. Astar Testing & InspectionSASINo ratings yet

- PQR Run SheetDocument1 pagePQR Run SheetsahadNo ratings yet

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocument5 pagesQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.No ratings yet

- WPQ CS SmawDocument1 pageWPQ CS Smawniket0No ratings yet

- Soal CswipDocument1 pageSoal Cswipakun jeparaNo ratings yet

- Test Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)Document1 pageTest Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)yskushwah16No ratings yet

- Fit-Up and Daily Welding Visual Inspection ReportDocument1 pageFit-Up and Daily Welding Visual Inspection ReportAws AbduljaleelNo ratings yet

- Hardness Pro Form1Document2 pagesHardness Pro Form1gst ajah100% (1)

- WPS Asme IxDocument4 pagesWPS Asme Ixjcarlosherrerac7100% (1)

- 12.6 Welding Procedures List (Li-002)Document31 pages12.6 Welding Procedures List (Li-002)Ana GameroNo ratings yet

- Welder Wise Repair PercentageDocument135 pagesWelder Wise Repair PercentageaakashNo ratings yet

- Submerged Arc Welding (Saw)Document5 pagesSubmerged Arc Welding (Saw)Nnaji Chukwuma SlamNo ratings yet

- ASME 9 Multi Process Welding Procedures QW200Document2 pagesASME 9 Multi Process Welding Procedures QW200Teodor EzaruNo ratings yet

- Storing and Redrying Electrodes-Lincoln ElectricDocument3 pagesStoring and Redrying Electrodes-Lincoln ElectricjasminneeNo ratings yet

- Acceptable Grade of Plate Material (API 650)Document1 pageAcceptable Grade of Plate Material (API 650)juantamad02No ratings yet

- Weld Repair Rate - MFJO542Document2 pagesWeld Repair Rate - MFJO542Salahuddin Farooqui100% (1)

- PWHT Procedure For Petrol Steel - CoreDocument9 pagesPWHT Procedure For Petrol Steel - CoreSuleyman HaliciogluNo ratings yet

- Gate & Globe PDFDocument0 pagesGate & Globe PDFZoebairNo ratings yet

- 1662 15Document117 pages1662 15RajamanikkamNo ratings yet

- FInal QAP HDPE WeldingDocument2 pagesFInal QAP HDPE Weldingkannagi198No ratings yet

- WOPQ Form English1Document2 pagesWOPQ Form English1oaperuchenaNo ratings yet

- SAIC-L-2136 Rev 0Document3 pagesSAIC-L-2136 Rev 0philipyapNo ratings yet

- WPS-PQR ListDocument1 pageWPS-PQR ListSandra SandersNo ratings yet

- DPR FormatDocument79 pagesDPR FormatMITHUNNo ratings yet

- Rapid p0030 CPP U0030 Qac Mom 0024 Quality MeetingDocument13 pagesRapid p0030 CPP U0030 Qac Mom 0024 Quality MeetingAtuk Safiz100% (1)

- SAIC-LT-2007 LeaK Testing-Vacuum BoxDocument3 pagesSAIC-LT-2007 LeaK Testing-Vacuum BoxKirubhakarPooranamNo ratings yet

- Oil Gas Construction Factory L.L.CDocument2 pagesOil Gas Construction Factory L.L.CRenny DevassyNo ratings yet

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- QC - 08 PTCDocument5 pagesQC - 08 PTCmahendraNo ratings yet

- Ferrite Content MeasurementDocument5 pagesFerrite Content MeasurementFasil Paruvanath100% (1)

- SAIC-W-2078 Review PWHT Proc For TankDocument5 pagesSAIC-W-2078 Review PWHT Proc For Tankkarioke mohaNo ratings yet

- WPS PQR 12 PDFDocument9 pagesWPS PQR 12 PDFVinay YadavNo ratings yet

- VP16 PDFDocument13 pagesVP16 PDFKara WhiteNo ratings yet

- Weld Repair Rev. 1Document3 pagesWeld Repair Rev. 1vinas kusdinarNo ratings yet

- Samples ITPDocument4 pagesSamples ITPHassan SajidNo ratings yet

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- 57 PQRDocument13 pages57 PQRAbdul Tri Hamdani Hamdani100% (1)

- Table of Content: SR. TitleDocument2 pagesTable of Content: SR. TitlePratik KarekarNo ratings yet

- WPS Pipe 08'' SHD 40 SMAW REV02Document2 pagesWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNo ratings yet

- P01-Welding Consm ControlDocument5 pagesP01-Welding Consm ControlvenkateshNo ratings yet

- NDE TABLE For HEADER BOX - R0 Modified With Type 1 Joint ofDocument9 pagesNDE TABLE For HEADER BOX - R0 Modified With Type 1 Joint ofrony16novNo ratings yet

- Wps MainlineDocument5 pagesWps MainlineAlfian FebriansyahNo ratings yet

- Wps Sp14 Reva PDFDocument9 pagesWps Sp14 Reva PDFravi00098No ratings yet

- Electrode Backing RegisterDocument4 pagesElectrode Backing RegisterSimbu Arasan100% (1)

- Hard Facing Overlay PDF FreeDocument2 pagesHard Facing Overlay PDF Freemayav1No ratings yet

- Welding Procedure Specification For GTAWDocument9 pagesWelding Procedure Specification For GTAWraja reyhanNo ratings yet

- WPSDocument42 pagesWPSjoehodoh100% (1)

- 10 NDE ControlDocument6 pages10 NDE ControlShahbaz AlamNo ratings yet

- Asme 9 DatosDocument47 pagesAsme 9 Datosvichu_villamarNo ratings yet

- A106 Seamless Carbon Steel Pipe: Hydrostatic TestingDocument7 pagesA106 Seamless Carbon Steel Pipe: Hydrostatic TestingTan Chee MingNo ratings yet

- Process Flow Diagram: 10-12-2011 Part NameDocument4 pagesProcess Flow Diagram: 10-12-2011 Part NameVenu Gopal RaoNo ratings yet

- 1Document4 pages1Venu Gopal RaoNo ratings yet

- IsometricsDocument4 pagesIsometricsMuhammedHafisNo ratings yet

- (732-Itp-40 (V-6905) 42000-SNG-69-42000P-MS-5733-504-0000-06Document10 pages(732-Itp-40 (V-6905) 42000-SNG-69-42000P-MS-5733-504-0000-06sathi11189No ratings yet

- Annexure-I For Gem Bid No:Gem/2021/B/1451378 Dated: 19-08-2021Document15 pagesAnnexure-I For Gem Bid No:Gem/2021/B/1451378 Dated: 19-08-2021Sravan DasariNo ratings yet

- WPQ Template (Asme Ix) No LogoDocument4 pagesWPQ Template (Asme Ix) No LogorcpretoriusNo ratings yet

- ESAB ExtractPage34-35DDocument16 pagesESAB ExtractPage34-35DDries VandezandeNo ratings yet

- ESAB ExtractPage20-21cDocument8 pagesESAB ExtractPage20-21cDries VandezandeNo ratings yet

- ESAB ExtractPage32-33DDocument17 pagesESAB ExtractPage32-33DDries VandezandeNo ratings yet

- ExtractPage40 41D PDFDocument21 pagesExtractPage40 41D PDFDries VandezandeNo ratings yet

- ESAB ExtractPage35-36DDocument16 pagesESAB ExtractPage35-36DDries VandezandeNo ratings yet

- ESAB ExtractPage17-18cDocument9 pagesESAB ExtractPage17-18cDries VandezandeNo ratings yet

- ESAB ExtractPage39-40DDocument17 pagesESAB ExtractPage39-40DDries VandezandeNo ratings yet

- ESAB ExtractPage15-16cDocument9 pagesESAB ExtractPage15-16cDries VandezandeNo ratings yet

- ESAB ExtractPage29-30cDocument9 pagesESAB ExtractPage29-30cDries VandezandeNo ratings yet

- ExtractPage35 36c PDFDocument8 pagesExtractPage35 36c PDFDries VandezandeNo ratings yet

- ExtractPage38 39c PDFDocument8 pagesExtractPage38 39c PDFDries VandezandeNo ratings yet

- Oxy-Fuel Cutting & Welding Outfits Edge Series and G-Series Kits - ContentsDocument4 pagesOxy-Fuel Cutting & Welding Outfits Edge Series and G-Series Kits - ContentsDries VandezandeNo ratings yet

- ExtractPage40 41c PDFDocument12 pagesExtractPage40 41c PDFDries VandezandeNo ratings yet

- Regulator/flowmeter Combination OptiflowDocument5 pagesRegulator/flowmeter Combination OptiflowDries VandezandeNo ratings yet

- Regulator/flowmeter Combination OptiflowDocument5 pagesRegulator/flowmeter Combination OptiflowDries VandezandeNo ratings yet

- Regulators G Series Regulators: Featuring Tube Overpressure Relief MechanismDocument4 pagesRegulators G Series Regulators: Featuring Tube Overpressure Relief MechanismDries VandezandeNo ratings yet

- Regulators Edge Linemaster Series: Ideal For Industrial Sector UsesDocument4 pagesRegulators Edge Linemaster Series: Ideal For Industrial Sector UsesDries VandezandeNo ratings yet

- Sandvik - Technical Guide - Materials ISODocument41 pagesSandvik - Technical Guide - Materials ISOznovak77100% (1)

- Column Design ExcelDocument4 pagesColumn Design Excelvimal patelNo ratings yet

- Weldability Testing For Advanced MaterialsDocument8 pagesWeldability Testing For Advanced MaterialsJim BetsingerNo ratings yet

- Qicc MV Power CableDocument150 pagesQicc MV Power CableRaja MariyappanNo ratings yet

- Detailed DrawingsDocument1 pageDetailed DrawingsTAFADZWA K CHIDUMANo ratings yet

- Gas Tungsten Arc WeldingDocument1 pageGas Tungsten Arc WeldingabhibawaNo ratings yet

- Fire SprinkleDocument6 pagesFire Sprinklersgs gunungsawoNo ratings yet

- Api 571 - 2020Document54 pagesApi 571 - 2020Reddy BusaNo ratings yet

- Quantitative Extraction of Bitumen From Bituminous Paving MixturesDocument12 pagesQuantitative Extraction of Bitumen From Bituminous Paving Mixturessebastian novoa0% (1)

- Gadus S2 V 1000 Ad 2 PDFDocument2 pagesGadus S2 V 1000 Ad 2 PDFsrikanth siddhardhaNo ratings yet

- 3 - Metal Casting Processes (Chapter 8)Document103 pages3 - Metal Casting Processes (Chapter 8)faisalNo ratings yet

- Sulfinol D Evaluation.Document24 pagesSulfinol D Evaluation.Clibert RodríguezNo ratings yet

- MD - IMO - 269 - EU of ACS2 Sys. Cont.Document1 pageMD - IMO - 269 - EU of ACS2 Sys. Cont.remakermaritime.cgpNo ratings yet

- BCI Members ListDocument10 pagesBCI Members Listsehj888No ratings yet

- 002 Steel StructuralDocument16 pages002 Steel Structuraljalv.mendoza25No ratings yet

- 01 Boundary Wall - BrochureDocument6 pages01 Boundary Wall - BrochureTantan AñesNo ratings yet

- Caravan SpecificationDocument5 pagesCaravan SpecificationVimala PonnusamyNo ratings yet

- Craft Cluster PRESENTATIONDocument33 pagesCraft Cluster PRESENTATIONSWAPNIL KRISHNANo ratings yet

- Sigunit L535 Af PDS PDFDocument3 pagesSigunit L535 Af PDS PDFnajmuddinNo ratings yet

- Cambridge IGCSE: CHEMISTRY 0620/32Document16 pagesCambridge IGCSE: CHEMISTRY 0620/32Tshegofatso SaliNo ratings yet

- PolyMax PC PIS EN V1.1Document16 pagesPolyMax PC PIS EN V1.1Hector GarciaNo ratings yet

- Tata Pravesh Doors RCP Cue - Effective From 1st Aug 2019Document1 pageTata Pravesh Doors RCP Cue - Effective From 1st Aug 2019mayank1208No ratings yet

- TL 11 Adingkolor RB 07 2020 enDocument3 pagesTL 11 Adingkolor RB 07 2020 enFilip PopordanoskiNo ratings yet

- QC ReportDocument12 pagesQC ReportManikandan MNo ratings yet

- Inserto DeltonDocument76 pagesInserto DeltonAdrián RoyoNo ratings yet

- Crealco ApplicationsDocument1 pageCrealco ApplicationswittypeeNo ratings yet

- CBLM Apply Appropriate Sealant or AdhesiveDocument33 pagesCBLM Apply Appropriate Sealant or AdhesiveMark Kevin DaitolNo ratings yet

- Repsol Ypf Maxus, Indonesia: Region Stimulation Laboratory ReportDocument5 pagesRepsol Ypf Maxus, Indonesia: Region Stimulation Laboratory ReportizzybjNo ratings yet