Professional Documents

Culture Documents

Cri Fuel System PDF

Cri Fuel System PDF

Uploaded by

jasyadiCopyright:

Available Formats

You might also like

- Atlas Copco Boomer L2D Operators InstructionsDocument120 pagesAtlas Copco Boomer L2D Operators InstructionsHai Van100% (14)

- Mechanical Design Engineer Interview QuestionsDocument4 pagesMechanical Design Engineer Interview QuestionssuseevNo ratings yet

- Autolube System (HYD) OverviewDocument21 pagesAutolube System (HYD) OverviewDaniel Alfonso Diaz FloresNo ratings yet

- Adjust Valve EC200DDocument5 pagesAdjust Valve EC200DHeru Hoo0% (1)

- Surface Production Operation EquipmentDocument10 pagesSurface Production Operation Equipmentapi-201334376No ratings yet

- D155A-2 # 57001 Up SEBM018602 PDFDocument462 pagesD155A-2 # 57001 Up SEBM018602 PDFJoko Sukariono100% (6)

- PC 1250 Elect ControlDocument43 pagesPC 1250 Elect Controlanggie100% (1)

- Spesifications of Hino Ranger FM 260,320 Series (6X4)Document5 pagesSpesifications of Hino Ranger FM 260,320 Series (6X4)MuhaiminNo ratings yet

- Common Rail Fuel System - SpecificationsDocument4 pagesCommon Rail Fuel System - Specificationssengottaiyan100% (1)

- Machine Control SystemDocument43 pagesMachine Control SystemanggieNo ratings yet

- DX700LC PDFDocument20 pagesDX700LC PDFA Ramos GabyNo ratings yet

- Bca Sheet MultiflowDocument55 pagesBca Sheet Multiflowbumatio latiNo ratings yet

- Power Train Volvo FMX370Document56 pagesPower Train Volvo FMX370haqiardinalNo ratings yet

- Engine Valve Tune Guideline HD785-7 Rev29112017 PDFDocument17 pagesEngine Valve Tune Guideline HD785-7 Rev29112017 PDFHari Ary100% (1)

- Bulldozer d65pDocument10 pagesBulldozer d65pRisky UpNo ratings yet

- HarisDocument28 pagesHarisZen PNo ratings yet

- Bus Truck Tractor Brake PerformanceDocument56 pagesBus Truck Tractor Brake PerformancedeshpandeamolNo ratings yet

- Failure Code Display Algorithm For ECMVDocument4 pagesFailure Code Display Algorithm For ECMValcowo100% (1)

- Accelerator Control, Fuel & Exhaust Systems: GI MADocument12 pagesAccelerator Control, Fuel & Exhaust Systems: GI MAaymendabNo ratings yet

- Positive Crankcase Ventilation (PCV) (Text p17) : 27 February 2 006 at KTB Jak Arta MFTBC R&D DivisionDocument6 pagesPositive Crankcase Ventilation (PCV) (Text p17) : 27 February 2 006 at KTB Jak Arta MFTBC R&D DivisionRose Myny100% (1)

- SM HD 785-7 Sen05900-17Document2,302 pagesSM HD 785-7 Sen05900-17Ongky FirnandoNo ratings yet

- Common Rail System Diesel Engine Technology PDFDocument26 pagesCommon Rail System Diesel Engine Technology PDFFedima100% (1)

- Brake System DiagnosisDocument69 pagesBrake System DiagnosisIlyas Nur AfshohiNo ratings yet

- Form NEW TSR 2016Document2 pagesForm NEW TSR 2016Ega YudhaNo ratings yet

- Meca Sheet: Remove & Install PNC-A01-002-001-01 EngineDocument3 pagesMeca Sheet: Remove & Install PNC-A01-002-001-01 EngineIndah Widya Putri100% (1)

- Service Manual Nissan PDFDocument39 pagesService Manual Nissan PDFayi darwisNo ratings yet

- Periodic Service 1000 Hours PC 200-8: Present By: Muh Arif Budiawan SyamDocument28 pagesPeriodic Service 1000 Hours PC 200-8: Present By: Muh Arif Budiawan SyamMuh Arief Budiawan Arief100% (1)

- Topik 4Document214 pagesTopik 4Daniel Dale Ambo Sibarani100% (1)

- Fuel Injection Pump PDFDocument7 pagesFuel Injection Pump PDFGANAPATHY MNo ratings yet

- PM PC1250SP-8Document25 pagesPM PC1250SP-8Teguh Imam AdriNo ratings yet

- Basic Engine: Replace Fuel ElementDocument6 pagesBasic Engine: Replace Fuel Elementraymond ngoNo ratings yet

- Analisa Penyebab Low Speed All AttachmentDocument65 pagesAnalisa Penyebab Low Speed All Attachment07 Dimas Pramudya WNo ratings yet

- Taufik Hidayat Gultom PS3 D375Document26 pagesTaufik Hidayat Gultom PS3 D375Dava JrNo ratings yet

- General Information: 018-001 SpecificationsDocument10 pagesGeneral Information: 018-001 SpecificationsLaiqNo ratings yet

- Maintenance Fowa - Fuel - 50305Document20 pagesMaintenance Fowa - Fuel - 50305darwin100% (1)

- MTS Steering Brake Dozer - Grader KomatsuDocument6 pagesMTS Steering Brake Dozer - Grader KomatsuRizal MerahNo ratings yet

- Product Knowledge Renault Trucks-PrintDocument25 pagesProduct Knowledge Renault Trucks-PrintAris NurrochmanNo ratings yet

- Common RailDocument16 pagesCommon RailRaikhan Syafiq100% (2)

- D155A-6 Power Train System: Dubai Training and Demonstration CenterDocument20 pagesD155A-6 Power Train System: Dubai Training and Demonstration CenterMichael DavidNo ratings yet

- (CRI) Engine Fuel Filters PDFDocument7 pages(CRI) Engine Fuel Filters PDFJoko Sukariono100% (1)

- Sistem Kemudi & RemDocument171 pagesSistem Kemudi & RemAndikaNo ratings yet

- THF6 - .Joystick Control PDFDocument12 pagesTHF6 - .Joystick Control PDFmusafirNo ratings yet

- Air Sistema HandlingDocument20 pagesAir Sistema Handlingdarwin100% (1)

- EMS GasolineDocument39 pagesEMS GasolineKha TrầnNo ratings yet

- EFIDocument37 pagesEFITia SetiawanNo ratings yet

- Hoist, Torque Converter, and Brake System Troubleshooting: Pantalla AnteriorDocument17 pagesHoist, Torque Converter, and Brake System Troubleshooting: Pantalla AnteriorLENIN JHAIR VALDERRAMA SEGURANo ratings yet

- List Item Autolube GracoDocument1 pageList Item Autolube Gracotantoh84No ratings yet

- Hydraulic and Steering System PDFDocument8 pagesHydraulic and Steering System PDFPutra Jawa100% (1)

- Radiator Core Cleaning For D375A-6 (R5)Document2 pagesRadiator Core Cleaning For D375A-6 (R5)alcowo100% (2)

- Fuel System: Operación de SistemasDocument15 pagesFuel System: Operación de SistemasAlex HSNo ratings yet

- PC400 400LC-8R PDFDocument8 pagesPC400 400LC-8R PDFAsmar FixNo ratings yet

- Owner's Manual EN - PRAMAC - LSW8-LSW5-LSW3 - Rev 06Document31 pagesOwner's Manual EN - PRAMAC - LSW8-LSW5-LSW3 - Rev 06miguel taipeNo ratings yet

- 10Pm ClinicDocument31 pages10Pm ClinicAnonymous ByaV1f100% (1)

- 24d03 EFI Diesel Common Rail PDFDocument16 pages24d03 EFI Diesel Common Rail PDFSurya Irawan100% (1)

- Monograde Vs Multigrade OilsDocument3 pagesMonograde Vs Multigrade OilsmdavilasNo ratings yet

- PM Clinic WA500-3LEDocument3 pagesPM Clinic WA500-3LEJheison ValenciaNo ratings yet

- Common Rail Diesel Engine Management 1 PDFDocument13 pagesCommon Rail Diesel Engine Management 1 PDFMarranNo ratings yet

- Brochure Cen00820-01 PC210210LC-10M0 PDFDocument32 pagesBrochure Cen00820-01 PC210210LC-10M0 PDFHenry SimangunsongNo ratings yet

- Belaz 75137 Usa and CanadaDocument2 pagesBelaz 75137 Usa and CanadabasNo ratings yet

- PC 300 PDFDocument12 pagesPC 300 PDFHell Yeah100% (1)

- Lab Manual Hydraulics and Pneumatics .Document56 pagesLab Manual Hydraulics and Pneumatics .Aniket ChavanNo ratings yet

- Curvas, Gobernadores, Full Timing, Full Setting, MUI, HEUIDocument318 pagesCurvas, Gobernadores, Full Timing, Full Setting, MUI, HEUIRoberto Carrasco100% (4)

- Maintenance & Service - I Course Code: 4360201: Page 1 of 12Document12 pagesMaintenance & Service - I Course Code: 4360201: Page 1 of 12Aaqib SurtiNo ratings yet

- N Step 1 NissanDocument1,415 pagesN Step 1 NissanJoko Sukariono100% (9)

- What Is An Informal LetterDocument10 pagesWhat Is An Informal LetterJoko SukarionoNo ratings yet

- 1ge PDFDocument8 pages1ge PDFJoko SukarionoNo ratings yet

- Introduction and General Service SafetyDocument47 pagesIntroduction and General Service SafetyJoko Sukariono100% (2)

- (CRI) Engine Fuel Filters PDFDocument7 pages(CRI) Engine Fuel Filters PDFJoko Sukariono100% (1)

- 4fuel Injection PumpDocument9 pages4fuel Injection PumpJoko Sukariono100% (2)

- SEKN5003 R KIT For New Connector PDFDocument23 pagesSEKN5003 R KIT For New Connector PDFJoko SukarionoNo ratings yet

- SEKN5005 Deutsch C TIPS PDFDocument7 pagesSEKN5005 Deutsch C TIPS PDFJoko SukarionoNo ratings yet

- At04222a2filter PDFDocument8 pagesAt04222a2filter PDFJoko SukarionoNo ratings yet

- III. ENGINE DIESEL (Engine System) PDFDocument75 pagesIII. ENGINE DIESEL (Engine System) PDFJoko Sukariono100% (4)

- Harness Checker Box PDFDocument2 pagesHarness Checker Box PDFJoko SukarionoNo ratings yet

- II. ENGINE DIESEL (Komponen Engine) PDFDocument34 pagesII. ENGINE DIESEL (Komponen Engine) PDFJoko SukarionoNo ratings yet

- Sheet Metal Forming ProcessesDocument34 pagesSheet Metal Forming ProcessesIzi100% (12)

- A4 SEBM024301 (T&A Troubleshooting) PDFDocument330 pagesA4 SEBM024301 (T&A Troubleshooting) PDFJoko Sukariono100% (2)

- E 500 SpecificationDocument6 pagesE 500 SpecificationAgustin BerriosNo ratings yet

- Practice Exam 2Document4 pagesPractice Exam 2Clariza Mae PerniaNo ratings yet

- 17.2. Propeller Construction.Document10 pages17.2. Propeller Construction.Anuruddha Rukmal100% (1)

- User Guide C3R5 - DA - 20210325Document159 pagesUser Guide C3R5 - DA - 20210325jose francisNo ratings yet

- 2013 en SG LightDocument56 pages2013 en SG LightAmit Sarkar100% (1)

- PETRO Pump 240V 70lpm CW Integrated FMSDocument2 pagesPETRO Pump 240V 70lpm CW Integrated FMSFelipe HernandezNo ratings yet

- Pile Driving Equipments: Prepared By: C.Uma U06CE056Document23 pagesPile Driving Equipments: Prepared By: C.Uma U06CE056ankitbalyan100% (2)

- Latest Developments in Ammonia Production TechnologyDocument21 pagesLatest Developments in Ammonia Production TechnologyAnonymous msVFza100% (3)

- (##) Pneumatic Double Axis JCB ModelDocument8 pages(##) Pneumatic Double Axis JCB ModelmohanNo ratings yet

- Lecture 5 - Hydraulic Systems of Machine ToolsDocument56 pagesLecture 5 - Hydraulic Systems of Machine ToolsAli FaycalNo ratings yet

- Ground School TupiDocument37 pagesGround School TupiGustavo CastilhoNo ratings yet

- Lada Niva Dakar Preparation Part2 PDFDocument16 pagesLada Niva Dakar Preparation Part2 PDFhamoNo ratings yet

- Pressure Transducer DesignDocument112 pagesPressure Transducer DesignSumeet GhodkeNo ratings yet

- Ford Sierra 0903-WD Wire DiagramDocument47 pagesFord Sierra 0903-WD Wire Diagramhalo35100% (1)

- Clock OilsDocument35 pagesClock Oilsbrandonhill7No ratings yet

- Executive SummaryDocument38 pagesExecutive SummaryThiru Voyage InteligentsNo ratings yet

- Paschal 400 Level Siwes ReportDocument28 pagesPaschal 400 Level Siwes ReportPeter PaschalNo ratings yet

- Bma4723 Vehicle Dynamics Chap 22Document35 pagesBma4723 Vehicle Dynamics Chap 22Fu HongNo ratings yet

- Mechanical and Wear Behavior of AA7075 Aluminum Matrix Composites Reinforced by Al 2 O 3 NanoparticlesDocument9 pagesMechanical and Wear Behavior of AA7075 Aluminum Matrix Composites Reinforced by Al 2 O 3 NanoparticlesARULKUMARSUBRAMANIANNo ratings yet

- Dynamic Behaviour of Coke Drums Psvs During Blocked Outlet ConditionDocument164 pagesDynamic Behaviour of Coke Drums Psvs During Blocked Outlet Conditionck19654840No ratings yet

- 87 190E 190e2point6 OMDocument113 pages87 190E 190e2point6 OMCenk KORKUTURNo ratings yet

- CH - 36Document5 pagesCH - 36mpusNo ratings yet

- Optimization of AMDP-ABROD Furnace For Rice and Grain DryingDocument26 pagesOptimization of AMDP-ABROD Furnace For Rice and Grain DryingEd CasasNo ratings yet

- List of Protective RelaysDocument2 pagesList of Protective RelaysalekyaNo ratings yet

- Automotive Engine Test Bed For Mechanical Engineering Laboratory Course PDFDocument128 pagesAutomotive Engine Test Bed For Mechanical Engineering Laboratory Course PDFAngel OfrenNo ratings yet

- Rhspray Cond MSP: SL - No Description Unit Reference ActualDocument24 pagesRhspray Cond MSP: SL - No Description Unit Reference ActualsprotkarNo ratings yet

- Lucas Tvs Interview QuestionsDocument2 pagesLucas Tvs Interview QuestionsGomathi SankarNo ratings yet

- Navtec HydraulicAccessoriesDocument3 pagesNavtec HydraulicAccessoriesJim Haig100% (1)

Cri Fuel System PDF

Cri Fuel System PDF

Uploaded by

jasyadiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cri Fuel System PDF

Cri Fuel System PDF

Uploaded by

jasyadiCopyright:

Available Formats

PT UNITED TRACTORS Tbk

TRAINING CENTER DEPARTEMENT

SITE SANGATTA

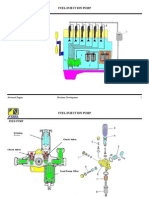

CRI FUEL SYSTEM

PT. THIESS CONTRACTORS INDONESIA

Page 1 of 11

TRAINING REPORT

CRI FUEL SYSTEM

PT. THIESS CONTRACTOR INDONESIA

TRAINING CENTRE DEPARTMENT

SANGATTA

TRAINING REPORT

TC SGT/TR Report/ABR/180507 /REV 00

PT UNITED TRACTORS Tbk

TRAINING CENTER DEPARTEMENT

SITE SANGATTA

CRI FUEL SYSTEM

PT. THIESS CONTRACTORS INDONESIA

Page 2 of 11

CONTENT

FOREWARD

TRAINING PROGRAM

CURRICULUM

SYLABUS

TRAINING REPORT

TRAINING REPORT

TC SGT/TR Report/ABR/180507 /REV 00

PT UNITED TRACTORS Tbk

TRAINING CENTER DEPARTEMENT

SITE SANGATTA

CRI FUEL SYSTEM

PT. THIESS CONTRACTORS INDONESIA

Page 3 of 11

FOREWORD

The concept of Total Service in PT United Tractors Tbk is established to support customers in

achieving the highest operating efficiency. This concept is an integrated part of United

Tractors' business philosophy which aims "to become your partner-in-business by providing

full support to ensure the achievement of your lowest life-time cost per total output". Total

Service is not limited to after-sales support only but covers a wide range of services from

pre-sales consultation, equipment inspection, equipment maintenance, to customer training.

It is our commitment that each single unit of customer's equipment will receive our full

support.

Align with the concept of Total Service, education and training program is aimed at

developing the human resources' skills in heavy equipment operation and maintenance.

Realizing that knowledge and practical skills are both essential for efficient equipment

operation and maintenance, United Tractors has established a modern and well-equipped

Training Center where as much as 5000 participants per year can undergo effective training.

The training facilities include various demo equipment, classrooms with up-to-date audiovisual equipment, and a testing area for operator training.

Our instructors and trainers are highly qualified and conversant with the latest developments

in equipment operation and maintenance. Apart from providing education and training for

UT's internal requirements, the Training Center is also open for customers to upgrade the

knowledge and skills of their operators and supervisors.

TRAINING REPORT

TC SGT/TR Report/ABR/180507 /REV 00

CRI FUEL SYSTEM

PT UNITED TRACTORS Tbk

PT. THIESS CONTRACTORS INDONESIA

TRAINING CENTER DEPARTEMENT

SITE SANGATTA

Page 4 of 11

I. TRAINING PROGRAM

I.

II.

COURSE NAME

Common Rail Injection Fuel System

After the training, participants should be able to carry out

Preventive Maintenance engine 6D140E-3, Trouble shooting

engine 6D140E-3 especially in Fuel system on PC750-7, PC8007 and PC1800-6 based on shop manual and operation

maintenance manual. The points are,

1. Describing :

a. Safety

b. Structure, function and location of components

c. Preventive maintenance procedure

d. Measurement, testing and adjusting procedure

e. Trouble analysis

2. Performing :

a. Machine inspection

b. Trouble shooting

c. Reporting

III. METHODE

1. Class room (66,67%)

a. Lecture

b. Discussion

c. Case study

2. Practice (33,33%)

a. Demonstration

b. Practice

IV.

SUBJECT

1.

2.

3.

4.

5.

6.

7.

V.

FACILITIES

1. Classroom

a. Overhead projector/Viewer

b. Audio visual

c. Hand out

2. Practice (Workshop/Field)

a. Common tools

b. Special tools

c. Machine : PC800-7, PC1800-6

VI.

DURATION

OBJECTIVES

VII. PARTICIPANT

Introduction.

Fuel Line.

Fuel Supply Pump.

Common Rail.

Injector.

Electronic Control System.

Trouble Shooting.

3 (Two) working days

participants

VIII.PASS CRITERIA :

1. Attendance min. 90% of total training days

2. Evaluation test :

a. Theory :

70

b. Practice :

70

IX.

1.Certificate is awarded to trainees who fulfill pass criteria

2.Acknowledgement is awarded to trainees who attends 90 % of

total days but can not achieve the minimum score.

CERTIFICATE

TRAINING REPORT

TC SGT/TR Report/ABR/180507 /REV 00

CRI FUEL SYSTEM

PT UNITED TRACTORS Tbk

PT. THIESS CONTRACTORS INDONESIA

TRAINING CENTER DEPARTEMENT

SITE SANGATTA

Page 5 of 11

II. CURRICULUM

NO

SUBJECT

THEORY

TIME (HOUR)

PRACTICE

TOTAL

INTRODUCTION

60

FUEL LINE

60

30

90

FUEL SUPPLY PUMP

120

60

180

COMMON RAIL

60

60

120

INJECTOR

60

60

120

ELECTRONIC CONTROL SYSTEM

360

150

510

TROUBLE SHOOTING

180

120

300

EVALUATION TEST

60

TRAINING REPORT

60

60

TOTAL

960

480

1440

PERCENTAGE

66.67%

33.33%

100%

TC SGT/TR Report/ABR/180507 /REV 00

PT UNITED TRACTORS Tbk

TRAINING CENTER DEPARTEMENT

SITE SANGATTA

CRI FUEL SYSTEM

Page 6 of 11

PT. THIESS CONTRACTORS INDONESIA

III. SYLABUS

SUBJECT I. INTRODUCTION

DESCRIPTION

OBJECTIVES

NO

1

Introduction

A. General overview of Engine

6D140E-3

a. Overall Drawing

b. Engine Spesification

B. Features of CRI Fuel System

a. Electronic Control

b. Environment Regulation

Fuel Line

A. Fuel Piping

a. Low Pressure Circuit

b. High Pressure Circuit

B. Fuel Filter

C. Fuel Cooler.

D. Remove and Install of Fuel Line

E. Inspection & Measurement of

Fuel Line

Fuel Suplly Pump

A. Feed Pump

B. Overflow Valve

C. By Pass Valve

D. High Pressure Pump

a. PCV

b. Delivery Valve

G. Remove & Install Fuel Supply

Pump.

H. Inspection & Measurement Fuel

Supply Pump.

TRAINING REPORT

60

60

TIME (HOUR)

THEORY PRACTICE TOTAL

1. The Participants should

be understand, able to

explain the structure,

function and location of

CRI Fuel line.

2.

The Participants should be

able to perform Remove

and Install of fuel line and

able to perform inspection

and measurement.

SUBJECT III. FUEL SUPPLY PUMP

DESCRIPTION

OBJECTIVES

NO

3

The Participants should be

understand and able to

explain the engine

spesification and features

of CRI fuel system.

SUBJECT II. FUEL LINE

DESCRIPTION

OBJECTIVES

NO

2

TIME (HOUR)

THEORY PRACTICE TOTAL

60

30

90

TIME (HOUR)

THEORY PRACTICE TOTAL

1. The Participants should

be understand, able to

explain the structure,

function and location of

Fuel supply pump.

2. The Participants should

be able to perform

Remove and Install of fuel

line and able to perform

inspection and

measurement.

120

60

180

TC SGT/TR Report/ABR/180507 /REV 00

PT UNITED TRACTORS Tbk

TRAINING CENTER DEPARTEMENT

SITE SANGATTA

SUBJECT IV. COMMON RAIL

DESCRIPTION

OBJECTIVES

NO

4

Common Rail

A. Common Rail Fuel Inlet Port

B. Pressure Limiter

C. Flow Damper Valve

D. Remove & Install of Commmon

Rail.

E. Inspection & Measurement of

Common Rail.

Injector

A. Injectors fuel inlet port

B. Injector operation.

C. Injector wiring.

D. Remove and Install of Injector

E. Inpesction and Measurement of

Injector

TRAINING REPORT

Page 7 of 11

TIME (HOUR)

THEORY PRACTICE TOTAL

1. The Participants able to

explain the structure,

function and location of

common rail compo nents.

2. The participants shoulbe

able to perform remove

and install, and inspection

and measurement of

common rail

SUBJECT V. INJECTOR

DESCRIPTION

OBJECTIVES

NO

5

CRI FUEL SYSTEM

PT. THIESS CONTRACTORS INDONESIA

60

60

120

TIME (HOUR)

THEORY PRACTICE TOTAL

1. The Participants able to

explain the structure,

function and location of

injector.

2. The participants should

be able to perform remove

and install, and inspection

and measurement of

injector

60

60

120

TC SGT/TR Report/ABR/180507 /REV 00

PT UNITED TRACTORS Tbk

TRAINING CENTER DEPARTEMENT

SITE SANGATTA

NO

6

SUBJECT VI. ELECTRONIC CONTROL SYSTEM

DESCRIPTION

OBJECTIVES

Electronic Control System

A. Basic Mechatronic

a. Input

b. Process

c. Output

B. ECM Power Supply

C. Input

a. Temperature Sensors

- Coolant temperature sensor

- Fuel temperature sensor

b. Pressure sensor/switch

- Oil pressure switch

- Common rail pressure sensor

- Boost pressure sensor

c. Throttle sensor

- Fuel control dial

d. Speed & Position Sensor

- Ne Sensor

- G Sensor

e. Others

- Start signal

- Etc

D. Process

a. Fuel Metering

b. Fuel Timing

c. Safety / Protection

d. Exhaust Gas Regulating

E. Output

a. PCV Solenoid

b. TWV Solenoid

F. Remove & Install of Electronic

component

G. Inspection & Measurement of

Electronic Component

Trouble Shooting

A. Eight Step Trouble Shooting

B. Trouble Shooting Based on Error

Code.

C. Trouble Shooting based on

Symptom

TRAINING REPORT

Page 8 of 11

TIME (HOUR)

THEORY PRACTICE TOTAL

1. The Participants able to

explain the structure,

function and location of

electronic control system

components.

2. The participants should

be able to perform remove

and install, and inspection

and measurement of

electronic components

SUBJECT VII. TROUBLE SHOOTING

DESCRIPTION

OBJECTIVES

NO

7

CRI FUEL SYSTEM

PT. THIESS CONTRACTORS INDONESIA

360

150

410

TIME (HOUR)

THEORY PRACTICE TOTAL

1. The Participants able to

explain the eight step

trouble shooting.

2. The participants should

be perform the trouble

shooting based on error

code and symptom

180

120

300

TC SGT/TR Report/ABR/180507 /REV 00

PT UNITED TRACTORS Tbk

TRAINING CENTER DEPARTEMENT

SITE SANGATTA

SUBJECT VIII. EVALUATION TEST

DESCRIPTION

OBJECTIVES

NO

8

CRI FUEL SYSTEM

EVALUATION TEST

A. Theoritical Test

Evaluate the training

TOTAL

TIME (HOUR)

THEORY PRACTICE TOTAL

60

TIME (HOUR)

THEORY PRACTICE TOTAL

960

TRAINING REPORT

Page 9 of 11

PT. THIESS CONTRACTORS INDONESIA

480

1440

TC SGT/TR Report/ABR/180507 /REV 00

PT UNITED TRACTORS Tbk

TRAINING CENTER DEPARTEMENT

SITE SANGATTA

TRAINING REPORT

CRI FUEL SYSTEM

PT. THIESS CONTRACTORS INDONESIA

Page 10 of 11

TC SGT/TR Report/ABR/180507 /REV 00

PT UNITED TRACTORS Tbk

TRAINING CENTER DEPARTEMENT

SITE SANGATTA

CRI FUEL SYSTEM

PT. THIESS CONTRACTORS INDONESIA

Page 11 of 11

Sangatta, 19 May 2007

Reported by,

Abraham Richsan

PT. UNITED TRACTORS Tbk

TRAINING CENTRE DEPARTMENT

Jl. Tango Delta, Road HRDS

KPC Mine Site, Sangatta

Kalimantan Timur

Phone

Fax

:

:

:

TRAINING REPORT

(0549) 21414, 21415, 21416 Ext 210.

(0549) 21414

tcsgt@unitedtractors.com

TC SGT/TR Report/ABR/180507 /REV 00

You might also like

- Atlas Copco Boomer L2D Operators InstructionsDocument120 pagesAtlas Copco Boomer L2D Operators InstructionsHai Van100% (14)

- Mechanical Design Engineer Interview QuestionsDocument4 pagesMechanical Design Engineer Interview QuestionssuseevNo ratings yet

- Autolube System (HYD) OverviewDocument21 pagesAutolube System (HYD) OverviewDaniel Alfonso Diaz FloresNo ratings yet

- Adjust Valve EC200DDocument5 pagesAdjust Valve EC200DHeru Hoo0% (1)

- Surface Production Operation EquipmentDocument10 pagesSurface Production Operation Equipmentapi-201334376No ratings yet

- D155A-2 # 57001 Up SEBM018602 PDFDocument462 pagesD155A-2 # 57001 Up SEBM018602 PDFJoko Sukariono100% (6)

- PC 1250 Elect ControlDocument43 pagesPC 1250 Elect Controlanggie100% (1)

- Spesifications of Hino Ranger FM 260,320 Series (6X4)Document5 pagesSpesifications of Hino Ranger FM 260,320 Series (6X4)MuhaiminNo ratings yet

- Common Rail Fuel System - SpecificationsDocument4 pagesCommon Rail Fuel System - Specificationssengottaiyan100% (1)

- Machine Control SystemDocument43 pagesMachine Control SystemanggieNo ratings yet

- DX700LC PDFDocument20 pagesDX700LC PDFA Ramos GabyNo ratings yet

- Bca Sheet MultiflowDocument55 pagesBca Sheet Multiflowbumatio latiNo ratings yet

- Power Train Volvo FMX370Document56 pagesPower Train Volvo FMX370haqiardinalNo ratings yet

- Engine Valve Tune Guideline HD785-7 Rev29112017 PDFDocument17 pagesEngine Valve Tune Guideline HD785-7 Rev29112017 PDFHari Ary100% (1)

- Bulldozer d65pDocument10 pagesBulldozer d65pRisky UpNo ratings yet

- HarisDocument28 pagesHarisZen PNo ratings yet

- Bus Truck Tractor Brake PerformanceDocument56 pagesBus Truck Tractor Brake PerformancedeshpandeamolNo ratings yet

- Failure Code Display Algorithm For ECMVDocument4 pagesFailure Code Display Algorithm For ECMValcowo100% (1)

- Accelerator Control, Fuel & Exhaust Systems: GI MADocument12 pagesAccelerator Control, Fuel & Exhaust Systems: GI MAaymendabNo ratings yet

- Positive Crankcase Ventilation (PCV) (Text p17) : 27 February 2 006 at KTB Jak Arta MFTBC R&D DivisionDocument6 pagesPositive Crankcase Ventilation (PCV) (Text p17) : 27 February 2 006 at KTB Jak Arta MFTBC R&D DivisionRose Myny100% (1)

- SM HD 785-7 Sen05900-17Document2,302 pagesSM HD 785-7 Sen05900-17Ongky FirnandoNo ratings yet

- Common Rail System Diesel Engine Technology PDFDocument26 pagesCommon Rail System Diesel Engine Technology PDFFedima100% (1)

- Brake System DiagnosisDocument69 pagesBrake System DiagnosisIlyas Nur AfshohiNo ratings yet

- Form NEW TSR 2016Document2 pagesForm NEW TSR 2016Ega YudhaNo ratings yet

- Meca Sheet: Remove & Install PNC-A01-002-001-01 EngineDocument3 pagesMeca Sheet: Remove & Install PNC-A01-002-001-01 EngineIndah Widya Putri100% (1)

- Service Manual Nissan PDFDocument39 pagesService Manual Nissan PDFayi darwisNo ratings yet

- Periodic Service 1000 Hours PC 200-8: Present By: Muh Arif Budiawan SyamDocument28 pagesPeriodic Service 1000 Hours PC 200-8: Present By: Muh Arif Budiawan SyamMuh Arief Budiawan Arief100% (1)

- Topik 4Document214 pagesTopik 4Daniel Dale Ambo Sibarani100% (1)

- Fuel Injection Pump PDFDocument7 pagesFuel Injection Pump PDFGANAPATHY MNo ratings yet

- PM PC1250SP-8Document25 pagesPM PC1250SP-8Teguh Imam AdriNo ratings yet

- Basic Engine: Replace Fuel ElementDocument6 pagesBasic Engine: Replace Fuel Elementraymond ngoNo ratings yet

- Analisa Penyebab Low Speed All AttachmentDocument65 pagesAnalisa Penyebab Low Speed All Attachment07 Dimas Pramudya WNo ratings yet

- Taufik Hidayat Gultom PS3 D375Document26 pagesTaufik Hidayat Gultom PS3 D375Dava JrNo ratings yet

- General Information: 018-001 SpecificationsDocument10 pagesGeneral Information: 018-001 SpecificationsLaiqNo ratings yet

- Maintenance Fowa - Fuel - 50305Document20 pagesMaintenance Fowa - Fuel - 50305darwin100% (1)

- MTS Steering Brake Dozer - Grader KomatsuDocument6 pagesMTS Steering Brake Dozer - Grader KomatsuRizal MerahNo ratings yet

- Product Knowledge Renault Trucks-PrintDocument25 pagesProduct Knowledge Renault Trucks-PrintAris NurrochmanNo ratings yet

- Common RailDocument16 pagesCommon RailRaikhan Syafiq100% (2)

- D155A-6 Power Train System: Dubai Training and Demonstration CenterDocument20 pagesD155A-6 Power Train System: Dubai Training and Demonstration CenterMichael DavidNo ratings yet

- (CRI) Engine Fuel Filters PDFDocument7 pages(CRI) Engine Fuel Filters PDFJoko Sukariono100% (1)

- Sistem Kemudi & RemDocument171 pagesSistem Kemudi & RemAndikaNo ratings yet

- THF6 - .Joystick Control PDFDocument12 pagesTHF6 - .Joystick Control PDFmusafirNo ratings yet

- Air Sistema HandlingDocument20 pagesAir Sistema Handlingdarwin100% (1)

- EMS GasolineDocument39 pagesEMS GasolineKha TrầnNo ratings yet

- EFIDocument37 pagesEFITia SetiawanNo ratings yet

- Hoist, Torque Converter, and Brake System Troubleshooting: Pantalla AnteriorDocument17 pagesHoist, Torque Converter, and Brake System Troubleshooting: Pantalla AnteriorLENIN JHAIR VALDERRAMA SEGURANo ratings yet

- List Item Autolube GracoDocument1 pageList Item Autolube Gracotantoh84No ratings yet

- Hydraulic and Steering System PDFDocument8 pagesHydraulic and Steering System PDFPutra Jawa100% (1)

- Radiator Core Cleaning For D375A-6 (R5)Document2 pagesRadiator Core Cleaning For D375A-6 (R5)alcowo100% (2)

- Fuel System: Operación de SistemasDocument15 pagesFuel System: Operación de SistemasAlex HSNo ratings yet

- PC400 400LC-8R PDFDocument8 pagesPC400 400LC-8R PDFAsmar FixNo ratings yet

- Owner's Manual EN - PRAMAC - LSW8-LSW5-LSW3 - Rev 06Document31 pagesOwner's Manual EN - PRAMAC - LSW8-LSW5-LSW3 - Rev 06miguel taipeNo ratings yet

- 10Pm ClinicDocument31 pages10Pm ClinicAnonymous ByaV1f100% (1)

- 24d03 EFI Diesel Common Rail PDFDocument16 pages24d03 EFI Diesel Common Rail PDFSurya Irawan100% (1)

- Monograde Vs Multigrade OilsDocument3 pagesMonograde Vs Multigrade OilsmdavilasNo ratings yet

- PM Clinic WA500-3LEDocument3 pagesPM Clinic WA500-3LEJheison ValenciaNo ratings yet

- Common Rail Diesel Engine Management 1 PDFDocument13 pagesCommon Rail Diesel Engine Management 1 PDFMarranNo ratings yet

- Brochure Cen00820-01 PC210210LC-10M0 PDFDocument32 pagesBrochure Cen00820-01 PC210210LC-10M0 PDFHenry SimangunsongNo ratings yet

- Belaz 75137 Usa and CanadaDocument2 pagesBelaz 75137 Usa and CanadabasNo ratings yet

- PC 300 PDFDocument12 pagesPC 300 PDFHell Yeah100% (1)

- Lab Manual Hydraulics and Pneumatics .Document56 pagesLab Manual Hydraulics and Pneumatics .Aniket ChavanNo ratings yet

- Curvas, Gobernadores, Full Timing, Full Setting, MUI, HEUIDocument318 pagesCurvas, Gobernadores, Full Timing, Full Setting, MUI, HEUIRoberto Carrasco100% (4)

- Maintenance & Service - I Course Code: 4360201: Page 1 of 12Document12 pagesMaintenance & Service - I Course Code: 4360201: Page 1 of 12Aaqib SurtiNo ratings yet

- N Step 1 NissanDocument1,415 pagesN Step 1 NissanJoko Sukariono100% (9)

- What Is An Informal LetterDocument10 pagesWhat Is An Informal LetterJoko SukarionoNo ratings yet

- 1ge PDFDocument8 pages1ge PDFJoko SukarionoNo ratings yet

- Introduction and General Service SafetyDocument47 pagesIntroduction and General Service SafetyJoko Sukariono100% (2)

- (CRI) Engine Fuel Filters PDFDocument7 pages(CRI) Engine Fuel Filters PDFJoko Sukariono100% (1)

- 4fuel Injection PumpDocument9 pages4fuel Injection PumpJoko Sukariono100% (2)

- SEKN5003 R KIT For New Connector PDFDocument23 pagesSEKN5003 R KIT For New Connector PDFJoko SukarionoNo ratings yet

- SEKN5005 Deutsch C TIPS PDFDocument7 pagesSEKN5005 Deutsch C TIPS PDFJoko SukarionoNo ratings yet

- At04222a2filter PDFDocument8 pagesAt04222a2filter PDFJoko SukarionoNo ratings yet

- III. ENGINE DIESEL (Engine System) PDFDocument75 pagesIII. ENGINE DIESEL (Engine System) PDFJoko Sukariono100% (4)

- Harness Checker Box PDFDocument2 pagesHarness Checker Box PDFJoko SukarionoNo ratings yet

- II. ENGINE DIESEL (Komponen Engine) PDFDocument34 pagesII. ENGINE DIESEL (Komponen Engine) PDFJoko SukarionoNo ratings yet

- Sheet Metal Forming ProcessesDocument34 pagesSheet Metal Forming ProcessesIzi100% (12)

- A4 SEBM024301 (T&A Troubleshooting) PDFDocument330 pagesA4 SEBM024301 (T&A Troubleshooting) PDFJoko Sukariono100% (2)

- E 500 SpecificationDocument6 pagesE 500 SpecificationAgustin BerriosNo ratings yet

- Practice Exam 2Document4 pagesPractice Exam 2Clariza Mae PerniaNo ratings yet

- 17.2. Propeller Construction.Document10 pages17.2. Propeller Construction.Anuruddha Rukmal100% (1)

- User Guide C3R5 - DA - 20210325Document159 pagesUser Guide C3R5 - DA - 20210325jose francisNo ratings yet

- 2013 en SG LightDocument56 pages2013 en SG LightAmit Sarkar100% (1)

- PETRO Pump 240V 70lpm CW Integrated FMSDocument2 pagesPETRO Pump 240V 70lpm CW Integrated FMSFelipe HernandezNo ratings yet

- Pile Driving Equipments: Prepared By: C.Uma U06CE056Document23 pagesPile Driving Equipments: Prepared By: C.Uma U06CE056ankitbalyan100% (2)

- Latest Developments in Ammonia Production TechnologyDocument21 pagesLatest Developments in Ammonia Production TechnologyAnonymous msVFza100% (3)

- (##) Pneumatic Double Axis JCB ModelDocument8 pages(##) Pneumatic Double Axis JCB ModelmohanNo ratings yet

- Lecture 5 - Hydraulic Systems of Machine ToolsDocument56 pagesLecture 5 - Hydraulic Systems of Machine ToolsAli FaycalNo ratings yet

- Ground School TupiDocument37 pagesGround School TupiGustavo CastilhoNo ratings yet

- Lada Niva Dakar Preparation Part2 PDFDocument16 pagesLada Niva Dakar Preparation Part2 PDFhamoNo ratings yet

- Pressure Transducer DesignDocument112 pagesPressure Transducer DesignSumeet GhodkeNo ratings yet

- Ford Sierra 0903-WD Wire DiagramDocument47 pagesFord Sierra 0903-WD Wire Diagramhalo35100% (1)

- Clock OilsDocument35 pagesClock Oilsbrandonhill7No ratings yet

- Executive SummaryDocument38 pagesExecutive SummaryThiru Voyage InteligentsNo ratings yet

- Paschal 400 Level Siwes ReportDocument28 pagesPaschal 400 Level Siwes ReportPeter PaschalNo ratings yet

- Bma4723 Vehicle Dynamics Chap 22Document35 pagesBma4723 Vehicle Dynamics Chap 22Fu HongNo ratings yet

- Mechanical and Wear Behavior of AA7075 Aluminum Matrix Composites Reinforced by Al 2 O 3 NanoparticlesDocument9 pagesMechanical and Wear Behavior of AA7075 Aluminum Matrix Composites Reinforced by Al 2 O 3 NanoparticlesARULKUMARSUBRAMANIANNo ratings yet

- Dynamic Behaviour of Coke Drums Psvs During Blocked Outlet ConditionDocument164 pagesDynamic Behaviour of Coke Drums Psvs During Blocked Outlet Conditionck19654840No ratings yet

- 87 190E 190e2point6 OMDocument113 pages87 190E 190e2point6 OMCenk KORKUTURNo ratings yet

- CH - 36Document5 pagesCH - 36mpusNo ratings yet

- Optimization of AMDP-ABROD Furnace For Rice and Grain DryingDocument26 pagesOptimization of AMDP-ABROD Furnace For Rice and Grain DryingEd CasasNo ratings yet

- List of Protective RelaysDocument2 pagesList of Protective RelaysalekyaNo ratings yet

- Automotive Engine Test Bed For Mechanical Engineering Laboratory Course PDFDocument128 pagesAutomotive Engine Test Bed For Mechanical Engineering Laboratory Course PDFAngel OfrenNo ratings yet

- Rhspray Cond MSP: SL - No Description Unit Reference ActualDocument24 pagesRhspray Cond MSP: SL - No Description Unit Reference ActualsprotkarNo ratings yet

- Lucas Tvs Interview QuestionsDocument2 pagesLucas Tvs Interview QuestionsGomathi SankarNo ratings yet

- Navtec HydraulicAccessoriesDocument3 pagesNavtec HydraulicAccessoriesJim Haig100% (1)