Professional Documents

Culture Documents

Control and Interfacing of Motors With Ni-Labview Using Ni-Myrio

Control and Interfacing of Motors With Ni-Labview Using Ni-Myrio

Uploaded by

Muhammad Rizky KaisupyCopyright:

Available Formats

You might also like

- PLC Programming from Novice to Professional: Learn PLC Programming with Training VideosFrom EverandPLC Programming from Novice to Professional: Learn PLC Programming with Training VideosRating: 5 out of 5 stars5/5 (1)

- Inplant Training ReportDocument30 pagesInplant Training ReportTirumala Venkatesh100% (1)

- RT - Ruane and T P O'Neill PDFDocument85 pagesRT - Ruane and T P O'Neill PDFbaskaran ayyapparajNo ratings yet

- Dell ServerDocument3 pagesDell ServerSenthil Vel KNo ratings yet

- Control of DC Motor in Labview by Using Ni-MyrioDocument4 pagesControl of DC Motor in Labview by Using Ni-MyrioIJSTENo ratings yet

- Prototype CNC Machine DesignDocument7 pagesPrototype CNC Machine DesignSuprapto ToNo ratings yet

- Design and Implementation of An Architecture For A Remotely Operated PLC Laboratory Using LabviewDocument8 pagesDesign and Implementation of An Architecture For A Remotely Operated PLC Laboratory Using LabviewTJPRC PublicationsNo ratings yet

- Pioneering Method To Analyse Depression in Human Being Using Audio-Video ParametersDocument6 pagesPioneering Method To Analyse Depression in Human Being Using Audio-Video ParametersEditor IJRITCCNo ratings yet

- Industrial Automation Using Modern Controls MonitoDocument6 pagesIndustrial Automation Using Modern Controls MonitoSucii AnggraiiniiNo ratings yet

- Ijert Ijert: Control of AC Motor Using LabviewDocument4 pagesIjert Ijert: Control of AC Motor Using LabviewCatalyn AlexandruNo ratings yet

- Ijert Ijert: Control of AC Motor Using LabviewDocument4 pagesIjert Ijert: Control of AC Motor Using LabviewahmetNo ratings yet

- PLC SCADA Training ReportDocument37 pagesPLC SCADA Training ReportAarif HussainNo ratings yet

- PLC, Scada TrainingDocument47 pagesPLC, Scada TrainingSandeep Kumar100% (1)

- Grid Tied Multilevel Inverter With Power Quality Monitoring Using Myrio and LabviewDocument5 pagesGrid Tied Multilevel Inverter With Power Quality Monitoring Using Myrio and LabviewMuhammad Sohaib ShahidNo ratings yet

- Design of Smart Car Using LabviewDocument6 pagesDesign of Smart Car Using LabviewSrinivas VeeruNo ratings yet

- Embedded PLC Implementation Using ARMDocument5 pagesEmbedded PLC Implementation Using ARMsnehagoyankaNo ratings yet

- Monitoring and Controlling Electricity ConsumptionDocument11 pagesMonitoring and Controlling Electricity ConsumptionDiego BustosNo ratings yet

- 00 - ArtículoDocument7 pages00 - Artículoheidy pintoNo ratings yet

- "Vehicle Monitering System Using Labview": National Institute of Technology Warangal-560004Document20 pages"Vehicle Monitering System Using Labview": National Institute of Technology Warangal-560004ambica thripuralaNo ratings yet

- Data Acquisition in LabVIEWDocument14 pagesData Acquisition in LabVIEWAASHIR AHMAD JASKANINo ratings yet

- Project Report: PLC & ScadaDocument44 pagesProject Report: PLC & ScadaAhmed SamiNo ratings yet

- Ethernet Control AC Motor Via PLC Using Labview: Nader N. Barsoum, Pin Rui ChinDocument10 pagesEthernet Control AC Motor Via PLC Using Labview: Nader N. Barsoum, Pin Rui ChinJihun WooNo ratings yet

- 0383.team ψ senior designDocument13 pages0383.team ψ senior designaku bulletNo ratings yet

- Fault Diagnostician of Induction Machine Using LabviewDocument5 pagesFault Diagnostician of Induction Machine Using LabviewJimmy Arias (JimmyStron)No ratings yet

- Internship Report HamzaDocument38 pagesInternship Report HamzaQasim MuhammadNo ratings yet

- Main Report2Document59 pagesMain Report2Diwakar DiwakarNo ratings yet

- Project Training ReportDocument17 pagesProject Training ReportrutvikNo ratings yet

- Voice Based Wireless Industrial Automation With Enhanced Feedback SystemDocument5 pagesVoice Based Wireless Industrial Automation With Enhanced Feedback SystemRekhaPadmanabhanNo ratings yet

- Control Systems Lab Hamza 4Document29 pagesControl Systems Lab Hamza 4Muhammad Hamza FarooqNo ratings yet

- P5. - Remote Monitoring and Control of VFD Fed 3-Phase Induction Motor With PLC and labVIEW SoftwareDocument7 pagesP5. - Remote Monitoring and Control of VFD Fed 3-Phase Induction Motor With PLC and labVIEW SoftwareMarco ParedesNo ratings yet

- PLC & SCADA Training ReportDocument44 pagesPLC & SCADA Training Reportneeraj meena100% (2)

- Modelling and Analysis of Induction Motor Using LabviewDocument11 pagesModelling and Analysis of Induction Motor Using LabviewNituNo ratings yet

- Training Report: Bachelor of TechnologyDocument46 pagesTraining Report: Bachelor of TechnologyHelloprojectNo ratings yet

- Automated Guided Vehicle (AGV) Full TextDocument62 pagesAutomated Guided Vehicle (AGV) Full Textazriffaris100% (2)

- Low Cost Data Acquisition Setup For Electrical Machines LaboratoryDocument6 pagesLow Cost Data Acquisition Setup For Electrical Machines LaboratorySarat MishraNo ratings yet

- Es Project Report 06Document23 pagesEs Project Report 06munizahqNo ratings yet

- Design of High Fidelity Building Energy Monitoring SystemDocument58 pagesDesign of High Fidelity Building Energy Monitoring SystemMohammed selimNo ratings yet

- Industrial WLANsDocument29 pagesIndustrial WLANsmichael_mccabe_18No ratings yet

- NI CaseStudy Cs 14833Document4 pagesNI CaseStudy Cs 14833XundaBugrillNo ratings yet

- Development of Control Algorithms in Matlab/Simulink: SciencedirectDocument5 pagesDevelopment of Control Algorithms in Matlab/Simulink: SciencedirectJunn Ree MontillaNo ratings yet

- Ijert Ijert: Control of AC Motor Using LabviewDocument4 pagesIjert Ijert: Control of AC Motor Using LabviewMihai BogdanNo ratings yet

- Implementing Palletization Application of 4-Axis Igus Robot ManipulatorDocument20 pagesImplementing Palletization Application of 4-Axis Igus Robot ManipulatorKV SAI KIRANNo ratings yet

- NI CaseStudy Cs 14833Document5 pagesNI CaseStudy Cs 14833Eduardo Barredo HernandezNo ratings yet

- Spy Robot Wireless Video Surveillance Using ArduinoDocument5 pagesSpy Robot Wireless Video Surveillance Using ArduinoEyob SintNo ratings yet

- Embedded Design Training ReportDocument52 pagesEmbedded Design Training ReportAshish YadavNo ratings yet

- Project Report On Robotic ArmDocument28 pagesProject Report On Robotic Armpatel ketan84% (25)

- Control Systems Lab4Document29 pagesControl Systems Lab4Muhammad Hamza FarooqNo ratings yet

- Digital Distance Relay Modeling and Testing Using LabVIEW and MATLAB SimulinkDocument55 pagesDigital Distance Relay Modeling and Testing Using LabVIEW and MATLAB SimulinkK Vijay Bhaskar ReddyNo ratings yet

- Touch Screen Based Industrial Crane ControllingDocument3 pagesTouch Screen Based Industrial Crane ControllingijsretNo ratings yet

- Monitoring and Controlling of BLDC Motor Using IOTDocument5 pagesMonitoring and Controlling of BLDC Motor Using IOTVIVA-TECH IJRI100% (1)

- Gujarat Technological University: Ac Motor ControllerDocument17 pagesGujarat Technological University: Ac Motor ControllerEngineers worldNo ratings yet

- Wireless Control of ImDocument5 pagesWireless Control of ImdineshkumarNo ratings yet

- DC Motor Speed Controller Design Using Pulse WidthDocument12 pagesDC Motor Speed Controller Design Using Pulse WidthHerman BachtiarNo ratings yet

- Internship 3Document38 pagesInternship 3S K B COMPUTERSNo ratings yet

- VC 3Document28 pagesVC 3Reethika SNo ratings yet

- Industrial Fault Indication System Using Avr MicrocontrollerDocument15 pagesIndustrial Fault Indication System Using Avr Microcontrollersri_palakolanuNo ratings yet

- MarintronicsDocument7 pagesMarintronicsNazmus SakibNo ratings yet

- PLC Based Solar Panel With Tilting Arrangement: April 2016Document9 pagesPLC Based Solar Panel With Tilting Arrangement: April 2016Paul TodericNo ratings yet

- Seth Jai Parkash Mukand Lal Institute of Engg. and Technology (Jmit) Radaur YAMUNA NAGAR (2011-2015)Document46 pagesSeth Jai Parkash Mukand Lal Institute of Engg. and Technology (Jmit) Radaur YAMUNA NAGAR (2011-2015)dinesh66jattNo ratings yet

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsFrom EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsNo ratings yet

- PowerFactory Applications for Power System AnalysisFrom EverandPowerFactory Applications for Power System AnalysisFrancisco M. Gonzalez-LongattNo ratings yet

- SBG (Nilai), German, Oil Distribution TransformerDocument12 pagesSBG (Nilai), German, Oil Distribution TransformerpeakfortuneNo ratings yet

- 8 Channel Current To Modbus Rtu Dat10017 IDocument3 pages8 Channel Current To Modbus Rtu Dat10017 IVishnu PatidarNo ratings yet

- Yardworks ManualDocument64 pagesYardworks ManualghobaNo ratings yet

- Efficient Performance Optimization of SOA-MZI DevicesDocument5 pagesEfficient Performance Optimization of SOA-MZI DevicesIvan Cuadros ChavezNo ratings yet

- TR 220 Operational ManualDocument76 pagesTR 220 Operational ManualSabby_SXBNo ratings yet

- Alternators: Quality With Value GuaranteedDocument3 pagesAlternators: Quality With Value GuaranteedinformationbankNo ratings yet

- ECE Sem 5 SyllabusDocument2 pagesECE Sem 5 SyllabusDaksh SharmaNo ratings yet

- EQ Magazine April 2010Document70 pagesEQ Magazine April 2010heavensetmNo ratings yet

- C To VHDL Converter in A Codesign Environment: June 1994Document11 pagesC To VHDL Converter in A Codesign Environment: June 1994Vivek SinghNo ratings yet

- Motor Starter Components and StandardsDocument20 pagesMotor Starter Components and StandardsJellyn BaseNo ratings yet

- A Project Report On Mini Inverter 12V To 220V: Submitted byDocument31 pagesA Project Report On Mini Inverter 12V To 220V: Submitted byCuriosity FeedsNo ratings yet

- Jecklin DiskDocument2 pagesJecklin DiskgilgoosNo ratings yet

- C-Data FTTH Epon Onu Fd10C-DATA FTTH EPON ONU FD101H1h - 1fe - Specification v3Document6 pagesC-Data FTTH Epon Onu Fd10C-DATA FTTH EPON ONU FD101H1h - 1fe - Specification v3tembelizatNo ratings yet

- Analog Electronics: Op-Amp Circuits and Active FiltersDocument43 pagesAnalog Electronics: Op-Amp Circuits and Active FiltersSin SideNo ratings yet

- Ic Data1Document3 pagesIc Data1Ssr ShaNo ratings yet

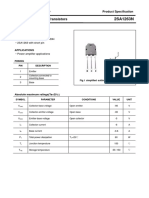

- Silicon PNP Power Transistors: Inchange Semiconductor Product SpecificationDocument4 pagesSilicon PNP Power Transistors: Inchange Semiconductor Product SpecificationRuben MapaloNo ratings yet

- A 1.2-V Dynamic Bias Latch-Type Comparator in 65-Nm CMOS With 0.4-MV Input NoiseDocument11 pagesA 1.2-V Dynamic Bias Latch-Type Comparator in 65-Nm CMOS With 0.4-MV Input NoiseburakgonenNo ratings yet

- YLR-U Series DatasheetDocument2 pagesYLR-U Series DatasheetAliali MohamedNo ratings yet

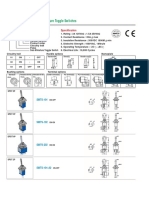

- TSK Klyuch Mts 102 3a 250v 6a 125vac SPDT On On 0Document8 pagesTSK Klyuch Mts 102 3a 250v 6a 125vac SPDT On On 0Matilda BenteforNo ratings yet

- NO QTY Nama Barang Merk Price, IDR Peralatan Uji Silang Metode Gel TestDocument6 pagesNO QTY Nama Barang Merk Price, IDR Peralatan Uji Silang Metode Gel TestKalbaridahNo ratings yet

- Living Ring-Opening Metathesis PolymerizationDocument29 pagesLiving Ring-Opening Metathesis PolymerizationTiago Breve da SilvaNo ratings yet

- Speed Control of DC Motor Using Ultrasonic SensorDocument12 pagesSpeed Control of DC Motor Using Ultrasonic SensorKADUSKAR PALASHNo ratings yet

- Fuji PID PXR459 Operation ManualDocument83 pagesFuji PID PXR459 Operation ManualmelferNo ratings yet

- Datasheets DS TQ401 EA401 IQS450-EnDocument12 pagesDatasheets DS TQ401 EA401 IQS450-EnEDBNo ratings yet

- αξεσουαρ SKODA CITIGO SPORTDocument7 pagesαξεσουαρ SKODA CITIGO SPORTSkoda Club PeloponnhsouNo ratings yet

- A History of Z MeasurementDocument63 pagesA History of Z MeasurementactecNo ratings yet

- 12124332Document3 pages12124332Cukaj AgostinNo ratings yet

- NKC 2012300-12Document1 pageNKC 2012300-12Nguyễn Quang HuyNo ratings yet

Control and Interfacing of Motors With Ni-Labview Using Ni-Myrio

Control and Interfacing of Motors With Ni-Labview Using Ni-Myrio

Uploaded by

Muhammad Rizky KaisupyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Control and Interfacing of Motors With Ni-Labview Using Ni-Myrio

Control and Interfacing of Motors With Ni-Labview Using Ni-Myrio

Uploaded by

Muhammad Rizky KaisupyCopyright:

Available Formats

IJIRST International Journal for Innovative Research in Science & Technology| Volume 1 | Issue 8 | January 2015

ISSN (online): 2349-6010

Control and Interfacing of Motors With NILabView Using NI-MYRIO

K. Mohamed Hussain

UG Student

Department of Instrumentation and Control Engineering

Saranathan College of Engineering Trichy

R. Allwyn Rajendran Zepherin

UG Student

Department of Instrumentation and Control Engineering

Saranathan College of Engineering Trichy

M. Shantha Kumar

UG Student

Department of Instrumentation and Control Engineering

Saranathan College of Engineering Trichy

S. Abirami

Assistant Professor

Department of Instrumentation and Control Engineering

Saranathan College of Engineering Trichy

Abstract

Motors are the necessary machines in the production of Robots and many Automation and Electrical, Electronic and Mechanical

devices. This article deals with motors which are to be interfaced with the help of NI-MYRIO through NI-LabVIEW software.

NI-MYRIO has inbuilt Analog and Digital signal Ports which provide necessary voltage and current to drive or to give excitation

to a medium/high voltage dc or ac circuit. Relay Circuits require 5V signal from NI-MYRIO to provide 12V input for the DC

Motor. When NI-MYRIO is interfaced with motors and PC installed with LabVIEW 2014, then with the help of PC or a

Smartphone one can control the movements of the DC Motor

Keywords: NI-LabVIEW, NI-MYRIO, DC Motors, PC, Relay Circuit.

_______________________________________________________________________________________________________

I. INTRODUCTION

DC motor depends on the fact that like magnet poles deters and unlike magnetic poles attracts each other. A coil of wire with a

current flowing through it produces an electromagnetic field aligned with the core of the coil. By switching the current on or off

in a coil its magnetic field can be switched on or off or by switching the direction of the current in the coil the direction of the

produced magnetic field can be switched 180[1]. A simple DC motor naturally has a fixed set of magnets in the stator and

an armature by a successions of two or more windings of wire enfolded in shielded heap slots around iron pole pieces (called

stack teeth) with the ends of the wires ending on a commutator.

The armature comprises the mounting bearings that retain it in the middle of the motor and the power shaft of the motor and

the commutator networks. The winding in the armature remains to loop all the way round the armature and practices either single

or parallel electrodes (wires), and can loop numerous intervals around the stack teeth. The whole sum of current directed to the

coil, the coil's magnitude and what it's enfolded around command the power of the electromagnetic field produced. The

arrangement of whirling a specific coil on or off commands what track the active electromagnetic fields are pointed. By

switching on and off coils in order a turning magnetic field can be produced[2]. These rotating magnetic fields interrelate with the

magnetic fields of the magnets (permanent or electromagnets) in the fixed part of the motor (stator) to generate a force on the

armature which causes it to rotate. In certain DC motor schemes the stator fields use electromagnets to create their magnetic

fields which permit more control over the motor [3]. At high power intensities, DC motors are almost always ventilated via forced

air.

The quick implementation of the Personal Computers in the past 2 decades catalysed a emergence in instrumentation for

experiment, measurement, and robotics. One of the foremost improvements ensuing from the omnipresence of the PC is the

notion of virtual instrumentation, which deals numerous profits to engineers and experts who necessitate improved throughput,

precision, and performance. A virtual instrument contains of an industry-standard PC or computer terminal furnished with

dominant application software, economical hardware such as plug-in panels, and driver software, which composed accomplish

the tasks of conventional instruments.

Virtual instruments symbolize an ultimate modification from conventional hardware-centred instrumentation arrangements to

software-centred systems that use the computing power, efficiency, presentation, and connectivity competencies of widespread

desktop computers and workspaces[4]. Though the PC and assimilated circuit technology have practiced noteworthy

developments in the past 20 years, it is software that actually delivers the influence to construct on this influential hardware basis

to build virtual instruments, resulting enhanced methods to update and considerably lessen cost. Through virtual instruments,

engineers and experts construct measurement and automation structures that ensemble their requirements precisely (userdefined) as a substitute of being restricted by traditional fixed-function instruments (vendor-defined).

All rights reserved by www.ijirst.org

146

Control and Interfacing of Motors With NI-LabView Using NI-MYRIO

(IJIRST/ Volume 1 / Issue 8 / 025)

LabVIEW (short for Laboratory Virtual Instrument Engineering Workbench) is a system-design platform and progress

atmosphere for a visual programming language from National Instruments[5]. The graphical language is termed "G". Initially

created aimed at the Apple Macintosh in 1986, LabVIEW is universally employed for data acquisition, instrument control,

and industrial automation on a multiplicity of platforms comprising Microsoft Windows, numerous versions of UNIX, Linux,

and Mac OS X. The newest version of LabVIEW is LabVIEW 2014, released in August 2014.

Todays engineering students are being asked to not only master the fundamental elements of engineering, but to develop an

appreciation for a complete system. To ensure that they graduate prepared to engage in modern engineering, students need to be

immersed in real-world system design well in advance of graduation using the same technology they will see in their careers.

NI myRIO is the innovatory instrument that resides the influence of the LabVIEW RIO structure, a universally accepted,

industry recognized hardware/software scheme method, in the hands of learners. With a steady method to culture progressive

notions in embedded and FPGA programming, learners can create learning this technology at a level suitable for them while

educationalists increase the buoyancy that this instrument can convoy learners from preliminary to progressive developments [5].

NI myRIO provides the powerful hardware and software technology required for learners to comprehensive significant projects

in a single term while being guaranteed that they are learning on an instrument that formulates them for their careers as skilled

engineers.

II. HARDWARE TOOLS

The control and interfacing of motor with NI-MYRIO using NI-LabVIEW requires the following components. They are ordered

in terms of their specifications and usage as follows:

(1) Personal Computer with NI-LabVIEW installed.

(2) DC Motor.

(3) NI-MYRIO.

(4) Relay Circuit.

A. Personal Computer with NI-LabVIEW:

One can be able to control the motor using either a desktop or laptop computers with NI-LabVIEW software installed in it. In

recent times National Instruments introduced latest version of LabVIEW software i.e. NI-LabVIEW 2014. The latest upgraded

version has more additional features and advanced technologies such as NI-MYRIO driver software, vision and motion and

robotics toolkit etc.

Fig. 1: Personal Computer Installed With LabVIEW

B. DC MOTOR:

In this experiment we are using 12 volt DC motor to provide free motion with load. Motor converts the Electrical energy into

Mechanical energy by the principle of electromagnetism. When the Conductor is placed in the Electric field, and when excitation

is given to the Magnets, due to attraction, the Conductor rotates thus produces a mechanical force.

Fig. 2: 12V DC MOTOR

C. NI-MYRIO:

The word RIO stands for Reconfigurable Input Output. NI-MYRIO is one of the best products of National Instruments which

can able to do the process of Image Processing programs, Hardware interfacing programs such as motors, gears and levers etc.

NI-MYRIO has Xilinx which is thereby a combination of Dual Core ARM Cortex A-9 Processor and FPGA embedded on it. It

has Integrated WIFI, Analog I/O ports and Digital I/O ports and many others as described in the following figure.

All rights reserved by www.ijirst.org

147

Control and Interfacing of Motors With NI-LabView Using NI-MYRIO

(IJIRST/ Volume 1 / Issue 8 / 025)

Fig. 3: NI-MYRIO

D. Relay Circuit:

Since 15V ports of NI-MYRIO are less (i.e. +/-15port only available), it is not enough to drive 12V DC Motor pairs. Hence a

12V Relay Circuits with 5V excitation pulse are used to drive the Motors (for example 4 Motors of a Toy Car). NI-MYRIO has 4

Ports to produce 5V DC Supply to Relay Circuits which can be used to provide 12V from a Battery to a DC Motor. The Relay

Circuit with 8 Relays is shown below.

Fig. 4: An 8-Relay Circuit

III. LABVIEW PROGRAMMING FOR MOTOR INTERFACING

The main three components of VI in NI-LabVIEW are Front Panel, Block Diagram and Connector Panel. The Block Diagram

has many Functional Blocks which are helpful for the development of program whereas a Front Panel is the one which is used

for Displaying and controlling functions. The Connector Panel is used for connecting a VI with other VIs and SubVIs.

A. Block Diagram:

As discussed earlier, the Block Diagram consists of several functional blocks which are used for programming. The Block

Diagram is the one which connects the controls, and indicators with the series of functions such as Structures, Clusters, Arrays,

Vision Assistant, Data Acquisition and much more. The program for the control of DC motor consists of the following Block

Diagram.

All rights reserved by www.ijirst.org

148

Control and Interfacing of Motors With NI-LabView Using NI-MYRIO

(IJIRST/ Volume 1 / Issue 8 / 025)

Fig. 5: Block Diagram - True Case

Fig. 6: Block Diagram - False Case

The Block Diagram consists of Boolean inputs namely Motor 1, Motor 2 which represents ON-OFF inputs to the motor. The

case structure is used to select between the True and False cases. In true case 5 volts is given as a constant to the NI-MYRIO

Analog output port as shown in the true case Block Diagram (Figure 5). Similarly, In false case 0 volt is given as a constant to

the NI-MYRIO Analog output port as shown in the true case Block Diagram (Figure 6).

When Boolean Motor 1/Motor 2 switch is ON, NI-MYRIO generates 5 volts to the relay circuit in which Motor 1/Motor 2 is

connected thereby switching ON the relay circuit. Similarly, When Boolean Motor 1/Motor 2 switch is OFF, NI-MYRIO

generates 0 volt to the relay circuit in which Motor 1/Motor 2 is connected thereby switching OFF the relay circuit.

B. Front Panel:

The front panel is used for the purpose of controlling and displaying. In this motor control, the Front panel consists of two

Boolean controls for ON/OFF of the motor. These Boolean controls are given to the corresponding case structure in order to

ON/OFF the motor.

Fig. 6: Front Panel of Motor Interfacing

IV. NI-MYRIO IMPLEMENTATION

The 5V supply to the Relay circuit can be given with the help of NI-MYRIO using NI-LabVIEW program. Since these are

Virtual Instruments, they are very easy to program and deploy. To do this, basic configuration should be known and that will be

given by the following diagram once the NI-MYRIO is launched and configured.

All rights reserved by www.ijirst.org

149

Control and Interfacing of Motors With NI-LabView Using NI-MYRIO

(IJIRST/ Volume 1 / Issue 8 / 025)

Fig. 7: NI-MYRIO Connection Code and Diagram

The channels which are mentioned in the figure are used for the necessary supply of 5V to the Relay Circuit. This is based on

the program that is done on the Block Diagram side of VI for the corresponding channels (LEFT and RIGHT) as shown in Figure

6. Proper grounding at the AGND terminal should be given for the safe use of Instruments and Motors.

V. RESULT AND CONCLUSION

The NI-MYRIO controlled Motors running capability will be based on the condition that when Boolean Controls Motor1/Motor2

is turned ON/OFF there is a Delay of 1second for the response of change in controls in motor and the Delay is also for the

Turning ON and OFF of the entire Motor System. This minimum delay is always present due to transfer of control pulse from

PC to Motor via NI-MYRIO and Relay circuit since these are controlled virtually through the Computer.

NI-MYRIO has inbuilt Analog and Digital signal Ports which provide necessary voltage and current to drive or to give

excitation to a medium/high voltage dc or ac circuit. Relay Circuits require 5V signal from NI-MYRIO to provide 12V input for

the DC Motor. Hence, NI-MYRIO is interfaced with motors and PC installed with LabVIEW 2014, then with the help of PC or a

Smartphone we thus controlled the movements of the DC Motor [FORWARD, LEFT and RIGHT].

REFERENCES

[1]. Herman, Stephen. Industrial Motor Control. 6th ed. Delmar, Cen gage Learning, 2010. Page 251.

[2]. Ohio Electric Motors. DC Series Motors: High Starting Torque but No Load Operation Ill-Advised. Ohio Electric Motors, 2011. Archived 20 July 2011

[3]. http://en.m.wikipedia.org/wiki/Direct_current_motor

[4]. http://www.ni.com/NI-Tutorial-4752-en.pdf.

[5]. HANS-PETTER HALVORSEN Introduction to LabVIEW page-1.

[6]. http://www.ni.com/white-paper/52093/en/myrio.

All rights reserved by www.ijirst.org

150

You might also like

- PLC Programming from Novice to Professional: Learn PLC Programming with Training VideosFrom EverandPLC Programming from Novice to Professional: Learn PLC Programming with Training VideosRating: 5 out of 5 stars5/5 (1)

- Inplant Training ReportDocument30 pagesInplant Training ReportTirumala Venkatesh100% (1)

- RT - Ruane and T P O'Neill PDFDocument85 pagesRT - Ruane and T P O'Neill PDFbaskaran ayyapparajNo ratings yet

- Dell ServerDocument3 pagesDell ServerSenthil Vel KNo ratings yet

- Control of DC Motor in Labview by Using Ni-MyrioDocument4 pagesControl of DC Motor in Labview by Using Ni-MyrioIJSTENo ratings yet

- Prototype CNC Machine DesignDocument7 pagesPrototype CNC Machine DesignSuprapto ToNo ratings yet

- Design and Implementation of An Architecture For A Remotely Operated PLC Laboratory Using LabviewDocument8 pagesDesign and Implementation of An Architecture For A Remotely Operated PLC Laboratory Using LabviewTJPRC PublicationsNo ratings yet

- Pioneering Method To Analyse Depression in Human Being Using Audio-Video ParametersDocument6 pagesPioneering Method To Analyse Depression in Human Being Using Audio-Video ParametersEditor IJRITCCNo ratings yet

- Industrial Automation Using Modern Controls MonitoDocument6 pagesIndustrial Automation Using Modern Controls MonitoSucii AnggraiiniiNo ratings yet

- Ijert Ijert: Control of AC Motor Using LabviewDocument4 pagesIjert Ijert: Control of AC Motor Using LabviewCatalyn AlexandruNo ratings yet

- Ijert Ijert: Control of AC Motor Using LabviewDocument4 pagesIjert Ijert: Control of AC Motor Using LabviewahmetNo ratings yet

- PLC SCADA Training ReportDocument37 pagesPLC SCADA Training ReportAarif HussainNo ratings yet

- PLC, Scada TrainingDocument47 pagesPLC, Scada TrainingSandeep Kumar100% (1)

- Grid Tied Multilevel Inverter With Power Quality Monitoring Using Myrio and LabviewDocument5 pagesGrid Tied Multilevel Inverter With Power Quality Monitoring Using Myrio and LabviewMuhammad Sohaib ShahidNo ratings yet

- Design of Smart Car Using LabviewDocument6 pagesDesign of Smart Car Using LabviewSrinivas VeeruNo ratings yet

- Embedded PLC Implementation Using ARMDocument5 pagesEmbedded PLC Implementation Using ARMsnehagoyankaNo ratings yet

- Monitoring and Controlling Electricity ConsumptionDocument11 pagesMonitoring and Controlling Electricity ConsumptionDiego BustosNo ratings yet

- 00 - ArtículoDocument7 pages00 - Artículoheidy pintoNo ratings yet

- "Vehicle Monitering System Using Labview": National Institute of Technology Warangal-560004Document20 pages"Vehicle Monitering System Using Labview": National Institute of Technology Warangal-560004ambica thripuralaNo ratings yet

- Data Acquisition in LabVIEWDocument14 pagesData Acquisition in LabVIEWAASHIR AHMAD JASKANINo ratings yet

- Project Report: PLC & ScadaDocument44 pagesProject Report: PLC & ScadaAhmed SamiNo ratings yet

- Ethernet Control AC Motor Via PLC Using Labview: Nader N. Barsoum, Pin Rui ChinDocument10 pagesEthernet Control AC Motor Via PLC Using Labview: Nader N. Barsoum, Pin Rui ChinJihun WooNo ratings yet

- 0383.team ψ senior designDocument13 pages0383.team ψ senior designaku bulletNo ratings yet

- Fault Diagnostician of Induction Machine Using LabviewDocument5 pagesFault Diagnostician of Induction Machine Using LabviewJimmy Arias (JimmyStron)No ratings yet

- Internship Report HamzaDocument38 pagesInternship Report HamzaQasim MuhammadNo ratings yet

- Main Report2Document59 pagesMain Report2Diwakar DiwakarNo ratings yet

- Project Training ReportDocument17 pagesProject Training ReportrutvikNo ratings yet

- Voice Based Wireless Industrial Automation With Enhanced Feedback SystemDocument5 pagesVoice Based Wireless Industrial Automation With Enhanced Feedback SystemRekhaPadmanabhanNo ratings yet

- Control Systems Lab Hamza 4Document29 pagesControl Systems Lab Hamza 4Muhammad Hamza FarooqNo ratings yet

- P5. - Remote Monitoring and Control of VFD Fed 3-Phase Induction Motor With PLC and labVIEW SoftwareDocument7 pagesP5. - Remote Monitoring and Control of VFD Fed 3-Phase Induction Motor With PLC and labVIEW SoftwareMarco ParedesNo ratings yet

- PLC & SCADA Training ReportDocument44 pagesPLC & SCADA Training Reportneeraj meena100% (2)

- Modelling and Analysis of Induction Motor Using LabviewDocument11 pagesModelling and Analysis of Induction Motor Using LabviewNituNo ratings yet

- Training Report: Bachelor of TechnologyDocument46 pagesTraining Report: Bachelor of TechnologyHelloprojectNo ratings yet

- Automated Guided Vehicle (AGV) Full TextDocument62 pagesAutomated Guided Vehicle (AGV) Full Textazriffaris100% (2)

- Low Cost Data Acquisition Setup For Electrical Machines LaboratoryDocument6 pagesLow Cost Data Acquisition Setup For Electrical Machines LaboratorySarat MishraNo ratings yet

- Es Project Report 06Document23 pagesEs Project Report 06munizahqNo ratings yet

- Design of High Fidelity Building Energy Monitoring SystemDocument58 pagesDesign of High Fidelity Building Energy Monitoring SystemMohammed selimNo ratings yet

- Industrial WLANsDocument29 pagesIndustrial WLANsmichael_mccabe_18No ratings yet

- NI CaseStudy Cs 14833Document4 pagesNI CaseStudy Cs 14833XundaBugrillNo ratings yet

- Development of Control Algorithms in Matlab/Simulink: SciencedirectDocument5 pagesDevelopment of Control Algorithms in Matlab/Simulink: SciencedirectJunn Ree MontillaNo ratings yet

- Ijert Ijert: Control of AC Motor Using LabviewDocument4 pagesIjert Ijert: Control of AC Motor Using LabviewMihai BogdanNo ratings yet

- Implementing Palletization Application of 4-Axis Igus Robot ManipulatorDocument20 pagesImplementing Palletization Application of 4-Axis Igus Robot ManipulatorKV SAI KIRANNo ratings yet

- NI CaseStudy Cs 14833Document5 pagesNI CaseStudy Cs 14833Eduardo Barredo HernandezNo ratings yet

- Spy Robot Wireless Video Surveillance Using ArduinoDocument5 pagesSpy Robot Wireless Video Surveillance Using ArduinoEyob SintNo ratings yet

- Embedded Design Training ReportDocument52 pagesEmbedded Design Training ReportAshish YadavNo ratings yet

- Project Report On Robotic ArmDocument28 pagesProject Report On Robotic Armpatel ketan84% (25)

- Control Systems Lab4Document29 pagesControl Systems Lab4Muhammad Hamza FarooqNo ratings yet

- Digital Distance Relay Modeling and Testing Using LabVIEW and MATLAB SimulinkDocument55 pagesDigital Distance Relay Modeling and Testing Using LabVIEW and MATLAB SimulinkK Vijay Bhaskar ReddyNo ratings yet

- Touch Screen Based Industrial Crane ControllingDocument3 pagesTouch Screen Based Industrial Crane ControllingijsretNo ratings yet

- Monitoring and Controlling of BLDC Motor Using IOTDocument5 pagesMonitoring and Controlling of BLDC Motor Using IOTVIVA-TECH IJRI100% (1)

- Gujarat Technological University: Ac Motor ControllerDocument17 pagesGujarat Technological University: Ac Motor ControllerEngineers worldNo ratings yet

- Wireless Control of ImDocument5 pagesWireless Control of ImdineshkumarNo ratings yet

- DC Motor Speed Controller Design Using Pulse WidthDocument12 pagesDC Motor Speed Controller Design Using Pulse WidthHerman BachtiarNo ratings yet

- Internship 3Document38 pagesInternship 3S K B COMPUTERSNo ratings yet

- VC 3Document28 pagesVC 3Reethika SNo ratings yet

- Industrial Fault Indication System Using Avr MicrocontrollerDocument15 pagesIndustrial Fault Indication System Using Avr Microcontrollersri_palakolanuNo ratings yet

- MarintronicsDocument7 pagesMarintronicsNazmus SakibNo ratings yet

- PLC Based Solar Panel With Tilting Arrangement: April 2016Document9 pagesPLC Based Solar Panel With Tilting Arrangement: April 2016Paul TodericNo ratings yet

- Seth Jai Parkash Mukand Lal Institute of Engg. and Technology (Jmit) Radaur YAMUNA NAGAR (2011-2015)Document46 pagesSeth Jai Parkash Mukand Lal Institute of Engg. and Technology (Jmit) Radaur YAMUNA NAGAR (2011-2015)dinesh66jattNo ratings yet

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsFrom EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsNo ratings yet

- PowerFactory Applications for Power System AnalysisFrom EverandPowerFactory Applications for Power System AnalysisFrancisco M. Gonzalez-LongattNo ratings yet

- SBG (Nilai), German, Oil Distribution TransformerDocument12 pagesSBG (Nilai), German, Oil Distribution TransformerpeakfortuneNo ratings yet

- 8 Channel Current To Modbus Rtu Dat10017 IDocument3 pages8 Channel Current To Modbus Rtu Dat10017 IVishnu PatidarNo ratings yet

- Yardworks ManualDocument64 pagesYardworks ManualghobaNo ratings yet

- Efficient Performance Optimization of SOA-MZI DevicesDocument5 pagesEfficient Performance Optimization of SOA-MZI DevicesIvan Cuadros ChavezNo ratings yet

- TR 220 Operational ManualDocument76 pagesTR 220 Operational ManualSabby_SXBNo ratings yet

- Alternators: Quality With Value GuaranteedDocument3 pagesAlternators: Quality With Value GuaranteedinformationbankNo ratings yet

- ECE Sem 5 SyllabusDocument2 pagesECE Sem 5 SyllabusDaksh SharmaNo ratings yet

- EQ Magazine April 2010Document70 pagesEQ Magazine April 2010heavensetmNo ratings yet

- C To VHDL Converter in A Codesign Environment: June 1994Document11 pagesC To VHDL Converter in A Codesign Environment: June 1994Vivek SinghNo ratings yet

- Motor Starter Components and StandardsDocument20 pagesMotor Starter Components and StandardsJellyn BaseNo ratings yet

- A Project Report On Mini Inverter 12V To 220V: Submitted byDocument31 pagesA Project Report On Mini Inverter 12V To 220V: Submitted byCuriosity FeedsNo ratings yet

- Jecklin DiskDocument2 pagesJecklin DiskgilgoosNo ratings yet

- C-Data FTTH Epon Onu Fd10C-DATA FTTH EPON ONU FD101H1h - 1fe - Specification v3Document6 pagesC-Data FTTH Epon Onu Fd10C-DATA FTTH EPON ONU FD101H1h - 1fe - Specification v3tembelizatNo ratings yet

- Analog Electronics: Op-Amp Circuits and Active FiltersDocument43 pagesAnalog Electronics: Op-Amp Circuits and Active FiltersSin SideNo ratings yet

- Ic Data1Document3 pagesIc Data1Ssr ShaNo ratings yet

- Silicon PNP Power Transistors: Inchange Semiconductor Product SpecificationDocument4 pagesSilicon PNP Power Transistors: Inchange Semiconductor Product SpecificationRuben MapaloNo ratings yet

- A 1.2-V Dynamic Bias Latch-Type Comparator in 65-Nm CMOS With 0.4-MV Input NoiseDocument11 pagesA 1.2-V Dynamic Bias Latch-Type Comparator in 65-Nm CMOS With 0.4-MV Input NoiseburakgonenNo ratings yet

- YLR-U Series DatasheetDocument2 pagesYLR-U Series DatasheetAliali MohamedNo ratings yet

- TSK Klyuch Mts 102 3a 250v 6a 125vac SPDT On On 0Document8 pagesTSK Klyuch Mts 102 3a 250v 6a 125vac SPDT On On 0Matilda BenteforNo ratings yet

- NO QTY Nama Barang Merk Price, IDR Peralatan Uji Silang Metode Gel TestDocument6 pagesNO QTY Nama Barang Merk Price, IDR Peralatan Uji Silang Metode Gel TestKalbaridahNo ratings yet

- Living Ring-Opening Metathesis PolymerizationDocument29 pagesLiving Ring-Opening Metathesis PolymerizationTiago Breve da SilvaNo ratings yet

- Speed Control of DC Motor Using Ultrasonic SensorDocument12 pagesSpeed Control of DC Motor Using Ultrasonic SensorKADUSKAR PALASHNo ratings yet

- Fuji PID PXR459 Operation ManualDocument83 pagesFuji PID PXR459 Operation ManualmelferNo ratings yet

- Datasheets DS TQ401 EA401 IQS450-EnDocument12 pagesDatasheets DS TQ401 EA401 IQS450-EnEDBNo ratings yet

- αξεσουαρ SKODA CITIGO SPORTDocument7 pagesαξεσουαρ SKODA CITIGO SPORTSkoda Club PeloponnhsouNo ratings yet

- A History of Z MeasurementDocument63 pagesA History of Z MeasurementactecNo ratings yet

- 12124332Document3 pages12124332Cukaj AgostinNo ratings yet

- NKC 2012300-12Document1 pageNKC 2012300-12Nguyễn Quang HuyNo ratings yet