Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

6 views2.2 Operational Cost: Executive Summary

2.2 Operational Cost: Executive Summary

Uploaded by

Fauzan NazifOperational cost includes raw material cost, packaging cost, utilities cost, salary cost, maintenance cost, and patent cost. Raw material cost depends on supplier location and quantity ordered, while utilities include electricity, water, and telecommunications. Salary cost is based on regional minimum wage and job position, and maintenance cost supports equipment and facilities. Patents must be obtained for new products and renewed annually to prevent plagiarism.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- Managerial Accounting Hilton 9th EditionDocument34 pagesManagerial Accounting Hilton 9th EditionCheongMin50% (2)

- Cost Accounting and Control by Sir ChuaDocument92 pagesCost Accounting and Control by Sir ChuaAnalyn Lafradez100% (3)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- ACT 600 Advanced Managerial Accounting: Accumulating and Assigning Costs To ProductsDocument43 pagesACT 600 Advanced Managerial Accounting: Accumulating and Assigning Costs To ProductsAli H. AyoubNo ratings yet

- Cost Accounting CHPTR 2Document6 pagesCost Accounting CHPTR 2Keisha Lynch75% (4)

- Hilton Chapter 2 Assigned Homework Exercises 10thDocument9 pagesHilton Chapter 2 Assigned Homework Exercises 10thWynona Gaile PagdonsolanNo ratings yet

- Chap002 Basic Cost ManagementDocument36 pagesChap002 Basic Cost ManagementAneukphon Ryan Pramanda IsniNo ratings yet

- Economic ReportDocument9 pagesEconomic ReportYeeXuan TenNo ratings yet

- Module 5 PROCESS COSTINGDocument19 pagesModule 5 PROCESS COSTINGMark Laurence SanchezNo ratings yet

- Managerial Accounting 2nd Edition Hilton Solutions ManualDocument10 pagesManagerial Accounting 2nd Edition Hilton Solutions ManualMaryBalljswt100% (62)

- Estimating: Assoc. Prof. Seti Mariam AyopDocument17 pagesEstimating: Assoc. Prof. Seti Mariam Ayopan_taniaNo ratings yet

- Managerial Accounting 2nd Edition Hilton Solutions ManualDocument35 pagesManagerial Accounting 2nd Edition Hilton Solutions Manualiramitchellwnumr100% (30)

- Ppe Unit-VDocument42 pagesPpe Unit-VSiriganti RakeshNo ratings yet

- More Practices For CH1Document2 pagesMore Practices For CH1lalaNo ratings yet

- Managerial Accounting Creating Value in A Dynamic Business Environment 11th Edition Hilton Solutions ManualDocument36 pagesManagerial Accounting Creating Value in A Dynamic Business Environment 11th Edition Hilton Solutions Manualrenewerelamping1psm100% (26)

- Dwnload Full Managerial Accounting Creating Value in A Dynamic Business Environment 11th Edition Hilton Solutions Manual PDFDocument36 pagesDwnload Full Managerial Accounting Creating Value in A Dynamic Business Environment 11th Edition Hilton Solutions Manual PDFjohncastroebx0100% (11)

- Manufacturing CostDocument20 pagesManufacturing Costchristian ReyesNo ratings yet

- Process CostingDocument11 pagesProcess CostingsunilNo ratings yet

- Production CostDocument80 pagesProduction CostRamez AlaliNo ratings yet

- Basic Cost Management Concepts: Mcgraw-Hill/IrwinDocument52 pagesBasic Cost Management Concepts: Mcgraw-Hill/IrwinDaMin ZhouNo ratings yet

- Economics of Plant Design (Report)Document10 pagesEconomics of Plant Design (Report)Hamizah Mieza100% (1)

- Estimation and CostingDocument14 pagesEstimation and CostingAvik Poudel100% (2)

- Dwnload Full Managerial Accounting 2nd Edition Hilton Solutions Manual PDFDocument35 pagesDwnload Full Managerial Accounting 2nd Edition Hilton Solutions Manual PDFwoollyprytheeuctw100% (15)

- Acctba3 E2-1, E2-2, E2-3Document13 pagesAcctba3 E2-1, E2-2, E2-3DennyseOrlido100% (2)

- Unit 5Document43 pagesUnit 5Kama RajNo ratings yet

- Dwnload Full Managerial Accounting Creating Value in A Dynamic Business Environment Canadian Edition Canadian 2nd Edition Hilton Solutions Manual PDFDocument35 pagesDwnload Full Managerial Accounting Creating Value in A Dynamic Business Environment Canadian Edition Canadian 2nd Edition Hilton Solutions Manual PDFjohncastroebx0100% (11)

- Costacctg13 SM ch02Document26 pagesCostacctg13 SM ch02Yenny TorroNo ratings yet

- CH 2 Solutions Solution S For Chapter 2Document20 pagesCH 2 Solutions Solution S For Chapter 2Getachew MuluNo ratings yet

- Process Costing Module 9 MergedDocument50 pagesProcess Costing Module 9 MergedJoy DipasupilNo ratings yet

- Costing and Project EvaluationDocument37 pagesCosting and Project Evaluationdani2611No ratings yet

- Cost Concepts and Behaviors-EEP-lec5Document25 pagesCost Concepts and Behaviors-EEP-lec5Ramendra KumarNo ratings yet

- 500va Inverter: Small Industries Service Institute, AgartalaDocument10 pages500va Inverter: Small Industries Service Institute, AgartalaAvishek DuttaNo ratings yet

- Chapter 2 Job Order CostingDocument72 pagesChapter 2 Job Order CostingLORENZE VIRNUEL UCAB IBA�EZ0% (1)

- Solutions Manual For Managerial Accounting Creating Value in A Dynamic Business Environment Canadian Edition Canadian 2nd Edition by HiltonDocument33 pagesSolutions Manual For Managerial Accounting Creating Value in A Dynamic Business Environment Canadian Edition Canadian 2nd Edition by HiltonssabasalimNo ratings yet

- Managerial Accounting Creating Value in A Dynamic Business Environment Canadian Edition Canadian 2nd Edition Hilton Solutions ManualDocument26 pagesManagerial Accounting Creating Value in A Dynamic Business Environment Canadian Edition Canadian 2nd Edition Hilton Solutions ManualRobertPerkinsqmjk100% (63)

- Full Download Managerial Accounting Creating Value in A Dynamic Business Environment Canadian Edition Canadian 2nd Edition Hilton Solutions ManualDocument36 pagesFull Download Managerial Accounting Creating Value in A Dynamic Business Environment Canadian Edition Canadian 2nd Edition Hilton Solutions Manuallinderleafeulah100% (37)

- Solution Manual For Managerial Accounting Creating Value in A Dynamic Business Environment 11th Edition Hilton Platt 125956956X 9781259569562Document36 pagesSolution Manual For Managerial Accounting Creating Value in A Dynamic Business Environment 11th Edition Hilton Platt 125956956X 9781259569562richardwilsonmgftzpsjxq100% (28)

- Lecture 1, Identifying Costs (Sol)Document3 pagesLecture 1, Identifying Costs (Sol)MO'MEN ROSHDYNo ratings yet

- 19728ipcc CA Vol1 Cp9Document22 pages19728ipcc CA Vol1 Cp9manoNo ratings yet

- Estimation of Total Operating CostDocument21 pagesEstimation of Total Operating CostteklayNo ratings yet

- Topic 6 - Process Costing ADocument5 pagesTopic 6 - Process Costing AFaizah MKNo ratings yet

- Relevant Cost Cases and QuestionsDocument8 pagesRelevant Cost Cases and Questionskert1234No ratings yet

- Company Profile Current Cost Sheet Analysis Suggestions/improvements On Current Costing Process Based Costing Approach Analysis of Opportunity CostDocument13 pagesCompany Profile Current Cost Sheet Analysis Suggestions/improvements On Current Costing Process Based Costing Approach Analysis of Opportunity Costyash sarohaNo ratings yet

- CostingDocument5 pagesCostingabhi24052008No ratings yet

- Voltage StabilizerDocument11 pagesVoltage StabilizerShreekant KashyapNo ratings yet

- Cost Concepts and TerminologiesDocument13 pagesCost Concepts and TerminologiesAprile AnonuevoNo ratings yet

- Introduction To Built Up RatesDocument20 pagesIntroduction To Built Up Ratessyamly 9802100% (1)

- AMC Lecture 2Document40 pagesAMC Lecture 2James HowellNo ratings yet

- Chap 2 Basic Cost Management Concepts and Accounting For Mass Customization OperationsDocument15 pagesChap 2 Basic Cost Management Concepts and Accounting For Mass Customization OperationsMarklorenz SumpayNo ratings yet

- TD3 - Quotation (EN)Document3 pagesTD3 - Quotation (EN)Hieu NguyenNo ratings yet

- Tute 3 Homework - Cost Terms, Concepts and ClassificationsDocument3 pagesTute 3 Homework - Cost Terms, Concepts and ClassificationsKyleNo ratings yet

- Act 441 Process CostingDocument9 pagesAct 441 Process CostingShahriar AkashNo ratings yet

- CostDocument11 pagesCostBD EntertainmentNo ratings yet

- Project Process Costing Mcom 1 1Document39 pagesProject Process Costing Mcom 1 1kalpesh1956No ratings yet

- Estimation and CostingDocument22 pagesEstimation and CostingAvinash KowtaNo ratings yet

- Managerial Accounting and Cost Concepts This Chapter Explains That in Managerial Accounting The Term Cost Is Used in Many Different Ways. TheDocument36 pagesManagerial Accounting and Cost Concepts This Chapter Explains That in Managerial Accounting The Term Cost Is Used in Many Different Ways. TheSohaib ArifNo ratings yet

- Managerial Accounting - Ch.1Document2 pagesManagerial Accounting - Ch.1Ammar HussainNo ratings yet

- Absorption CostingDocument4 pagesAbsorption Costingghazi askariNo ratings yet

- Chapter No.02: Costs, Concepts, Uses and ClassificationsDocument20 pagesChapter No.02: Costs, Concepts, Uses and ClassificationsNaqibwafaNo ratings yet

2.2 Operational Cost: Executive Summary

2.2 Operational Cost: Executive Summary

Uploaded by

Fauzan Nazif0 ratings0% found this document useful (0 votes)

6 views1 pageOperational cost includes raw material cost, packaging cost, utilities cost, salary cost, maintenance cost, and patent cost. Raw material cost depends on supplier location and quantity ordered, while utilities include electricity, water, and telecommunications. Salary cost is based on regional minimum wage and job position, and maintenance cost supports equipment and facilities. Patents must be obtained for new products and renewed annually to prevent plagiarism.

Original Description:

exsum

Original Title

EXUM ASG4

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentOperational cost includes raw material cost, packaging cost, utilities cost, salary cost, maintenance cost, and patent cost. Raw material cost depends on supplier location and quantity ordered, while utilities include electricity, water, and telecommunications. Salary cost is based on regional minimum wage and job position, and maintenance cost supports equipment and facilities. Patents must be obtained for new products and renewed annually to prevent plagiarism.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

6 views1 page2.2 Operational Cost: Executive Summary

2.2 Operational Cost: Executive Summary

Uploaded by

Fauzan NazifOperational cost includes raw material cost, packaging cost, utilities cost, salary cost, maintenance cost, and patent cost. Raw material cost depends on supplier location and quantity ordered, while utilities include electricity, water, and telecommunications. Salary cost is based on regional minimum wage and job position, and maintenance cost supports equipment and facilities. Patents must be obtained for new products and renewed annually to prevent plagiarism.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 1

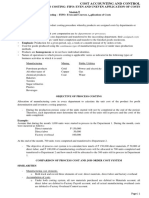

EXECUTIVE SUMMARY

2.2 Operational Cost

Operational cost is a cost that needed for a plant to be operated in every year. Operational

cost include, raw material cost, packaging cost, utilities cost, salary cost, maintenance cost, and

patent cost. Raw material cost depends on quantity of raw material we ordered and supplier

location. Every time we ordered raw materials there will be distribution cost of it. So, consider to

choose supplier thar located near our plant if possible. Packaging cost consider amount of

package needed every cycle of production, and also amount of secondary packaging (box)

needed for distribution purpose. Utilities is everything that supported production process like,

electricity, water, etc. Because we are UKM Industry our utilities was supplied by government

like PLN and PDAM that cost based on their rules. Salary cost must be consider the regional

minimum wage, in depok. Every single postion has different wage that depends on their job

desk. Maintenance cost needed to maintain our production process. Every cycle of production we

used same equipments, so those equipments need a maintenance to keep its performance. Patent

cost is needed to protect our product from plagiarism. Every new product must pay for patent

and must be renewed every year.

Conclusion

Operational cost consist of material cost, packaging cost, utilities cost, salary cost,

maintenance cost, and patent cost.

Supplier location and amount ordered determine distribution cost.

Utilites cost include electricity cost, water cost, and telecommunication cost.

Regional minimum wage and jobdesk determine the salary cost.

Maintenance cost allocated for building, and equipments.

Every new product need patent as a protection from plagiarism.

Patent cost must be renewed every year.

You might also like

- Managerial Accounting Hilton 9th EditionDocument34 pagesManagerial Accounting Hilton 9th EditionCheongMin50% (2)

- Cost Accounting and Control by Sir ChuaDocument92 pagesCost Accounting and Control by Sir ChuaAnalyn Lafradez100% (3)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- ACT 600 Advanced Managerial Accounting: Accumulating and Assigning Costs To ProductsDocument43 pagesACT 600 Advanced Managerial Accounting: Accumulating and Assigning Costs To ProductsAli H. AyoubNo ratings yet

- Cost Accounting CHPTR 2Document6 pagesCost Accounting CHPTR 2Keisha Lynch75% (4)

- Hilton Chapter 2 Assigned Homework Exercises 10thDocument9 pagesHilton Chapter 2 Assigned Homework Exercises 10thWynona Gaile PagdonsolanNo ratings yet

- Chap002 Basic Cost ManagementDocument36 pagesChap002 Basic Cost ManagementAneukphon Ryan Pramanda IsniNo ratings yet

- Economic ReportDocument9 pagesEconomic ReportYeeXuan TenNo ratings yet

- Module 5 PROCESS COSTINGDocument19 pagesModule 5 PROCESS COSTINGMark Laurence SanchezNo ratings yet

- Managerial Accounting 2nd Edition Hilton Solutions ManualDocument10 pagesManagerial Accounting 2nd Edition Hilton Solutions ManualMaryBalljswt100% (62)

- Estimating: Assoc. Prof. Seti Mariam AyopDocument17 pagesEstimating: Assoc. Prof. Seti Mariam Ayopan_taniaNo ratings yet

- Managerial Accounting 2nd Edition Hilton Solutions ManualDocument35 pagesManagerial Accounting 2nd Edition Hilton Solutions Manualiramitchellwnumr100% (30)

- Ppe Unit-VDocument42 pagesPpe Unit-VSiriganti RakeshNo ratings yet

- More Practices For CH1Document2 pagesMore Practices For CH1lalaNo ratings yet

- Managerial Accounting Creating Value in A Dynamic Business Environment 11th Edition Hilton Solutions ManualDocument36 pagesManagerial Accounting Creating Value in A Dynamic Business Environment 11th Edition Hilton Solutions Manualrenewerelamping1psm100% (26)

- Dwnload Full Managerial Accounting Creating Value in A Dynamic Business Environment 11th Edition Hilton Solutions Manual PDFDocument36 pagesDwnload Full Managerial Accounting Creating Value in A Dynamic Business Environment 11th Edition Hilton Solutions Manual PDFjohncastroebx0100% (11)

- Manufacturing CostDocument20 pagesManufacturing Costchristian ReyesNo ratings yet

- Process CostingDocument11 pagesProcess CostingsunilNo ratings yet

- Production CostDocument80 pagesProduction CostRamez AlaliNo ratings yet

- Basic Cost Management Concepts: Mcgraw-Hill/IrwinDocument52 pagesBasic Cost Management Concepts: Mcgraw-Hill/IrwinDaMin ZhouNo ratings yet

- Economics of Plant Design (Report)Document10 pagesEconomics of Plant Design (Report)Hamizah Mieza100% (1)

- Estimation and CostingDocument14 pagesEstimation and CostingAvik Poudel100% (2)

- Dwnload Full Managerial Accounting 2nd Edition Hilton Solutions Manual PDFDocument35 pagesDwnload Full Managerial Accounting 2nd Edition Hilton Solutions Manual PDFwoollyprytheeuctw100% (15)

- Acctba3 E2-1, E2-2, E2-3Document13 pagesAcctba3 E2-1, E2-2, E2-3DennyseOrlido100% (2)

- Unit 5Document43 pagesUnit 5Kama RajNo ratings yet

- Dwnload Full Managerial Accounting Creating Value in A Dynamic Business Environment Canadian Edition Canadian 2nd Edition Hilton Solutions Manual PDFDocument35 pagesDwnload Full Managerial Accounting Creating Value in A Dynamic Business Environment Canadian Edition Canadian 2nd Edition Hilton Solutions Manual PDFjohncastroebx0100% (11)

- Costacctg13 SM ch02Document26 pagesCostacctg13 SM ch02Yenny TorroNo ratings yet

- CH 2 Solutions Solution S For Chapter 2Document20 pagesCH 2 Solutions Solution S For Chapter 2Getachew MuluNo ratings yet

- Process Costing Module 9 MergedDocument50 pagesProcess Costing Module 9 MergedJoy DipasupilNo ratings yet

- Costing and Project EvaluationDocument37 pagesCosting and Project Evaluationdani2611No ratings yet

- Cost Concepts and Behaviors-EEP-lec5Document25 pagesCost Concepts and Behaviors-EEP-lec5Ramendra KumarNo ratings yet

- 500va Inverter: Small Industries Service Institute, AgartalaDocument10 pages500va Inverter: Small Industries Service Institute, AgartalaAvishek DuttaNo ratings yet

- Chapter 2 Job Order CostingDocument72 pagesChapter 2 Job Order CostingLORENZE VIRNUEL UCAB IBA�EZ0% (1)

- Solutions Manual For Managerial Accounting Creating Value in A Dynamic Business Environment Canadian Edition Canadian 2nd Edition by HiltonDocument33 pagesSolutions Manual For Managerial Accounting Creating Value in A Dynamic Business Environment Canadian Edition Canadian 2nd Edition by HiltonssabasalimNo ratings yet

- Managerial Accounting Creating Value in A Dynamic Business Environment Canadian Edition Canadian 2nd Edition Hilton Solutions ManualDocument26 pagesManagerial Accounting Creating Value in A Dynamic Business Environment Canadian Edition Canadian 2nd Edition Hilton Solutions ManualRobertPerkinsqmjk100% (63)

- Full Download Managerial Accounting Creating Value in A Dynamic Business Environment Canadian Edition Canadian 2nd Edition Hilton Solutions ManualDocument36 pagesFull Download Managerial Accounting Creating Value in A Dynamic Business Environment Canadian Edition Canadian 2nd Edition Hilton Solutions Manuallinderleafeulah100% (37)

- Solution Manual For Managerial Accounting Creating Value in A Dynamic Business Environment 11th Edition Hilton Platt 125956956X 9781259569562Document36 pagesSolution Manual For Managerial Accounting Creating Value in A Dynamic Business Environment 11th Edition Hilton Platt 125956956X 9781259569562richardwilsonmgftzpsjxq100% (28)

- Lecture 1, Identifying Costs (Sol)Document3 pagesLecture 1, Identifying Costs (Sol)MO'MEN ROSHDYNo ratings yet

- 19728ipcc CA Vol1 Cp9Document22 pages19728ipcc CA Vol1 Cp9manoNo ratings yet

- Estimation of Total Operating CostDocument21 pagesEstimation of Total Operating CostteklayNo ratings yet

- Topic 6 - Process Costing ADocument5 pagesTopic 6 - Process Costing AFaizah MKNo ratings yet

- Relevant Cost Cases and QuestionsDocument8 pagesRelevant Cost Cases and Questionskert1234No ratings yet

- Company Profile Current Cost Sheet Analysis Suggestions/improvements On Current Costing Process Based Costing Approach Analysis of Opportunity CostDocument13 pagesCompany Profile Current Cost Sheet Analysis Suggestions/improvements On Current Costing Process Based Costing Approach Analysis of Opportunity Costyash sarohaNo ratings yet

- CostingDocument5 pagesCostingabhi24052008No ratings yet

- Voltage StabilizerDocument11 pagesVoltage StabilizerShreekant KashyapNo ratings yet

- Cost Concepts and TerminologiesDocument13 pagesCost Concepts and TerminologiesAprile AnonuevoNo ratings yet

- Introduction To Built Up RatesDocument20 pagesIntroduction To Built Up Ratessyamly 9802100% (1)

- AMC Lecture 2Document40 pagesAMC Lecture 2James HowellNo ratings yet

- Chap 2 Basic Cost Management Concepts and Accounting For Mass Customization OperationsDocument15 pagesChap 2 Basic Cost Management Concepts and Accounting For Mass Customization OperationsMarklorenz SumpayNo ratings yet

- TD3 - Quotation (EN)Document3 pagesTD3 - Quotation (EN)Hieu NguyenNo ratings yet

- Tute 3 Homework - Cost Terms, Concepts and ClassificationsDocument3 pagesTute 3 Homework - Cost Terms, Concepts and ClassificationsKyleNo ratings yet

- Act 441 Process CostingDocument9 pagesAct 441 Process CostingShahriar AkashNo ratings yet

- CostDocument11 pagesCostBD EntertainmentNo ratings yet

- Project Process Costing Mcom 1 1Document39 pagesProject Process Costing Mcom 1 1kalpesh1956No ratings yet

- Estimation and CostingDocument22 pagesEstimation and CostingAvinash KowtaNo ratings yet

- Managerial Accounting and Cost Concepts This Chapter Explains That in Managerial Accounting The Term Cost Is Used in Many Different Ways. TheDocument36 pagesManagerial Accounting and Cost Concepts This Chapter Explains That in Managerial Accounting The Term Cost Is Used in Many Different Ways. TheSohaib ArifNo ratings yet

- Managerial Accounting - Ch.1Document2 pagesManagerial Accounting - Ch.1Ammar HussainNo ratings yet

- Absorption CostingDocument4 pagesAbsorption Costingghazi askariNo ratings yet

- Chapter No.02: Costs, Concepts, Uses and ClassificationsDocument20 pagesChapter No.02: Costs, Concepts, Uses and ClassificationsNaqibwafaNo ratings yet