Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

1K viewsAsme B1 20 3 PDF

Asme B1 20 3 PDF

Uploaded by

Chandhu Kurian ThampiCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Lead Sheet 716-X000Document1 pageLead Sheet 716-X000Chandhu Kurian ThampiNo ratings yet

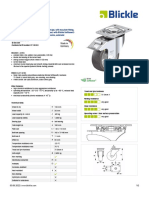

- Blickel Caster Antistatic-1Document2 pagesBlickel Caster Antistatic-1Chandhu Kurian ThampiNo ratings yet

- Structural Steel: BS EN 1090Document1 pageStructural Steel: BS EN 1090Chandhu Kurian ThampiNo ratings yet

- LH ALTH 101K 3 FI AS - 852511 - 0 - 0 - 0 - enDocument2 pagesLH ALTH 101K 3 FI AS - 852511 - 0 - 0 - 0 - enChandhu Kurian ThampiNo ratings yet

- City Pool - Policy InfoDocument6 pagesCity Pool - Policy InfoChandhu Kurian ThampiNo ratings yet

- DS DIN 11864-1 11850 Aseptic Unions PDFDocument7 pagesDS DIN 11864-1 11850 Aseptic Unions PDFChandhu Kurian ThampiNo ratings yet

- CME4002 Hydrogen Economy: Professor K M ThomasDocument31 pagesCME4002 Hydrogen Economy: Professor K M ThomasChandhu Kurian ThampiNo ratings yet

- Magnetic Characterisation O F Giant Magnetoresistance (GMR) EffectsDocument12 pagesMagnetic Characterisation O F Giant Magnetoresistance (GMR) EffectsChandhu Kurian ThampiNo ratings yet

Asme B1 20 3 PDF

Asme B1 20 3 PDF

Uploaded by

Chandhu Kurian Thampi0 ratings0% found this document useful (0 votes)

1K views30 pagesOriginal Title

108810650-ASME-B1-20-3.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

1K views30 pagesAsme B1 20 3 PDF

Asme B1 20 3 PDF

Uploaded by

Chandhu Kurian ThampiCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 30

INDD 81-20-3 76 MM 2595532 0077959 O20 mm

ANSI-B1.20.3

ADOPTION NOTICE

ANSI-B1.20.3, “Pipe Threads, Inch, Dryseal," was adopted on

October 3, 1994 for use by the Department of Defense (DoD).

Proposed Changes by DoD activities must be submitted to the

DoD Adopting Activity: Commanding Officer, Naval

Construction Battalion Center, Code 156, 1000 23rd Avenue,

Port Hueneme, CA 93043-4301. DoD activities may obtain

copies of this standard from the Standardization Document

Order Desk, 700 Robbins Avenue, Building 4D, Philadelphia,

PA 19111-5094. The private sector and other Government

agencies may purchase copies from the American National

Standards Institute, 11 West 42nd Street, New York, NY

10036.

Custodians: Adopting Activity

Army - GL Navy - YD-1

Navy ~ YD-1

Air Force - 11

DLA - IS

AREA THDS

DISTRIBUTION STATEMENT A. Approved for public release;

distribution is unlimited.

ASHE 81-20-3 7h MM 2595512 0011875 9 mm SE

LD

PRERPPROVED-B2~

AMERICAN NATIONAL STANDARD

Dryseal Pipe Threads

(Inch)

LL

ANSI B1.20.3 - 1976

(REVISION AND REDESIGNATION OF 82.2-1968)

SECRETARIAT

SOCIETY OF AUTOMOTIVE ENGINEERS

THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS

PUBLISHED BY

THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS

United Engineering Center 3.45 East 47th Street New York, N.Y. 10017

ASME BL.20-3 7b MM 2595522 OOL187b O mm

No part of this document may be reproduced in any form, in an electronic

retrieval system or otherwise, without the prior written permission of the

publisher.

Copyright® 1977 by

‘THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS

All Rights Reserved

Printed in US.A,

ASHE BL-20-3 7b MM 2595522 0011877 2 mm

FOREWORD

In 1913 a Committee on the Standardization of Pipe Threads was organized for the purpose of re-

editing and expanding the Briggs Standard. The American Gas Association and The American Society of

Mechanical Engineers served a8 joint sponsors. After six years of work, this committee completed the

revised standard for taper pipe thread which was published in the ASME “Transactions” of 1919, and

‘was approved as an American Standard by the then American Engineering Standards Committee (later

changed to American Standards Association) in December, 1919. It was the first standard to receive this

designation under the ASA procedure, and was lator republished in pamphlet form.

In the years which followed, the neod fora further revision of this American Standard became

as woll as the necessity of adding to it the recent dovelopments in pipe threading practice. Accordingly, the

Sectional Committee on the Standardization of Pipe Threads, B2, was organized in 1927 under the joint

sponsorship of the A.G.A. and the ASME.

During the following 15 years, several meetings were held loading to approval by the members of the

Sectional Committee, of the April 1941 draft. The revision was approved by the sponsors and ASA and

published as an American Standard in October 1942,

Shortly after publication of the 1942 standard, the Committee undertook preparation of a complete

revision. The text and tables were re-arranged and expanded to include Dryseal pipe threads, and an exten-

sive appendix was added to provide additional data on the application of pipe threads and to record in

abbreviated form the several special methods which were established for gaging some of the various applica-

tions of pipe threads

The resulting proposal was designated an American Standard on December 11, 1945. The section

covering Dryseal Pipe Threads in ASA B2.1-1945 was deleted and developed as a separate standard desig-

nated ASA B2.2-1960, Dryscal Pipe Threads. Another updating occurred with republication as USAS B2.2-

1968,

In 1973, Standards Committee B2 was absorbed by American National Standards Institute Standard

Committee Bi and reorganized as subcommittee 20. A complete rewrite of the B2.2-1968 document was

undertaken with the product thread data in separate documents from the gaging standards for Dryseal Pipe

‘threads. The system of renumbering, to include metric revisions, is as follows:

ANSIBI.203-1976 Inch Dryseal Pipe Threads

ANSIBI204-1976 Metric Dryseal Pipe Threads

ANSI BI-20.5-197 Gaging for Inch Dryseal Pipe Threads

ANSIBI.20.6-197 Gaging for Metric Dryseal Pipe Threads

Since the product thread documents are being published before completion of the new gaging stan-

dards, the gaging data in the B2.2-1968 Standard should be used until superseded by publication of the

new B1.20.5 and B1.20.6 gaging standards.

ANSI B1.20.3 and B1,20.4 were approved by ANSI Committee BI for publication as official ANSI

Standards and thereupon submitted to the Secretariat and the American National Standards Institute. They

‘were approved and formally designated as American National Standards on November 18, 1976,

ASHE B1.20.3 7b MM 2595512 0011876 4 mm

AMERICAN NATIONAL STANDARDS COMMITTEE B1

Standardization and Unification of Screw Threads

(the following i the roster of the Committe a

time of approval ofthis standard)

Organized... eee sees = June, 1921

Reorganized... eee vee e ce eee. February, 1929

‘SPONSORS: Society of Automotive Engineers

‘scope:

‘The American Society of Mechanical En:

Nomenclature of screw threads; form of threads; diameter and pitches of screws for

various uses; classification of thread fits, tolerances and allowances for threaded parts:

and the gaging of threads. Screw threads for fire hose couplings are not included within

the scope.

7... Baumgartner, Chairman

J.B. Levy, Vio-Chalrman

'.W. Taylor, Serotary

AEROSPACE INDUSTRIES ASSOCIATION OF AMERICA, INC.

Propulsion Technical Committee

D-H, Secord, Prt & Whitney Aircraft, B, Harford, Connecticut

[National Aerospace Standards Committoe

, L. Wall, MeDonell Aezaft Company, St. Lous, Mssouth

AIRCRAFT LOCKNUT MANUFACTURERS ASSOCIATION

‘Charles Fineran, ESNA Division, American Amerace Corporation, Union, NJ.

AIR INDUSTRIES CORPORATION

‘Edward Clark, Ait Indust

8 Corporation, Garden Grove, California

Alex Butovieh, Aternae, Al Inductees Corporation, Garden Grove, California

AMERICAN MEASURING TOOL MANUFACTURERS ASSOCIATION

ale Dodge, Pennoyer-Dodge Company, Glendale, California

AMERICAN SOCIETY OF MECHANICAL ENGINEERS, THE,

Edward MeHugh, Professor, Clarkson College of Technology, Potsdam, Now York

ANTIFRICTION BEARING MANUFACTURERS ASSOCIATION

Wiliam 4. Derner, Beating Division, FMC Corporation, Indianapolis Indiana

ASSOCIATION OF AMERICAN RAILROADS

Enginooring Division

1G. C. Herrick, New York Contel System, New York, New York

BELOIT TOOL CORPORATION

Philo V. Pastore, Belolt To0l Corpor

dO. Heinze, Altorna

ton, South Beto, tino

Beloit Tool Corporation, South Beloit, lin

BENDIX CORPORATION, THE.

Dale Story, The Bendix Corporation, South Beloit, Iinois

CLARK EQUIPMENT COMPANY

'D. N. Badgley, Clack Equipment Company, Battle Creek, Michigan

oe

__ -——-

ASHE B1-20-3 7 MM 2595512 0012879 & Ml

(COMPUTERS & BUSINESS EQUIPMENT MANUFACTURERS ASSOCIATION

‘1. G, Atwater (observer) International Business Machine Corporation, Endicott, New York

COMPRESSED GAS ASSOCIATION, INC.

'M, E. Steczynski, Steczynski & Associates, Chicago, llinois

EA. Olson, Altomate, Compressed Gas Associate, Inc, New York, New York

DEFENSE INDUSTRIAL SUPPLY CENTER

‘E1/Sehwarte, Defense Industrial Supply Cente, Philadelphia, Pennsyivania

Francie S.Ciccarone, Altomate, Defense Industial Supply Center, Philadelphia, Pennsylvania

FARM & INDUSTRIAL EQUIPMENT INSTITUTE.

1G. W, Stockwel (observer, International Harvester Co, Hinsle, inols

FORD MOTOR COMPANY

‘SE, Mallon, Ford Motor Company, Dearborn, Michigan

AF. Nagy, Alternate, Ford Motor Company, Deasbom, Michigan

(GEOMETRIC TOOL CORPORATION

ES. Zook, Geometric Tool, New Haven, Connecticut

GREENFIELD TAP & DIE DIVISION OF TRW INC.

1D. J. Emanuel, Greenfield Tape & Die, A United-Greenfield Division of TRW Ine. Greenfield, Massachusetts

HANSON-WHITNEY COMPANY, THE

S. Kanter, The Hanson-Whitney Company, Hartford, Connecticut

HLSHEAR CORPORATION

1M, tf, Schuster, HiShear Corporation, Torrance, California

INDUSTRIAL FASTENERS INSTITU

. Baumgartner, Charman, Standard Presed Steel Company, Jenkintown, Penayivania

2B. Belford Industral Fastonors Institute, Cleveland, Ohlo

M, Horrs, Altorate, Bethlehem Steel Company, Lebanon, Pennsylvania

. Wheeler, Azmco Steel Corporation, Kansas City, Missouri

M% Groover, Bethichom Stool Company, Lobanon, Pennsylvania

E, MeCullough, Alternate, Standard Pressed Steel Company, Jenkintown, Pennsylva

. Metturray, Russel, Busdsall & Ward Bolt & Nut Company, Post Chester, New York

JOHNSON GAGE COMPANY, THE

'R. S. Chamerds, The Johison Gage Co» bloomed, Connectiont

Stanley Johnson, Alternate, The Johnson Gage Co, Bloomfield, Connecticut

MANUFACTURERS STANDARDIZATION SOCIBTY OF THE VALVE & FITTINGS INDUSTRY

LR. Wolshman, Grinnc Corp., Providence, Rhode Island

METAL CUTTING TOOL INSTITUTE,

Tap and Die Division

©. G. Erickson, Pratt & Whitney Small Tool Divison, Colt Industries, Inc, W. Hartford, Connecticut

NATIONAL AUTOMATIC SPRINKLER & FIRE CONTROL ASSOCIATION

Frank Hils, Coligan Fyt-Protexion, Indianapolis, Indiana

‘Ray Malek, Paul J. Gruneav Company, Milwaukee, Wisconsin

NATIONAL ELECTRICAL MANUFACTURERS ASSOCIATION

F. V. Kupchak, Westinghouse Electsic Corporation, Pittsburgh, Pennsylvania

LB. Levy, Vice-Chairman, Genera Bletsio Company, Schenectady, New York

RL. Manca, Alternate, National Eloctical Manufacturers Association, New York, New York

NATIONAL MACHINE TOOL BUILDERS" ASSOCIATION

Thomas Lenhart, The Cleveland Twist Dill Company, Cleveland, Ohio

REED ROLLED THREAD DIE COMPANY

Joseph F. Dickson, Reed Rolled Thread Dle Company, Nolden, Massachusetts

SOCIETY OF AUTOMOTIVE ENGINEERS

CM, Baker J, Monde, Indiana

J.-E Long, GM Corporation, GM Technical Center, Warren, Michigan

1L. A. Strang, Caterpillar Tractor Company, Pooza,Iinols

RRRO RRA

ASME BL-20-3 7b MH 2595512 0011880 2 mm

SOCIETY OF MANUFACTURING ENGINEERS

‘M. Davidson, ‘Taredco Company, Troy, Michigan

J. S. Urso, Sepulveda, California

Date story, The Bendix Corporation, South Belo, Tints

‘SOCKET SCREW PRODUCTS BUREAU

E. J. Holdman, The Holo-Krome Serew Corporation, Hartford, Connecticut

‘TELEPHONE GROUP, THE

A. H. Van Horm, Bell Telophone Laboratories, Ine, Columbus, Ohio

F. P. Balacok, Alternate, Bell Telephone Laboratories, Inc, Columbus, Ohio

L. L. Paris, Alternate, Western Electric Company, Inc, Chicago, Minoks

U.S, MACHINE, CAP, WOOD & TAPPING SCREW BUREAU

'R. M. Byrne, US. Sexow Service Bureaus, New York, Now York

E, F. Tauscher, tomate, Pholl Manufectusing Company, Chicago, Hlinois

US. DEPARTMENT OF THE ARMY

Irwin Rosen, USA Mobility Equipment Company, Fort Belvoir, Virginia

1M. L. Froschtonicht, Altomate, Redstone Arsenal, Alabama

John Moddams, Alternate, US. Arony Materiel Command, Alexandria, Viginia

Woeraliat Arsenal

J. J. Foote, Watocdit, New York

US. DEPARTMENT OF COMMERCE

‘National Bureau of Standards

A. G. Strang, National Bureau of Standards, Optical Physes Division, Washington, D.C.

US, DEPARTMENT OF THE NAVY

‘Naval Sho Engineering Center (NSC)

Kelty, Naval Ship Systoms Command, Wathington, D.C.

US, DEPARTMENT OF THE AIR FORCE

Edward Sosnowski, Aeronautical Systems Division, Wright Patterson Air Force Base, Dayton, Ohio

F. Hannon, Alternate, Aeronautical Systems Division, WrightPatterson Air Fores Base, Dayton, Ohio

A. 8. Norwood, Robbins Air Force Bass,

VALLEY BOLT COMPANY

6. 0. Franklin, Maton, Towa

VAN KEUREN COMPANY

‘A. W. Lampore, The Van Keuren Company, Watertown, Massuchustts

INDIVIDUAL MEMBERS

, Adamiek, fobserve), Pheolt Manufacturing Company, Chicago, Ilnois

T. Appleton, Jefferson, Massachusots

E, our, Santa Monica, Califoria

S. Brown, Roanoke, Vitgiia

FF, Cramer, Des Moines, Washington

4, Donahuo, Xerox Corporation, Rochester, New York

W. Drescher, Bulova Watch Company, Ine, Flushing, Now York

1H. Fullmer fobeorvr), Sitver Springs, Maryland

E, Hoy, The Pipe Machinery Company, Wickliffe, Ohio

v.

c

ez

‘Mocha, Xerox Corporation, Rochester, New York

‘Mastorson, Waterlict, Now York

Miler (observer), Santa Maxis, Calfornis

‘Muanchinger, Continental Screw Company, Now Bedford, Massachusetts

i Tisch, Desert Hot Springs, California

Trowridge, GM Technical Center, Warren, Michigan

‘stson, Philadelphia, Pennsylvania

SPPERDPESMBSERDY

ASME BL-20-3 76 MM 25955L2 OOLL881 4 mm

PERSONNEL OF SUBCOMMITTEE NO, 20 ON PIPE THREADS

1. Badly, Chairman, Clark Equipment Company Battle Crk, Mishlgan

. Bour, Gardena, California

4. Browning, Southern Gage Company, Erin, Tennessee

A. Casner, Youngstown Stes! Company, Youngstown, Ohio

(©, Crinednst, Consulting Engincer,Pltsbuzgh, Pennsylvania

Davideon, Southfield, Michigan

W, Eison, General Motors Technical Center, Warren, Michiean

Foldheim, Secretary, The Weatherhead Company, Cleveland, Ohio

>. Heinze, Regal Beloit Corporation, South Beloit, ilinoie

Hinske,Parksr-Hannitin Corporation, Tube Fitting Division, Cleveland, Ohio

Hubbard, Long Island Lighting Company, Hickevlle, New York

‘Kanter, The Hanson: Whitnoy Company, Tlartford, Connecticut

. Keaton, Vio Chairman, Geneeal Motors Technical Center, Warten, Michigan

Matlock, Stockham Valves & Fittings, Binmingham, Alabama

Piotrowski, Mack Tracks, Ine, Allentown, Pennsylvania

Pastore, Regal-Belot Cozporation, South Beloit, linois

Fol, Deere & Company, Molin

‘oso, Southern Gage Company, Eri, Tennesiee

4. Ross, Whesling-Pitisburgh Steel Corporation, Benvwood, West

‘J. Schim, Ford Motor Company, Dearborn, Michiran

‘Shiela, Tackes Bvans Manufacturing Company, Jackson, Misssppl

Turton, The Bendix Corporation, South Beloit, Iinols

A, G. Strong, National Bureau of Standards, Washington, DC.

Rxeoapaneoe

rinia

RR ORESDEESMOSSPREES DED

vil

Section 1

Ad

12

13

13.1

132

14

14.

ALI

1412

14.13

14.14

142

Appendix B

Appendix C

Table

ca

C2

C3

cA

cs

C6

c7

1 Recommended Limitations of Assembly Among the Various Types of Dryseal Threads .

2 Referones Dimensions for Assembled Engagement of Dryseal Pipe Threads

“ASME B1-20-3 7b MM 2595Si2 0011882 b a

Product Threads

Introduction,

‘Throad Types .

‘Thread Designations a

NPTF Thread Class «

Designation of Plated

Applications.

‘Type.

NPIF oo...

PIR-SAB SHORT. -

NPSF .

NPSI. .

CLASS :

NPTE CLASS 1.

NPTF CLASS 2.

‘Assembly Limitations.

‘Thread Form and Tolerance

Basie Dimensions.

NPTE Threads .

PTF-SAE SHORT, Extemal Threads, -

PTF-SAB SHORT, Internal Threads

NPSF Threads.

NPSI Threads . .

Lotter Symbols and Fi

Symbols Designating the Dimensions of Pipe Threads

Formulas for Diamote

‘Suggested Tap Drill Sizes for Internal Dryseal Pipe Threads... .

Special Short, Spectal Extra Short, Fine, and Special Diameter-Pitch

CONTENTS

mnd Notation

Threads

x and Length of Thread .

‘Combination Dryseal Pipe Threads .

Dryseal Special Short Taper Pipe Thread, PTF-SPL SHORT

Diyseal Special Extra Short Taper Pipe Thread, PTF-SPL EXTRA SHORT

Limitations of Assembly. ... . een

Dryseal Fine Taper Thread Series, F-PTF.

Drysoal Special Diameter Pitch Combination Sevies, SPL-PTF «

Formulas for Diamete

Designations.

sr and Length of Thread

3 Basic Dimensions for NPTF Threads -

4 Basic Dimensions for PTF-SAE SHORT, Bxtemal Threads

15

15

15

15

16

16

16

16

ASME 81-20-3 7h MM 2595512 0011883 8 ml

Page

‘Table 5 Basie Dimensions for PTF-SAB SHORT, Internal Threads, 9

6 Dimensional Data for NPSF Threads . 10

7 Dimensional Data for NPSI Threads . 10

AI Pipe Thread Symbols... .. 12

BI Suggested Tap Diil Sizes for Internal Dryseal Pipe Threads 14

C1 Basic Dimensions of Diyseal Fine Taper Pipe Thread, F-PTF.. ees. 1B

2 Be Dimensions of Dye Specal Taper Pipe Tea SL (Fr Thin Wal

‘Nominal Size OD Tubing) 19

Figure 1 Extreme Mating Conditions for Dryseal Pipe Threads... ap 2

2 ‘Thread Form and Limits on Root and Crest Tuncation of Product Threads : 6

Al Application of Pipe Thread Symbols. 13

C1 Comparison of Special Dryseal Threads with Standard Length Dryseal Threads... 1s. 17

ASME 82-20-3 7b MM 2595512 0011864 T mm

‘ANSI B1.203-1976

AMERICAN NATIONAL STANDARD

INCH DRYSEAL PIPE THREADS

SECTION |

PRODUCT THREADS

1.1 Introduction

Dryseal pipe threads are based on the USA (Amer

ican) pipe thread, however, they differ from the USA

(American) pipe ‘thread in’ that they are designed to

seal pressuretight joints without the necessity of using

sealing compounds. To accomplish this some modifi-

cation of thread form and greater accuracy in manu

facture is required. The roots of both the external

and intemal threads are truncated slightly more than

the crests, ie. roots have wider flats than cress, so

that metal-to-metal contact occurs at the crests and

roots coincident with or prior to flank contact, see

Figure 1. ‘Thus as the threads are assembled by

‘wrenching, the roots of the threads crush the sharper

crests of the mating threads, This sealing action at

both tho major and minor diameters tends to prevent

spiral leakage and makes the joints pressuretight with

‘out the necessity of using sealing compounds, provided

that the mating threads are in ecvordance with stan-

dard specifications and tolerances and are not dam-

aged by galling in assembly. Tho control of crest and

root truncation is simplified by tho use of properly

designed threading tools. Also, itis desirable that both

‘oxternal and internal threads have full thread height

for the Ly length. However, where not funetionally

objectionable, the use of a compatible lubricant or

sealant may be used to minimize the possibility of

galling. This is desirable in assembling Dryseal pipe

threads in refrigeration and other systems to effect a

pressuretight seal.!

1.1.1 In order to obtain a pressure tight seal using

Dryseal pipe threads without a sealer, it is necessary

to hold crest and root truncation of both internal and

external threads within the limits specified. Unless

this is done by use of threading tools with the crest

and root truncation controlled so as to assure repro-

"The roflgeration industry hus gonorally accopted tho use of

‘Mfeaiant to oblain an absolute preituretisht Joint, wien

“ssembling taper pipe threads.

duction on the product threads, itis necessary to use

a system of measuring or a system of gaging and mea-

suring to determine conformance.

1.1.2 Bven without truncation gages, the standard

practice of using two separate thread gages forDryseal

pipe threads, each with a difference in truncation,

length of engagement and point of engagement, pro:

vides more detailed check of angle, lead and taper

doviations than is required for non-dryseal taper pipe

threads.

1.4.3 One method of checking crest truncation is by

using 6 step plain gages. It should be recognized that

this method may give misleading results in that the

crest truncation of tho product threads is always less

(at narrower) than that indicated by the position of

the gages, the degree of inconsistency depending on

the angle, ead and taper deviations present in the

product thread.

1.4.4 Another method employs both crest and root

truncation check gages. The root check gage is made

with a thread form having an included angle of 50

grees and with a smaller gage crest flat than the

root flat to be checked. The major diameter of this

sage is controlled in relation to 6 gaging steps in a

similar manner to the plain 6 step erest check gage.

Like the crest check gage, the results may be some.

what misleading except that in the case of the root

chock gage, the root truncation of the product thread

is always more (flat wider) than is indicated by the

position of the gages.

1.1.8 Unless lead, angle and taper of product threads

are vety well controlled, use of 6 step crest and root

check gages will result in product threads with nar-

rower crest flats and wider root flats than envisioned

by the dryseal tolerances. Use of such a gaging system

could result in rejection of threads which would ac-

tually conform to the dryseal tolerances specified.

‘The only completely reliable referee mothod for deter-

mining whether crest and root truncation has be

ASME B1-20-3 7b Mm@ 2595512 0021885 1 mw

AMERICAN NATIONAL STANDARD

INCH ORYSEAL PIPE THREADS

held within tolerance is direct measurement of the ex

ternal thread flats and measurement of these flats on

2 cast or section of the internal thread,

1.1.6 This standard covers two classes of NPTF Dry-

seal pipe threads; Class 1 and Class 2, The classes differ

only in inspection requirements, with Class 1 threads

exactly those standardized in ANSI B2.2-1968 (in-

spection of root and crest truncation not specified).

Class 2 threads are identical to Class 1 threads exeopt

that inspection of root and crest truncation is re-

quited. For Class 2 threads, direct measurement of

crest and root truncation is the referee mothod, These

classes do not apply to other than NPTF Dryseal pipe

threads,

1.1.7 All dimensions in this standard including all

tables are in inches unless otherwise noted.

NOCLEARANCE ~

(Basic)

MOMMY

TWIERNAL THREAD,

NO CLEARANCE

(Basic)

‘ANSI 81,20.3-1976

4.2 Thread Types

Extemal Dryseal pipe threads are tapered only. In-

ternal Dryseal pipe threads may be either straight or

tapered, a specified. Also, thread lengths may be

either “standard” or “short,” depending on the re-

quirements of the application. The short external

thread is obtained by shortening the standard thread

by one pitch at the small end, A short internal taper

thread is obtained by shortening the standard thread

by one pitch at the large end. Accordingly, there are

four standard types of Dryseal pipe threads, as

follows:

‘Type 1 ~ Dryseal USA (American) Standard Taper

ipe Thread, NPTF

‘Type 2 — Dryseal SAE Short Taper Pipe Thread,

PTE-SAE SHORT

‘Type 3 ~ Dryseal USA (American) Standard Fuel

Internal Straight Pipe Thread, NPSF

‘Type 4 — Dryseal USA (American) Standard Inter

mediate Internal Straight Pipe Thread,

NPSI

MAXIMUM

INTERFERENCE

(AXIMUM

MATERIAL,

CONDITION

MAXIMUM

INTERFERENCE

Drovido tho maxnum interference,

NOTE: When threaded joint are made up wrenchtight,

‘the direction of interference only, therefore the maximum matecil

fou a the ight i estabised by having the ext

{a Intended thatthe Manis and the oteste and roots sh

1 combinstion of sharpot crests and fattest root, witch

FIG 1. EXTREME MATING CONDITIONS FOR DRYSEAL PIPE THREADS

ASHE 81.20-3 7b WH 2595522 OODLE 3 mm

AMERICAN NATIONAL STANDARD

INCH DRYSEAL PIPE THREADS

1.3 Thread Designations and Notation

‘The above types of Dryseal pipe threads are desig-

nated by specifying in sequence the nominal size

designations, thread series symbol, and class, as

follows:

Yo-27 NPTR-1

Yo-27 NPTR-2

Yo-27 PTF-SAE SHORT

Yq-27 NPSF

‘f-27 NPSI

Each of the letters in the symbols has a definite

significance as follows:

National (American) Standard

P = Pipe

T= Taper

S = Straight

Fuel and Oil

I = Intermediate

1.3.1 NPTF Thread Class. Two classes of NPTF

threads have been established: Class 1 and Class 2,

Class 1 signifies that specific inspection of root and

crest truncation is not required, while class 2 signifies

that such is required.

Since class notation is introduced in this standard

there will undoubtedly be a long period of time be-

fore users completely adopt the new classification. Ia

cases where class is not denoted, the thread shall bo

considered Class 1

1.3.2 Designation of Plated Threads. The product

specifications of this standard do notinclude an allow-

ance for plating. If plating is desired, it may be neces-

sary to modify the threads since the same final gaging

requirements must be satisfied for plated and un-

plated parts. This may be emphasized by adding the

words AFTER PLATING to the designation, For

‘manufacturing purposes, notes for plated taper pipe

threads may specify the gage limits (turns engagoment)

before plating followed by tho words “BEFORE

PLATING.” These should be followed by the stan-

dard gage limits (tus engagement) after plating and

the words “AFTER PLATING,” Examples of optional

designations for an external thread having 0.0002 inch

plating thickness are:

%-18 NPTF-1, or

-18 NPTF-1 AFTER PLATING, or

%-18 NPTF-1, L RING GAGE LIMITS

2% to 4% tums engagement before plating

2% to 4% turns engagement after plating

p18 NPTP-1, Ly RING GAGE LIMITS

2% to 3¥ turms beyond actual Ly gage turns en-

‘agement before and after plating.

‘ANSI 81.20.-1976

Example of optional designations for internal thread

with 0.0002 inch plating thickness i:

%-18 NPTE-1, or

4-18 NPTE-1 AFTER PLATING, or

%-18 NPTP-1, L, PLUG GAGE LIMITS

3 to 4% turns engagement before plating

2% to 4¥ turns engagement after plating

%y-18 NPTP-1, Ly PLUG GAGE LIMITS

2% to 3% turns beyond actual Ly gage turns en:

‘agement bofore and after plating

‘14 Applications

14.1 Type

1.4.1.1 NPTF. This typo applios to both external

and internal threads and is suitable for pipe joints in

practically every type of service. OF all Dryseal pipe

threads, NPTF extemal and internal threads mated

are generally conceded to be superior for strength and

seal since they have the longest length of thread and

theoretically, interference (sealing) occurs at every en-

‘aged thread root and crest. Use of tapered internal

threads, such as NPTF or PTF-SAB SHORT in hard

or brittie materials having thin sections will minimize

the possibility of fracture,

1.4.1.2 PTF-SAE Short. External threads of this

type conform in all respects with NPTF threads, ex-

cept that the thread length has been shortened by

eliminating one thread from the small entering) end.

‘These threads are designed for applications where

clearance is not sufficient for the full thread length of

NPTF threads or for economy of material, where the

full thread length is not necessary. PTF-SAB SHORT

extemal threads are intended for assembly with NPSL

threads, but may also be assembled with NPTF in-

‘temal threads. They are not designed for and at ex:

treme tolerance limits may not assemble with PTF-

SAE SHORT internal or NPSF thread.

Internal threads of this type conform in all respects

with NPTF threads, except that the throad longth has

bbeen shortened by eliminating one thread from the

large (entry) end. These throads are designed for thin

‘materials where thickness is not sufficient for the full,

thread length of NPTF threads or for economy in tap-

ping where the full thread length is not necessary.

PTE-SAE SHORT intemal threads are primarily in-

tended for assembly with NPTF external threads,

‘They are not designed for and atthe extreme tolerance

limits may not assemble with PTF-SAE SHORT ex-

‘temal threads,

Pressure-tight joints without the use of lubricant

for sealer can best be assured whore mating com-

ponents are both threaded with NPTF threads, This

ASME 81.20-3 7b MM 2595512 0011887 5 mm

AMERICAN NATIONAL STANDARD

INCH DRYSEAL PIPE THREADS

should be considered before specifying PTR-SAR

SHORT external or internal threads.

1.4.1.3 NPSF. Threads of this type are straight

(cylindrical) instead of tapered and intemal only.

‘They.are more economical to produce than tapered

internal threads, but when assembled do not offer as,

strong a guaranteo of sealing since root and crest in-

terforence will not occur forall threads, NPSF threads

are generally used with soft or ductile materials

which will tend to adjust at assembly to the taper of

external threads, but may be used in hard or brittle

‘materials whore the section is thick. They are primarily

intended for assembly with NPTF extemal threads

(For other applications see Appendix C.)

1.4.14 NPSI. Threads of this type are straight

(cylindrical) instead of tapered, internal only, and are

slightly larger in diameter than NPSF threads but

have the same tolerance and thread length, They are

more economical to produce than tapered threads

and may be used in hard or brittle materials where

the section is thick or where there is little expansion

at assembly with external tapor threads. As with

NPSF threads, NPSI threads when assembled do not

offer as strong a guarantee of sealing as do tapered in-

ternal threads. NPSI threads are primarily intended

for assembly with PTF-SAE SHORT external threads,

but can be used with NPTF external threads,

1.4.2 Class

1.4.2.1 NPTF Class 1. Threads made to this class

are designed to interfere (seal) at root and crest when

‘mated, but inspection of crest and root truncation for

acceptance is not required. Consequently, Class 1

tlureads are intended for applications where close con-

{rol of tooling is required for conformance of trunce

tion or where sealing is accomplished by means of a

sealant applied to the threads,

1.4.2.2 NPTF Class 2. Threads made to this class

aro theoretically identical to those made to Class 1,

however, inspection of root and crest truncation is re-

quired. Consequently, where a sealant is not used,

there is more assurance of a pressure-tight seal for

(Class 2 thieads than for Class 1 threads.

1.5 Assombly Limitations

1.8.1 As described in par. 1.2, hore aro four types of

standaed Dryseal pipe threads. Types 1 a

ANSI 81.203-1976

‘tapored and can be made as both oxternal and internal

threads. Types 3 and 4 are straight threads and are

‘made only as internal threads. When selecting the

combination of external and internal threads to be

‘mated, Table 1 should be used as guideline, Approxi-

‘mate values for length of engagement for various as

somblies are given in Table 2

1.8.2 Another important factor to consider in the

design and manufacture of Dryseal pipe threads is the

effect of out-of-roundness which is possible between

the wrench-tight mated parts in final assembly. This

will vary depending on the method for producing the

‘thread in conjunction with the elasticity and/or duc-

tility of the mating parts and the resultant confor-

‘mance at final assembly.

1.6 Thread Form and Tolerance

Dryseal pipe threads are triangular with truncated

roots and crests. The angle between the flanks of the

thread is 60 degrees when measured on an axial plane

and the line bisecting this angle is perpendicular to

the axis of both the taper and straight threads making

cach half angle equal to 30 degrees, Thread form and

limits on erest and root truncation are given in Figure

2. Although the erests and roots of the Drysoal threads

are theoretically flat, they may be rounded providing

their contour is within the limits shown in Figure 2.

‘They are truncated parallel to the pitch line on both

product and gage threads.

‘There is no specified tolerance on product pitch

diameter, except for internal straight pipe threads,

Basic size of the product thread is defined using the

basic dimensions covered in paragraph 1,7 and devia-

tions from basic size not defined by a specific toler

ance are defined entirely by the gages used for ac-

ceptance. In particular, the maximum deviation of

functional size from basic is plus and minus 1 turn for

NPTF, plus O minus 1% turns for PTF-SAE SHORT,

plus 0 minus 1% turns for NPSF and plus 1 minus %

turns for NPSI of the Ly gage. In addition, the 2 or

ZL gage must correlate within plus and minus % turns

of the actual Ly gage position on each specific taper

throaded part

netral taper of tapered threads is 0.0625 +

inch per inch of length.

UASHE 81-20-3 7h MM 2595532 OOLL888 7 mm

AMERICAN NATIONAL STANDARD

INCH DRYSEAL PIPE THREADS.

‘Table 1 Recommended Limitation of Assembly among the

‘Various Types of Dryseal Threads!

External Drysoal thread: For Assembly with Internal Dryseal thread

Type [ Table Description “Type | Table Deseiption

1 4 | NPTE caperea), 1 4 | NPR Gapered) int hd

ext thd 224 | 6 | pr-SAH SHORT (tapered), int thd

325 | 7 | Nese catraignty, int thd

42.56] 8 _| PSI (traighd int thd

| 5 | PEF-SARSHORT (apowod) | 4 | 8 | NPSI Giraighd int hd

ext thd 1 4_| NTP (apered) nt tha

+ Am assembly with atraight internal pipe thretds and taper external pis thread is frequently more advan

fgcous then an all taper thread semmbly, particularly In automotive and other alled industries where

Sebaoiny and rapid production ate major considerations Drysoa! teads are not used in assembles In

‘hich both components have straight pipe threads

= Browurtight Joints without the use fs alan ean best bo assured where both components are threaded

‘with NPTF (Cll tong treads), snes theoretically inerforence (sealing) occurs a all threads, but there

re two fess threads gaged thes for NPT ssomblls, When straight intornal toads are used, there fine

{erterence only at one thread depending on duclity of materials

oPTF-SAE SHORT external Uncads ate primary intended for asombly with type

‘ut can also be wed with type I-NPTF internal threads, They are not designed f

tance hits,

SPEE'SAE SHORT internal theeads aro pelmatly Intended for assembly with type

threads: They are not designed for, and ct extreme tolerance mils may not assemble with, type 2-PT =

SAE SHORT external threads.

tno external straight Drysal thread,

NPS interoat th ‘Primarily intended for ssombly with type 2-1

‘But wil alo assemble wit fll longth type 1 NPT external threads

LNPSI internal threads

fy not assemble with, ype 2-PTE-SAE SHORT internal treads oF type S-NPSE internal

PTE-SAK SHORT external threads

‘Table 2 Reference Dimensions for Assembled Engagement of Dryseal Pipe Threads

‘ANSI B1.203-1078

“Approximate Length of Thread Engagoment “Approximate Length of Thread Bngagement

[NPIF External Thad Assembled Into PTF-SAB SHORT External Thad Assembled Into

p | FIFSAE PIF-SAE

Size Nr were | nese | PRESAE) pst | onere |. nese | "Shon

Internat | toterat | internat | SHORT | internat} tnternat | tnternat |. Thtemat

Thwead, | Thread, | thread, | It | Tinead, | Thread, | Thread,

t+% | £4250 | 1,42 |t+150| L,+2 | tise| Lely

1 2 3 4 5 6 7 3 3

-21 | 027 025 023 022 0.23 on 020 os

=a | 027 025 023 022 0.23 022 020 ous

18 | 039 037 034 oat 034 oat 0.28 0.26

Internat thread tabulated full thread lengths do not include countersink beyond the interseetion of the plteh line and the chamfer cone

Gaing reference point)

FF —

ASME B1.20-3 76 MM 2595512 0011892 7 mm

AMERICAN NATIONAL STANDARD

INCH DRYSEAL PIPE THREADS ANSI 81.20.3-1976

1.7.3 PTF-SAE SHORT, Internal Threads

Hao eNcacemenr (Li sHont) +La

“FONE TURN FULL THREAD ee

(L1 shor)

[eee

ME

A

Es Eo cE;

(See TABLE 3)

‘Table § Basic Dimensions for PTF-SAE Short, Internal Threads

wy | PDat Bnd ot and Enpigenent | =nsthof item

a PT | int Thad a aes ull Threed

ie |G show : Gi, Shortt | shor Tap

Tach Tach inch [ thd_| toch [ thd | Inch [Tha | Inch

Ya-27 | 0.03708 | o27ee7 | 0.600 | 432 | 0.230 | 322 | o2sa | 632 | o4sea

=27 | 003m | 037129 | orsis | 436 | o1z44 | 336 | 02356 | 636 | o4sze

i -18 | oossss | oaasis |o2278 | 410 | o172 | 310 | 03389 | 610 | o6r22

% =18 | oosss6 | 0.62354 | 02400 | 432 | oss | 332 | oasis | 632 | oats

% ~14 | 007143 | 0.77397 | 0.3200 | 448 | o24ss | 348 | 04629 | cas | osors

% -14 | oo7as | ogee | 03390 | 4.75 | o2676 | 375 | o4sio | 675 | o910s

1 ~11% | 08696 | 1.23320 | 04000 | 460 | 03130 | 360 | 05739 | 660 | 1.0956

1% —114 | oogess | 1157795 | 04200 | 483 | 0.3330 | 33 | 05939 | 6as | 1136

1% —11% | 00866 | 1.81691 | 0.4200 | 483 | 03330 | 383 | 05939 | 683 | 11156

2 —11% | oosess | 229084 | 0430 | sor | 03490 | 401 | oos9 | 701 | 11316

2m — 8 | 012500] 275435 | 0.6820 | s4s | 03570 | 446 | 09320 | 146 | 1.6820

3 8 | o.12s00| -.38069 | 07660 | 613 | ostio | si3_| 10160 | 813 | 1.7660

‘4 Internal thread tabulate full thread lengths do not include countersink beyond the intorsection of the pitch ne and the

charnfer cone (gaging reference point).

ASME BL-20-3 76 MM 259S5b2 0001893 0 mm

AMERICAN NATIONAL STANDARD

INCH DAYSEAL PIPE THREADS. ‘ANSI B1.20.3-1976

1.7.4 NPSF Threads

Table 6 Dimensional Data for NPSF Threads

3 Pitch Diamoter® ‘Minor Diameter | Desired Minimum Full Thread Length

: Mind Max Min Tach Th

he 27 0.2768 0.2803 0.2482 ost 844

eam 0.3692 0377 0.3406 031 B44

w -18 o.4ss2 0.4908 aaa oar Baa

ys 0.6205 0.6257 05776 050 9.00

wu 0.7700 0.1167 0.7133 066 919

MoM 0.9805 09872 0.9238 0.66 9.9

1-1 12284 1.2365 1.1600 078 898

‘The pitch dlameter of the tapped hole as indicated by the taper plug sage ie slishtly larger than the vlues given due to

the gare having to enter approximately turn to engage fut ful thread

major and minor diameters of the internal

full tread longths do not include countersak beyond the inferseetion of the piteh ty

reference point)

4 Minimum pitch di

© Maximum pitch

2p thread taper,

ead (Table 3) minus smal

1.7.5 NPSI Threads

Table 7 Dimensional Data for NPSI Threads

% Pitch Diameter® Minor Diameter? [ Desired Minimum Full Thread Length®

" Mind Maxt Min Inch Th

Ye 20 02791 0.2826 0.2505 ost 844

igo oats 0.3750 0.3429 031 Bas

w =18 0.4886 0.4938 o4as7 oa7 844

4-18 0.6240 0.6292 o-ssit 050 9.00

4-14 ores o7e12 o-80 0.66 9.9

yom 0.9850 0.9917 0.9283 0.66 9.19

ron 1.2338 1.2420 1165s o78 898

Footnotes, b, cand d as shown under Table 6 apply also to Table

e°"Maximatn pitch diameter fb the same at the Ey pith Glamotar st large end of iternal thread (Table 3) plus (are) 7

thread taper

10

ASME B1-20-3 76 Ml 2.

95512 0001694 2 mm

APPENDIX A

LETTER SYMBOLS AND FORMULAS

AA Symbols Designating the Dimensions of Pipe

‘Thread Elements

Standard letter symbols to designate the dimen-

sions of pipe threads are given in Table AL. The ap-

plication of pipe thread symbolsisillustrated in Figure

AL

A. Formulas for Diameter and Length of Thread

Basic diameter and length of thread for different

sizes given in Tables 3, 4, and 5, ae based on the fl-

Towing forms:

Basi pitch diameter of thread at small end of NPTF

cktornal thread

Bq =D ~(0.08D+ 1.1)

Basic pitch dlametor of thread at small end of PTF-

SAE Short external thread

Eq Short =D ~ (0.05D + 1.037)p

u

Basic pitch diameter of throad at large end of NPTF

internal thread.

By = Bo + (0.06251, Basic)

Basic pitch diameter of thread at large end of PTF

‘SAE Short internal thread

B, Short = By Short + (0.0625L, Short)

Basic length of NPTF external full and effective length

‘thread

(08D + 68)p

Basic length of PTF-SAE Short external full and ef

fective length thread.

Z, Short = (0.8 + 5.8) p

Basic length of NPTF internal full and effectivelength

‘thread = 2 Basic + Ls

Basic length of PTF-SAE Short internal full and ef-

fective length thread =, Short +L

whore D = outside diameter of pipo

P = pitch of thread

ASME B1-20-3 76 MM 2595512 0011895 4 mm

APPENDIX A

Table A1_ Pipe-thread Symbols (See Fig A1)

‘SYMBOLS DIMENSIONS REMARKS.

> Outside diameter of pipe.

@ Tso diameter of pipe.

t Wall thickness of pips

Dy Major diamotae Subseipt x denotes plane containing the diameter. For @

Be Pitch diameter. | | ppouitions of planes se below.

Ke Minor dlamote? 1) | subscripts, of m designating external and internal threads,

respectively, may also be used if necessary.

bx Length of theead from plane of pipe |For axial posiion of plane containing basic diameter, see

fend ‘to. plane containing basio | — below.

lametor Dy, By, oF Ke

v Length of vanish” one” (washout)

threads DEFINITIONS OF PLANES DENOTED BY SUBSCRIPT x

b beta), Half apex anple of pltch cone of taper

‘hues.

(gamma) ‘Angle of chamfer at ond of pipe mea- Plano of pip ond

Sured froma plane normal to the Plane of handtight engagement or

te, lane at mouth of eoupling (ex

4 Handtight standoff feo of coupling fluding recess, if preset). On

rom plane containing vanish point British pipe threads tis is desig

‘on pipe.

™ Length from plano of handtight on

‘ayemont 10 the face of coupling

fn intemally threaded mombor. [x= 2. Plane at which vanish tzeads on pipe

Distance of gaging stop of plug gage commence,

‘rom face of wing goge for band. |x =3 +++ Plane in coupling reached by end of

tight engagement. Standoft ‘ips in wrencled condition.

Ln Leagtt from centerline of coupling, Gy is measured from plane con-

‘ace of flange, ot bottom of in: taining. pipe end in position of

tomal thread chamber to face of Ihandvght engagement)

ting, xe Plane. containing vanish point of

baw. ‘Width of beating face on coupling thread on pipe

ray) Angle of chamfer at bottom of recess |x = 5 + Plane at which

‘OF countorbore meastzed frm the ‘thread

nt of pipe

« (epsiton) Half apex angle of vanish cone,

[Length from centerline of coupling

face of flange, or bottom of int

temmal thread. chamber to end of

pe wrenched engagement.

by (1) Length of stright fll thcad (seo

Table D.

(2) Length from plane of handtght

‘engagement fo small end of full

Internal taper thread

° Diamator of zee or counterbore in

iting

‘ Dept of reco oF counterbore in fit:

ting

Note: Additional special subscripts are as follows: Plane

Dine ofthe API gage point at's spocfied length from the plane of vanish pot

OF Me "Lg thread ring gage” for the National

Outside diameter of coupling or hub

of iting

a6 Taper (compressed-aae cylinder valve inlet

Inthe plane ofthe pipe endfor eiling joints. Plane x = 7 Is the

tex = 8 the plane of the large end

nection) thread. Plane

== 91s the plane of the small ond of tho "L, thread plug gage” for the National Gas Tape (Compressed as eylindor

inte) thes

2

ASME 81.20-3 76 MM 2595512 OOl189b & mm

courtine) aa

CENTERLINE OF CONNECTION, FACE OF

FLANGE, OR BOTTOM OF THREAD CHAMBER

— PLANE OF THE END OF THEPIPE

AT WRENCH TIGHT ENGAGEMENT

| REFERENCE PLANE ZERO

4

— FITTING (INTERNAL THREAD)

/— PLANE OF HANDTIGHT ENGAGEMENT

PLANE OF COMPLETE THREAD LENGTH

13S4n TWNN31x3 -TWNEBINI

PLANE OF VANISH POINT

yee

A | | ovane oF errecTive THREAD LENGTH

PIPE (EXTERNAL THREAD)

t

niga

PLANE OF VANISH

Pont

vapor

43Sun TWNEBANI

|

FIG At APPLICATION OF PIPE THREAD SYMBOLS

(See Table At)

13

ASME BL-20-3 7b M™ 2595522 OOLL897 6 mm

APPENDIX B

SUGGESTED TAP DRILL SIZES FOR INTERNAL DRYSEAL PIPE THREADS

The drill diameters given in Table BI are for taper ‘Taper pipe threads of improved quality are ob-

tnd straight internal pipe threads and will usually tained when the holes are taper reamed after drilling

permit the tapping of accoptable throads in free- and before tapping. Standard taper pipe reamers are

machining brass or steel provided tho drills correctly used and, as in drilling, the actual siz of the hole de-

sharpened. When hard metals or other similar materials pends upon the material and is best determined by

are to be drilled and tapped, it may be necessary to trial

use a drill of slightly larger diameter whereas some soft

materials may require a smaller size.

cous cole

Sia? Bia

Table 81. Suggested Tap Drill Sizes For Internal Dryseal Pipe Threads

Taper Pipe thead Stig Pipe Tvead

Minor Dall For Us Da For Ue

Jrbsbte| diameter Without Reamer With Reamer :

Dal |_AatDitance minor arf &

loversie [T, 2 » iamoter | ™OH| Suazesod

Size cal Dl

cut [rncorett| sup gua [TCO] gua Dall | Dall te

Suggested Suggested size

(eas) catpait | Sweet |'carpear | Sued

rit size | “sizo_| Pe esr [ ast

1 4 5 6 7 s [2 | it

‘he~27 | 00038 | 0244s | 02378 | 0240s | cr co242)| 0.2336 |*a" 0234 | ose | o2sos| o2s4s [sv cae,

27 | oo0ss | 0.367 | 0298 | 0.3323 | “ar 0.3284 | *%y (0328) | 0.3406 | 0:3429| 0.3362 [R" 0.339)

we —18 | 0.0047 | 0.4362 | o.42s8 | 04315 | he dari | 4 (0.422) | 04422 | 0.4457| 04375 | he (0438)

% ~18 | 0.0089 | 0.5708 | o.s604 | 0.5659 | 4, (0-562)| 0.5555 | %he (0.863) | 0.5776 | 0.5811 | 0.5727 |. (0.578)

(0.688) | 0.7133 | 0.7180] 0.7082 | “Ya €.703)

(o.s91) | 09238 | 0.9283] 09178 | 4 (0.922)

(1.128) | 1.1600 | 1.1655] 1.1520 |1%,° (0.156)

(1469)

vw —14 | ooost | 0:7034 | 0.6901 | 0.6988 | “he (0:702)] 0.6850

% —14 | 0.0060 | 0.9127 | 0.8993 | 0.9067 | *%. 0.906)| 0.8933

1 = 11% ooo | 4.1470 | 1.1307 | 1.1390 fay G14} 1.1227

1% — 11) o.o100 | 490s | 14742 | 1480s |i, 484) 1.4682

vs = 11%} 0.0120 | 1.7298 | 1.7132 | 17s f% a.n19)| 1.7012 he 4.703)

2 —11%| 0.0160 | 22024 | 21861 | 21864 fy. isa) 21701 BYE, 372)

2% — 8 [0.0180 | 2.6234 | 2'6000 | 260s4 [2% @.605)| 25820 bY, @s78)

3 = a [oo200 | s2aas | s.2211 | 32245 fae, G.230)| 3.2011 fa, G.203)

2 4 values equal column 2 values minus column 1 value.

Column 6 values equal column 3 values minus column 1 value.

€ Gotumn 10 values equa cofumn 8 values minus column 1 values

{Some dil sizes listed! may not be standard Gril, and In ome ease, standard metic dell sizes may bo closer to the theoretical dil sie

14

ASME B2-20-3 7b MM 2595512 0012898 7 mm

APPENDIX C

SPECIAL SHORT, SPECIAL EXTRA SHORT, FINE, AND SPECIAL

DIAMETER-PITCH COMBINATION DRYSEAL PIPE THREADS.

‘The SAE Dryseal pipe thread series are based on

thread length. Full thread lengths and clearance for

Dryseal Standard and SAB SHORT series are shown

in Tables 3, 4, 5, 6, and 7 of the standard, and the

differences between’ thom are described in the text

under the series headings. These full thread lengths

and clearances should be used in design applications

wherever possible,

Design limitations, economy of material, perma-

nent installation or other limiting conditions may not

permit the use of either of the full thread lengths and

shoulder lengths in the preceding tables for the above

thread series, To most those conditions two special

thread series have been established as shown in Fig,

C1 and the deviations from standard practice are de-

seribed below.

C.1 Dryseal Speci

SPL SHORT

‘Threads of this series conform in all respects to the

PTF-SAE SHORT threads except that the full thread

length has been further shortened by eliminating one

tluead at the large end of external threads or elimi-

‘nating one thread at the small ond of internal threads

Gaging is the same as for PTF-SAE SHORT except

the Ly ting thread gage for external thread length and

taper or the Ls plug thread gage for internal thread

length and taper cannot be used. Tolerance must be

altered and coordinated as described in paragraph C.3.

‘The designation of this series thread is as follows:

Yo-27 PTE-SPL SHORT

Short Taper Pipe Thread, PTF-

.2 Dryseal Special Extra Short Taper Pipe Thread,

PTF-SPL EXTRA SHORT.

‘Threads of this series conform in all respects to the

PIF-SAE SHORT threads excopt that the full thread

Jength has been further shortened by eliminating two

threads at the large end of external threads or elimi-

nating two threads at the small end of intemal

threads. Gaging is the same as for PTF-SAE SHORT.

except the La ring thread gage for external thread

length and taper or the L3 plug thread gage for in-

1s

femal thread length and taper cannot be used. Toler-

ance must be altered and co-ordinated as described

paragraph C.3. The designation of this series thread is.

as follows:

27 PTR-SPL EXTRA SHORT

ca ions of Assembly

Standard combinations and applications of the var-

fous series Dryseal pipe threads are given in the pre-

ceding thread descriptions. However, where special

combinations are used, additional considerations as

outlined below must be obsorved. These should be

designated with the suffix “SPL” and gaging toler-

ance should be specified.

PTR SAE SHORT

Inna

EIESILSHORT ye NOME INRERNA,

ERTERWAL, | gtihtare, Ssh stow

SHORT HRTERAL INTERNAL

PERSMLSHORT gy

IRA A err sapsioxr

Pirsmexrna ASSEMBLE ETS

"Only when the extornal thread of the internal thread or

‘both are held closer than the stands

fort towerd the minimum andthe intern

‘maximum pitch dlameter fo provide a ianimum of one

{rn hand ‘engagement. At extrome tolerance limite the

Shortened full tread lengths reduce hand engagement and

PEF SPL SHORT

EXTERNAL May** NPTF or NPSI

PTF SPL BEXTRA ASSEMBLE INTERNAL

SHORT EXTERNAL ‘WITH

TERROR uae

‘Only when the internal thread or the external thread or

ave held closer than the stendard tolerance, the In-

xtoral toward the

‘ne limits the shortened fll th

mmsko-up and threads may not #0

ASME B1.20-3 7b M™ 2595512 0011899 1 a

C.4 Dryseal Fine Taper Thread Series, F-PTF

‘The noed for finer pitches for nominal pipe sizes

has brought into uso applications of 27 threads per

inch to Ye and % pipe sizes. There may be other

needs which require finer pitches for larger pipe sizes.

It is recommended that the existing threads per inch

be applied to next size larger pipe size fur a fine

theead series such as are shown in Table Cl. This

Series applies to external and internal threads of full

length and is suitable for applications where threads

finer than NPTF are required.

C5 Dryseal Special Diameter-Pitch Combination

Series, SPL-PTF

Other applications of diameter-pitch combinations

hhave also come into use where taper pipe threads are

applied to nominal size thin wall tubing such as aro

shown in Table C2. This series applies to external and

internal threads of full length and is applicable to thin

wall nominal outside diameter tubing. The number of

threads is uniform at 27 per inch

6 Formulas for Diameter and Length of Thread

Basic diameter and length of thread for sizes of

Dryseal Fine Taper Pipe Thread, F-PTF, and Dryseal

Special Taper Pipe Thread, SPL-PTF, given in Tables

CI and C2 are based on the following formulas:

D = outside diameter of pipe or tubing

P= pitch of thread

‘Diametral taper = 0.0625 inch per inch of length

16

Basic pitch diameter at small end of extornal thread:

Eo =D —(0.0SD + 1.1)p

Basie pitch diameter at large end of internal thread:

By = Bo + 0.0625 Ly =D ~ 0.0625 p

Basic pitch diameter at large end of external thread:

Ey = Bo + 0.0625 Ly =D —0.675 p

Basie pitch diameter at small end of internal thread:

Ey = Bo — 0.0625 Ls =D — (0.05 D+ 1.2875) p

Basic length of thread for hand engagement:

1, =(08D+38)p

Basic length of full and effective thread:

Ly =@8D+68)p

Basic length of internal thread from end of hand en:

‘gigement, Ko, to small end of internal thread,

13 =3p

Tolerance shall be equal to plus or minus the taper

of one thread on the diamoter.

C.7 Designations

‘The designation for a fine thread series pipe thread

should include letter F and omit letterN, for example:

4-27 F-PTE, The designation for a special thread

Series pipe thread should include abbreviation SPL,

for special and omit letter. Also, the outside diameter

of tubing should be given, for example:

4-27 SPL-PTF, OD 0.500.

ASME 81.20-3 7b M@ 2595512 0021900 4 mm

ORYSEAL USA (AMERICAN.

StaNond SACHMME PALER re

THREAD, DESIGNATED AS:

NEE

ORYSEAL USA (AMERICAN)

STANDARO INTERNAL TARER PIPE

THREAD, DESIGNATED AS!

‘ONE THREAD

DRYSEAL SAE SHORT.

EXTERNAL TapeR PIPE

‘THREAD, GESIONATED As:

PTF-SAE SHOFT |

fe-one THREAD

Ee

RYSEAL SAE SHORT.

INTERNAL TAPER PIPE

‘THREAD, DESIGNATED AS:

BIFSSAE SHORT

E Es

DAYSEAL SPECIAL sHoRT

ie EXTERNAL TAPER PIPE

t "THREAD, DESIGNATED As:

PTFSSPL SHORT

ONE THREAD

| opvseas seeciat shomr

INTERNAD TAPER Pipe

THREAD, DESIGNATED Ast

\ BTRSSPL SHORT

ONE THREAD

ORYSEAL SPECIAL ExrRA SHORT

EXTERNAL TAPER PIPE

‘THREAD, GESIGNATED Ast

PTe-SPCEXTRA SHORT

He fone THREAD

Ee

ORYSEAL SPECIAL EXTRA SHORT

INTERNAL TAPER PIPE

THREAD, DESIGNATED Ast

t PTESSPUERTAA SHORT

E,

FIG C1 COMPARISON OF SPECIAL LENGTH DRYSEAL THREADS WITH STANDARD

LENGTH DRYSEAL THREADS

7

“ASME B1-20-3 7b M™ 2595512 OOL190) 6 mm

iano enenceenr (Li)+L3

LLatagp sHouvoer LeNoT#t

LAT MAX.INT, THO. PD,

—— | —

“FONE TURN FOUL THREAD

LA

L 4 4 ook bo, TNRBRE 5

Table C1 Basic Dimensions of Dryseal Fine Taper Pipe Thread, F-PTF

n Vanish Ths

ent ret ee | een Length | V Plus Full by wide Outsideloutside

ich | Smut | Tamme | tarse | Small | and oral, | tad tat FRO!) tues | Di | Dia

Sie | “(| orext | otnt | ortxt | of tne | Pavanoment | Mhvoadts ruver | a | yen et poe

a(t L,) fine 4, +2,)) shoulder Draw | Fitting| Pipe

Thread | Thread | Thread | Thread 3)

foal oman marlin. REX GL) | Clearance 0) | ©

" ‘ ® lev 1p +0)

Tach | Inch | inch | Inch | Inch | inch [Thad | tnch [thd | inch [tha | toh | incn [tha | toch | tach

% — 27 [0.03708 [0.49826 [0.30807 [o.sisot |o9132 | 0.157| 4.23| 0.268 | 7.23]0.1296| 3 [oa97s foaini| 3.0 | o.s46| 0.540

%~ 21 {0.03708 | 0.63301 | 0.68307 | 0.65001 0.62607 | 0.161 | 4.34) 0.272 | 7.34]0.1296 | 3.5 Joaois patst| 30 | ost | o67s

4% ~ 18] 0.05886 | 0.77655 | 0.79205 | 0.80249 | 0.76613 | 0.248 | 4.47] o.ats | 7-47 o-1944 | 33 | 0.6096 fo.t67| 3.0 | 0.850 | 0.840

24 ~ 18] 0.08556 | 0.98597 | 1.00210 | 1.01247 | 0.97558 | 0.258 | 4.68] 0.424 | 7.68]0.1940| 3.5 |0.6189 fo.is67| 3.0 | 1.060] 1.050

1 ~ 14 ]o.07s43 |1.23173 | 1.28342 | 1.26679 | 1.21834 | 0.347| 4s] 0.561 | 7.85 ]0.2800 | 3.5 Jo.s109 o.2143| 3.0 | 1.327] 131s

1% — 14 Jo.o7143 | 1.57550] 1.59837 | 1.61181 | 56211 | 0.366 | 5.13] 0-581 | 8.13]0.2500 | 3.5 |0.8306 fo.2143| 3.0 | 1.672 | 1.660

v4 = 14 [0.07143 | 1182466 | 1.83839 | 185176 | 1.80125 | 0.380 | 5.32] 0.594 | 8.32|0.2500 | 35 Jo.seas fo2ids| 30 | 1.912 1900

2. ~ 14 [0.07143 [2.28794] 2.31338 [2.32675 | 227485 | 0.407 | 5:70] 0.621 | a.70]0.2500| 3.5 [o.a7sa fo.2143| 3.0 | 2.387 | 2.375

1 External thread tabulated full hread ongths include chamfors not exceeding one pitch (thread) longth

S Internal thgead tabulated fal thread lengths do not Include countersink beyond the Intersection of the pitch line and the chamfer cone (eating

reference poi)

ASME 81.20-3 7b MM 2595512 0011902 8 mm

HaNo enoacewenr (Li)+ Lo

Se ae Pace aga PF AT MAK UT THO PD

Lgt347P SHOULOER LENGTH.

Table C2_ Basic Dimensions of Dryseal Spacial Taper Pipe Thread, SPL-PTF

(For Thin Wall Nominal Size OD Tubing)

Put | Pat

tage | tame Length of Full hea

Tubing Pitch Endo | ado Boch at Thread a

De | se | Ow tn | ext een at dysly® |,

‘Thread | Thread " Ext i

@) |

Tosh ich | toh | Inch | toon [td _| toon [ted] tne | Tht

03704 [045093 Jos6a0s [o47so0 foasia [oasse | 42 |o2se7 | 72 [oun | 30

0.03708 |o.s8310 [0.59308 [0.0000 fosreis {ois9s | 43 |o2ms | 73 Joa | 30

‘203706 [0.10787 [ora180s [o.72500 |o.70093 Joes0 | 44 [oar | 74 Joan | 30

1.03708 [0.83264 [o.t430s loasooo Joaaszo foes? | 43 [oar | 73 Jou | a0

1.03704 Joasaso fo.sse0s |o97s00 foasoas {oro | 46 [oasis | 76 losin | 30

° ead lange lactde chamfers not excedlag one pitch (head) lensth

This donoter nomin

ted full thd lengths do not include countersink beyond the intersection of the pitch Hne andthe chamfer

otnt).

Dutsile diameter of tubing and should not be confused with nominal pipe diameter and

read designations.

Cy

QQ

ASHE 82.20-3 76 MM 2595512 0011903 T mm

AMERICAN NATIONAL STANDARDS FOR

SCREW THREADS, THREADING TOOLS AND FASTENERS

ISO Metric Screw Threads (not an ANSI Standard) codes eteee nese esses eee BL Report

Unified Inch Screw Threads (UN and UNR Thread Form). «200021222207 *BLI-1974

Gages and Gaging for Unified Inch Scrow Threads 1 B12-1974

‘Acme Screw Threads Fe 5 eee BI5-1973

Nomenclature, Definitions and Letter Symbols for Screw Threads... ........ BL7=1965 (R1972)

Stub Acme Screw Threads, - BLB-1973

Buttress Inch Scrow Threads 7°/45° Form with 0.6 Pitch Basi Hei of Thread) ngage BL9-1973

Unified Miniature Screw Threads . BI.10-1958

Microscope Objective Thread. 1958 (R1972)

Class 5 Interforence-Fit Thread obs0e on cennuenmace BLI2-1972

“American Gaging Practice for Metric Screw Thueads, 2222222222222 IILIIN prieasn

Hose Coupling Screw Threads : 1-196 (R1974)

‘Taps-Cut and Ground Threads : B94.9-1971

Twist Drills. : ‘B94.1Li967 (R1972)

Small Solid Rivets - BIB.

Large Rivets... ‘i SaSEOSeoouUEG ee pists

Square and Hex Bolts and Sorews. 222020222. is2!

Square and Hex Nuts. . : oe feeetss: BI8.2.2-1972

Socket Cap, Shoulder and Sa Screws os ee gels

Round Head Bolts. Snegeeonndesccdad Bia

Wood Screws LITT bis.6.1-1972

Slotted Head Cap Screws, Sau ead Sot Soevs and Slotted Headles Set Screws +++ BI8.6.2-1972

‘Machine Screws and Machine Screw Nuts. ... . . 5 +B18.6.3-1972

Slotted and Recessed Head Tapping Screws and Metallic Drive Screws, - 1. 1 Bi8.614-1966 (R1975)

oneal Purposs Sr Tubuar Rivets, ull Tubular Rivets and Riot Caps : BI8.7-1972

levis Pins and Cotter Pins een a : BI8.8.1-1972

Plow Bolts B18.9-1958 (R1971)

‘Track Bolts end Nuts | + BIB.10-1963 (1975)

Miniature Screws... . dog o + BI8.11-1961 (R1975)

Glossary of Terms for Mechanical Fasteners fees ee eS D172 B1si12-1962 (R1975)

‘Screw and Washer Assemblies~SEMS : + BI8.13-1965 (R1975)

Forged Byebolts . Sogcocosee Dilee ets. BI8.15-1969

Wing Nuts, Thumb Secews and ing Screws | 5 B18.17-1968 (1975)

Lock Washers . ToL... B18.21,1-1972

Plain Washers . ee B18.22.1-1965 (R1975)

Beveled Washers «1.11... 5 Beprenoana +++ B18.23.1-1967 (R1975)

3 ‘No0076

— ——

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Lead Sheet 716-X000Document1 pageLead Sheet 716-X000Chandhu Kurian ThampiNo ratings yet

- Blickel Caster Antistatic-1Document2 pagesBlickel Caster Antistatic-1Chandhu Kurian ThampiNo ratings yet

- Structural Steel: BS EN 1090Document1 pageStructural Steel: BS EN 1090Chandhu Kurian ThampiNo ratings yet

- LH ALTH 101K 3 FI AS - 852511 - 0 - 0 - 0 - enDocument2 pagesLH ALTH 101K 3 FI AS - 852511 - 0 - 0 - 0 - enChandhu Kurian ThampiNo ratings yet

- City Pool - Policy InfoDocument6 pagesCity Pool - Policy InfoChandhu Kurian ThampiNo ratings yet

- DS DIN 11864-1 11850 Aseptic Unions PDFDocument7 pagesDS DIN 11864-1 11850 Aseptic Unions PDFChandhu Kurian ThampiNo ratings yet

- CME4002 Hydrogen Economy: Professor K M ThomasDocument31 pagesCME4002 Hydrogen Economy: Professor K M ThomasChandhu Kurian ThampiNo ratings yet

- Magnetic Characterisation O F Giant Magnetoresistance (GMR) EffectsDocument12 pagesMagnetic Characterisation O F Giant Magnetoresistance (GMR) EffectsChandhu Kurian ThampiNo ratings yet