Professional Documents

Culture Documents

14ATCE Tech Sess 43 SPE 170812 Final

14ATCE Tech Sess 43 SPE 170812 Final

Uploaded by

romedic36Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

14ATCE Tech Sess 43 SPE 170812 Final

14ATCE Tech Sess 43 SPE 170812 Final

Uploaded by

romedic36Copyright:

Available Formats

SPE 170812

Ensuring The Safety Of Onsite Personnel And

Neighboring Community During Workover And Welltesting Activities With A High H2S Risk Potential - A Case

Study

Hughes Warwick Stanley, OMV Petrom; Andrea Ferrante and Elie Daher, United Safety

Slide 2

The Challenge of Sour Gas

Hydrogen sulfide attacks the respiratory and CNS

of the victim resulting in death at around 1000 ppm.

Slightly heavier than air. Communities situated

downwind are at high risk.

Ensure the safety of personnel and neighboring

community by following industry standards.

SPE 170812 Ensuring The Safety Of Onsite Personnel And Neighboring Community During

Workover And Well-testing Activities With A High H2S Risk Potential - A Case Study

Hughes Warwick Stanely, Andrea Ferrante and Elie Daher

Slide 3

The Site

Found 8% H2S and 24%

CO2

Located 250 meters away

from nearby village

Population: approximately

4,500

A failure or gas release

could have severe

consequences.

Google map of 20 Adjud Exploration Well

SPE 170812 Ensuring The Safety Of Onsite Personnel And Neighboring Community During

Workover And Well-testing Activities With A High H2S Risk Potential - A Case Study

Hughes Warwick Stanely, Andrea Ferrante and Elie Daher

Slide 4

Solution

Prevent exposure by:

Regular monitoring to

ensure no pressure build up

in the annulus or tubing.

Develop a site-specific

Emergency Response Plan

(ERP) and define

Emergency Planning Zone.

Conduct extensive H2S training.

Demonstrate competence through onsite and offsite drills.

Win support and confidence of local stakeholders.

SPE 170812 Ensuring The Safety Of Onsite Personnel And Neighboring Community During

Workover And Well-testing Activities With A High H2S Risk Potential - A Case Study

Hughes Warwick Stanely, Andrea Ferrante and Elie Daher

Slide 5

Solution: Planning Phase

September 2012

Review of 20 Adjud

project and initial

HAZID and Needs

assessment.

November 2012

Definition of

vocational training

needs, gap analysis

and breathing air

equipment needs

assessment.

October 2012

First draft for site

and public

protection Gas

Detection Layout to

be reviewed upon

EPZ availability.

January 2013

Operator full HAZID

exercise involving

partners, contactors

and subcontractors.

December 2012

Monitoring Wind

Speed and

Direction.

March 2013

Safety company

conducts intensive

H2S/ERP training

campaign prior to

start of project.

February 2013

Finalize EPZ and

ERP, customization

of H2S detection

and protection

measures.

SPE 170812 Ensuring The Safety Of Onsite Personnel And Neighboring Community During

Workover And Well-testing Activities With A High H2S Risk Potential - A Case Study

Hughes Warwick Stanely, Andrea Ferrante and Elie Daher

Slide 6

Solution: Identifying the EPZ and EAZ

Emergency Planning Zone

Emergency Awareness Zone

EAZ (600 meters)

Nearest

Village

To town 2 Km.

To village 1 Km.

Slide 7

Solution: Wind Direction Study

Wind speed and direction data

as component for dispersion

models

Wind data was considered in

locating briefing (muster) areas.

Two areas were selected as safe

briefing (muster) areas.

Conducted four months of monitoring to make statistically

valid conclusions.

SPE 170812 Ensuring The Safety Of Onsite Personnel And Neighboring Community During

Workover And Well-testing Activities With A High H2S Risk Potential - A Case Study

Hughes Warwick Stanely, Andrea Ferrante and Elie Daher

Slide 8

Solution: Monitoring and Detection Equipment

Fixed H2S monitoring and detection

system

Audible and visual warning alarms

Emergency battery power back-up

Multi-gas detector

Measure atmospheric concentrations up

to 300 ppm

H2S and SO2 Monitor

Placed close to the houses and village

area

Personal H2S monitors for all personnel

SPE 170812 Ensuring The Safety Of Onsite Personnel And Neighboring Community During

Workover And Well-testing Activities With A High H2S Risk Potential - A Case Study

Hughes Warwick Stanely, Andrea Ferrante and Elie Daher

Slide 9

Solution: Warning and Alarm Systems

Location of H2S warning alarms, audible and visual:

Drillers console (audible and light)

Engine's area (audible and light)

Mud pit area (audible and light)

Living quarters (audible at all levels)

Main office of the rig (audible and light)

Shale shakers area (audible and light)

Wellsite perimeter fence alarm sirens

112 dB with three activation buttons

Manually activated by the Well Services Supervisor

SPE 170812 Ensuring The Safety Of Onsite Personnel And Neighboring Community During

Workover And Well-testing Activities With A High H2S Risk Potential - A Case Study

Hughes Warwick Stanely, Andrea Ferrante and Elie Daher

Slide 10

Solution: Proper Training

H2S Awareness &

Emergency Response

Training of personnel and

local firefighting brigade

Proper equipment

maintenance

Community outreach and

education

Date of

Training

March

2011

April

2013

May

2013

Venue/

Location

20 Adjud

Well

20 Adjud

Well

20 Adjud

Well

Total No. of Participants

No. of

Participants

161

227

37

425

SPE 170812 Ensuring The Safety Of Onsite Personnel And Neighboring Community During

Workover And Well-testing Activities With A High H2S Risk Potential - A Case Study

Hughes Warwick Stanely, Andrea Ferrante and Elie Daher

Slide 11

Solution: Offsite and Onsite Drills

One drill every three days.

Emergency H2S drills conducted prior

to entry into a known, unknown or

suspected H2S zone.

Prior to special operations such as

venting, wireline, coiled tubing, and

well-testing operations.

20 emergency H2S muster, man

down and evacuation drills

conducted while testing.

Drills

Emergency muster

Use of Self-Contained

Breathing Apparatus

(SCBA)

Use of cascade system

Rescue procedure

Emergency evacuation

procedures

SPE 170812 Ensuring The Safety Of Onsite Personnel And Neighboring Community During

Workover And Well-testing Activities With A High H2S Risk Potential - A Case Study

Hughes Warwick Stanely, Andrea Ferrante and Elie Daher

Slide 12

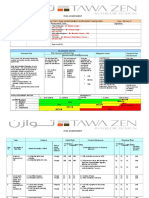

Emergency Levels and Response Strategies

Category 1

Low alarm condition

10ppm H2S and/or

2ppm SO2

Stop work,

investigate alarm

Report incident and

remedy

Return to work

Category 2

High alarm condition or

danger to life condition at

the rig site

20ppm H2S and/or

5ppm SO2

Stop work, investigate

alarm

Remedy if possible

Return to work

Evacuate well site if

necessary

Shut in well if

necessary

Stop flaring if

necessary

Ignite rig if necessary

Category 3

High alarm, danger

outside rig site

20ppm H2S and/or

5ppm SO2

Stop work and

investigate alarm

Remedy if possible

Return to work

Evacuate well site if

necessary

Shut in well if

necessary

Stop flaring if

necessary

Ignite rig if

necessary

Evacuate village as

necessary

Slide 13

Emergency Response Guideline

Level 1

Evaluation

Criteria

Within

Monitoring

Zone

Evaluation

Criteria

Within

Monitoring

Zone

Isolation

Personnel

H2S / SO2

Monitoring

Observation

Post

Entry Control

Point

Level 2

Level 3

1ppm H2S

2 9 ppm H2S

10 ppm H2S

Alert mode and monitor

concentrations.

Monitor concentrations and

request to Shelter-in-Place.

Immediate evacuation must

take place.

1ppm SO2

2 ppm SO2

5 ppm SO2

Advise public to evacuate

area on a voluntary basis.

Evacuation of the area should Evacuation is mandatory.

begin.

Roadblock set up at site

security checkpoint.

Roadblocks set up based on

wind direction within EPZ or

at outer edge.

Roadblocks set up based on

wind direction at outer

perimeter of the EPZ. May

expand into the EAZ.

Only authorized personnel Authorized personnel within

Authorized personnel within

on site.

affected area.

EPZ.

Within the well location, set Within the well location, set up mobile monitor based on wind

up mobile monitor around

conditions and direction between wellsite and public.

wellsite.

Determine outer perimeter of plume.

Personnel requested to be mobile. Follow evacuation routes

Alert Standby

and remain in contact with H2S Safety personnel to

determine the extent of zone expansion.

Alert Standby

Slide 14

Results: Active Role of Community

Engaged local mayors office

Voluntary

evacuation at Level 1 for special needs residents

Mandatory evacuation at Level 2

Provide Shelter Reception Center

Engaged ISU Vranca

Produced

an ISU intervention plan.

Informs public in the Emergency Awareness Zone

Evacuation starts with closest communities/situated downwind.

Win support of local community

Offsite

drills showed competence in emergency response.

Evacuation as primary protection measure.

Well-testing and workover operations ran smoothly.

SPE 170812 Ensuring The Safety Of Onsite Personnel And Neighboring Community During

Workover And Well-testing Activities With A High H2S Risk Potential - A Case Study

Hughes Warwick Stanely, Andrea Ferrante and Elie Daher

Slide 15

Conclusion

Value of continuous personnel training

Continuous improvement improves workforce efficiency reducing

operating costs through lesser incidents and productivity losses.

Increased public confidence in operator

Practice transparency. Communicate risks involved in operations.

Emergency drills showed competence to respond appropriately in

case of emergencies.

Setting a new benchmark for safety in the region

Establish a working relationship with a dedicated safety solutions

provider to lead the safety program implementation and improve

the reputation and overall sustainability of the Oil and Gas

industry.

SPE 170812 Ensuring The Safety Of Onsite Personnel And Neighboring Community During

Workover And Well-testing Activities With A High H2S Risk Potential - A Case Study

Hughes Warwick Stanely, Andrea Ferrante and Elie Daher

Slide 16

Works Cited

American Petroleum Institute. API Recommended Practices 49 Recommended Practice for Drilling and Well Servicing

Operations Involving Hydrogen Sulfide. Washington, D.C.: API, 2001.

American Petroleum Institute. API Recommended Practices 55 Recommended Practice for Oil and Gas Producing and Gas

Processing Plant Operations Involving Hydrogen Sulfide. Washington, D.C.: API, 2005.

American Petroleum Institute. API Recommended Practices 68 on Oil and Gas Well Servicing and Workover Operations

Involving Hydrogen Sulphide. Washington, D.C.: API, 1998.

ECD. Commission Directive 2009/161/EU of 17 December 2009. Official Journal of the European Union: L 338,

87-89. 2009. http://eur-lex.europa.eu/legalcontent/EN/TXT/PDF/?uri=CELEX:32009L0161&from=ENlex.europa.eucontent/EN/TXT/PDF/?uri=CELEX:32009L0161&fro

m=EN (accessed March 31, 2014).

Occupational Safety and Health Administration. Oil and Gas Well Drilling and Servicing eTool: General Safety and Health

Hydrogen Sulfide Gas. https://www.osha.gov/SLTC/etools/oilandgas/general_safety/h2s_monitoring.html_br (accessed

March 7, 2014).

Pachiu L., Mustaciosu R., and Dudau R. Oil and gas regulation in Romania: Overview. Energy and Natural Resources MultiJurisdictional Guide (2014).

http://uk.practicallaw.com/cs/Satellite?blobcol=urldata&blobheader=application%2Fpdf&blobkey=id&blobtable=MungoBlobs&

blobwhere=1247833806217&ssbinary=true (accessed April 15, 2014).

Slide 17

Acknowledgements / Thank You / Questions

Warwick Stanley Hughes

Senior Completions Engineer

OMV PETROM S. A.

Petrom City

4th Floor, B 500

No 22 Coralilor, Sector 1

Bucharest, Romania

Mob: 0040 (0) 732 820 202

Email: Hughes.Warwick@petrom.com

Andrea Ferrante

Business Development Manager

Servizi Integrati di Sicurezza S.r.l.

United Safety Int. Group

Via Mare Adriatico 72/E 65010

Spoltore (PE) Italy

Tel: +39 085 4971521

Fax: +39 085 4973121

Mob: +39 348 7071 906

Email: andrea.ferrante@sisworld.net

You might also like

- John Deere 4055 4255 4455 4555 4755 4955 Shopmanual Sec WatDocument20 pagesJohn Deere 4055 4255 4455 4555 4755 4955 Shopmanual Sec Watdoris97% (32)

- Generic Risk AssessmentDocument8 pagesGeneric Risk Assessmentmorgojoyo100% (3)

- Fire Mock Drill Report - Sample - Rls Human CareDocument6 pagesFire Mock Drill Report - Sample - Rls Human CareTalent mvproductionNo ratings yet

- CHAPTER 4 Restaurant ReviewsDocument9 pagesCHAPTER 4 Restaurant ReviewsElvan RamadyaNo ratings yet

- Risk Assessment and Method Statement: Project InformationDocument9 pagesRisk Assessment and Method Statement: Project InformationYuri NovichenkoNo ratings yet

- Emergency Management Plan - 20130319 CommentedDocument14 pagesEmergency Management Plan - 20130319 Commentedkirandevi1981No ratings yet

- Method Statement & Risk Assessment: Industrial Security Doors LTDDocument8 pagesMethod Statement & Risk Assessment: Industrial Security Doors LTDNathi MaphangaNo ratings yet

- ADCO Interview Quesiton and AnswerDocument5 pagesADCO Interview Quesiton and AnswerAmal Jagadi100% (2)

- Section B G Safe Helicopter Operations in Support of The Global Offshore Wind IndustryDocument115 pagesSection B G Safe Helicopter Operations in Support of The Global Offshore Wind Industryromedic36No ratings yet

- Chapter 06 - Behind The Supply CurveDocument90 pagesChapter 06 - Behind The Supply CurveJuana Miguens RodriguezNo ratings yet

- Element Seven: Risk Management & Contingency PlanDocument15 pagesElement Seven: Risk Management & Contingency Planapi-3738896No ratings yet

- Rules and Guidelines For Safety in E&P Operations & Contingency PlanningDocument18 pagesRules and Guidelines For Safety in E&P Operations & Contingency PlanningRavikumar mahadevNo ratings yet

- HSE PLAN Generic RA PDFDocument5 pagesHSE PLAN Generic RA PDFテレブリコ ジェファーソン100% (1)

- Colloquium 2012 Risk AssessmentDocument6 pagesColloquium 2012 Risk AssessmentCraig Darryl Skull PeadeNo ratings yet

- ADCO Interview Quesiton and Answer-1Document4 pagesADCO Interview Quesiton and Answer-1Behraz Ismail100% (1)

- Volume 1 Focus PDFDocument47 pagesVolume 1 Focus PDFAjay Kumar GuptaNo ratings yet

- 02.emergency Services Rev.1Document8 pages02.emergency Services Rev.1arunmirandaNo ratings yet

- Emergency Response PlanDocument8 pagesEmergency Response PlanMuhammad ShafiqueNo ratings yet

- Induction Slide ASGDocument19 pagesInduction Slide ASGSami UllahNo ratings yet

- Health & Safety Inspection Report No.18. ReplyDocument11 pagesHealth & Safety Inspection Report No.18. Replyloveson709100% (2)

- Safety Questionnairre / Test: Emergency Removal of Sick or Injured People From An AreaDocument8 pagesSafety Questionnairre / Test: Emergency Removal of Sick or Injured People From An AreaHasrul SunNo ratings yet

- Drop Cover HoldOn PublicAdministratorsDocument69 pagesDrop Cover HoldOn PublicAdministratorsRuby RoseNo ratings yet

- Emergency Response - MasonDocument20 pagesEmergency Response - MasonMario PetrovichNo ratings yet

- The University of Faisalabad: Environmental Engineering-IIDocument47 pagesThe University of Faisalabad: Environmental Engineering-IINomi khanNo ratings yet

- Coronavirus (COVID-19) Local Highways Safe Operating Procedures - Protecting Our Workforce Guidance DocumentDocument12 pagesCoronavirus (COVID-19) Local Highways Safe Operating Procedures - Protecting Our Workforce Guidance DocumentMILENKA YSABEL UCEDA PUICONNo ratings yet

- 13/02/2013 Ir Radioactive Source Stuck Outside Industrial Radiography ContainerDocument10 pages13/02/2013 Ir Radioactive Source Stuck Outside Industrial Radiography ContainerHari krishnanNo ratings yet

- 2023 Decon SOPsDocument47 pages2023 Decon SOPsBV GutzNo ratings yet

- Trench Rescue Technician LevelDocument28 pagesTrench Rescue Technician LevelForum Pompierii100% (1)

- H2S Contingency PlanDocument33 pagesH2S Contingency PlanAnonymous JMuM0E5YO100% (1)

- Hazard Descriptions PDFDocument19 pagesHazard Descriptions PDFShakeel AhmedNo ratings yet

- 2013 SHDocument88 pages2013 SHeastNo ratings yet

- Emergency Procedures PDFDocument13 pagesEmergency Procedures PDFMalik Khuram ShazadNo ratings yet

- Approved Hemp For Installation of New Crude Oil Heater Package at Dps Dal-13-110Document12 pagesApproved Hemp For Installation of New Crude Oil Heater Package at Dps Dal-13-110Roshin99No ratings yet

- Failure To Recognise Hydrogen Sulphide Hazards: Lessons Not Learned - Part 6Document3 pagesFailure To Recognise Hydrogen Sulphide Hazards: Lessons Not Learned - Part 6Ardhendu SamantaNo ratings yet

- Risk Assessment: Project Manager Project Engineer HSE Officer/engineer First AiderDocument5 pagesRisk Assessment: Project Manager Project Engineer HSE Officer/engineer First AiderOvais FarooqNo ratings yet

- Road SafetyDocument38 pagesRoad SafetyPtn DhavalNo ratings yet

- Alnajim Alzahir Co. - Emergency Evacuation Drill On 10-May-2022Document12 pagesAlnajim Alzahir Co. - Emergency Evacuation Drill On 10-May-2022Abdullah TwfeeqNo ratings yet

- Noise Hazards Associated With The Call Centre IndustryDocument9 pagesNoise Hazards Associated With The Call Centre IndustryBagas Zaki MNo ratings yet

- Waverley RAMSDocument16 pagesWaverley RAMSJakub WiechaNo ratings yet

- Fire Protection MethodsDocument3 pagesFire Protection MethodsEquilibrium EngineersNo ratings yet

- Hse QuestionaireDocument5 pagesHse QuestionaireAfshadNo ratings yet

- Nitric AcidDocument4 pagesNitric AcidTheresa PutriNo ratings yet

- Pollution PortDocument49 pagesPollution PortCorto MalteseNo ratings yet

- Emergency Plan Guidelines: Policy StatementDocument9 pagesEmergency Plan Guidelines: Policy StatementSaim AliNo ratings yet

- January 1: H.S.E. Questionnaire AnswersDocument38 pagesJanuary 1: H.S.E. Questionnaire AnswersAlam ShamsherNo ratings yet

- FRONT OFFICE SERVICES - Chapter 4Document33 pagesFRONT OFFICE SERVICES - Chapter 4Centienne BatemanNo ratings yet

- Safe WorkingDocument142 pagesSafe Workingrizonico0% (1)

- Procedure 36 5 Participate in A Mock Environmental Exposure EventDocument2 pagesProcedure 36 5 Participate in A Mock Environmental Exposure Eventparji santosaNo ratings yet

- Environmental TrainingDocument45 pagesEnvironmental Trainingali128100% (1)

- Emergency Response Plan and PreparednessDocument7 pagesEmergency Response Plan and Preparednessradha krishnaNo ratings yet

- Cifca-Admin-01v0 2Document11 pagesCifca-Admin-01v0 2api-288135784No ratings yet

- 1 - 074320 - EOP 1001 - Well Ignition GuidelinesDocument19 pages1 - 074320 - EOP 1001 - Well Ignition Guidelinesdaburto2No ratings yet

- CH 7Document33 pagesCH 7johnny chauNo ratings yet

- Emergency Response Planning Kec - Epc Waste Collection Area Constction - SibaDocument8 pagesEmergency Response Planning Kec - Epc Waste Collection Area Constction - SibaAli AlahmaNo ratings yet

- Table Top Exercise (Tte) Cc7 - Activity: 1 Intake-11: Name: Kamatchi Sundaram Neelakantan NRIC No: S 236JDocument14 pagesTable Top Exercise (Tte) Cc7 - Activity: 1 Intake-11: Name: Kamatchi Sundaram Neelakantan NRIC No: S 236JKamatchiNo ratings yet

- Hse Induction: Welcome To UMM AL HAYMAN-W 300/132/11 KV SubstationDocument61 pagesHse Induction: Welcome To UMM AL HAYMAN-W 300/132/11 KV SubstationJinadNo ratings yet

- OCP 123 Noise ProcedureDocument7 pagesOCP 123 Noise Procedurematam natarajNo ratings yet

- Operational Guidance Fire and Rescue Authorities: GRA 4.3 GRA 2.1.1Document26 pagesOperational Guidance Fire and Rescue Authorities: GRA 4.3 GRA 2.1.1mulyadiNo ratings yet

- Medical Centre Exemplar - Supporting DocumentsDocument7 pagesMedical Centre Exemplar - Supporting DocumentsRamesh MishraNo ratings yet

- Occupational Radiation Protection in the Uranium Mining and Processing IndustryFrom EverandOccupational Radiation Protection in the Uranium Mining and Processing IndustryNo ratings yet

- Experience in the Management of Radioactive Waste After Nuclear Accidents: A Basis for PreplanningFrom EverandExperience in the Management of Radioactive Waste After Nuclear Accidents: A Basis for PreplanningNo ratings yet

- Radio Receiver Technology: Principles, Architectures and ApplicationsFrom EverandRadio Receiver Technology: Principles, Architectures and ApplicationsNo ratings yet

- Walking Is WorkingDocument1 pageWalking Is Workingromedic36No ratings yet

- Fatality During The Erection of Telecom Tower. ENGDocument4 pagesFatality During The Erection of Telecom Tower. ENGromedic36No ratings yet

- WTSR 4th Edition P1 Approval of General ProvisionsjkDocument12 pagesWTSR 4th Edition P1 Approval of General Provisionsjkromedic36No ratings yet

- Turbine Inspection Checklist - SafetyCultureDocument21 pagesTurbine Inspection Checklist - SafetyCultureromedic36No ratings yet

- WTSR 4th Edition P6 Procedure The Appointment of Persons v1jkDocument35 pagesWTSR 4th Edition P6 Procedure The Appointment of Persons v1jkromedic36No ratings yet

- Captur 1007 8 - ENGDocument248 pagesCaptur 1007 8 - ENGromedic36No ratings yet

- QP CascadeDocument1 pageQP Cascaderomedic36No ratings yet

- TSK5UG GWO BST Manual Handling: The National Access and Rescue CentreDocument29 pagesTSK5UG GWO BST Manual Handling: The National Access and Rescue Centreromedic36No ratings yet

- Wind Project Safety Audit - SafetyCultureDocument22 pagesWind Project Safety Audit - SafetyCultureromedic36No ratings yet

- COUNCIL DIRECTIVE 96 82 EC On The Control of Major-Accident Hazards Involving Dangerous SubstancesDocument37 pagesCOUNCIL DIRECTIVE 96 82 EC On The Control of Major-Accident Hazards Involving Dangerous Substancesromedic36No ratings yet

- COMMISSION DIRECTIVE 2006 15 EC Establishing A Second List of Indicative Occupational Exposure Limit ValuesDocument4 pagesCOMMISSION DIRECTIVE 2006 15 EC Establishing A Second List of Indicative Occupational Exposure Limit Valuesromedic36No ratings yet

- Webversiong SBD Report WTG Access and Egress ReportjkDocument46 pagesWebversiong SBD Report WTG Access and Egress Reportjkromedic36No ratings yet

- G+ Safe by Design Workshop Report: WTG Access To The Transition Piece (Below Airtight Deck)Document37 pagesG+ Safe by Design Workshop Report: WTG Access To The Transition Piece (Below Airtight Deck)romedic36No ratings yet

- Flange Leak Testing ProgramDocument5 pagesFlange Leak Testing Programromedic36No ratings yet

- 10 Outlets Available: 7,5 Bar / 100 PsiDocument1 page10 Outlets Available: 7,5 Bar / 100 Psiromedic36No ratings yet

- Section A G Safe Helicopter Operations in Support of The Global Offshore Wind IndustryDocument23 pagesSection A G Safe Helicopter Operations in Support of The Global Offshore Wind Industryromedic36No ratings yet

- Good Practice Guideline The Safe Management of Small Service Vessels Used in The Offshore Wind Industry 2nd EditionDocument105 pagesGood Practice Guideline The Safe Management of Small Service Vessels Used in The Offshore Wind Industry 2nd Editionromedic36No ratings yet

- G+ Safe by Design Workshop Report Update: WTG Service Lifts - Follow-Up On Workshop ConclusionsDocument52 pagesG+ Safe by Design Workshop Report Update: WTG Service Lifts - Follow-Up On Workshop Conclusionsromedic36No ratings yet

- Intercompany Profit Transactions - BondsDocument50 pagesIntercompany Profit Transactions - BondsJeremy JansenNo ratings yet

- Concrete Discharge Time (ASCC)Document1 pageConcrete Discharge Time (ASCC)V. ManilalNo ratings yet

- Experiment No.4 Generatiton of Sequence With MATLABDocument12 pagesExperiment No.4 Generatiton of Sequence With MATLABDaniel BobisNo ratings yet

- Formal Treason Claim (S) Reported To The Office Massachusetts Governor Charlie Baker (R-Ma)Document3 pagesFormal Treason Claim (S) Reported To The Office Massachusetts Governor Charlie Baker (R-Ma)Mohan Harihar100% (1)

- SECOND Semester, AY 2022-2023: Mission VisionDocument34 pagesSECOND Semester, AY 2022-2023: Mission Visionjeyyy BonesssNo ratings yet

- Training Memorandum of Agreement/Waiver: Polytechnic University of The Philippines Quezon City BranchDocument3 pagesTraining Memorandum of Agreement/Waiver: Polytechnic University of The Philippines Quezon City BranchAnton ArponNo ratings yet

- Salconmas SDN BHD V Ketua Setiausaha Kementerian Dalam Negeri & AnorDocument24 pagesSalconmas SDN BHD V Ketua Setiausaha Kementerian Dalam Negeri & AnorZueidriena HasanienNo ratings yet

- Digital Camer A Remote Control Cell Phone Mp3 Player Telephone Audio System Compac T DiskDocument3 pagesDigital Camer A Remote Control Cell Phone Mp3 Player Telephone Audio System Compac T Diskfelipe100% (1)

- Chapter N Shear CenterDocument6 pagesChapter N Shear CenterDem Austria EspinoNo ratings yet

- Company Profile CLS-SDocument12 pagesCompany Profile CLS-SwagihNo ratings yet

- Module I. Obligations and ContractsDocument3 pagesModule I. Obligations and ContractsMa Leslie BuhanghangNo ratings yet

- Corrosion in MetalsDocument5 pagesCorrosion in MetalsJitendra KumarNo ratings yet

- Competitive Tactics: TacticDocument18 pagesCompetitive Tactics: TacticRaniella SarmientoNo ratings yet

- Business Form Three Term 3 Holiday AssignmentDocument4 pagesBusiness Form Three Term 3 Holiday Assignmentbalozi training InstituteNo ratings yet

- Simple Circuit Design Tutorial For PoE ApplicationsDocument10 pagesSimple Circuit Design Tutorial For PoE ApplicationsTayyeb AliNo ratings yet

- V11 EngDocument10 pagesV11 EngMuhammad SalmanNo ratings yet

- Duolingo 50 Words Essay Questions and AnswerDocument7 pagesDuolingo 50 Words Essay Questions and AnswerMaria AgnesNo ratings yet

- Nestle Waters Forecasting Improv Ment SlidesDocument37 pagesNestle Waters Forecasting Improv Ment Slidesamitwin1983No ratings yet

- A Meta-Analysis of Passive Descent Versus Immediate Pushing in NulliparousDocument10 pagesA Meta-Analysis of Passive Descent Versus Immediate Pushing in NulliparousNoraNo ratings yet

- Roger Goodell's Memo To NFL TeamsDocument2 pagesRoger Goodell's Memo To NFL TeamsThe Denver PostNo ratings yet

- Oracle Access ManagerDocument22 pagesOracle Access ManagerMohamed Omar SileemNo ratings yet

- Vesda Laser Focus 250Document2 pagesVesda Laser Focus 250WERMERMNo ratings yet

- Triple Compliant, Lightweight, Flexible ArmorDocument1 pageTriple Compliant, Lightweight, Flexible ArmorvictoriaNo ratings yet

- Tec Recruitment 2021Document5 pagesTec Recruitment 2021RAJ MENo ratings yet

- Japan, US Struggle To Find Crashed Jet and Its 'Secrets': Tokyo (AFP)Document2 pagesJapan, US Struggle To Find Crashed Jet and Its 'Secrets': Tokyo (AFP)Annastasya ParestiNo ratings yet

- Database Design: INFO2040 Distributed Computing Technologies TopicsDocument11 pagesDatabase Design: INFO2040 Distributed Computing Technologies TopicsTriztan Sutrisno RompasNo ratings yet

- Part List 2630.180 - 2640.180Document20 pagesPart List 2630.180 - 2640.180Otoniel Cardenas100% (1)