Professional Documents

Culture Documents

HOS (Heavy Oilfield Separable Compressor) Brochure

HOS (Heavy Oilfield Separable Compressor) Brochure

Uploaded by

akamalapuriCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HOS (Heavy Oilfield Separable Compressor) Brochure

HOS (Heavy Oilfield Separable Compressor) Brochure

Uploaded by

akamalapuriCopyright:

Available Formats

Hos COMPRESSORS

YOUR AUTHORIZED PACKAGER

YOUR AUTHORIZED PACKAGER

YOUR AUTHORIZED PACKAGER

ONE SHIP CANAL PARKWAY BUFFALO, NY 14218

PH: +1.716.362.9550 WWW.COBEY.COM

ONE SHIP CANAL PARKWAY BUFFALO, NY 14218

PH: +1.716.362.9550 WWW.COBEY.COM

ONE SHIP CANAL PARKWAY BUFFALO, NY 14218

PH: +1.716.362.9550 WWW.COBEY.COM

YOUR AUTHORIZED PACKAGER

YOUR AUTHORIZED PACKAGER

YOUR AUTHORIZED PACKAGER

HOS

compressors

The heavy oilfield separable

compressor for big jobs.

gas recovery, and many other

applications. They are suited not

only for sweet natural gas services,

but can be built to handle sour

natural gas, propane, carbon dioxide, air, nitrogen, and most other

gases.

As an alternative to more costly

other competing units, the HOS

compressor provides a platform

for process applications, but

retains key design features like

water-cooled cylinders and forcelubrication. The lower cost and

rapid delivery of packaged HOS

compressors can be applied to

hydrogen, nitrogen, and other process requirements.

With more than 15 years of experience in our closed-loop test facility

using a variety of field gases,

D-R assures the integrity of the

HOS compressor design and

performance.

Six-throw HOS compressor installed in China.

Dresser-Rand brings more than

60 years of separable compressor

operating experience to the heavyduty HOS compressor line.

These rugged compressors are

engineered for higher horsepower

gas field applications, including gas

lift, gas gathering, pipeline boosting, gas transmission, underground

gas storage (injection and withdrawal), fuel gas boosting, landfill

Rated to 7,200 hp (5370 kW) and

1,500 rpm with design pressures

up to and exceeding 6,600 psig

(455.05 bar), HOS compressors

provide long life due to their heavyduty construction. They are available in two-, four- or six-throw

configurations and in cylinder sizes

ranging from 3.75 (95.3 mm) to

26.5 (673.1 mm). The rigid, cast

iron compressor frame is heavily

ribbed and reinforced, with integrally cast crosshead extensions

to handle almost any gas field

requirement.

AVAILABLE IN GAS OR WATERCOOLED CONFIGURATIONS

HOS compressor cylinders are gascooled for most applications. For

special applications, the HOS

compressor is available with

water-cooled cylinders that provide

additional protection in higher

temperature services. Each system is designed and engineered to

match your operating needs.

Gas-cooled HOS cylinders utilize

a solid bore cylinder barrel cast

in nodular iron. The 26 (660.4

mm) / 26.5 (673.1 mm) cylinder

is a two-piece, valve-in-head type

cylinder.

Water-cooled HOS cylinders are

of similar construction, but are

jacketed for circulating coolant.

A full line-up of higher pressure,

forged steel cylinders are available

in sizes 3.75 (95.3 mm) to 6.5

(165.1 mm).

The line-up also includes a pipeline

cylinder for gas pipeline transmission and a storage cylinder for

gas injection and withdrawal

applications.

The HOS compressor uses either

solid or hollow aluminum or cast

iron pistons depending on service

conditions, balance, and inertia

forces. Integral steel pistons and

rods may be used in high-pressure

applications.

A SINGLE SOURCE FOR ALL

YOUR COMPRESSION NEEDS

HOS compressors offer many

benefits to gas compressor users,

whether used in a standard or

customized package, in rental

service, or purchased outright.

Dresser-Rand and its distributors

can provide single-source responsibility, including engineering, manufacturing, packaging, installation,

parts, and service.

With HOS compressors on the job,

you can expect less maintenance

and less fuel consumption. D-R

and its distributors support the

HOS compressor line with a

network of computerized parts

warehouses, and overhaul/revamp

facilities located throughout the

U.S. and Canada.

Rugged design for smooth operati

Every HOS compressor includes components

designed to enhance performance. The compressor

frame and cylinders are matched to provide years

of smooth, reliable, efficient compression service

when operated within OEM recommendations.

The open top frame construction ensures rigidity

while providing large access areas for maintenance

and inspection.

A full-length distance piece with an oversized door

also provides easy access. The unique thru-bolt

distance piece is designed for improved load

carrying ability. Cylinder performance is optimized

because multiple valve sizes can be used with the

same size cylinder. Large valve areas improve

efficiency, and oversized gas passages reduce

valve losses. Optional high-volume, manually

operated variable volume clearance pockets

provide clearance for greater capacity control.

High-strength, nodular iron

crossheads feature shim-adjustable

aluminum shoes at the top and

bottom. Surface-hardened crosshead

pins are full floating for optimum reliability. Crosshead pin bushings are tri-metal

bronze with babbitt overlay.

The heavy-duty forged a

is balanced and rifle-dr

lubrication. The cranksh

to reduce horizontal mo

are aluminum with micr

ion, long life, and efficiency.

D-R PF valve (with ported

valve sealing plate).

alloy steel crankshaft

rilled for pressure

haft is counterweighted

oments. Main bearings

ro-babbitt overlay.

D-R Magnum valve

(mini-Poppet element).

Both valves use D-Rs

exclusive Hi-Temp nonmetallic

wear parts material.

Precision aluminum alloy

main bearings have microbabbit overlay and are

pressure lubricated. Bronze

thrust shoes and two-piece

precision tri-metal bronze

crankpin bearings ensure

better heat dissipation,

reliability, and increased

life.

Forged steel connecting rods are rifle-drilled for

pressure lubrication and feature high-strength

bolts with rolled threads. Crankpin bearings are

tri-metal bronze with a micro-babbitt overlay

plate for added start-up protection and corrosion

resistance. Connecting rod pin bushings are

tri-metal bronze with babbitt overlay.

Induction-hardened AISI 4142 steel piston rods feature

rolled threads for optimum fatigue strength. Each piston

rod is wet-magnetic-particle inspected. Every piston rod

thread form is inspected using Johnson gauging.

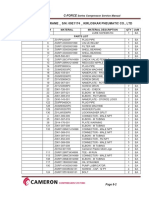

Ratings

Model

Stroke

in. (mm)

Number of

Cylinders

Nominal Rated

Power

hp (kW)

Max. Allowable

Operating Rod Load

lbs. (kN)

Rated

rpm

5HOS2

5 (127)

2,400 (1790)

60,000 (267)

1,500

5HOS4

5 (127)

4,800 (3580)

60,000 (267)

1,500

5HOS6

5 (127)

7,200 (5370)

60,000 (267)

1,500

6HOS2

6 (152.4)

2,000 (1492)

60,000 (267)

1,200

6HOS4

6 (152.4)

4,000 (2983)

60,000 (267)

1,200

6HOS6

6 (152.4)

6,000 (4475)

60,000 (267)

1,200

7HOS2

7 (177.8)

2,200 (1641)

60,000 (267)

1,000

7HOS4

7 (177.8)

4,400 (3281)

60,000 (267)

1,000

7HOS6

7 (177.8)

6,000 (4475)

60,000 (267)

1,000

Standard Features

Optional Features

A direct-drive, positive displacement gear-type frame lube oil

pump, with cooler and frame-mounted full-flow oil filter

Drilled, tapped, and plugged indicator holes on all cylinders

Vented, full-floating, filled Teflon packing rings with cast iron

back-up rings

Filled Teflon, multi-piece combination rings, that perform double

duty as both compression and rider rings

Variable volume clearance pocket

Frame-fed block distribution system

External frame oil relief valve

Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . One piece, cast iron, high-strength

Crosshead pins . . . . . . . . . . . . . . . . . . . . Alloy-steel, hardened, super-finished

Main bearings . . . . . . . . . . . . . . . . . . . . Aluminum with micro-babbit overlay

Crosshead pin bushings . . . . . . . . . . . . . . . . . . . . . . . . . . . .Tri-metal bronze

Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Forged steel

Piston rods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Alloy steel, rolled threads

Crankpin bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Tri-metal bronze

Connecting rods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Forged steel

Oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Gear-type, direct drive

Connecting rod bolts . . . . . . . . . . . . . . . . . . . . . . . . Alloy steel, rolled threads

Oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Full-flow, 10 micron

Connecting rod bushings . . . . . . . . . . . . . . . . . . . . . . . . . . . Tri-metal bronze

Oil cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Shell-and-tube

Crossheads . . . . . . . . . . . . . . Nodular iron, shim-adjustable aluminum shoes

Lubricator . . . . . . . . . . . . . . . . . . . . . . . . . . . . Flange mounted, direct drive

26.50 (673.1)

26.00 (660.4)

24.50 (622.3)

23.00 (584.2)

22.00 (558.8)

20.50 (520.7)

19.00 (482.6)

17.50 (444.5)

16.25 (412.7)

15.00 (381.0)

14.00 (355.6)

13.00 (330.2)

12.25 (311.1)

11.50 (292.1)

10.50 (266.7)

9.50 (241.3)

8.00 (203.2)

7.00 (177.8)

6.00 (152.4)

280 (19.69)

280 (19.69)

280 (19.69)

350 (24.61)

350 (24.61)

470 (33.04)

470 (33.04)

545 (38.32)

600 (42.18)

745 (52.38)

750 (52.73)

855 (60.1)

1050 (73.82)

1265 (89.0)

1650 (116.0)

1925 (135.4)

2200 (154.7)

2750 (193.3)

2750 (193.3)

4.75 (120.7)

3.75 to 7.00

(95.3 to 177.8)

2750 (193.3)

6600 to 4000

(422 to 281)

MAWP

psig

(kg/cm2)

No Jacket

495 (34.8)

644 (45.3)

855 (60.1)

1025 (72.1)

1265 (89.0)

1595 (112.2)

1650 (116.0)

1925 (135.4) &

2750 (193.3)

1925 (135.4)

Torsional studies

Flywheel (if required)

Dynamic valve analysis

Pump-to-point cylinder lubrication

Electric drive lubricator

Dual oil filter

Automatic unloading devices

Manual frame pre-lube pump

83.12"

2111.2 mm

48"

48"

42.12"

1219.2 mm 1219.2 mm 1069.8 mm

42.12"

1069.8 mm

B

C

B

D

48"

48"

32.88"

1219.2 mm 1219.2 mm 835.1 mm

Standard Cylinder offering and dimensions

MAWP

psig

(kg/cm2)

Jacketted

179.12" (4549.6 mm) (6 throw)

104.4" (2651.7 mm) (4 throw)

Frame Specifications and Dimensions

Cylinder

Size

in. (mm)

Dresser-Rand TC3 (HVOF) coated

piston rods

17-4 PH or Carpenter custom 450

stainless steel piston rods

Purged packing and purged wiper case

Two-compartment distance piece

Crankcase and lubricator oil heaters

Crankcase explosion relief devices

Main bearing RTDs

E

21.88"

555.7 mm

A

in. (mm)

B

in. (mm)

C

in. (mm)

D

in. (mm)

61.75 (1568.5)

61.75 (1568.5)

62.5 (1587.5)

62.5 (1587.5)

62.5 (1587.5)

59.5 (1511.3)

59.5 (1511.3)

58.75 (1492.3)

58.75 (1492.3)

58.5 (1485.9)

58.5 (1485.9)

57.75 (1466.9)

57.75 (1466.9)

57 (1447.8)

57.5 (1460.5)

57.5 (1460.5)

59 (1498.6)

58 (1473.2)

59.62 (1514.5)

22.38 (568.3)

22.38 (568.3)

23.62 (600.1)

23.12 (587.4)

23.12 (587.4)

20.75 (527.1)

20.75 (527.1)

20 (508.0)

20 (508.0)

19.75 (501.7)

19.75 (501.7)

19.25 (489.0)

19.25 (489.0)

18.18 (461.9)

18.62 (473.1)

18.87 (479.4)

20.38 (517.5)

18 (457.2)

20.62 (523.9)

84.12 (2136.8)

84.12 (2136.8)

85.62 (2174.9)

85.62 (2174.9)

85.62 (2174.9)

80.25 (2038.4)

80.25 (2038.4)

78.75 (2000.3)

78.75 (2000.3)

78.75 (2000.3)

78.75 (2000.3)

77 (1955.8)

77 (1955.8)

75.18 (1909.7)

76.12 (1933.6)

76.38 (1939.9)

79.38 (2016.1)

76 (1930.4)

80.25 (2038.4)

106 (2692.4)

106 (2692.4)

108 (2743.2)

107 (2717.8)

107 (2717.8)

102 (2590.8)

102 (2590.8)

101 (2565.4)

101 (2565.4)

100 (2540)

100 (2540)

99 (2514.6)

99 (2514.6)

97 (2463.8)

98 (2489.2)

98 (2489.2)

101 (2565.4)

98 (2489.2)

102 (2590.8)

32 (812.8)

32 (812.8)

48 (1219.2)

48 (1219.2)

48 (1219.2)

40.62 (1031.9)

40.62 (1031.9)

40 (1016.0)

40 (1016.0)

39.25 (997.0)

39.25 (997.0)

42 (1066.8)

42 (1066.8)

37 (939.8)

41.5 (1054.1)

38 (965.2)

40.56 (1030.3)

40.25 (1022.4)

51.5 (1308.1)

58 (1473.2)

18.25 (463.6)

76.25 (1936.8)

98 (2489.2)

48.12 (1222.4)

VARY DEPENDING ON PIPING NEEDS

Lined cylinders are available as well as special purpose cylinders for storage and pipeline applications.

E

in. (mm)

For more information on the

HOS compressor, visit

www.dresser-rand.com/gfc

or contact us at:

Dresser-Rand

Gas Field Compressors

1354 South Sheridan Road

Tulsa, Oklahoma 74112-5416 USA

Tel: (Intl +1) 918-254-4099

Fax: (Intl +1) 918-252-9055

E-mail: GFC@dresser-rand.com

Dresser-Rand

Reciprocating Operations

100 Chemung Street

Painted Post, NY 14870 USA

Tel: (Intl +1) 607-937-2011

Fax: (Intl +1) 607-937-2905

For a complete list of D-R products

and services, visit us on the Internet at

www.dresser-rand.com or contact us

at the following locations:

Dresser-Rand

Corporate Headquarters

West8 Tower, Suite 1000

10205 Westheimer Road

Houston, Texas 77042

Tel: (Intl +1) 713-354-6100

Fax: (Intl +1) 713-354-6110

E-mail: info@dresser-rand.com

Regional Headquarters

The Americas

West8 Tower, Suite 1000

10205 Westheimer Road

Houston, Texas 77042

Tel: (Intl +1) 713-354-6100

Fax: (Intl +1) 713-354-6110

E-mail: info@dresser-rand.com

European Served Areas (ESA)

(Europe, Eurasia, Middle East, Africa)

Dresser-Rand S.A.

31 Boulevard Winston Churchill

Cedex 7013

Le Havre 76080 France

Tel: (Intl +33) 2-35-25-5225

Fax: (Intl +1) 2-35-25-5366 / 5367

Asia-Pacific

Dresser-Rand Asia Pacific Sdn Bhd

Unit 9-4, 9th Floor

Bangunan Malaysian Re

17 Lorong Dungun

Damansara Heights

50490 Kuala Lumpur, Malaysia

Tel: (Intl +60) 3-2093-6633

Fax: (Intl +60) 3-2093-2622

Form 85198-09

2008 Dresser-Rand

This brochure comprises a general overview of the Dresser-Rand products described herein. It is solely for informational purposes,

does not represent a warranty or guarantee of the information contained herein, and is not to be construed as an offer to sell

or solicitation to buy. Contact Dresser-Rand for detailed design and engineering information suitable to your specific applications.

Dresser-Rand reserves the right to modify its products and related product information at any time without prior notice.

You might also like

- D E F Op InstDocument85 pagesD E F Op Instwilber100% (2)

- 59T Thru 110Q Manual Rev 20050926Document62 pages59T Thru 110Q Manual Rev 20050926tonyeldNo ratings yet

- Parts List: Frame AssemblyDocument202 pagesParts List: Frame Assemblylouati100% (1)

- JOY SUPERIOR and Cooper MH-66 PDFDocument2 pagesJOY SUPERIOR and Cooper MH-66 PDFcarlos felipe botello paezNo ratings yet

- B412kvsra Ir ManualDocument1,633 pagesB412kvsra Ir Manuallenin fajardo100% (2)

- Dresser-Rand: Service ManualDocument1 pageDresser-Rand: Service ManualTu PhamNo ratings yet

- Sperre LL2 77 CompressorDocument1 pageSperre LL2 77 CompressorTanay ShahNo ratings yet

- Dresser RandDocument4 pagesDresser RandBams ArifinNo ratings yet

- WindBack SealDocument2 pagesWindBack SealMongkonkehaChanachonNo ratings yet

- Kleiberit PUR 501 - FISPQDocument8 pagesKleiberit PUR 501 - FISPQYuri SouzaNo ratings yet

- Epson 3800 3880 SMDocument306 pagesEpson 3800 3880 SMIon IonutNo ratings yet

- HOS Frame and Running Gear Data Standard Frame and Running Gear AssembliesDocument8 pagesHOS Frame and Running Gear Data Standard Frame and Running Gear AssembliesJose Luis Rattia100% (1)

- A-VIP Compressor BrochureDocument6 pagesA-VIP Compressor BrochureAvrinFakherniaNo ratings yet

- D VipDocument6 pagesD VipClemente Rafael Marval EscalonaNo ratings yet

- Dresser-Rand - MANUAL 7SHF162Document502 pagesDresser-Rand - MANUAL 7SHF162DAVIS VELASQUEZ100% (2)

- Screw Compressor GH-series Instruction Manual: GH250S/L, GH320SDocument111 pagesScrew Compressor GH-series Instruction Manual: GH250S/L, GH320SManh PhamNo ratings yet

- Howden - FFP Free Floating Piston Lowres PDFDocument4 pagesHowden - FFP Free Floating Piston Lowres PDFdigecaNo ratings yet

- WGDocument89 pagesWGagiba100% (1)

- Superior - Cylinder Databook - ValvesDocument8 pagesSuperior - Cylinder Databook - ValvesJake NavarreteNo ratings yet

- Ingersol-Rand-Air-Compressor PHE Booster Eng DataDocument46 pagesIngersol-Rand-Air-Compressor PHE Booster Eng Datadevilsharma100% (2)

- Er 96-1-1 - Ariel JG Jga ToolsDocument4 pagesEr 96-1-1 - Ariel JG Jga ToolsJeff LNo ratings yet

- Smart ChoicesDocument32 pagesSmart ChoicesSUN RAVINo ratings yet

- Force Feed Lubrication Sysytem ImprovementsDocument8 pagesForce Feed Lubrication Sysytem Improvementsdiego yecid millan mendozaNo ratings yet

- DDDocument3 pagesDDAnkush Sehgal100% (1)

- Compressor Over-Lubrication PresentationDocument38 pagesCompressor Over-Lubrication Presentation1mmahoneyNo ratings yet

- Ariel Compressor Balance SheetDocument130 pagesAriel Compressor Balance Sheetariel.garayNo ratings yet

- Manual 99 LDDocument20 pagesManual 99 LDCristianNo ratings yet

- 825 Series Product Overview & General DataDocument30 pages825 Series Product Overview & General Datamauricio cañonNo ratings yet

- Special Edition Tensioner JuneDocument3 pagesSpecial Edition Tensioner JuneDjebali MouradNo ratings yet

- SEBU8099 Maint PDFDocument102 pagesSEBU8099 Maint PDFAhmed KamalNo ratings yet

- Intro DR Engines July2018Document31 pagesIntro DR Engines July2018Russell DezemeNo ratings yet

- Rod ReversalDocument21 pagesRod ReversalandresNo ratings yet

- Ajax PresentationDocument34 pagesAjax PresentationJesus lopezNo ratings yet

- Manual Champion Pl70Document32 pagesManual Champion Pl70De Luna BraulioNo ratings yet

- Atlas Copco Stationary Compressor GA315 GA355 GA400 GA450 GA500Document59 pagesAtlas Copco Stationary Compressor GA315 GA355 GA400 GA450 GA500oussama bouabNo ratings yet

- Compressor Gas NaturalDocument44 pagesCompressor Gas NaturaldpomahNo ratings yet

- ARO 2019 66625 7 2 Inch Metallic PRO SERIES Diaphragm Pump Manual Fluid SectionDocument8 pagesARO 2019 66625 7 2 Inch Metallic PRO SERIES Diaphragm Pump Manual Fluid Sectionmohamed musaNo ratings yet

- 1 1Document9 pages1 1Ankush SehgalNo ratings yet

- Ariel KBK KBT ManualDocument193 pagesAriel KBK KBT Manualariel.garayNo ratings yet

- Ariel Build Book F-13989 PDFDocument133 pagesAriel Build Book F-13989 PDFhugoheloNo ratings yet

- Ariel J. Lubrication System-03 04 04Document43 pagesAriel J. Lubrication System-03 04 04Manuel LiñeiroNo ratings yet

- Product Overview-WH FramesDocument43 pagesProduct Overview-WH FramesArzyman100% (1)

- Aatisbh Sehgal CV PDFDocument5 pagesAatisbh Sehgal CV PDFAnkush SehgalNo ratings yet

- Er 108 1Document3 pagesEr 108 1DIEGO YECID MILLAN MENDOZANo ratings yet

- Waukesha V HP Series 4Document4 pagesWaukesha V HP Series 4rohizatNo ratings yet

- High Pressure CompressorsDocument16 pagesHigh Pressure CompressorsnghiaNo ratings yet

- JGR JGJ enDocument137 pagesJGR JGJ enKarlosant MJ100% (1)

- Waukesha F11gsi - Valve Clearence - CompressionDocument2 pagesWaukesha F11gsi - Valve Clearence - Compressionnicol_sg100% (1)

- Installation and Removal of Interference Compressor Drive Coupling Hubs, Edit BMDocument3 pagesInstallation and Removal of Interference Compressor Drive Coupling Hubs, Edit BMjose luis rattiaNo ratings yet

- G3606 - Lehw0039-02 P1Document4 pagesG3606 - Lehw0039-02 P1Martin KratkyNo ratings yet

- DS CF90D4Document1 pageDS CF90D4arieprachmanNo ratings yet

- R&P Material DetailsDocument20 pagesR&P Material DetailsinamNo ratings yet

- Hoerbiger Recip Compressor Training PDFDocument18 pagesHoerbiger Recip Compressor Training PDFnajamsyed6754No ratings yet

- Ariel Air CompressorDocument4 pagesAriel Air CompressorCelso FernandesNo ratings yet

- DPC 2802 Startup ProcedureDocument6 pagesDPC 2802 Startup ProcedureMuhammad Asad100% (1)

- Ajax Cause & EffectDocument3 pagesAjax Cause & EffectgustavoespinosamNo ratings yet

- Ariel Corporation: Kbu/KbzDocument2 pagesAriel Corporation: Kbu/KbzAlfredoNo ratings yet

- 65007-PQA Quincy QSBDocument150 pages65007-PQA Quincy QSBjarmaryemNo ratings yet

- MOSBrochure PDFDocument6 pagesMOSBrochure PDFabisaNo ratings yet

- Caster ConceptsDocument83 pagesCaster Conceptssuperman3kNo ratings yet

- Manual de Instalación Bomba Quintuplex Pentair MA-300Document32 pagesManual de Instalación Bomba Quintuplex Pentair MA-300zayagoraNo ratings yet

- New Internationalist - May June 2023Document84 pagesNew Internationalist - May June 2023akamalapuriNo ratings yet

- AAA Digital India2Document19 pagesAAA Digital India2akamalapuriNo ratings yet

- Industrial Test Setup For Autotuning of PID ControDocument9 pagesIndustrial Test Setup For Autotuning of PID ControakamalapuriNo ratings yet

- 70 MMSCFDCompressor Plant BahrainDocument1 page70 MMSCFDCompressor Plant BahrainakamalapuriNo ratings yet

- Perdev Module 3Document13 pagesPerdev Module 3Renelyn JacoNo ratings yet

- Air Track Gizmo - ExploreLearningDocument4 pagesAir Track Gizmo - ExploreLearningJeremy Gomez-RojasNo ratings yet

- Premium HC: 120 Halfcell Monocrystalline High Performance Solar ModuleDocument2 pagesPremium HC: 120 Halfcell Monocrystalline High Performance Solar ModuleMujahed Al-HamatiNo ratings yet

- Ehaccp - Allergen Control StatementDocument1 pageEhaccp - Allergen Control StatementAlfred RangelNo ratings yet

- Control of Spinal Anesthesia-Induced Hypotension in Adults - PMCDocument14 pagesControl of Spinal Anesthesia-Induced Hypotension in Adults - PMCAkash SharmaNo ratings yet

- OHara PDFDocument17 pagesOHara PDFTomás HidalgoNo ratings yet

- Comm - Name Comm - Code Comm - WT Index20122013 I Primary Articles (A) - Food ArticlesDocument48 pagesComm - Name Comm - Code Comm - WT Index20122013 I Primary Articles (A) - Food ArticlesNavin SanjeevNo ratings yet

- X PPT CH 12 ElectricityDocument12 pagesX PPT CH 12 ElectricityAakriti100% (1)

- KONAN Emmanuel Sales Technical Engineer 16 Juin 23Document1 pageKONAN Emmanuel Sales Technical Engineer 16 Juin 23EMMANUEL KONANNo ratings yet

- Operation Reasrech On IglooDocument18 pagesOperation Reasrech On IglooMd Yeasin ArafatNo ratings yet

- Cobra XRS9690Document45 pagesCobra XRS9690marwan71No ratings yet

- HT Billing System - May'2022Document2 pagesHT Billing System - May'2022V.Sampath RaoNo ratings yet

- Validation ConceptsDocument41 pagesValidation ConceptsSyed Ghazanfar AliNo ratings yet

- Module 1 What Is Geography and TourismDocument22 pagesModule 1 What Is Geography and TourismLeanne Abegail EstabilloNo ratings yet

- Therapeutic Diet Manual: DIRECTIVE #4311Document27 pagesTherapeutic Diet Manual: DIRECTIVE #4311DuNo ratings yet

- Bronchial Hygiene or Airway Clearance TechniquesDocument139 pagesBronchial Hygiene or Airway Clearance TechniquesPiyush Salgaonkar100% (1)

- 10 Science TP 11 1Document5 pages10 Science TP 11 1Ananaya BansalNo ratings yet

- Asme A13.1 - 1996Document27 pagesAsme A13.1 - 1996lohv100% (1)

- Grammar 04 18Document5 pagesGrammar 04 18zsuzsi_harangoz2218No ratings yet

- Schiavi Enc Met Page015Document1 pageSchiavi Enc Met Page015Adel AdelNo ratings yet

- Exercise # 1: Statistics and ProbabilityDocument6 pagesExercise # 1: Statistics and ProbabilityAszyla ArzaNo ratings yet

- هاشم عدي حاتم سيارات ثاني التجربة الثانيهDocument6 pagesهاشم عدي حاتم سيارات ثاني التجربة الثانيههاشم عديNo ratings yet

- Visual Storytelling The Digital Video Documentary - Original PDFDocument44 pagesVisual Storytelling The Digital Video Documentary - Original PDFjparanoti100% (1)

- CR Unit 1 &11 (Part A &B)Document12 pagesCR Unit 1 &11 (Part A &B)durai muruganNo ratings yet

- MEP MyanmarDocument27 pagesMEP Myanmarempty87No ratings yet

- Industrial RoboticsDocument77 pagesIndustrial RoboticsIslam Fouad100% (4)

- The Harrod-Domar Growth ModelDocument6 pagesThe Harrod-Domar Growth ModelSimeonNo ratings yet

- 1 s2.0 S0264127522004105 MainDocument11 pages1 s2.0 S0264127522004105 MainAsimov RiyazNo ratings yet