Professional Documents

Culture Documents

Using Lime For Acid Neutralization

Using Lime For Acid Neutralization

Uploaded by

anaazizOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Using Lime For Acid Neutralization

Using Lime For Acid Neutralization

Uploaded by

anaazizCopyright:

Available Formats

USING LIME FOR ACID NEUTRALIZATION

A PROVEN SOLUTION!

LIME MEETS THE ENVIRONMENTAL CHALLENGE: In today's industrialized society,

many processes create acidic waste streams. Wastewater discharge permits generally require

that acidic waste be neutralized to the range of pH 6.0 - 9.0. In the future, many facilities may be

forced by changing permit requirements to treat and reuse all wastewaters. To achieve these

goals, lime neutralization is the best solution.

LIME IS THE NEUTRALIZING MATERIAL OF CHOICE: Neutralization of acidic waste

streams involves raising the pH, usually by adding an alkaline chemical, such as lime. There are

several other chemicals that can also be used, but due to cost, handling problems, high total

dissolved solids in the effluent, or mobility of heavy metals in the sludge, lime is the neutralizing

material of choice. As highlighted in the table below, when considering the cost of neutralizing

agents and alkali requirements, lime is the most cost-effective option to neutralize acids.

Comparison of Common Neutralizing Materials1-3

Lime

(Calcium Oxide or

Hydroxide)

Product

Form of Material

Soda Ash

(Sodium Carbonate)

Caustic Soda

(Sodium Hydroxide)

Magnesium

Hydroxide

Solid - CaO

Powder-Ca(OH)2

Slurry 35%-Ca(OH)2

Powder - Na2CO3

Solution 15%-Na2CO3

Solution 50%-NaOH

Slurry 58%-Mg(OH)2

Alkali Requirement

Per Ton H2SO4

Per Ton HCl

As CaO:

1,240 lbs.

1,670 lbs.

2,160 lbs.

2,900 lbs.

1,630 lbs.

2,190 lbs.

1,190 lbs.

1,600 lbs.

Cost Per Ton of

Neutralizing Agent

(on a dry basis)

CaO - $60

Ca(OH)2 - $80

Slurry Ca(OH)2 - $100

Cost Stable

Na2CO3 - $80

Cost Variable

NaOH - $280

Cost Highly Variable

Mg(OH)2 - $300

Cost Increasing

Cost to Neutralize

1 Ton of H2SO4

CaO - $37

Ca(OH)2 - $66

Slurry Ca(OH)2 - $82

Na2CO3 - $86

NaOH - $228

Mg(OH)2 - $179

Maximum pH @ 25 C

12.45

>11

14

10.6

Sludge Profile

Heavy, Low Volume,

but easy handling, even if

heavy metals present

High Volume,

gel-like when heavy

metals present

High Volume,

gel-like when heavy

metals present

Heavy, Low Volume

Insoluble calcium metal

hydroxyl salts

Soluble sodium salts

Soluble sodium salts

Soluble magnesium

metal hydroxyl salts

Low

High

High

High

Moderately fast-acting to

complete neutralization

Moderately fast-acting to

complete neutralization

Extremely fast-acting to

complete neutralization

Fairly slow-acting to

95% complete

neutralization

Salts

TDS (total

dissolved solids)

Reaction Time

Page 2

Factors to consider when choosing a neutralizing material include the cost of the material, the

amount of sludge produced, the handling characteristics of the sludge, the leaching

characteristics of the sludge, and the resulting quality of the effluent.* Lime is most economical,

but also offers other advantages.

Caustic soda and soda ash are generally less effective--yielding the lowest volume of sludge and

the highest dissolved solids content in the effluent. These neutralizing agents also tend to

produce gel-like and hard-to-handle sludges. Furthermore, the heavy metals contained in the

sodium-based sludges are highly leachable. Therefore, unless the acid waste stream is extremely

clean, these two materials can be easily eliminated from consideration.

For most waste streams, the two leading neutralizing candidates are lime and magnesium

hydroxide. Lime neutralizes more quickly and completely, which can reduce the size of

equipment. Magnesium hydroxide yields somewhat less sludge per unit volume than lime.

However, magnesium hydroxide effluent is generally higher in total dissolved solids.

Lime is the neutralizing agent of choice in almost all applications. Lime sludges are heavy, low

volume, easy to handle, and easy to clarify. Most metals contained in the sludge are insoluble

and will not readily leach into the environment. Finally, lime is the low cost reagent in terms of

neutralizing value.

For more information, including on-line ordering of NLA's bulletin on Acid Neutralization with

Lime, check NLAs website at http://www.lime.org. For more technical information, contact

your local lime supplier (a list appears on the website above).

REFERENCES:

(1) Acid Neutralizers Calm the Wastewaters. Hairston, Deborah W., Chemical Engineering, Dec. 1996.

(2) Acid Neutralization with Lime. National Lime Association, Bulletin No. 216, 1995.

(3) Comparing Acid Waste Stream Neutralization Methods. Teringo, John, Plant Engineering, Nov. 1990.

National Lime Association

200 N. Glebe Road, Suite 800

Arlington, Virginia 22203-3728

Phone: 703-243-5463

Fax: 703-243-5489

E-Mail: natlime@lime.org

Web Address: http://www.lime.org

September 2000

Reactions between acids and alkalies are exothermic and sometimes violent. Thus proper (normal and

customary) safety precautions should be strictly followed.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Lab10CoastalErosion 1Document1 pageLab10CoastalErosion 1ramizaNo ratings yet

- Final Report Prod WaterDocument460 pagesFinal Report Prod WaterAnonymous 4PVjmlEv8100% (1)

- No Engineers In: The Boardroom?Document4 pagesNo Engineers In: The Boardroom?aakashtrivediNo ratings yet

- Light and Matter - A Very Brief History: Tom Heinzl Umeå University Umeå University 22 SEPTEMBER 2010Document34 pagesLight and Matter - A Very Brief History: Tom Heinzl Umeå University Umeå University 22 SEPTEMBER 2010aakashtrivediNo ratings yet

- Order in Petition No. 534/TT/2014Document7 pagesOrder in Petition No. 534/TT/2014aakashtrivediNo ratings yet

- Competition Rule Book: GamesDocument18 pagesCompetition Rule Book: GamesaakashtrivediNo ratings yet

- EnergyDocument66 pagesEnergyaakashtrivediNo ratings yet

- Ring Bus - 2Document7 pagesRing Bus - 2aakashtrivediNo ratings yet

- RSTP ProtocolDocument5 pagesRSTP ProtocolaakashtrivediNo ratings yet

- TheDream GurbakshChahalDocument49 pagesTheDream GurbakshChahalaakashtrivedi100% (1)

- Earthing123 YesDocument43 pagesEarthing123 YesaakashtrivediNo ratings yet

- System EarthingDocument43 pagesSystem EarthingaakashtrivediNo ratings yet

- Earth GRD NoteDocument33 pagesEarth GRD NoteaakashtrivediNo ratings yet

- Baima A4Document2 pagesBaima A4aakashtrivediNo ratings yet

- Exc System FundamentalsDocument50 pagesExc System FundamentalsaakashtrivediNo ratings yet

- CFBC Boilers in China - Present and FutureDocument5 pagesCFBC Boilers in China - Present and FutureaakashtrivediNo ratings yet

- 2 (1) 2boilerDocument31 pages2 (1) 2boileraakashtrivediNo ratings yet

- Gearbox Failure of Large Gas Turbine Generator Case StudyDocument2 pagesGearbox Failure of Large Gas Turbine Generator Case StudyJesusNo ratings yet

- Fateh Sagar LakeDocument8 pagesFateh Sagar LakeMadan ChaudharyNo ratings yet

- Study of Ground Water in Perungudi Area of ChennaiDocument9 pagesStudy of Ground Water in Perungudi Area of ChennaiiisteNo ratings yet

- Port &gujarathi StreetsynopsisDocument12 pagesPort &gujarathi StreetsynopsissalmanNo ratings yet

- Application of Low Fouling RO Membrane Elements For Reclamation of Municipal WastewaterDocument17 pagesApplication of Low Fouling RO Membrane Elements For Reclamation of Municipal Wastewaterzerocool86No ratings yet

- I-751 Firelock Alarm Check ValveDocument24 pagesI-751 Firelock Alarm Check ValveMartin Bravo SerranoNo ratings yet

- Building Regs Part H DrainageDocument43 pagesBuilding Regs Part H DrainageJohn LiebermanNo ratings yet

- Guidelines On Environmental and Ecological Considerations For River Channel Design (DSD)Document77 pagesGuidelines On Environmental and Ecological Considerations For River Channel Design (DSD)Kwok Yiu ChowNo ratings yet

- Clean Water and SanitationDocument2 pagesClean Water and SanitationRamzan Alam SagarNo ratings yet

- F 200Document39 pagesF 200kashifNo ratings yet

- Desalination Industry-1 APDADocument55 pagesDesalination Industry-1 APDAKeity MartinNo ratings yet

- Ethanol: Safety Data SheetDocument7 pagesEthanol: Safety Data SheetAulia Rahma IsnaenyNo ratings yet

- Infiltration and PercolationDocument15 pagesInfiltration and PercolationNoreenel Lintag BorjaNo ratings yet

- 78BDocument3 pages78BJamie SchultzNo ratings yet

- Social JHS 1 - 1Document4 pagesSocial JHS 1 - 1mac100% (2)

- 300 - CHP - EPA (Final) W-AppsDocument244 pages300 - CHP - EPA (Final) W-AppsmgkalfasNo ratings yet

- Final Report-A Pilot ProjectDocument73 pagesFinal Report-A Pilot Projectewald cronjeNo ratings yet

- BOD and COD RemovalDocument13 pagesBOD and COD Removaldesireeh200950% (2)

- List - (Annexure H)Document59 pagesList - (Annexure H)shrutiNo ratings yet

- A Detailed Lesson PlanDocument12 pagesA Detailed Lesson PlanAlyssa AntonioNo ratings yet

- Dr. Y. B.Sontakke: Joint Director (WPC) Maharashtra Pollution Control Board Mumbai-400022Document37 pagesDr. Y. B.Sontakke: Joint Director (WPC) Maharashtra Pollution Control Board Mumbai-400022Sanjukta MajhiNo ratings yet

- In This Project We Will Design A Treatment Station, So We: - Pond ClassificationDocument16 pagesIn This Project We Will Design A Treatment Station, So We: - Pond ClassificationSayed Abo ElkhairNo ratings yet

- Ecological Survey of TidalLink Lakes Badin Sindh PakistanDocument81 pagesEcological Survey of TidalLink Lakes Badin Sindh PakistanSyed Najam KhurshidNo ratings yet

- RA 9275 The Clean Water Act of 2004 GASPANDocument31 pagesRA 9275 The Clean Water Act of 2004 GASPANCyril Kaye DolorzoNo ratings yet

- 111 Introduction - 231114 - 174458Document33 pages111 Introduction - 231114 - 174458Dawit TesfayNo ratings yet

- -Document17 pages-Mariko CalandaNo ratings yet

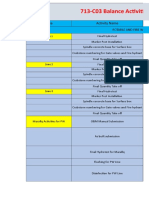

- 713-C03 MEHANICAL Balance WorkDocument6 pages713-C03 MEHANICAL Balance WorkSavad AlwyeNo ratings yet

- Module - 4 Design of Disposal StationDocument16 pagesModule - 4 Design of Disposal StationFaran Masood FASTNU100% (1)