Professional Documents

Culture Documents

STL Manual Auto Control

STL Manual Auto Control

Uploaded by

ghanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

STL Manual Auto Control

STL Manual Auto Control

Uploaded by

ghanCopyright:

Available Formats

1.

Basic Program Design Examples

1.18 STL Manual/Auto Control

Auto

Manual

Clip

X0

Transfer

X1

Release

Conveyor A

Conveyor B

Control Purpose:

z

When the button Manual is pressed, the robotic arm will begin to execute the manual control

process: pressing Clip to clip the product from conveyor A, pressing Transfer to move the

product to the conveyor B, and pressing Release to release the product and send it away by

conveyor B.

When the button Auto is pressed, the robotic arm will begin to execute the auto control

process once: clip product (keep holding this product before releasing) transfer product

(the action takes 2 sec) release the product. Auto control process can be performed one

more time if the button Auto is pressed again.

Manual control process and auto control process are interlocked.

Devices:

Device

1-24

Function

X0

Auto button. X0 goes from OFF to ON when pressed.

X1

Manual button. X1 goes from OFF to ON when pressed

X2

Clip button. X2 will be ON when pressed.

X3

Transfer button. X3 will be ON when pressed.

X4

Release button. X4 will be ON when pressed.

S0

Initial step

S20

Auto control step

S21

Manual control step

T0

2 sec timer

Y0

Product clipping/releasing. Y0 is ON/OFF when clipping/releasing the product

Y1

Product transferring

DVP-PLC Application Examples

1. Basic Program Design Examples

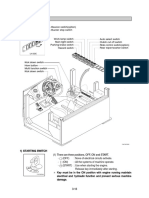

Control Program:

M1002

S0

S

X0

X1

S20

S

SET

S0

SET

S20

Auto Control Button

SET

S21

Manual Control Button

SET

Y0

Clipping Product

TMR

T0

K20

T0

Y1

T0

RST

Transferring Product

Y0

Releasing Product

Y0

Clipping Product

S0

S21

S

X2

SET

X3

Y1

X4

Y0

RST

Transferring Product

Y0

Releasing Product

S0

RET

Program Description:

z

When X0 goes from OFF to ON, the step S20 will be set to execute auto control process one

time, and the manual control process will be prohibited at the same time. Auto control

process can be performed one more time if the button Auto is pressed again.

The auto control process performed by the robotic arm: clipping product when X0 = ON

(keep holding this product before releasing) transferring product when Y1 = ON (the

action takes 2 sec) releasing the product when Y0 = OFF.

When X1 goes from OFF to ON, the step S21 will be set to execute manual control process

one time, and the auto control process will be prohibited at the same time.

The manual control process performed by the robotic arm: pressing Clip(X2) to clip the

product from conveyor A, pressing Transfer(X3) to move the product to the conveyor B, and

pressing Release(X4) to release the product and send it away by conveyor B.

DVP-PLC Application Examples

1-25

You might also like

- Ch6 Evans BA1e Case SolutionDocument30 pagesCh6 Evans BA1e Case Solutionyarli77770% (1)

- User Manual-Stringing Machine-Pro's Pro Tomcat MT-400Document10 pagesUser Manual-Stringing Machine-Pro's Pro Tomcat MT-400kippcamNo ratings yet

- SX 2 XGQ 50F ProgramingDocument22 pagesSX 2 XGQ 50F ProgramingLinh50% (2)

- Arburg 221 ManualDocument92 pagesArburg 221 ManualZeljko Djukic73% (15)

- ZJ-LCD-M Manual Instruction Flow Meter DisplayDocument7 pagesZJ-LCD-M Manual Instruction Flow Meter Displaypatrick50% (6)

- Notice Tokai Lar-216 en AnglaisDocument9 pagesNotice Tokai Lar-216 en AnglaisCalvin StreetingNo ratings yet

- Doosan Servo Driven Tail Stock MANUAL - ENGDocument5 pagesDoosan Servo Driven Tail Stock MANUAL - ENGmarkoskitp100% (1)

- Calibration Procedure UKDocument15 pagesCalibration Procedure UKartNo ratings yet

- PLC Applications Workbook - Dayanand, RickyDocument240 pagesPLC Applications Workbook - Dayanand, RickyPeter Nomikos100% (1)

- Manual Fresadora X4 SyilDocument78 pagesManual Fresadora X4 SyilCarlosNo ratings yet

- HMP1 User Manual.00Document8 pagesHMP1 User Manual.00Manuel AlarconNo ratings yet

- IV-H Series IV-HG Series: User's ManualDocument134 pagesIV-H Series IV-HG Series: User's ManualEdgar Orendain ArriagaNo ratings yet

- FWD Rev Three Phase Motor Using Timer PDFDocument1 pageFWD Rev Three Phase Motor Using Timer PDFghanNo ratings yet

- WHB04B-4:4 WHB04B-6:6Document15 pagesWHB04B-4:4 WHB04B-6:6Marko CuricNo ratings yet

- Interlocking Examples PDFDocument2 pagesInterlocking Examples PDFghanNo ratings yet

- Tutorial 2Document5 pagesTutorial 2Shreyash ButleNo ratings yet

- SrgvaevfafDocument4 pagesSrgvaevfafbassistbaseNo ratings yet

- Manual StrandjackDocument17 pagesManual StrandjackSusanto HidayatNo ratings yet

- Counter Applications PDFDocument3 pagesCounter Applications PDFghanNo ratings yet

- Manual of GH500-Standard Model For Your Reference-Topwell LivDocument13 pagesManual of GH500-Standard Model For Your Reference-Topwell LivromdreNo ratings yet

- 8X8 BitmultiplierDocument26 pages8X8 BitmultiplierRenju TjNo ratings yet

- 1.21. Tipos y Apli de Tornos CNCDocument19 pages1.21. Tipos y Apli de Tornos CNCCarlos Alberto Andrade NaranjoNo ratings yet

- Instruction of 3D Tube Bender (DOBLADORA DE TUBOS CHINA)Document19 pagesInstruction of 3D Tube Bender (DOBLADORA DE TUBOS CHINA)MauricioNo ratings yet

- Monitoring Mouse ActivityDocument5 pagesMonitoring Mouse ActivityaarthiNo ratings yet

- Motor Conditional ControlDocument1 pageMotor Conditional ControlghanNo ratings yet

- Maquina FanucDocument24 pagesMaquina FanucpatricioNo ratings yet

- 21 BLOkon - 02 - 1.0 - ManualDocument24 pages21 BLOkon - 02 - 1.0 - Manualgetasew altasebNo ratings yet

- Body Control Module: Ed BCMDocument30 pagesBody Control Module: Ed BCMpapipapiiNo ratings yet

- PLCProject 10Document2 pagesPLCProject 10ASDF LKJNo ratings yet

- Electron Pneumatic CircuitDocument59 pagesElectron Pneumatic CircuitArun SìvaNo ratings yet

- Note-9 Timer OperationDocument28 pagesNote-9 Timer OperationAndeeNo ratings yet

- 05 DVP PLC Application Examples PDFDocument169 pages05 DVP PLC Application Examples PDFAlexCanenciaNo ratings yet

- Ascon IO XS ENDocument1 pageAscon IO XS ENthiodoroNo ratings yet

- Lava Aire Italia - Amit Misty Misting Fan - Owners ManualDocument7 pagesLava Aire Italia - Amit Misty Misting Fan - Owners ManuallavaheatitaliaNo ratings yet

- Switches: Starting Switch There Are Three Positions, OFF, ON and START. 1)Document5 pagesSwitches: Starting Switch There Are Three Positions, OFF, ON and START. 1)JuNo ratings yet

- Installation ManualDocument9 pagesInstallation ManualDenis RaudseppNo ratings yet

- 改新500说明书Document13 pages改新500说明书JoseNo ratings yet

- TronicDocument20 pagesTronicgrzegorzNo ratings yet

- PLC Application Exercise - LDDocument33 pagesPLC Application Exercise - LDMazarel AurelNo ratings yet

- Nice 3000控制系统常见问题解决指南.zh Cn.enDocument20 pagesNice 3000控制系统常见问题解决指南.zh Cn.enTroubleshootingNo ratings yet

- Start Up and ChecksDocument12 pagesStart Up and ChecksGamal Hari PrasetyoNo ratings yet

- PLC ActivityDocument2 pagesPLC ActivityHarsha KotuwegedaraNo ratings yet

- Gemini 7561 PDFDocument9 pagesGemini 7561 PDFwww_lili_pulpaNo ratings yet

- Industrial Automation Group AssignmentDocument5 pagesIndustrial Automation Group Assignmenteyoule abdiNo ratings yet

- GantryProductOperationManual (10.118.48.x) NewUIDocument104 pagesGantryProductOperationManual (10.118.48.x) NewUInabil aliliNo ratings yet

- DSP NK105 Operating Instruction DSP Control System DSP Operate ManualDocument7 pagesDSP NK105 Operating Instruction DSP Control System DSP Operate ManualMd. Atiqur Rahman TalukdarNo ratings yet

- MaintWRD 2 - enDocument7 pagesMaintWRD 2 - envojtech.salzmannNo ratings yet

- Toyota TVIP System ProgrammingDocument11 pagesToyota TVIP System Programmingcheerios353No ratings yet

- Short Operating Manual ALLROUNDER 221 KDocument92 pagesShort Operating Manual ALLROUNDER 221 Km asifNo ratings yet

- As58 (Pfaff)Document16 pagesAs58 (Pfaff)jongaeckNo ratings yet

- Carbonated Filler MannuelDocument8 pagesCarbonated Filler MannuelDániel CLNo ratings yet

- lc090 2 Way Car Alarm System Host ManualDocument11 pageslc090 2 Way Car Alarm System Host Manualhebert.taypeNo ratings yet

- Vacuum Robot QQ2LT User ManualDocument14 pagesVacuum Robot QQ2LT User ManualMartinKennethMichalskyNo ratings yet

- Daitsu APD12 New ManualDocument26 pagesDaitsu APD12 New ManualGeorge ShanidzeNo ratings yet

- KPA 400 Software Manual V2.0Document5 pagesKPA 400 Software Manual V2.0danNo ratings yet

- User Manual For Bluetooth Pro Controller For Nintendo SwitchDocument6 pagesUser Manual For Bluetooth Pro Controller For Nintendo SwitchDiego Jose Del Angel HerreraNo ratings yet

- E21 Operation Manual: (Version: V1.04)Document27 pagesE21 Operation Manual: (Version: V1.04)Тимур АлиевNo ratings yet

- Manual of IC Control Panel 1Document7 pagesManual of IC Control Panel 1elektrikal medisafeNo ratings yet

- 12V Central Lock Universal Remote For Keyless Entry P/N 900.550Document10 pages12V Central Lock Universal Remote For Keyless Entry P/N 900.550MohamedNo ratings yet

- Fujifilm X100VI: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsFrom EverandFujifilm X100VI: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsNo ratings yet

- Programme Title:: (Dd/mm/yyyy) (XXX)Document4 pagesProgramme Title:: (Dd/mm/yyyy) (XXX)ghanNo ratings yet

- Why Jesus Became ManDocument6 pagesWhy Jesus Became Manghan100% (1)

- Water and Waste Water Management Solutions: Modern Storage Tank Inspection TechniquesDocument26 pagesWater and Waste Water Management Solutions: Modern Storage Tank Inspection TechniquesghanNo ratings yet

- API 5ct S Pipe Drifts Casing Data ChartDocument1 pageAPI 5ct S Pipe Drifts Casing Data ChartghanNo ratings yet

- Product Information Bulletin: Handling ToolsDocument7 pagesProduct Information Bulletin: Handling ToolsghanNo ratings yet

- AerodynamicsDocument4 pagesAerodynamicsghan0% (1)

- IG4DB A 2 @28B : V/) /c.a (/) - /WZ Ax/z (../..d//az C-'/.Document3 pagesIG4DB A 2 @28B : V/) /c.a (/) - /WZ Ax/z (../..d//az C-'/.ghanNo ratings yet

- Technical Manual: 5 1/2" Clincher® Uht T 5 1/2" UHT B 5 1/2" LOCKJAW™ D P BDocument136 pagesTechnical Manual: 5 1/2" Clincher® Uht T 5 1/2" UHT B 5 1/2" LOCKJAW™ D P BghanNo ratings yet

- Wiper Seal Data Sheet A02 B 11782 1 enDocument2 pagesWiper Seal Data Sheet A02 B 11782 1 enghanNo ratings yet

- Head Clearances Around Screw Heads ... : Home Screws Index Page..Document2 pagesHead Clearances Around Screw Heads ... : Home Screws Index Page..ghanNo ratings yet

- Oilite CatalogueDocument26 pagesOilite CatalogueghanNo ratings yet

- Pub021 006 00 - 1112Document4 pagesPub021 006 00 - 1112HERRI MADJIDNo ratings yet

- Rtos 1Document22 pagesRtos 1VariNo ratings yet

- Iucaa NewDocument17 pagesIucaa Newarijit mannaNo ratings yet

- Mov A,#30h Mov r0,#40h Mov r1,#42 Loop: Mov @r0, A Inc r0 DJNZ r1, Loop .EndDocument80 pagesMov A,#30h Mov r0,#40h Mov r1,#42 Loop: Mov @r0, A Inc r0 DJNZ r1, Loop .EndAbhishek TiwariNo ratings yet

- Tecnicas Interpolacion Var ClimaDocument34 pagesTecnicas Interpolacion Var ClimaDaniel NúñezNo ratings yet

- Cambridge IGCSE: PHYSICS 0625/52Document12 pagesCambridge IGCSE: PHYSICS 0625/52Susan GeorgeNo ratings yet

- Solutions - AIATS JEE (Adv) - 2018 (CBT Mode) - Test-5A - Paper-1 - (22-04-2018) PDFDocument6 pagesSolutions - AIATS JEE (Adv) - 2018 (CBT Mode) - Test-5A - Paper-1 - (22-04-2018) PDFBHARAT CHANDWANINo ratings yet

- Nauticus Hull - Steel Plates UnstiffenedDocument90 pagesNauticus Hull - Steel Plates Unstiffenedbosskoj100% (1)

- Cryptography PHD Thesis PDFDocument7 pagesCryptography PHD Thesis PDFsuejonessalem100% (2)

- CBSE Class 8 Science WorksheetDocument2 pagesCBSE Class 8 Science Worksheetravilulla33% (3)

- Survey of Boosting From An Optimization Perspective: ICML 2009 TutorialDocument3 pagesSurvey of Boosting From An Optimization Perspective: ICML 2009 TutorialAugustoTexNo ratings yet

- Sec 06-01 PDFDocument26 pagesSec 06-01 PDFtempthereNo ratings yet

- 6890 Alcatel Lucent Delivering Comprehensive Enterprise DCC SecurityDocument11 pages6890 Alcatel Lucent Delivering Comprehensive Enterprise DCC SecurityAlexanderNo ratings yet

- Implementation of Circle, Line and Ellipse Drawing AlgorithmDocument35 pagesImplementation of Circle, Line and Ellipse Drawing AlgorithmPavithra RajaramNo ratings yet

- Lean Six Sigma Project Presentation TemplateDocument25 pagesLean Six Sigma Project Presentation TemplateNasrullah KhanNo ratings yet

- IR Drop PDFDocument3 pagesIR Drop PDFarammartNo ratings yet

- Imaging Den To Facial TraitsDocument25 pagesImaging Den To Facial TraitshaydarfadelNo ratings yet

- Red Book Section 122Document18 pagesRed Book Section 122Alejandro ViscarraNo ratings yet

- Ups Less TrafoDocument4 pagesUps Less Trafoleko17No ratings yet

- Ecology Ncert BIO Short Notes Deepak AIIMSonianDocument4 pagesEcology Ncert BIO Short Notes Deepak AIIMSoniantrivedit86No ratings yet

- Comprehension of Ratio (Lesson Plan)Document3 pagesComprehension of Ratio (Lesson Plan)Rayan CastroNo ratings yet

- Discussion Muir Wood Circular Tunnel in Elastic GroundDocument7 pagesDiscussion Muir Wood Circular Tunnel in Elastic GroundAmmar SohailNo ratings yet

- Engineering Thermodynamics Solutions ManualDocument32 pagesEngineering Thermodynamics Solutions ManualMahesh NadarNo ratings yet

- Bloch Sphere DerivationDocument3 pagesBloch Sphere DerivationPAVITHRAN SRIDHAR100% (1)

- Viki ProjectDocument31 pagesViki ProjectsingamNo ratings yet

- Quintel Product Datasheet QS86512 2 700 2400 8ft 65deg FEB 2017 Rev 1.6Document2 pagesQuintel Product Datasheet QS86512 2 700 2400 8ft 65deg FEB 2017 Rev 1.6Cecil PinPerNo ratings yet

- Ch3 ExtendedDocument79 pagesCh3 ExtendedMohammad Mahmudur RahmanNo ratings yet

- g9 Combined VariationDocument22 pagesg9 Combined VariationEggs eggyNo ratings yet

- P s l τ t s s τ s l P: Visit us at: www.nodia.co.inDocument1 pageP s l τ t s s τ s l P: Visit us at: www.nodia.co.inSameerChauhanNo ratings yet