Professional Documents

Culture Documents

CMP ZCP PDF

CMP ZCP PDF

Uploaded by

ghanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CMP ZCP PDF

CMP ZCP PDF

Uploaded by

ghanCopyright:

Available Formats

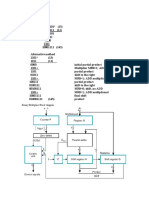

6.

Data Transmission and Comparison Design Examples

6.1

CMP - Material Mixing Machine

Control Purpose:

z

There are materials A and B in the mixing machine. Enabling the indicator(Y0) when the

Power On switch is pressed. Controlling the material A outlet (Y1) to start feeding and

starting the agitator Y3 by pressing the button Process(X1). When material A feeding

process reaches the set time D0, enabling the material B outlet(Y2) to start feeding while the

agitator keeps working. Stopping all processes when the whole mixing time(D1) is achieved.

Devices:

Device

Function

X0

X0 = ON when the Power On switch is pressed.

X1

X1 = ON when the button Process is pressed.

Y0

Power On Indicator

Y1

Material A outlet

Y2

Material B outlet

Y3

Agitator

D0

Feeding time of material A

D1

Total feeding time of material A and B

Control Program:

X0

Y0

X1

SET

Y3

TMR

T0

D1

CMP

D0

T0

ZRST

Y1

Y3

RST

T0

Y3

M0

M0

Y1

M1

Y2

M2

T0

DVP-PLC Application Examples

6-1

6. Data Transmission and Comparison Design Examples

Program Description:

z

When the Power On switch is pressed, X0 = ON. The Power On indicator Y0 will be ON. .

When Process button is pressed, X1 = ON. SET Y3 instruction will be executed so as to

execute TMR instruction. Timer T0 will be activated in this case.

At the same time, CMP instruction will also be executed. When the PV(present value) in T0

is smaller than the SV(set value) in D0, M0 = ON. Therefore, M0 will be ON to turn on coil Y1.

Material A feeding process will start. However, when the PV in T0 the SV in D0, M1 and

M2 will be ON but M0 will be OFF. Y2 will be ON in this case and the material B feeding

process will start while process A is stopped.

When the PV in T0 reaches the SV in D1, the NO(Normally Open) contact T0 will be ON to

execute ZRST and RST instructions. Y1, Y2, Y3 and T0 will be reset, and the agitator will

stop until the Process button is pressed again.

6-2

DVP-PLC Application Examples

6. Data Transmission and Comparison Design Examples

6.2

ZCP - Water Level Alarm Control

Control Purpose:

z

Controlling the water level in water tower by using analogue level measuring instrument.

When the water is at normal level, enable the normal level indicator. When there is only 25%

water volume in the water tower, start the feed water valve. When the level reaches the upper

bound, enable the alarm and stop the feed water valve.

Devices:

Device

Function

Y0

Feed water valve. ( The lower bound value = K1000)

Y1

Normal level indicator

Y2

Upper limit alarm. ( The upper bound value = K4000)

D0

Data register of the measuring value(K0~K4000)

Control Program:

M1000

FROM

K0

K6

D0

K1

ZCP

K1000

K4000

D0

M0

SET

Y0

M0

M1

Y1

M2

Y2

RST

Y0

Program Description:

z

The water level is measured by analogue level measuring instrument(Voltage output of

0~10V). Delta DVP04AD extension module converts the measured value into the value of

K0~K4000 and judges the water level by the value saved in D0

When the value in D0 < K1000(25% water volume), M0 = ON to set the feed water valve Y0.

When the value is between K1000~K4000, M1 = ON to set the normal level indicator Y1.

When the value > K4000(the level reaches the upper bound), M2 = ON to set the upper limit

alarm Y2. At the same time, Y0 will be reset, and the feed water valve will be shut down.

For the application of API78 FROM instruction, please refer to DVP-PLC Application

Manual Programming.

DVP-PLC Application Examples

6-3

You might also like

- Thyssenkrupp Elevator: Field MaintenanceDocument51 pagesThyssenkrupp Elevator: Field MaintenanceKSP KSP100% (5)

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- PLC Applications Workbook - Dayanand, RickyDocument240 pagesPLC Applications Workbook - Dayanand, RickyPeter Nomikos100% (1)

- PLC Advanced CommandsDocument43 pagesPLC Advanced CommandsghanNo ratings yet

- Experiment 1 - Process Control RigDocument15 pagesExperiment 1 - Process Control Rigzimbabwe100No ratings yet

- PLC ExercisesDocument28 pagesPLC ExercisesMohamed Amine100% (1)

- Chapter 8: PLC Programming Language - Basic InstructionsDocument57 pagesChapter 8: PLC Programming Language - Basic InstructionsNguyễn Tuấn HòaNo ratings yet

- PLC Application Exercise - LDDocument33 pagesPLC Application Exercise - LDMazarel AurelNo ratings yet

- 05 DVP PLC Application Examples PDFDocument169 pages05 DVP PLC Application Examples PDFAlexCanenciaNo ratings yet

- Selecting Execution of ProgramDocument2 pagesSelecting Execution of ProgramghanNo ratings yet

- Experiment 2 Level Control System: 1.0 ObjectiveDocument6 pagesExperiment 2 Level Control System: 1.0 ObjectiveElla Iloe IggoNo ratings yet

- Timer ApplicationsDocument28 pagesTimer ApplicationsghanNo ratings yet

- Level Control LoopDocument9 pagesLevel Control LoopHriday NathNo ratings yet

- PLC and Control System and AnalysisDocument10 pagesPLC and Control System and AnalysisM.AllaritNo ratings yet

- Counter Applications PDFDocument3 pagesCounter Applications PDFghanNo ratings yet

- Control of Temperature System 2Document18 pagesControl of Temperature System 2mustafa Al AsfourNo ratings yet

- Basic Concept: MultiplierDocument9 pagesBasic Concept: MultiplierFlorin UngureanuNo ratings yet

- Process ControlDocument21 pagesProcess ControlJamie ForsythNo ratings yet

- Labsheet 1 Sem 1 Sesi20142015Document11 pagesLabsheet 1 Sem 1 Sesi20142015Hafiz HazrnNo ratings yet

- ElevatorDocument27 pagesElevatorFatjon ArapiNo ratings yet

- Index Registers E, F Design Examples: 4.1 Summation of Continuous D RegistersDocument27 pagesIndex Registers E, F Design Examples: 4.1 Summation of Continuous D RegistersPaul PiguaveNo ratings yet

- Experiment 3: Level Measurement DLT 912: ObjectivesDocument5 pagesExperiment 3: Level Measurement DLT 912: ObjectivesKH200 73NG LIHUANo ratings yet

- Manual For Flow ControlDocument4 pagesManual For Flow ControlReeve Tang CsvNo ratings yet

- Economical Filter Valve Installation, Use and Maintenance ManualDocument13 pagesEconomical Filter Valve Installation, Use and Maintenance Manualhasanolan583No ratings yet

- Fosc-21 2009 08 18 Computer Storage Oscilloscope User's ManualDocument7 pagesFosc-21 2009 08 18 Computer Storage Oscilloscope User's ManualgorollanoNo ratings yet

- The PID Controller Experiment Card SO4201-5RDocument6 pagesThe PID Controller Experiment Card SO4201-5RAbdullahNo ratings yet

- MK 1000 ADocument4 pagesMK 1000 AAli AhmadNo ratings yet

- Electrical Engineering Lab V Course Code: Epo 660Document21 pagesElectrical Engineering Lab V Course Code: Epo 660Faiz BakarNo ratings yet

- Protem d404pdf Rele Temperatura de TrafosDocument16 pagesProtem d404pdf Rele Temperatura de TrafosIvan FrancoNo ratings yet

- Xmta 7000 PDFDocument4 pagesXmta 7000 PDFjonathan_calixto_4No ratings yet

- Tutorials On PLCs - NAHPIDocument7 pagesTutorials On PLCs - NAHPImarshal galilee djitsa0% (2)

- EKC312Document12 pagesEKC312bmw72No ratings yet

- Ic200cx QRG GBDocument58 pagesIc200cx QRG GBDouglasNo ratings yet

- 23mac0002 VL2023240502132 Ast02Document10 pages23mac0002 VL2023240502132 Ast02payalspatil22No ratings yet

- Mitsubishi Portfolio (PLC LAD)Document32 pagesMitsubishi Portfolio (PLC LAD)Regina WayiNo ratings yet

- Instrumentation and Control 402: Curtin University Department of Electrical and Computer EngineeringDocument6 pagesInstrumentation and Control 402: Curtin University Department of Electrical and Computer EngineeringShwu Ching JongNo ratings yet

- Quick Guide SPI1021: 1. Display and ControlsDocument8 pagesQuick Guide SPI1021: 1. Display and ControlsHenrics MayoresNo ratings yet

- C2 Level Control ExperimentDocument8 pagesC2 Level Control ExperimentHaha WoNgNo ratings yet

- LC2-Level Control II - Lab ReportDocument13 pagesLC2-Level Control II - Lab ReportKarishma GobinNo ratings yet

- CC !"#$ % & ' +) ,-.' ' +) , - c3'4/!!1564243) B@"Document7 pagesCC !"#$ % & ' +) ,-.' ' +) , - c3'4/!!1564243) B@"Kamrujjaman SakiNo ratings yet

- Jotter Notes Name: Pugallan A/L Nadarajah Date: 11/4/2016 ID No: 55213114377 Experiment No. and Title: Air Flow Process Control (AF922) ObjectivesDocument4 pagesJotter Notes Name: Pugallan A/L Nadarajah Date: 11/4/2016 ID No: 55213114377 Experiment No. and Title: Air Flow Process Control (AF922) Objectivestusen krishNo ratings yet

- ECE 210 Experiment 1Document3 pagesECE 210 Experiment 1mmnldzNo ratings yet

- Digiway Manual 2003Document36 pagesDigiway Manual 2003Tatenda BizureNo ratings yet

- 2255-1 ManualDocument6 pages2255-1 Manualgloriyeah2003No ratings yet

- Basic Program Design Examples: 1.2 Block in Parallel ConnectionDocument1 pageBasic Program Design Examples: 1.2 Block in Parallel ConnectionghanNo ratings yet

- Dust Emission, Pressure and Temperature Control: Documentation IndexDocument12 pagesDust Emission, Pressure and Temperature Control: Documentation IndexIng ZenerNo ratings yet

- EXP1-Basic Contro Circuit-2020Document8 pagesEXP1-Basic Contro Circuit-2020Shahidan KirkukyNo ratings yet

- Flow Control Report Final VersionDocument15 pagesFlow Control Report Final VersionKammy LaiNo ratings yet

- Level ControlDocument16 pagesLevel ControlQasim HabibNo ratings yet

- Tru-Sonic Manual NewDocument47 pagesTru-Sonic Manual Newpedropinocontreras100% (2)

- Real Time Control ApplicationDocument7 pagesReal Time Control ApplicationghanNo ratings yet

- 5220 ECOS Components PDFDocument25 pages5220 ECOS Components PDFEduardo Alves80% (5)

- Level Flow PCDocument10 pagesLevel Flow PCMurali TharanNo ratings yet

- PLC Ladder Examples 2021Document18 pagesPLC Ladder Examples 2021JosephNo ratings yet

- en PDFDocument4 pagesen PDFMarco GrijalbaNo ratings yet

- PLC Ladder Program To Control of EscalatorsDocument5 pagesPLC Ladder Program To Control of EscalatorsShahul AmeerNo ratings yet

- Exercises in Electronics: Operational Amplifier CircuitsFrom EverandExercises in Electronics: Operational Amplifier CircuitsRating: 3 out of 5 stars3/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Why Jesus Became ManDocument6 pagesWhy Jesus Became Manghan100% (1)

- Water and Waste Water Management Solutions: Modern Storage Tank Inspection TechniquesDocument26 pagesWater and Waste Water Management Solutions: Modern Storage Tank Inspection TechniquesghanNo ratings yet

- IG4DB A 2 @28B : V/) /c.a (/) - /WZ Ax/z (../..d//az C-'/.Document3 pagesIG4DB A 2 @28B : V/) /c.a (/) - /WZ Ax/z (../..d//az C-'/.ghanNo ratings yet

- Programme Title:: (Dd/mm/yyyy) (XXX)Document4 pagesProgramme Title:: (Dd/mm/yyyy) (XXX)ghanNo ratings yet

- API 5ct S Pipe Drifts Casing Data ChartDocument1 pageAPI 5ct S Pipe Drifts Casing Data ChartghanNo ratings yet

- AerodynamicsDocument4 pagesAerodynamicsghan0% (1)

- Product Information Bulletin: Handling ToolsDocument7 pagesProduct Information Bulletin: Handling ToolsghanNo ratings yet

- Technical Manual: 5 1/2" Clincher® Uht T 5 1/2" UHT B 5 1/2" LOCKJAW™ D P BDocument136 pagesTechnical Manual: 5 1/2" Clincher® Uht T 5 1/2" UHT B 5 1/2" LOCKJAW™ D P BghanNo ratings yet

- Wiper Seal Data Sheet A02 B 11782 1 enDocument2 pagesWiper Seal Data Sheet A02 B 11782 1 enghanNo ratings yet

- Head Clearances Around Screw Heads ... : Home Screws Index Page..Document2 pagesHead Clearances Around Screw Heads ... : Home Screws Index Page..ghanNo ratings yet

- Oilite CatalogueDocument26 pagesOilite CatalogueghanNo ratings yet