Professional Documents

Culture Documents

APA - Construction Pratices For Wood I-Joist Floor Vibration Retrofit

APA - Construction Pratices For Wood I-Joist Floor Vibration Retrofit

Uploaded by

Patrice AudetOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

APA - Construction Pratices For Wood I-Joist Floor Vibration Retrofit

APA - Construction Pratices For Wood I-Joist Floor Vibration Retrofit

Uploaded by

Patrice AudetCopyright:

Available Formats

D

Construction Practices for Wood

I-Joist Floor Vibration Retrofit

INTRODUCTION

Floor vibration is the natural result of dynamic forces acting upon a floor system, caused by something as simple as people

walking across a room. Regardless of floor type, all above-grade floors are subject to some degree of vibration. If the vibration is excessive, it can annoy a homes occupants, detract from their sense of comfort and security, and even lead to fears

about structural safety.

Fortunately, builders can minimize floor vibration through design considerations in new structures and retrofit of existing

structures. This APA publication covers some of the basic construction practices for retrofitting floors.

FLOOR VIBRATION RETROFIT

There are a variety of retrofitting options to consider as you seek ways to

minimize floor vibration in existing buildings. These options vary in effectiveness from one situation to another, and before choosing one or more of

them, you should first identify the cause of each vibration.

Removal of vibrating articles: Since items that vibrate can call attention to floor movement, simply move or remove the items. For example, you

might remedy a vibration problem by removing or rearranging the rattling

dishes in a china cabinet.

Soft-spot correction: Three common causes of vibration are unsupported joist ends (due to support settlement), dimensional change in supporting members, and inadequate attachment of floor sheathing to joists. In

some cases, the resulting soft spots may be eliminated by inserting shims at

appropriate locations.

Increasing floor stiffness or mass: You may be able to resolve vibration problems by increasing a floors stiffness or mass. Here are five options

to consider although some may not be feasible due to unavailable floor

space, inaccessible floor framing and/or other considerations:

ENGINEERED WOOD SYSTEMS

Construction Practices for Wood I-Joist Floor Vibration Retrofit

a) Floor joist reinforcement: To stiffen a floor system, attach 19/32-inch- or

23/32-inch-thick wood structural panels to both sides of each I-joist in the

vicinity of the problematic area. Use panels with the same depth as the

I-joist and install them with the strong panel axis running parallel to the joist

length. When nailing into the I-joist flanges, use the minimum nail spacing

recommendations published by the I-joist manufacturer or APA. Combining

a construction adhesive with the nails will further increase the stiffness of

the floor.

b) Floor sheathing/covering: To increase the stiffness across floor supports,

properly attach (i.e., glue-nail) thicker floor sheathing to the floor joists. The

added mass of an additional floor layer to the top of the joists has a positive

effect on floor performance. Hardwood flooring can also improve floor performance by reducing vibration.

c) Ceiling board attachment: The glue-nail attachment of gypsum ceiling

boards to the bottom of floor joists has a similar effect as the attachment of

an additional floor layer on top. An added benefit is that you may improve

the fire performance rating of the floor system.

Form No. EWS D720

Str

en

g

ax th

is

2004 APA The Engineered Wood Association

www.apawood.org

Construction Practices for Wood I-Joist Floor Vibration Retrofit

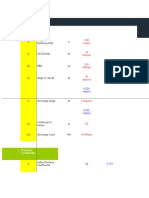

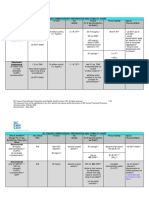

d) Bridging: By using methods

d1

d2

such as blocking, cross bridging, and bottom strapping, you

can increase floor stiffness in

Less

the across-the-joist direction.

than

Although this has little effect on

14'

Greater

than

the natural frequency of a floor

14'

system, it can significantly

I-joist

reduce the vibration amplitude

if it is attached with a continuBridging

or blocking

ous bottom strap. For floor systems of less than 14 feet, install

a single line of between-joist bridging at the mid-span. For longer spans, it is generally recommended that you install

two lines of between-joist bridging at the third-span locations.

e) Span reduction: You can drastically reduce floor vibration if you are able

to add an intermediate support to the floor span. You might introduce a

built-up, 2x lumber column in the location of the problem, a beam system

below the I-joists, or more foundation supports for crawl spaces.

While you might need to consider multiple options to address an existing

floor vibration problem, the nuisance effect can usually be mitigated. In

severe cases, consult a design professional or the I-joist manufacturer. See

APA Technical Note E710 for more information.

Form No. EWS D720

2004 APA The Engineered Wood Association

www.apawood.org

Construction Practices for Wood I-Joist Floor Vibration Retrofit

We have field representatives in many

major U.S. cities and in Canada who can

help answer questions involving APA and

APA EWS trademarked products. For additional assistance in specifying engineered

wood products, contact us:

APA THE ENGINEERED

WOOD ASSOCIATION

HEADQUARTERS

7011 So. 19th St.

Tacoma, Washington 98466

(253) 565-6600 Fax: (253) 565-7265

Addres

eb

s

W

www.apawood.org

PRODUCT SUPPORT HELP DESK

(253) 620-7400

E-mail Address: help@apawood.org

The product use recommendations in this

publication are based on the continuing programs of laboratory testing, product

research, and comprehensive field experience of Engineered Wood Systems. However,

because EWS has no control over quality of

workmanship or the conditions under which

engineered wood products are used, it cannot accept responsibility for product performance or designs as actually constructed.

Because engineered wood product performance requirements vary geographically, consult your local architect, engineer or design

professional to assure compliance with code,

construction, and performance requirements.

Issued August 2004

ENGINEERED WOOD SYSTEMS

Form No. EWS D720

2004 APA The Engineered Wood Association

www.apawood.org

You might also like

- Al Maths Pure Unit 6 MsDocument8 pagesAl Maths Pure Unit 6 MsHacjer EiNSTi3NNo ratings yet

- Various Types of Precast Concrete SlabsDocument33 pagesVarious Types of Precast Concrete SlabsLangit Pinagkait100% (14)

- Topic1 4 Structural Supporting 104Document31 pagesTopic1 4 Structural Supporting 104Baldaniya Bhakti100% (1)

- How to Build a Global Model Earthship Operation II: Concrete WorkFrom EverandHow to Build a Global Model Earthship Operation II: Concrete WorkNo ratings yet

- Complete Book of Framing: An Illustrated Guide for Residential ConstructionFrom EverandComplete Book of Framing: An Illustrated Guide for Residential ConstructionRating: 4 out of 5 stars4/5 (2)

- Improving Sound Insulation in Homes: WWW - Bre.co - Uk/acousticsDocument4 pagesImproving Sound Insulation in Homes: WWW - Bre.co - Uk/acousticshamdulmoeedNo ratings yet

- Acoustic Treatments Acoustic Treatments: Understanding Noise Transmission Between UnitsDocument4 pagesAcoustic Treatments Acoustic Treatments: Understanding Noise Transmission Between UnitsAnonymous LKUkoWqjoNo ratings yet

- N Stress Floor SlabDocument4 pagesN Stress Floor SlabBen Sim NitroNo ratings yet

- Theory of Structures - Floor SystemsDocument31 pagesTheory of Structures - Floor SystemsLawrence Babatunde OgunsanyaNo ratings yet

- Minimizing Floor Vibration by Design and RetrofitDocument0 pagesMinimizing Floor Vibration by Design and RetrofitCrosman StefanNo ratings yet

- Acoustic & Lighting SystemsDocument18 pagesAcoustic & Lighting Systemscyssa2202No ratings yet

- Long Span BeamsDocument9 pagesLong Span BeamsraktalNo ratings yet

- PosiStrut Floor and Roof Installation InstructionsDocument28 pagesPosiStrut Floor and Roof Installation InstructionsBrad La PortaNo ratings yet

- Anatomy of An IIC Rating: Sharon Paley, Ecore International, Lancaster, PennsylvaniaDocument3 pagesAnatomy of An IIC Rating: Sharon Paley, Ecore International, Lancaster, PennsylvaniaRamakrishnan AmbiSubbiah100% (1)

- HyJOIST Brochure (Jul 2008)Document28 pagesHyJOIST Brochure (Jul 2008)GPNo ratings yet

- Theory of Structures - Floor SystemsDocument31 pagesTheory of Structures - Floor SystemsLawrence Babatunde OgunsanyaNo ratings yet

- Tehnologia Posi StrutDocument35 pagesTehnologia Posi Strutdanut_docNo ratings yet

- SBS Design GuideDocument28 pagesSBS Design GuideKristjan IgastaNo ratings yet

- EnerSIP Construction ManualDocument53 pagesEnerSIP Construction ManualIvan Klyuchka100% (2)

- Mezzanine Floor GuideDocument3 pagesMezzanine Floor GuidedraftingNo ratings yet

- Mortar Less Block SystemsDocument4 pagesMortar Less Block SystemsCarlos Alejandro Molina Paz100% (2)

- Texto Fuente - BT3Document1 pageTexto Fuente - BT3Oviedo RocíoNo ratings yet

- Group 1 Report Cast in Place and Precast Slab TypesDocument55 pagesGroup 1 Report Cast in Place and Precast Slab TypesAlwyn RamosNo ratings yet

- Floor StiffnessDocument2 pagesFloor StiffnessKristin MunozNo ratings yet

- APA Rated Sheathing & Structural 1 Sheathing-LP OSBDocument5 pagesAPA Rated Sheathing & Structural 1 Sheathing-LP OSBhoojzteNo ratings yet

- How To Build A DeckDocument8 pagesHow To Build A DeckDavid Somes100% (2)

- Woodframemultistory Article PDFDocument19 pagesWoodframemultistory Article PDFLouis AndersonNo ratings yet

- Flat SlabDocument11 pagesFlat SlabMasroor Ansari100% (2)

- Floor Truss GuideDocument4 pagesFloor Truss GuideSamia H. BhuiyanNo ratings yet

- Install Prefinished Hardwood Flooring: The Quick Way ToDocument6 pagesInstall Prefinished Hardwood Flooring: The Quick Way Tok1l2d3No ratings yet

- Different Floor SystemsDocument25 pagesDifferent Floor Systemsfoush bashaNo ratings yet

- Comparison Study For Various Structural Slab SystemsDocument12 pagesComparison Study For Various Structural Slab SystemsIssam SalehNo ratings yet

- Section 09 Resilient Wood Flooring System Junckers Duobat 110+ SystemDocument3 pagesSection 09 Resilient Wood Flooring System Junckers Duobat 110+ SystemLindbladJunckersNo ratings yet

- Minimize Floor Vibration ProblemsDocument3 pagesMinimize Floor Vibration ProblemsDawit SolomonNo ratings yet

- Flat RoofDocument2 pagesFlat RoofHarry ThienNo ratings yet

- Site Cast Fla T Slab Construction: Group #5 - Concrete Research AssignmentDocument14 pagesSite Cast Fla T Slab Construction: Group #5 - Concrete Research Assignmentsanzio sanNo ratings yet

- Mini ProjectDocument14 pagesMini ProjectMr. Himanshu111100% (1)

- Preventing Annoying Floor Vibration: by Dr. Frank E. Woeste, P. EDocument4 pagesPreventing Annoying Floor Vibration: by Dr. Frank E. Woeste, P. EfraantoineNo ratings yet

- Long-Span, Open-Web TrussesDocument8 pagesLong-Span, Open-Web Trussesmina saadatNo ratings yet

- Steelwise Low Floor HeightsDocument2 pagesSteelwise Low Floor Heightsalberto rosadoNo ratings yet

- Aggregate Block Product GuideDocument24 pagesAggregate Block Product Guidemrafig5292No ratings yet

- 6034f4e970fc1d66dc4c9f13 - Handbok Posi-Joist v20-3 - ENG - LQDocument37 pages6034f4e970fc1d66dc4c9f13 - Handbok Posi-Joist v20-3 - ENG - LQranafoul42No ratings yet

- When Is Blocking - Bracing Within Wood-Frame Walls Required - WoodWorksDocument3 pagesWhen Is Blocking - Bracing Within Wood-Frame Walls Required - WoodWorksSamia H. BhuiyanNo ratings yet

- Waffle SlabDocument3 pagesWaffle Slabnarotham_medi4108100% (2)

- Designing Diaphragms Over Existing Board Floors or Roofs: Technical TopicsDocument4 pagesDesigning Diaphragms Over Existing Board Floors or Roofs: Technical Topicsyoshdog@gmail.comNo ratings yet

- Boral Silkwood Eng Floor Install GuideDocument8 pagesBoral Silkwood Eng Floor Install GuideRoss LoveladyNo ratings yet

- Benefits of Lattice GirderDocument1 pageBenefits of Lattice GirderkantkrisNo ratings yet

- Bison Hollow Core Floors March 2007Document15 pagesBison Hollow Core Floors March 2007walshceNo ratings yet

- Upper FloorsDocument15 pagesUpper Floorsangeline1559No ratings yet

- Flexible Resin Mouldings For Curved Applications: Interior or Exterior ApplicationsDocument2 pagesFlexible Resin Mouldings For Curved Applications: Interior or Exterior ApplicationsjewellyaNo ratings yet

- Construction Methodologies Ceiling FinishesDocument6 pagesConstruction Methodologies Ceiling FinishesDonita DaquizNo ratings yet

- Hard Side Cloud SystemDocument2 pagesHard Side Cloud SystemonspsnonsNo ratings yet

- To Utilize The Slab Thickness To Optimum Level, The Essential Aspects That Should Be Kept in Mind AreDocument12 pagesTo Utilize The Slab Thickness To Optimum Level, The Essential Aspects That Should Be Kept in Mind Arediana shaineNo ratings yet

- Installing A Floor-Based Unit: Tools MaterialsDocument1 pageInstalling A Floor-Based Unit: Tools MaterialsreacharunkNo ratings yet

- Flat Plate: Advantages of SystemDocument17 pagesFlat Plate: Advantages of Systemchad quizzaganNo ratings yet

- Group5 - Concrete Research Assignment - Building Tech4Document14 pagesGroup5 - Concrete Research Assignment - Building Tech4Sam AlvarezNo ratings yet

- VSL Product Watch Crigler Jan 08.532Document4 pagesVSL Product Watch Crigler Jan 08.532Lau Kim HwaNo ratings yet

- Wood DeckDocument24 pagesWood Deckdbogantesg9710No ratings yet

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- Build Your Own Six-Seater Picnic Table: Using 2 x 4 (50 x 100 mm) Lumber, #1From EverandBuild Your Own Six-Seater Picnic Table: Using 2 x 4 (50 x 100 mm) Lumber, #1No ratings yet

- G51MP Service FilesDocument53 pagesG51MP Service Files74747474No ratings yet

- G51MPDocument18 pagesG51MP74747474No ratings yet

- Girder TrussDocument0 pagesGirder Truss74747474No ratings yet

- Carrier Ratings 4-15-13Document1 pageCarrier Ratings 4-15-1374747474No ratings yet

- The SNG Blueprint Part 1 PDFDocument26 pagesThe SNG Blueprint Part 1 PDFAdrian PatrikNo ratings yet

- Microstructure and Defects in NanomaterialsDocument32 pagesMicrostructure and Defects in NanomaterialsSreedhar MadhanaNo ratings yet

- AirlinesDocument16 pagesAirlinesPipie SafikahNo ratings yet

- Depth (M) Soil Description Depth (M) Soil Description: Subsurface Exploration (SPT) Geoforma Engenharia LtdaDocument9 pagesDepth (M) Soil Description Depth (M) Soil Description: Subsurface Exploration (SPT) Geoforma Engenharia LtdaJAVIER ADRIANNo ratings yet

- Website Designing Company in DallasDocument6 pagesWebsite Designing Company in DallasRyan WilsonNo ratings yet

- Literature Survey On Smart Surveillance SystemDocument4 pagesLiterature Survey On Smart Surveillance SystemMuhammed NayeemNo ratings yet

- Nippon SteelDocument7 pagesNippon SteelAnonymous 9PIxHy13No ratings yet

- Bender-Http-Sample ReportDocument3 pagesBender-Http-Sample ReportNicoleNo ratings yet

- Lamp Ba t302Document16 pagesLamp Ba t302Yeni EkaNo ratings yet

- Anh - 10Document50 pagesAnh - 10Hưng PhúNo ratings yet

- PE Curriculum Grade 9-12Document2 pagesPE Curriculum Grade 9-12agungsportnetasNo ratings yet

- Case Study - SkyworksDocument46 pagesCase Study - SkyworksMohd Fadzli JiFadNo ratings yet

- VSX-830-K - Single Sheet - ENDocument2 pagesVSX-830-K - Single Sheet - ENEDNo ratings yet

- Git TaskDocument2 pagesGit TaskLissa JacksonNo ratings yet

- Chapter 5Document17 pagesChapter 5firomsaguteta12No ratings yet

- CD800 User Reference GuideDocument36 pagesCD800 User Reference GuideHarry MuñozNo ratings yet

- I) Height of Retaining Wall H: Preliminary DataDocument10 pagesI) Height of Retaining Wall H: Preliminary DataOmPrakashNo ratings yet

- MANUAL DESENVOLVIMENTO BSSV E24218Document146 pagesMANUAL DESENVOLVIMENTO BSSV E24218valdirsaraujoNo ratings yet

- Our Nation Is in Crisis Our People Are Suffering Let Us Stop Being Part of The Problem Let Us Be Part of The Solution Let Us Be Good CitizensDocument12 pagesOur Nation Is in Crisis Our People Are Suffering Let Us Stop Being Part of The Problem Let Us Be Part of The Solution Let Us Be Good CitizensWerba, Allysa Mae T.No ratings yet

- Light Rail TransitDocument4 pagesLight Rail TransitnalakasaNo ratings yet

- Chemo Stability Chart - AtoKDocument59 pagesChemo Stability Chart - AtoKAfifah Nur Diana PutriNo ratings yet

- Dict Qap007 v2.0 Cryptography PolicyDocument9 pagesDict Qap007 v2.0 Cryptography PolicyXuân LâmNo ratings yet

- Ñas, Crizelle S. BSHM 1-2Document3 pagesÑas, Crizelle S. BSHM 1-2Jophet Banabana MagalonaNo ratings yet

- Peritonitis Capd-1Document15 pagesPeritonitis Capd-1David SenNo ratings yet

- LESSON 3: Talk About Your Weekend or Holiday Plan Using VerbsDocument3 pagesLESSON 3: Talk About Your Weekend or Holiday Plan Using VerbsjoannaNo ratings yet

- UN Khashoggi Report June 2019Document99 pagesUN Khashoggi Report June 2019Anonymous p0KZKccNo ratings yet

- Aravalli Province: Shashwat Sinha Mtech GLT Iit RoorkeeDocument33 pagesAravalli Province: Shashwat Sinha Mtech GLT Iit RoorkeeGirijesh PandeyNo ratings yet

- Innovative Strategies For Flood-Resilient CitiesDocument50 pagesInnovative Strategies For Flood-Resilient CitiesDaisy100% (1)

- Electronics and Communication Engineering (EC) - 21.03.18Document1 pageElectronics and Communication Engineering (EC) - 21.03.18Dishani LahiriNo ratings yet