Professional Documents

Culture Documents

Title Explain Principles of The Chemical Recovery Process in The Production of Kraft Wood Pulp Level 4 Credits 5

Title Explain Principles of The Chemical Recovery Process in The Production of Kraft Wood Pulp Level 4 Credits 5

Uploaded by

Srinivasa Rao VenkumahanthiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Title Explain Principles of The Chemical Recovery Process in The Production of Kraft Wood Pulp Level 4 Credits 5

Title Explain Principles of The Chemical Recovery Process in The Production of Kraft Wood Pulp Level 4 Credits 5

Uploaded by

Srinivasa Rao VenkumahanthiCopyright:

Available Formats

NZQA registered unit standard

5680 version 5

Page 1 of 4

Title

Explain principles of the chemical recovery process in the production

of kraft wood pulp

Level

Credits

Purpose

People credited with this unit standard are able to explain: the

purpose of the chemical recovery process in the kraft cycle, the

black liquor evaporation process, the operating principles of a

recovery boiler, and the recausticising process.

This unit standard aims to provide knowledge of the principles

and equipment used in the recovery of chemicals in the kraft

process.

Classification

Wood Fibre Manufacturing > Pulp and Paper - Chemical Plants

Available grade

Achieved

Explanatory notes

1

All evidence requirements must be demonstrated and assessed in accordance with

the reference texts: Pulp & Papermaking Technology, Unit 84, Kraft Pulping

Chemical Recovery, and Unit 85, Soda AQ Pulping Chemical Recovery, (Australia:

Box Hill College of TAFE, 1998), available through Competenz PO Box 9005,

Newmarket, Auckland 1149.

Abbreviations used in this unit standard are:

BLOX black liquor oxidation

SBLOX strong black liquor oxidation

WBLOX weak black liquor oxidation.

Outcomes and evidence requirements

Outcome 1

Explain the purpose of the chemical recovery process in the kraft cycle.

Evidence requirements

1.1

Reasons for chemical recovery are identified and explained.

Range

1.2

chemical cost, economics, heat recovery, environmental.

Elements of the kraft cycle are identified and their functions are explained.

Range

Competenz

SSB Code 101571

digester, evaporators, BLOX, recovery boiler, causticiser.

New Zealand Qualifications Authority 2016

NZQA registered unit standard

1.3

5680 version 5

Page 2 of 4

Chemicals present in each stage are identified.

Range

chemicals sodium hydroxide, sodium sulphide, sodium

carbonate, sodium sulphate, calcium oxide, calcium hydroxide,

calcium carbonate.

Outcome 2

Explain the black liquor evaporation process.

Evidence requirements

2.1

The requirement to increase the black liquor solids is explained in terms of

combustion and safety.

2.2

Multiple effect evaporators and their operation are explained in terms of heat

exchange, heat recovery, vapour pressures, and solids contents.

2.3

Direct contact evaporator operation is explained in terms of solids, flue gas, and

odour generation.

Range

2.4

type cascade.

Types of black liquor oxidation are explained in terms of use of air, sodium

thiosulphate production, and odour control.

Range

types SBLOX, WBLOX.

Outcome 3

Explain the operating principles of a recovery boiler.

Evidence requirements

3.1

Functions of a recovery boiler are identified and explained in terms of

combustion, chemical conversion, and steam generation.

3.2

Components of the recovery boiler are identified and their functions are

explained in accordance with the reference text.

Range

3.3

superheater, boiler, economiser, electrostatic precipitator, liquor

heater, liquor guns, air ports.

Chemical changes resulting from combustion are identified for organic and

inorganic compounds.

Range

Competenz

SSB Code 101571

sodium carbonate, sodium sulphide, sodium hydroxide, sodium

sulphate, lignin.

New Zealand Qualifications Authority 2016

NZQA registered unit standard

5680 version 5

Page 3 of 4

Outcome 4

Explain the recausticising process.

Evidence requirements

4.1

Components of the causticising plant are identified and their functions are

explained.

Range

4.2

dregs washer, slaker, causticising tanks, clarifier, filter.

Chemical reactions taking place at the slaking, causticising, and lime kiln are

identified and explained.

Range

4.3

one reaction at each process is required.

Lime kilns are described and their operation is explained in terms of drying,

heating, and gas release.

Planned review date

31 December 2019

Status information and last date for assessment for superseded versions

Process

Version

Date

Last Date for Assessment

Registration

23 November 1995

N/A

Revision

27 January 1997

N/A

Review

25 February 1999

N/A

Review

18 December 2006

N/A

Review

24 October 2014

N/A

Consent and Moderation Requirements (CMR) reference

0173

This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do.

Please note

Providers must be granted consent to assess against standards (accredited) by NZQA,

before they can report credits from assessment against unit standards or deliver courses

of study leading to that assessment.

Industry Training Organisations must be granted consent to assess against standards by

NZQA before they can register credits from assessment against unit standards.

Providers and Industry Training Organisations, which have been granted consent and

which are assessing against unit standards must engage with the moderation system that

applies to those standards.

Requirements for consent to assess and an outline of the moderation system that applies

to this standard are outlined in the Consent and Moderation Requirements (CMR). The

Competenz

SSB Code 101571

New Zealand Qualifications Authority 2016

NZQA registered unit standard

5680 version 5

Page 4 of 4

CMR also includes useful information about special requirements for organisations wishing

to develop education and training programmes, such as minimum qualifications for tutors

and assessors, and special resource requirements.

Comments on this unit standard

Please contact Competenz qualifications@competenz.org.nz if you wish to suggest

changes to the content of this unit standard.

Competenz

SSB Code 101571

New Zealand Qualifications Authority 2016

You might also like

- K60002 - K60092 Manual REV CDocument22 pagesK60002 - K60092 Manual REV CJohan Mongua100% (1)

- Plastic Testing UL 746A TestingDocument7 pagesPlastic Testing UL 746A TestingAnonymous 8lxxbNcA0sNo ratings yet

- FM - 10 67 2Document11 pagesFM - 10 67 2keirajaviercruz0% (2)

- Astm d396 Fuel OilsDocument5 pagesAstm d396 Fuel Oilsjhon.rojas.ery1489No ratings yet

- Demonstrate Knowledge of Gas Combustion, Burners, Control Systems, and Flame ProtectionDocument3 pagesDemonstrate Knowledge of Gas Combustion, Burners, Control Systems, and Flame ProtectionGhulam AbbasNo ratings yet

- Title Operate and Maintain Gas-Fired Water Bath Heater Equipment in A Gas Network Level 4 Credits 4Document4 pagesTitle Operate and Maintain Gas-Fired Water Bath Heater Equipment in A Gas Network Level 4 Credits 4BensmatElHouariNo ratings yet

- Operate and Maintain Gas-Fired Water BatDocument4 pagesOperate and Maintain Gas-Fired Water Batluis piNo ratings yet

- Demonstrate and Apply Knowledge of Industrial Refrigeration System DesignDocument4 pagesDemonstrate and Apply Knowledge of Industrial Refrigeration System DesignVijay MummigattiNo ratings yet

- (Download PDF) Fuel Cell Systems Explained Third Edition Andrew Dicks Online Ebook All Chapter PDFDocument39 pages(Download PDF) Fuel Cell Systems Explained Third Edition Andrew Dicks Online Ebook All Chapter PDFthomas.scott449100% (9)

- Operate Boiler Circulating Pumps in A Thermal Electricity Generation Power StationDocument4 pagesOperate Boiler Circulating Pumps in A Thermal Electricity Generation Power StationMark KNo ratings yet

- Pumps in A Thermal Electricity Generation Power Station: Level 4 Credits 2 PurposeDocument4 pagesPumps in A Thermal Electricity Generation Power Station: Level 4 Credits 2 PurposeMark KNo ratings yet

- Title Clean The Gas Path of Aircraft Gas Turbine Engines Level 4 Credits 2Document3 pagesTitle Clean The Gas Path of Aircraft Gas Turbine Engines Level 4 Credits 2misba shaikhNo ratings yet

- AHRI 740 1998 Corrected TablesDocument21 pagesAHRI 740 1998 Corrected TablesBernardo LeorNo ratings yet

- Editedl. Meps and Labelling Programs-1Document33 pagesEditedl. Meps and Labelling Programs-1Helen B. AriasNo ratings yet

- Boiler Lay Up Procedure AEP1026Document17 pagesBoiler Lay Up Procedure AEP1026masoodismNo ratings yet

- Air Conditioners Determination - Exposure Draft March 2018Document64 pagesAir Conditioners Determination - Exposure Draft March 2018Kool PirateNo ratings yet

- EpaDocument56 pagesEpajohn_yutzy100% (1)

- Operate A Steam Turbine: Level 4 Credits 14 PurposeDocument4 pagesOperate A Steam Turbine: Level 4 Credits 14 PurposeMije SahajaNo ratings yet

- Modelling of Solid Recovered Fuel (SRF) Properties Based On Material Composition - Chloride QualityDocument13 pagesModelling of Solid Recovered Fuel (SRF) Properties Based On Material Composition - Chloride QualitySlovenaccNo ratings yet

- Performance Test by SEDADocument67 pagesPerformance Test by SEDAMohd AshakriNo ratings yet

- cs4 2ch2Document66 pagescs4 2ch2Sarfaraz KhanNo ratings yet

- SCRCostManualchapter Draftforpubliccomment6!5!2015Document101 pagesSCRCostManualchapter Draftforpubliccomment6!5!2015Mustika Putri PertiwiNo ratings yet

- Inventory Renewable Energy StandardsDocument41 pagesInventory Renewable Energy Standardskolombo1776No ratings yet

- Tga, Carbon Dioxide Capture From Flue GasDocument13 pagesTga, Carbon Dioxide Capture From Flue GasMuhammad Shahzad KhurramNo ratings yet

- Metering StandardsDocument101 pagesMetering StandardsJonathan Narh-DometeyNo ratings yet

- Nfpa 120 - 2023Document184 pagesNfpa 120 - 2023henrique.hs18No ratings yet

- SAEP 357cDocument5 pagesSAEP 357cAnonymous 4IpmN7OnNo ratings yet

- Guide To Good Industry Practice LPG Cylinder Filling FV2 PDFDocument60 pagesGuide To Good Industry Practice LPG Cylinder Filling FV2 PDFMarco CetiNo ratings yet

- Title Maintain Aircraft Mechanical Ice and Rain Protection Systems Level 4 Credits 6Document4 pagesTitle Maintain Aircraft Mechanical Ice and Rain Protection Systems Level 4 Credits 6BurhanudinUrcNo ratings yet

- Hydrocarbons DewDocument37 pagesHydrocarbons DewPasquale CutriNo ratings yet

- Title Maintain Control Valve Actuators and Positioners Level 3 Credits 5Document4 pagesTitle Maintain Control Valve Actuators and Positioners Level 3 Credits 5Sarah Shibu ThomasNo ratings yet

- Refrigerant Recover/Recycling Equipment: 1998 Standard ForDocument21 pagesRefrigerant Recover/Recycling Equipment: 1998 Standard ForMazen MohamedNo ratings yet

- NORSOK I-104 - Rev. 2 - June 1998Document51 pagesNORSOK I-104 - Rev. 2 - June 1998Walid LabidiNo ratings yet

- Waste Reduction in Metal Casting and Heat Treatment IndustryDocument224 pagesWaste Reduction in Metal Casting and Heat Treatment IndustryVedaraman Iyer100% (1)

- 1104 - Install Sub-Soil DrainageDocument4 pages1104 - Install Sub-Soil DrainagelaikienfuiNo ratings yet

- Carry Out Cathodic Protection System Troubleshooting Survey in The Gas Transmission IndustryDocument4 pagesCarry Out Cathodic Protection System Troubleshooting Survey in The Gas Transmission IndustryImam BuchairiNo ratings yet

- FCRC PR 01-02 Project3p22Document402 pagesFCRC PR 01-02 Project3p221jess6No ratings yet

- Title Carry Out Tests On Distribution Oil Filled Power Transformers of 33kV and Below 10 MVA Level 4 Credits 5Document6 pagesTitle Carry Out Tests On Distribution Oil Filled Power Transformers of 33kV and Below 10 MVA Level 4 Credits 5alifdotsNo ratings yet

- Astm D 3172 - 89 R02Document2 pagesAstm D 3172 - 89 R02phaindikaNo ratings yet

- Class Programme: Approval of ManufacturersDocument16 pagesClass Programme: Approval of ManufacturersalexNo ratings yet

- Demonstrate Knowledge of Stringing, Tensioning, and Terminating Transmission Network ConductorsDocument3 pagesDemonstrate Knowledge of Stringing, Tensioning, and Terminating Transmission Network ConductorsGhayas Ud-din DarNo ratings yet

- M 650 U 4Document30 pagesM 650 U 4dzardoniNo ratings yet

- BP - GP 32-48-In Service Inspection and Testing of Heat ExchangersDocument16 pagesBP - GP 32-48-In Service Inspection and Testing of Heat ExchangersAmr SolimanNo ratings yet

- PV 1425 (2008) Lubricating Oil Corrosivity TestDocument4 pagesPV 1425 (2008) Lubricating Oil Corrosivity TestMatthew TaylorNo ratings yet

- Converting Power Into Chemicals and Fuels Martin Bajus Full ChapterDocument67 pagesConverting Power Into Chemicals and Fuels Martin Bajus Full Chaptermichael.smith532100% (7)

- Saep 1025Document50 pagesSaep 1025Aneesh JosephNo ratings yet

- Asme Certification ProgDocument12 pagesAsme Certification ProgLai Mei EeNo ratings yet

- Gma 501Document11 pagesGma 501Mohamad Nadzri YahayaNo ratings yet

- Proposal Based On EN 14742Document19 pagesProposal Based On EN 14742Popescu IoanaNo ratings yet

- Centrífuga K60002 - K60092 Operation ManualDocument22 pagesCentrífuga K60002 - K60092 Operation ManualCamila LealNo ratings yet

- Food Production - Beverages Demonstrate Knowledge of Engineering Support Services For Beverage Manufacturing PlantsDocument6 pagesFood Production - Beverages Demonstrate Knowledge of Engineering Support Services For Beverage Manufacturing PlantsAaditya SinhaNo ratings yet

- Astm.d396 Fuel Oil SpecxDocument8 pagesAstm.d396 Fuel Oil SpecxMichael HengNo ratings yet

- Dda 42 ADocument32 pagesDda 42 AEtHical EmoTionNo ratings yet

- Quality and Reliability Aspects in Nuclear Power Reactor Fuel Engineering: Guidance and Best Practices to Improve Nuclear Fuel Reliability and Performance in Water Cooled ReactorsFrom EverandQuality and Reliability Aspects in Nuclear Power Reactor Fuel Engineering: Guidance and Best Practices to Improve Nuclear Fuel Reliability and Performance in Water Cooled ReactorsNo ratings yet

- Fine Particle (2.5 microns) Emissions: Regulations, Measurement, and ControlFrom EverandFine Particle (2.5 microns) Emissions: Regulations, Measurement, and ControlNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Project (Mechanical) Department - Attendance Sheet For The Month of September - 2017Document3 pagesProject (Mechanical) Department - Attendance Sheet For The Month of September - 2017Srinivasa Rao VenkumahanthiNo ratings yet

- Benitez Cap9Document44 pagesBenitez Cap9Srinivasa Rao VenkumahanthiNo ratings yet

- PMT-HelponExceltool Demo LockedDocument253 pagesPMT-HelponExceltool Demo LockedSrinivasa Rao VenkumahanthiNo ratings yet

- To, Income Tax Department - CPC, Post Bag No - 1, Electronic City Post Office, BENGALURU - 560 100, Karnataka - IndiaDocument1 pageTo, Income Tax Department - CPC, Post Bag No - 1, Electronic City Post Office, BENGALURU - 560 100, Karnataka - IndiaSrinivasa Rao VenkumahanthiNo ratings yet

- Tectyl 506 PDFDocument4 pagesTectyl 506 PDFjaskaran singhNo ratings yet

- Steam Trap Selection: Understanding SpecificationsDocument5 pagesSteam Trap Selection: Understanding SpecificationsSrinivasa Rao VenkumahanthiNo ratings yet

- 1 X 650 Tds Chemical Recovery Boiler - Pressure Parts Manufacuring Discrepancies (Tirchy)Document1 page1 X 650 Tds Chemical Recovery Boiler - Pressure Parts Manufacuring Discrepancies (Tirchy)Srinivasa Rao VenkumahanthiNo ratings yet

- Employee Certification LetterDocument1 pageEmployee Certification LetterSrinivasa Rao VenkumahanthiNo ratings yet

- Group Erw Seamless Product BrochureDocument6 pagesGroup Erw Seamless Product BrochureSrinivasa Rao VenkumahanthiNo ratings yet

- Tectyl 506 OilDocument1 pageTectyl 506 OilSrinivasa Rao VenkumahanthiNo ratings yet

- Scheduel For 1 X 400 Tds Upgradtion To 1 X 600 TdsDocument1 pageScheduel For 1 X 400 Tds Upgradtion To 1 X 600 TdsSrinivasa Rao VenkumahanthiNo ratings yet

- Commissioning Schedule 01Document30 pagesCommissioning Schedule 01Srinivasa Rao VenkumahanthiNo ratings yet

- NEW 1 X 2100 M Induced Drfat Cooling Tower: Data For Pumps Sl. No Description UOM Specification RemarksDocument1 pageNEW 1 X 2100 M Induced Drfat Cooling Tower: Data For Pumps Sl. No Description UOM Specification RemarksSrinivasa Rao VenkumahanthiNo ratings yet

- Kirana Items ListDocument10 pagesKirana Items ListSrinivasa Rao Venkumahanthi100% (1)

- Aew - 003Document3 pagesAew - 003Srinivasa Rao VenkumahanthiNo ratings yet

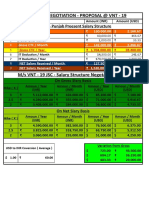

- VNT - 19Document1 pageVNT - 19Srinivasa Rao VenkumahanthiNo ratings yet

- Dial GaadgeDocument2 pagesDial GaadgeSrinivasa Rao VenkumahanthiNo ratings yet

- Bfs Deaerator RFQDocument2 pagesBfs Deaerator RFQSrinivasa Rao VenkumahanthiNo ratings yet

- Chimney Calculation SheetDocument14 pagesChimney Calculation SheetSrinivasa Rao VenkumahanthiNo ratings yet

- Total 183,051.21: SL - No Particulars Qty. Rate Weight in KG Amount Rs. PDocument2 pagesTotal 183,051.21: SL - No Particulars Qty. Rate Weight in KG Amount Rs. PSrinivasa Rao VenkumahanthiNo ratings yet

- Belt Sway Control PDFDocument29 pagesBelt Sway Control PDFSrinivasa Rao Venkumahanthi0% (1)

- Welding Manual Nov 2010Document187 pagesWelding Manual Nov 2010Sumit Chaurasia100% (4)

- Loss Incurred Due To Low Steam Economy in Evaporaor For The Month of Dec-16Document1 pageLoss Incurred Due To Low Steam Economy in Evaporaor For The Month of Dec-16Srinivasa Rao VenkumahanthiNo ratings yet

- Amino AcidsDocument6 pagesAmino AcidsserkanitoguapitoNo ratings yet

- Organic Compound Identification Using Infrared SpectrosDocument34 pagesOrganic Compound Identification Using Infrared SpectrosRohit SinghNo ratings yet

- Product Bulletin - PHPADocument1 pageProduct Bulletin - PHPAEliz MelizaNo ratings yet

- MaterialsDocument4 pagesMaterialsSilvio VarricchioNo ratings yet

- Grade VII ScienceDocument20 pagesGrade VII ScienceSunny BbaNo ratings yet

- Karl Fischer Water DeterminationDocument3 pagesKarl Fischer Water DeterminationEmad AliNo ratings yet

- TMP - 26271-I Transistor127230328Document7 pagesTMP - 26271-I Transistor127230328Prasath KumarNo ratings yet

- Lecture #2. Contact Between Solids. Solid Surfaces. Roughness of Surfaces. Characterization of Surface TopographyDocument10 pagesLecture #2. Contact Between Solids. Solid Surfaces. Roughness of Surfaces. Characterization of Surface TopographyAbdulla CamalNo ratings yet

- Biology NotesDocument161 pagesBiology NotesBlohsh KeenenNo ratings yet

- Chapter 5: Chemical Bonds 5.1 Understanding Formation of CompoundsDocument3 pagesChapter 5: Chemical Bonds 5.1 Understanding Formation of CompoundsMSKNo ratings yet

- Kosmetika Untuk Kesehatan Dan KecantikanDocument18 pagesKosmetika Untuk Kesehatan Dan KecantikanRoni XiddNo ratings yet

- Fluidised Bed Reactor 1Document10 pagesFluidised Bed Reactor 1Michael Kang'eriNo ratings yet

- Electrochemical Potential Controlling FlotationDocument12 pagesElectrochemical Potential Controlling FlotationAndrea Rivera YucraNo ratings yet

- 0620 m17 QP 62 PDFDocument8 pages0620 m17 QP 62 PDFMinakshiNo ratings yet

- Formula Sheet Final ExamDocument9 pagesFormula Sheet Final ExamKevin HuangNo ratings yet

- Food Research International: ReviewDocument14 pagesFood Research International: ReviewCamila Andrea VillamizarNo ratings yet

- Chapter 5 Hydrocarbon 5.2Document112 pagesChapter 5 Hydrocarbon 5.2AwatifNo ratings yet

- Chapter 7: Protein Function Part I: Myoglobin and HemoglobinDocument27 pagesChapter 7: Protein Function Part I: Myoglobin and HemoglobineliNo ratings yet

- Lysine Decarboxylase TestDocument3 pagesLysine Decarboxylase TestIsraa BioNo ratings yet

- XiGo Note 103 Silica Surface Area With The Acorn AreaDocument4 pagesXiGo Note 103 Silica Surface Area With The Acorn Areaprakush01975225403No ratings yet

- M2-Materials TechnologyDocument81 pagesM2-Materials Technologynr satiraNo ratings yet

- Lipids TestsDocument12 pagesLipids TestsNikki Nina Arabe BarcinasNo ratings yet

- Teachers GuideDocument10 pagesTeachers Guidemyral_4No ratings yet

- General Biology (Biol. 1012) : Course Instructor: Kabeta LegeseDocument48 pagesGeneral Biology (Biol. 1012) : Course Instructor: Kabeta LegeseKena MegersaNo ratings yet

- Crystal Growing Tips and Methods Xe0crhDocument7 pagesCrystal Growing Tips and Methods Xe0crhartprogressivaNo ratings yet

- Chemistry 9701 GCE A/AS Level For Examination in 2008Document70 pagesChemistry 9701 GCE A/AS Level For Examination in 2008Hubbak KhanNo ratings yet

- Secondary Metabolites 2003 PDFDocument149 pagesSecondary Metabolites 2003 PDFOctavio ZapataNo ratings yet

- Ropemanship and Knot TyingDocument44 pagesRopemanship and Knot TyingPHILLIP JOSEPH EBORDE94% (16)

- Tracking Environmental Change Using Lake Sediments. Volume 2: Physical and Geochemical MethodsDocument22 pagesTracking Environmental Change Using Lake Sediments. Volume 2: Physical and Geochemical MethodsHarmin Adijaya PutriNo ratings yet

- MSDS KathonDocument8 pagesMSDS KathonSuresh RamasamyNo ratings yet