Professional Documents

Culture Documents

Surge Tank Maint Bulletin PDF

Surge Tank Maint Bulletin PDF

Uploaded by

ihllhmOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Surge Tank Maint Bulletin PDF

Surge Tank Maint Bulletin PDF

Uploaded by

ihllhmCopyright:

Available Formats

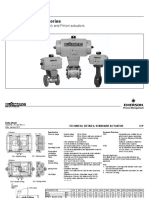

Choosing a Surge Tank and Determining Pressure Rise

Surge Tank Product Specifications

DADCO Surge Tanks are used with open-flow systems to increase the volume in the system thereby reducing the pressure

rise when cylinders are stroked. Operating with a lower pressure rise will decrease the wear on the nitrogen gas spring

components and reduce the load on the press. To determine the appropriate Surge Tank size for your system please

consider the design information provided. Note: All calculations are based on Isothermal conditions.

The Surge Tank is offered in two Models: F Free Flow Model has multiple open ports supplied

as standard for maximum flexibility when piping; M1 SMS-i Model has a bottom port for

attachement to a base plate. Gauges and shut-off ball valves are available upon request.

For assistance in determining appropriate Surge Tank size for your system, refer to the

instructions provided or contact DADCO with the cylinder size, length of stroke being used

and amount of pressure rise desired. DADCO 90.700 (Y-700) / 90.705 (Y-705) hose is

generally not recommended for use with Surge Tanks due to restricted flow capability.

In addition, DADCO offers a Force Calculator at www.dadco.net that calculates pressure rise, initial force and final

force during operation for linked systems with or without Surge Tanks.

U / UT / UH / UX Series

Internal Volume Adder Rod Volume Adder

Model

Vinternal

Vrod

(L/mm)

(L/mm)

U / UT / UH

Series

Volume

V0

(L)

UX Series

90.10 / 90.8 Series

ST.50.150.B29

Volume

V0

(L)

Internal Volume Adder Rod Volume Adder

Model

Vinternal

Vrod

(L/mm)

(L/mm)

Volume

V0

(L)

1000

0.0015

0.0006

0.0005

0.0363

0750

0.0013

0.0005

0.0041

1600

0.0025

0.0010

0.0075

0.0570

1500

0.0031

0.0010

0.0199

2600

0.0038

0.0016

0.0057

0.1264

3000

0.0050

0.0020

0.0337

4600

0.0062

0.0028

0.0210

0.2301

5000

0.0079

0.0033

0.0468

6600

0.0099

0.0044

0.0464

0.4594

7500

0.0123

0.0050

0.1257

9600

0.0151

0.0064

0.1135

0.7137

10000

0.0214

0.0071

0.2241

20000

0.0292

0.0133

0.2865

1.0590

G 1/8 Port

(Plugged)

4x

G 1/8 Port

(Plugged)

Preferred Mounts for Surge Tanks.

See the 90.10 /90.8 Catalog for mount details.

90.11

B11

Safety tab for

vertical mounting

90.21

B21

X+Y

X+Y

NOTE: B11 mount available

with ST.30-ST.75 models only

Surge Tank

ST.30

ST.50

ST.75

ST.100

95

120

150

195

117

137

152

157

Length:

Y

50

X+Y

4 x G 1/8 Port

(Supplied with 3

90.505.110 plugs)

Volume of Tank

VS.T.

0.59

1.05

1.71

100

0.85

1.44

2.33

3.99

150

1.10

1.83

2.94

5.06

200

1.35

2.22

3.56

6.13

250

1.60

2.62

4.17

7.20

300

1.85

3.01

4.78

8.27

350

2.10

3.40

5.40

9.34

400

2.35

3.79

6.01

10.41

F Free Flow Model

ST

D

X

Y

50

Solving for Pressure Rise when Nitrogen Gas Springs and Surge Tank is known:

To calculate the pressure rise of a Nitrogen Gas Spring and Surge Tank system, first calculate the internal volume of the gas

springs, where VG.S. = Internal Volume of Gas Springs, Vinternal = Internal Volume Adder, S = Stroke, V0 = Initial Volume and

N = Number of Gas Springs per Surge Tank.

VG.S. = (Vinternal *S + V0) * N

Next, calculate the volume of the system, where VS = Volume of the System, VG.S. = Volume of the Gas Springs and

VS.T. = Volume of the Surge Tank.

M1 SMS-i Model

30

95

50

120

75

150

3.74

4.72

5.91

7.67

117

137

152

157

4.61

5.39

5.98

6.18

0.59

100

195

Volume of Tank L (in3)

1.05

1.71

2.92

1.97

36

64

105

178

100

0.85

1.44

2.33

3.99

After the volume of the system is known, calculate the volume that the gas spring rods will displace when retracted, where

VDisplaced = Displaced Volume , Vrod = Rod Volume Adder, T = Travel and N = Number of Gas Springs per Surge Tank.

X+Y

Surge CYL

Tank REF

30

3000

50

5000

75

7500

100

10000

95

50

75

3.74

1.97

2.95

120

90

4.72

3.54

150

90

5.91

3.54

195 100

7.67

3.94

G

3/8

4.72

3/8

5.91

1/2

88

142

244

1.83

2.94

5.06

SMS-i Surge Tank Connection

5.91

67

112

180

309

200

1.35

2.22

3.56

6.13

7.87

82

136

217

374

7.20

DADCO Surge Tanks

ordered with the M1

operating system are used

in a SMS-i and have a

bottom port. These tanks

are attached to the base

plate with a sealing

washer and standard

mounting hardware.

2.62

4.17

98

160

254

439

300

1.85

3.01

4.78

8.27

11.81

113

184

292

505

350

2.10

3.40

5.40

9.34

13.78

128

208

329

570

400

2.35

3.79

6.01

10.41

232

367

635

15.74

144

38 50.5

1.50 1.99

1.00

1.50

3.35

150 4 x M12 31.8 50.8 98.5

52

1.60

120 4 x M10 25.4 38 78

3/8

1.00 1.50 3.07

120 4 x M10 25.4 38 85

1.10

250

1.00

4.72

150

9.84

4 x M10 25.4

3.94

1.25

2.00 3.88

Ordering Example:

ST.30. 150. TO. F

VS = VG.S. + VS.T.

90.29

D

See

CYL REF

See

CYL REF

B29

F E

M1

Bottom Port

2.92

G 1/8 Port

(Plugged)

Size:

30, 50, 75, 100

Length (Y):

50,100,150, 200, 250, 300, 400

VDisplaced = Vrod * T * N

Operating System:

F = Free Flow Fitting,

M1 = SMS-i (Bottom port + sealing component)

Mount Option:

TO = Basic Model. When not specified, default is TO. Mount

ordered with cylinder will be attached at factory.

Calculate the pressure rise where P.R. = Pressure Rise, VDisplaced = Displaced Volume and VS = System Volume.

P.R. =

VS

(VS VDisplaced)

Bulletin No. B14102

Application Example

Quantity 4, U.6600.100.TO Nitrogen Gas Springs with a 75 mm travel are linked in a system with

a ST.75.250 Surge Tank. What is the Pressure Rise?

Given: S = 100, T = 75; From the Tables: Vinternal = .0099, V0 =0.0464, VS.T. = 4.17, Vrod = 0.0044

VG.S. = (Vinternal *S + V0) * N

VG.S. = (.0099 * 100 + 0.0464) * 4 = 4.146 L

This manual provides product specifications, and a

step-by-step maintenance guide for DADCO Surge

Tanks.

Note that proper repair requires careful examination

of all component parts and replacement of any that

are worn or damaged. All DADCO replacement

parts are available from factory stock.

VS = VG.S. + VS.T.

VS = 4.146 + 4.17 = 8.316 L

VDisplaced = Vrod * T * N

VDisplaced = .0044 * 75 * 4 = 1.32 L

P.R. =

Comprehensive

Guide

VS

1

(VS VDisplaced)

Typically, DADCO Surge Tanks can be rebuilt in

less than five minutes by replacing only the o-rings.

P.R. = (8.316 / (8.316 1.32)) 1 = .19 or 19%

Surge Tank

Design, Installation &

Maintenance

After reviewing this guide, if you require any

additional training or have any questions please

contact DADCO for assistance.

Solving for the Surge Tank Size when the Gas Springs and Pressure Rise is known:

To calculate the appropriate surge tank when the gas springs and pressure rise is known, first calculate the volume that

the gas spring rods will displace when retracted, where VDisplaced = Displaced Volume , Vrod = Rod Volume Adder, T = Travel

and N = Number of Gas Springs per Surge Tank.

VDisplaced = Vrod * T * N

Next, calculate the internal volume of the gas springs, where VG.S. = Internal Volume of Gas Springs, Vinternal = Internal

Volume Adder, S = Stroke (S), V0 = Initial Volume and N = Number of Gas Springs per Surge Tank.

VG.S. = (Vinternal * S + V0) * N

After the volume of the gas spring is known, calculate the volume of the Surge Tank where VS.T. = Volume of the Surge

Tank, VDisplaced = Displaced Volume, P.R. = Pressure Rise and VG.S. = Internal Volume of Gas Springs.

VS.T. =

Please Note: As you proceed through the basic

steps outlined in this bulletin, take care to follow the

instructions. All DADCO products are permanently

marked with model and serial number. Please refer

to these numbers when performing repair work and

when ordering replacement parts.

DADCO, Inc. 2014 All Rights Reserved

VDisplaced

+ VDisplaced VG.S.

P.R.

Application Example

Quantity 4, U.6600.100.TO Nitrogen Gas Springs are linked in a system with a travel of 75 mm.

What Surge Tank should be added to the system to achieve a 20% Pressure Rise?

Given: S = 100, T = 75, P.R. = 20%; From the Tables: Vrod = 0.0044, Vinternal = .0099, V0 =0.0464,

VDisplaced = Vrod * T * N

VDisplaced = .0044 * 75 * 4 = 1.32 L

VG.S. = (Vinternal * S + V0) * N

VG.S. = (.0099 * 100 + .0464) * 4 = 4.146 L

VDisplaced

VS.T. =

+ VDisplaced VG.S.

P.R.

VS.T. = (1.32/.2) + 1.32 4.146 = 3.77 L

Miscellaneous Conversions:

43850 Plymouth Oaks Blvd.

Plymouth, Michigan USA 48170

1.734.207.1100 800.323.2687

Toll Free: 800.DADCO.USA

Fax: 1.734.207.2222

www.dadco.net

The closest Surge Tank is ST.75.250.

P (psi) = P (bar) * 14.50

Length (inch) =

Length (mm)

25.4

CAUTION: Always wear safety goggles when performing any maintenance work.

Surge Tank Repair Instructions

I. Exhausting System Pressure and Removing C-Ring

1. Exhaust nitrogen gas by opening

the bleed valve on the control panel.

Verify all pressure is exhausted by

reading the control panel gauge and

retracting the gas spring piston rods

into the tubes manually. If the rods

will not fully retract, STOP and contact

DADCO.

Tank with B29 Mount

2A. Remove the Safety Tab from top

of the Surge Tank using a hex key.

ST.30 uses a 5 mm hex key, ST.50 and

ST.75 use a 6 mm hex key and ST.100

uses a 10 mm hex key.

Note: It is not necessary to remove

a Surge Tank from a SMS or SMS-i

plate to perform maintenance if it is

mounted using the B11 mount or the

bottom tapped holes.

2B. Remove the Surge Tank with B29

Mount from the die then remove the

mount from the Surge Tank using a

hex key. ST.30 uses a 6 mm hex key,

ST.50 and ST.75 use a 7 mm hex key

and ST.100 uses a 10 mm hex key.

3. Remove the G1/8 Center Port Plug

and all additional port plugs using the

Port Servicing Tool (90.320.8) or a

5 mm hex key. Remove any fittings

located at the top of the Surge Tank.

4 . Ta p t h e S u rg e Ta n k H e a d

Assembly down into the Tube

Assembly. The Head Assembly only

needs to be tapped approximately

12 mm below the C-Ring. DO NOT

force it further into the Tube Assembly.

5. Using the Plastic Assembly Blade

(90.357), remove the dust cover from

the Surge Tank and discard.

6. Remove the C-Style Retaining

Ring using the C-Ring Removal Tool

(90.356). Position the correct hooked

end of the tool below the C-Ring. For

best results locate the tool near either

end of the C-Ring. Begin pushing it

toward the outside of the gas spring

can. The handles will close naturally,

and the C-Ring will be extracted as

you complete this motion.

2. Inspect the Tube Assembly for

any damage, especially around the

mouth of the Tube Assembly. Polish

out any scratches at the mouth of the

Tube Assembly to avoid damaging

seals during the reassembly process.

If damage to the Tube Assembly is

severe it must be replaced.

3. Choose the appropriate repair kit

(90.201ST.x) for the specific model you

are repairing. NOTE: Repair kits are

not interchangeable among models.

4. Using the Plastic Assembly Blade,

remove the O-ring Backup Ring from

the Surge Tank and discard.

5. Using the Plastic Assembly Blade,

remove the O-ring from the Surge

Tank and discard.

6. Turn over the Head so the ports are

facing bottom. Install the new O-ring

Backup Ring using the Plastic Assembly Blade. Verify that the O-ring does

not twist when installing.

7. Install the new O-ring using the

Plastic Assembly Blade. Verify that the

O-ring does not twist when installing.

The O-ring will be seated next to the

O-ring Backup Ring.

II. Replacing the O-rings

1. To remove the Head Assembly,

thread the T-Handle (90.320.2) into

the center port.

III. Reassembly

CAUTION: Before starting the reassembly process, be sure the repair area is clean. It is imperative that the Surge Tank be free of all contaminants upon reassembly. If this precaution is not taken it may lead to premature failure.

Tank with B29 Mount

1. Lubricate the inside wall of the tube

with entire contents of the bottle of

assembly oil then thread the T-Handle

into the center port of the Surge Tank

Head and install into the Head Assembly. The Head Assembly only needs

to be pushed down approximately 12

mm below the C-Ring. DO NOT force

it further into the Tube Assembly.

2. Insert the C-Style Retaining Ring

in the retaining ring groove using

a DADCO C-Ring Installation Tool

(90.352 or 90.352.10000) or standard

bench tools. Tap C-Ring into position.

Be sure C-Style Retaining Ring is fully

seated in retaining ring groove.

3. Using the T-Handle, pull up on

Surge Tank Head Assembly until it is

past the C-Ring and the top is flush

with the Tube Assembly.

4. Install the new Dust Cover

(90.246.x). Tap with a soft mallet

until the top of the Dust Cover rests

flush with the Tube Assembly.

5A. Install the Safety Tab at the top

of the Surge Tank using a key. ST.30

uses a 5 mm hex key, ST.50 and ST.75

use a 6 mm hex key and ST.100 uses

a 10 mm hex key.

5B. Attach the B29 Mount onto the

Surge Tank using a hex key. ST.30

uses a 6 mm hex key, ST.50 and ST.75

use a 7 mm hex key and ST.100 uses

a 10 mm hex key.

6. Install all the port plugs at the top

of the Surge Tank using the Port

Servicing Tool (90.320.8) or a 5 mm

hex key. You may install fittings and

attach your Surge Tank to your control

panel, making sure all connections are

tight and that the system nitrogen gas

spring rods are extended.

IV. Charging

Parts List

* Included in the Repair Kit

Head Assembly

Port Plug (x7)

90.505.110

*Dust Cover

90.246.10.

Model

Safety Tab

C-Style Retaining Ring

90.285.

Model

7. A tt a c h C h a rg i n g A s s e m bly

(90.310.040 or 90.310.045) to the

quick disconnect filler valve on the

control panel.

**O-ring Backup Ring

8. Open the main valve on the nitrogen

tank then set the desired charging

pressure on the regulator.

**O-ring

Repair Tools

T-Handle

90.320.2 M8 thread

To remove the Head Assembly

when disassembling and position

correctly when reassembling.

Tube Assembly

90.205.10. .

To remove the C-Style

Retaining Ring safely in a

single controlled motion.

Port Servicing Tool

90.320.8

Plastic Assembly Blade

90.357

To remove and

install port plugs.

To remove and install

the O-ring and

O-ring Backup Ring.

C-Ring Installation Tool

90.352 (01500 07500 Models)

90.352.10000 (10000 Model)

To insert the C-Style Retaining Ring into the retaining ring groove.

Model Stroke

C-Ring Removal Tool

90.356

Face Seal

EZ457238

Port Adapter

90.505.115

F = Free Flow Fitting (for SMS)

M1 = SMS-i (Bottom port + sealing component)

Repair Kits

Include an O-ring, O-ring Backup Ring,

Dust Cover, assembly oil and repair

instructions.

Model

Repair Kit

Model

Repair Kit

ST.30

90.201ST.03000

ST.75

90.201ST.07500

ST.50

90.201ST.05000

ST.100

90.201ST.10000

You might also like

- 06-321 Parts Manual Orbitrol EatonDocument8 pages06-321 Parts Manual Orbitrol Eatonorlandolanchipa100% (4)

- Caterpillar 3208 Diesel Engine SM Manual Copy OneDocument350 pagesCaterpillar 3208 Diesel Engine SM Manual Copy Oneswoods71588% (26)

- Indesit Widl 106ex SMDocument34 pagesIndesit Widl 106ex SMDaniel Cristina50% (2)

- Composite Boiler Aalborg PDFDocument2 pagesComposite Boiler Aalborg PDFihllhmNo ratings yet

- SDM 102 eDocument24 pagesSDM 102 eseaqu3stNo ratings yet

- Yukenmodularvalves Yuken CatDocument140 pagesYukenmodularvalves Yuken Catchidambaram kasi100% (1)

- SDM140EDocument36 pagesSDM140Eseaqu3stNo ratings yet

- SDM 080 eDocument28 pagesSDM 080 eseaqu3stNo ratings yet

- SDM 141 eDocument28 pagesSDM 141 eseaqu3stNo ratings yet

- H1000e K FJDocument8 pagesH1000e K FJSyarif HidayatullahNo ratings yet

- SDM 143 eDocument20 pagesSDM 143 eseaqu3st100% (1)

- IndesitwidlDocument34 pagesIndesitwidlJames T-rexNo ratings yet

- Ss 01059 eDocument8 pagesSs 01059 eDavid LapacaNo ratings yet

- Sds 150 eDocument16 pagesSds 150 ejbsb1No ratings yet

- Sys A CDocument40 pagesSys A Cdnageshm4n244No ratings yet

- Fisher 1190 Low-Pressure Gas Blanketing RegulatorDocument20 pagesFisher 1190 Low-Pressure Gas Blanketing Regulatorneurolepsia3790No ratings yet

- TFP950 10 2010Document6 pagesTFP950 10 2010elpelaracingNo ratings yet

- 23.bladder AccumlatorDocument12 pages23.bladder AccumlatorM S GokulNo ratings yet

- V SeguridadDocument8 pagesV SeguridadARJONA_JGNo ratings yet

- Tour and Andersson MD60 SpecificationsDocument14 pagesTour and Andersson MD60 SpecificationsblindjaxxNo ratings yet

- SD 6 eDocument16 pagesSD 6 eseaqu3stNo ratings yet

- Ab 4004 R13.0Document8 pagesAb 4004 R13.0Nguyen VuNo ratings yet

- Venta: Two-Way Plug Valve, Pressure Balanced PN 25 (362 Psi)Document5 pagesVenta: Two-Way Plug Valve, Pressure Balanced PN 25 (362 Psi)isombardNo ratings yet

- Re92105 2003-11Document32 pagesRe92105 2003-11Madhu RajagopalanNo ratings yet

- p177 02 PDFDocument4 pagesp177 02 PDFJuan ZamoraNo ratings yet

- Re 15224Document12 pagesRe 15224Ahmed Abd ElhakeemNo ratings yet

- Welding Consumables-Stainless SteelDocument27 pagesWelding Consumables-Stainless SteelibicengNo ratings yet

- Abovegroundhydrants Dropdownpillar 84-25-27 P7 PDFDocument4 pagesAbovegroundhydrants Dropdownpillar 84-25-27 P7 PDFLimhot SitanggangNo ratings yet

- k512 en MainDocument8 pagesk512 en MainSani PoulouNo ratings yet

- SD25Document20 pagesSD25Mauricio Ariel H. OrellanaNo ratings yet

- 2009-07!28!045630 Remove Install Electrohydraulic Control Module Transmission InstalledDocument3 pages2009-07!28!045630 Remove Install Electrohydraulic Control Module Transmission InstalledfulltransmissionNo ratings yet

- Rexworth Hydraulic MotorDocument28 pagesRexworth Hydraulic MotorSorin-Adrian Learschi100% (1)

- Unique Single Seat Valve-Simply UniqueDocument8 pagesUnique Single Seat Valve-Simply UniquelggomezupbNo ratings yet

- Olaer EhvDocument12 pagesOlaer EhvandinoNo ratings yet

- About Axial Displacement Pump A4VSoDocument68 pagesAbout Axial Displacement Pump A4VSomrkadu_61No ratings yet

- 160.75-RP1 (210) - Yk (G)Document92 pages160.75-RP1 (210) - Yk (G)JayashtonNo ratings yet

- Guth VSR Modulating ValvesDocument8 pagesGuth VSR Modulating ValvesRaul Guevara TorresNo ratings yet

- Pressure Pipe Fittings PDFDocument64 pagesPressure Pipe Fittings PDFmonkeyDivanNo ratings yet

- Series 909 Specification SheetDocument4 pagesSeries 909 Specification SheetWattsNo ratings yet

- Re91401 A2foDocument20 pagesRe91401 A2foTaz Juan GNo ratings yet

- Jacobs Brake 310-312 Parts Book On Caterpillar C10-C12 022040BDocument4 pagesJacobs Brake 310-312 Parts Book On Caterpillar C10-C12 022040Bviemey1952100% (3)

- Yuken Directional Control ValvesDocument193 pagesYuken Directional Control ValvesphaindikaNo ratings yet

- MDFO UK LowDocument17 pagesMDFO UK Lowmsn86No ratings yet

- SEVO 1230 Technical Data Sheets - All PDFDocument18 pagesSEVO 1230 Technical Data Sheets - All PDFYeni Paola SierraNo ratings yet

- Series R5U Characteristics: Pilot Operated Pressure Unloading ValveDocument5 pagesSeries R5U Characteristics: Pilot Operated Pressure Unloading ValveHarinderNo ratings yet

- Shut-Off Butterfly Valves 3 0 enDocument12 pagesShut-Off Butterfly Valves 3 0 en윤병택No ratings yet

- Fisa Tehnica Pompe MultifreeDocument10 pagesFisa Tehnica Pompe MultifreeOčtáv VátčoNo ratings yet

- CA Motors Product DetailsDocument25 pagesCA Motors Product DetailsP Venkata Suresh100% (2)

- Valvulas de AlivioV6XDocument2 pagesValvulas de AlivioV6XMaik AmayaNo ratings yet

- Maintenance Arpex enDocument39 pagesMaintenance Arpex enPatrick BaridonNo ratings yet

- Gas SpringsDocument122 pagesGas SpringsslavcecaciNo ratings yet

- Adixen 2021 SDDocument45 pagesAdixen 2021 SDRuben PiepersNo ratings yet

- Water Cooled Package Service NewDocument23 pagesWater Cooled Package Service NewDiêm Công ViệtNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Tank InstrumentsDocument10 pagesTank InstrumentsihllhmNo ratings yet

- Aalborg OmDocument4 pagesAalborg OmihllhmNo ratings yet

- Cleaning-In-Place in The Dairy IndustryDocument11 pagesCleaning-In-Place in The Dairy IndustryihllhmNo ratings yet

- Vapour Pressure HCL Water PDFDocument1 pageVapour Pressure HCL Water PDFihllhmNo ratings yet

- PFD&PID With AUtoCAD P&ID PDFDocument7 pagesPFD&PID With AUtoCAD P&ID PDFihllhmNo ratings yet

- Implementing Off Page ConnectorsDocument9 pagesImplementing Off Page ConnectorsihllhmNo ratings yet

- Navgathi-New Shipbuilding Project Management PDFDocument16 pagesNavgathi-New Shipbuilding Project Management PDFihllhm100% (1)

- QPM Oil Gas Petro Example PDFDocument4 pagesQPM Oil Gas Petro Example PDFihllhmNo ratings yet

- Ge Oil &gas Turbocompressor Trains On First Floating LNG Plant PDFDocument12 pagesGe Oil &gas Turbocompressor Trains On First Floating LNG Plant PDFihllhmNo ratings yet

- A High Capacity Floating LNG Design by Barend - PekDocument15 pagesA High Capacity Floating LNG Design by Barend - PekShaka Shalahuddin Shantika Putra100% (1)

- Chemical EquationsDocument6 pagesChemical EquationsihllhmNo ratings yet

- Claus Peter Halsig FLUORDocument24 pagesClaus Peter Halsig FLUORihllhm100% (1)

- LNG Industry, August 2016Document68 pagesLNG Industry, August 2016ihllhmNo ratings yet