Professional Documents

Culture Documents

000000003002000049

000000003002000049

Uploaded by

mhdsolehCopyright:

Available Formats

You might also like

- Bottom Ash ReportDocument30 pagesBottom Ash ReportmhdsolehNo ratings yet

- Flatlapping Polishing-Lamplan 2016 Indep-Mdef PDFDocument64 pagesFlatlapping Polishing-Lamplan 2016 Indep-Mdef PDFGowtham VishvakarmaNo ratings yet

- Impact of Increasing Contribution of Dispersed Generation On The Power SystemDocument50 pagesImpact of Increasing Contribution of Dispersed Generation On The Power SystemmhdsolehNo ratings yet

- Bor1991 - Effect of Pearlite Banding On Mechanical Properties of Perlitic SteelDocument12 pagesBor1991 - Effect of Pearlite Banding On Mechanical Properties of Perlitic SteelAlejandroAcuñaMaureiraNo ratings yet

- Turbo CS 8 CO2 CorrosionDocument23 pagesTurbo CS 8 CO2 CorrosionRonald GeorgeNo ratings yet

- EGF305 Topic 5-Intro To Failure Analysis PDFDocument34 pagesEGF305 Topic 5-Intro To Failure Analysis PDFasdfasdNo ratings yet

- Development of A Material Databook For Api STD 530Document10 pagesDevelopment of A Material Databook For Api STD 530Zenon Kociuba100% (1)

- Report Failure STUB-rev-00Document38 pagesReport Failure STUB-rev-00JORGE CAICEDONo ratings yet

- Experience With Maintaining A 40 Year Old Reformer: Ajay Joshi & Stan HeaneyDocument14 pagesExperience With Maintaining A 40 Year Old Reformer: Ajay Joshi & Stan Heaneyvaratharajan g rNo ratings yet

- EdtaDocument8 pagesEdtabalajikundetiNo ratings yet

- Beer Industry Corrosion ProblemDocument6 pagesBeer Industry Corrosion ProblemHemlata ChandelNo ratings yet

- CSB - Digest - Herrig Brothers - Propane Tank Explosion (1998)Document2 pagesCSB - Digest - Herrig Brothers - Propane Tank Explosion (1998)sl1828No ratings yet

- Pages Welding High Strength Bolts: Anchor Bolt and Construction Fastener ManufacturerDocument4 pagesPages Welding High Strength Bolts: Anchor Bolt and Construction Fastener ManufacturermauricioveracorreaNo ratings yet

- Engineering Approach To Control Corrosion Under Thermal Insulation (Cuti) in Petrochemical IndustriesDocument9 pagesEngineering Approach To Control Corrosion Under Thermal Insulation (Cuti) in Petrochemical IndustriesHuynh Phuc PhungNo ratings yet

- HRSG Final InspectionDocument8 pagesHRSG Final Inspectionmkarahan100% (1)

- RF Valves Descripcion General Valvula Pinch Con Actuador NeumaticoDocument5 pagesRF Valves Descripcion General Valvula Pinch Con Actuador NeumaticoRonulfo GutierrezNo ratings yet

- Coke Drum Anchor Bolt FailuresDocument7 pagesCoke Drum Anchor Bolt FailuresmirekwaznyNo ratings yet

- G 1Document3 pagesG 1choodeshNo ratings yet

- 5083 Material FatigueDocument142 pages5083 Material Fatiguecen1510353No ratings yet

- AL 6XN SourceBookDocument56 pagesAL 6XN SourceBookdrbeyerNo ratings yet

- A Review - Weight Loss Studies On The Corrosion Behavior of Some Metals in Various MediaDocument8 pagesA Review - Weight Loss Studies On The Corrosion Behavior of Some Metals in Various MediaRonald GarciaNo ratings yet

- Centralloy G 4852 Micro R: Material Data SheetDocument8 pagesCentralloy G 4852 Micro R: Material Data SheetNest NectureNo ratings yet

- Asme-Bpvc Sec II-A Int Vol 44Document8 pagesAsme-Bpvc Sec II-A Int Vol 44mostafa aliNo ratings yet

- Polythionic Acid Stress Corrosion CrackingDocument9 pagesPolythionic Acid Stress Corrosion CrackingMedina EldesNo ratings yet

- The Key Steps in Corrosion Failure AnalysisDocument4 pagesThe Key Steps in Corrosion Failure AnalysisAnySikaNo ratings yet

- Corrosion Handbook - Morris Place March 2008Document96 pagesCorrosion Handbook - Morris Place March 2008Bilal KhashanNo ratings yet

- Corrosion in The Crude Distillation Unit Overhead Line: Contributors and SolutionsDocument16 pagesCorrosion in The Crude Distillation Unit Overhead Line: Contributors and SolutionsMaría Alejandra Quintero PinillaNo ratings yet

- Model For Microbiologically Influenced Corrosion PDFDocument16 pagesModel For Microbiologically Influenced Corrosion PDFGenis Andres Castillo VillamizarNo ratings yet

- Topic-2: Corrosion Under Isolation (More About The Procedure, And/or Example of Certain CUI Plan) "Document12 pagesTopic-2: Corrosion Under Isolation (More About The Procedure, And/or Example of Certain CUI Plan) "tcsabaiNo ratings yet

- Aluminum Welding On Ship Structure ProblemsDocument14 pagesAluminum Welding On Ship Structure ProblemsMNNo ratings yet

- III 1 Epoxy Coatings and Cement Mortar Lining - CleanedDocument17 pagesIII 1 Epoxy Coatings and Cement Mortar Lining - CleanedKok WaiNo ratings yet

- Analysis of Steam Turbine Blade Failure LOW PRESSURE TURBINEDocument7 pagesAnalysis of Steam Turbine Blade Failure LOW PRESSURE TURBINEpoojaNo ratings yet

- Coated Bolts and OvertappingDocument2 pagesCoated Bolts and OvertappingRamazan ErdinçNo ratings yet

- Advanced Boiler TubeDocument2 pagesAdvanced Boiler TubeShailendra WaniNo ratings yet

- State of Maryland Final Report Task Force To Study Pinhole Leaks in Copper PlumbingDocument65 pagesState of Maryland Final Report Task Force To Study Pinhole Leaks in Copper PlumbingSyavash EnshaNo ratings yet

- 2600 Series Catalog R3Document38 pages2600 Series Catalog R3Mohammad Dzauqi AdamNo ratings yet

- On Oxygen-Induced Corrosion of An Oil Refinery Condensate Fraction at Ion UnitDocument17 pagesOn Oxygen-Induced Corrosion of An Oil Refinery Condensate Fraction at Ion UnitAzmi Mohammed NorNo ratings yet

- AWS G1.1-G1.1M-2006 Guide For The Ultrasonic Assembly of ThermoplasticsDocument96 pagesAWS G1.1-G1.1M-2006 Guide For The Ultrasonic Assembly of ThermoplasticsJeff MNo ratings yet

- Aluminum and Aluminum Alloys: Miutary Standardization HandbookDocument106 pagesAluminum and Aluminum Alloys: Miutary Standardization HandbookStefano BarbieriNo ratings yet

- Pipe Welding With WaveformDocument39 pagesPipe Welding With Waveformprabu prasadNo ratings yet

- 58 Weld Repairs - Creep PerformanceDocument21 pages58 Weld Repairs - Creep PerformanceLTE002No ratings yet

- Sensor TechnologiesDocument10 pagesSensor TechnologiesMiguel LiceagaNo ratings yet

- 20L - Polmeric Seals - E1-20170512Document23 pages20L - Polmeric Seals - E1-20170512andrea assanelli100% (2)

- Boiler MaterialsDocument5 pagesBoiler MaterialsRavi ShankarNo ratings yet

- Cold End CorrosionDocument15 pagesCold End Corrosiondafteri11No ratings yet

- Bridge Welding ProcessDocument151 pagesBridge Welding Processcentaury2013No ratings yet

- Condition Assessmen B&W Chap 45Document22 pagesCondition Assessmen B&W Chap 45Busairi AchmadNo ratings yet

- PDS - SP 8888 - High Temperature Novolac Pipeline Coating - 2017 03 13 PDFDocument3 pagesPDS - SP 8888 - High Temperature Novolac Pipeline Coating - 2017 03 13 PDFMohamed NouzerNo ratings yet

- Aws Publications Catalog: Summer 2010Document20 pagesAws Publications Catalog: Summer 2010saeedahmad901No ratings yet

- Alcoa Aerospace Briefing June92011Document20 pagesAlcoa Aerospace Briefing June92011Mark Evan SalutinNo ratings yet

- Comparing American and British Piping StandardsDocument7 pagesComparing American and British Piping Standardsyarzar17No ratings yet

- TRISTAR-Tube Expanders For Heat ExchangersDocument24 pagesTRISTAR-Tube Expanders For Heat Exchangersapostu sorinNo ratings yet

- Ceramic Coatings Improve Boiler Reliability and PerformanceDocument8 pagesCeramic Coatings Improve Boiler Reliability and PerformancedocturboNo ratings yet

- Preventing Htha Failures With The Buckeye ModelDocument2 pagesPreventing Htha Failures With The Buckeye ModelBangkit WidayatNo ratings yet

- Corrosion PDFDocument46 pagesCorrosion PDFNixon RamsaranNo ratings yet

- Abrasion Resistant Linings For Production and Conveying SystemsDocument28 pagesAbrasion Resistant Linings For Production and Conveying SystemsJim HaigNo ratings yet

- 55 Aluminum-Zinc Alloy Coated Steel Technical Bulletin 6 - Cut Edge Protection v20153Document2 pages55 Aluminum-Zinc Alloy Coated Steel Technical Bulletin 6 - Cut Edge Protection v20153Syed Raja AdeelNo ratings yet

- TS MaterialGuide en 2015.04Document52 pagesTS MaterialGuide en 2015.04Stefano MartelliNo ratings yet

- Corrosion and Materials Selection: A Guide for the Chemical and Petroleum IndustriesFrom EverandCorrosion and Materials Selection: A Guide for the Chemical and Petroleum IndustriesNo ratings yet

- Corrosion Prevention and Protection: Practical SolutionsFrom EverandCorrosion Prevention and Protection: Practical SolutionsRating: 4 out of 5 stars4/5 (1)

- Anchorage Economic DevelopmentDocument44 pagesAnchorage Economic DevelopmentmhdsolehNo ratings yet

- Data AnalyticsDocument56 pagesData AnalyticsmhdsolehNo ratings yet

- From Research To Innovation To Enterprise: The Case of SingaporeDocument7 pagesFrom Research To Innovation To Enterprise: The Case of SingaporemhdsolehNo ratings yet

- Value Creation & Value AppropriationDocument108 pagesValue Creation & Value Appropriationmhdsoleh100% (1)

- B Biio Om Ma Assss C Co Offiirriin NG G:: A AR Re en Ne Ew Wa Ab Blle e A Alltte Errn Na Attiiv Ve e Ffo Orr U Uttiilliittiie EssDocument2 pagesB Biio Om Ma Assss C Co Offiirriin NG G:: A AR Re en Ne Ew Wa Ab Blle e A Alltte Errn Na Attiiv Ve e Ffo Orr U Uttiilliittiie EssmhdsolehNo ratings yet

- Energy Management System Based On The PN-EN ISO 50001 - Implementation in Dzierzoni ÓwDocument17 pagesEnergy Management System Based On The PN-EN ISO 50001 - Implementation in Dzierzoni ÓwmhdsolehNo ratings yet

- 1504 Metals From MWIBA R. BungeDocument68 pages1504 Metals From MWIBA R. BungemhdsolehNo ratings yet

- Proper Sizing of Steam Header Drains Prevents Water InductionDocument7 pagesProper Sizing of Steam Header Drains Prevents Water InductionmhdsolehNo ratings yet

- FP - A.1 - EGAT - EGAT Fleet Capability On Generator Rotor RepairDocument7 pagesFP - A.1 - EGAT - EGAT Fleet Capability On Generator Rotor RepairmhdsolehNo ratings yet

- FP - A.1 - EGAT - EGATÔÇÖs Capability Enhancement On Electrical Protection ImprovementDocument6 pagesFP - A.1 - EGAT - EGATÔÇÖs Capability Enhancement On Electrical Protection ImprovementmhdsolehNo ratings yet

- FP - A.1 - Consequential Damage and Inspection Techniques From Lack of Lubrication, Steam Turbine CaseDocument14 pagesFP - A.1 - Consequential Damage and Inspection Techniques From Lack of Lubrication, Steam Turbine Casemhdsoleh100% (1)

- FP - A.1 - EGAT - A Novel Vented Lead-Acid Battery Performance Test Based 50% Hour Rate With Fully Discharged Rate Condition in EGAT Power Plant Experience PDFDocument4 pagesFP - A.1 - EGAT - A Novel Vented Lead-Acid Battery Performance Test Based 50% Hour Rate With Fully Discharged Rate Condition in EGAT Power Plant Experience PDFmhdsolehNo ratings yet

- MIUI 12 Latest Update Features 2020Document5 pagesMIUI 12 Latest Update Features 2020johnson veigasNo ratings yet

- Sensex Rolling ReturnsDocument1 pageSensex Rolling Returnsmaheshtech76No ratings yet

- TikTok Marketing - Cheat SheetDocument4 pagesTikTok Marketing - Cheat Sheetmariomr0890No ratings yet

- EC287 - Presentation To Community Board 4-RRA 03032022Document12 pagesEC287 - Presentation To Community Board 4-RRA 03032022Christina WilkinsonNo ratings yet

- Disjuntor SF1 - Dados ElétricosDocument1 pageDisjuntor SF1 - Dados ElétricosotavioalcaldeNo ratings yet

- Masidlak Eagles Form 2Document2 pagesMasidlak Eagles Form 2Rubie Anne SaducosNo ratings yet

- Course Promotional 3Document15 pagesCourse Promotional 3Alexander Klain AquiatanNo ratings yet

- 43 CA CPT Dec 2010 Question Paper With Answer Key 2Document6 pages43 CA CPT Dec 2010 Question Paper With Answer Key 2Vishal Gattani100% (1)

- Indian School of Business (ISB) PGP (Intended Major: Finance) - GMAT: 740Document1 pageIndian School of Business (ISB) PGP (Intended Major: Finance) - GMAT: 740Suprateek BoseNo ratings yet

- French, J. (2011) Why Nudging Is Not EnoughDocument11 pagesFrench, J. (2011) Why Nudging Is Not EnoughFrancisco SantosNo ratings yet

- Kabale University Students HandbookDocument20 pagesKabale University Students Handbookjesseokiror21No ratings yet

- FT096 20191112 Iso A4Document64 pagesFT096 20191112 Iso A4Jeff Zeitlin100% (4)

- CPA Instagram DominationDocument19 pagesCPA Instagram Dominationvomawew647No ratings yet

- Gun Rights Groups Sue Over California Carry Permit Requirements - CRPA v. LASD ComplaintDocument41 pagesGun Rights Groups Sue Over California Carry Permit Requirements - CRPA v. LASD ComplaintAmmoLand Shooting Sports NewsNo ratings yet

- Impact of COVID-19 On People's Livelihoods, Their Health and Our Food SystemsDocument4 pagesImpact of COVID-19 On People's Livelihoods, Their Health and Our Food Systemsjungkook jeonNo ratings yet

- Motorcycle Clutch SystemDocument15 pagesMotorcycle Clutch SystemSelazinap LptNo ratings yet

- Studentzone 02 2017Document3 pagesStudentzone 02 2017YahiaEl-obidyNo ratings yet

- TC15M 65M Manual PDFDocument15 pagesTC15M 65M Manual PDFReciclando ChatarraNo ratings yet

- Reading TextsDocument6 pagesReading TextsAbd TalepNo ratings yet

- Multi V5 + Chiller Scroll PDFDocument81 pagesMulti V5 + Chiller Scroll PDFFernando CabreraNo ratings yet

- Hybrid GrandglowDocument5 pagesHybrid Grandglowmohsan bilalNo ratings yet

- Animal Health 2011 (Equipment Catalog)Document86 pagesAnimal Health 2011 (Equipment Catalog)qadir-qadisNo ratings yet

- Drug Schedules and Prescription Writing Clifford M. Knapp, PH.DDocument36 pagesDrug Schedules and Prescription Writing Clifford M. Knapp, PH.DEman ElzeftawyNo ratings yet

- Offer LetterDocument1 pageOffer Letterahmadkahan5272No ratings yet

- API 686-Suction Line Slopes and ReducersDocument1 pageAPI 686-Suction Line Slopes and ReducersjpalauguillemNo ratings yet

- Mainboard Biosta Model P4M8P M7ADocument34 pagesMainboard Biosta Model P4M8P M7ARommel LoayzaNo ratings yet

- Cargo Handling & Stability - I: Captain Nazim ErsenDocument52 pagesCargo Handling & Stability - I: Captain Nazim ErsenberNo ratings yet

- DO - s2009 - 54 - PTA GUIDELINES - RecognizedDocument11 pagesDO - s2009 - 54 - PTA GUIDELINES - RecognizedArthur AguilarNo ratings yet

- 167867-2013-Optima Realty Corp. v. Hertz Phil. ExclusiveDocument8 pages167867-2013-Optima Realty Corp. v. Hertz Phil. ExclusiveYuri NishimiyaNo ratings yet

- APSC Mains GS5 Syllabus Topic ListDocument11 pagesAPSC Mains GS5 Syllabus Topic ListAdhish Bipul BarmanNo ratings yet

000000003002000049

000000003002000049

Uploaded by

mhdsolehCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

000000003002000049

000000003002000049

Uploaded by

mhdsolehCopyright:

Available Formats

Success Stor y

Endesa Improves Plant Inspections and

Reduces Boiler Tube Failures with EPRI

Pocket Field Guides

Endesa is using several EPRI pocket-sized field guides to implement good plant inspection practices at the utilitys fleet of coal-fired plants. Improved crew inspections are, in

turn, helping Endesa to reduce the rate of boiler tube failures.

Challenges of Outage Inspections

Tube failure is a common failure mechanism in fossil power plants. Many companies struggle to

manage and implement satisfactory failure reduction processes and procedures due to a lack

of technical understanding and engineering know-how. The key to reducing tube failure rate is

prevention, and the key to prevention is robust plant inspection. Knowing where to inspect,

EPRI Field Guides are

some of the best I have

ever seen due to the ease

what to look for, and what action to take are essential.

of use and understanding

Scheduled outages give plants the opportunity to inspect for conditions that could lead to

content, but also due to

unplanned outages if not addressed. When unplanned outages occur, the goal is normally to

return the boiler to service as quickly as possible. Equally important, however, is the need to

take the required time to determine and repair the root cause of the unplanned outage in order

to prevent a repeat failure.

of their deep technical

their portability and practicality, in the form of simple

charts, flow charts and

photographs. They always

As they balance these sometimes competing needs, plant crews are confronted with challenges.

are appreciated by hands-

Outages are hectic, and time is vital. Quick decisions are often needed, but the information to

on people.

mitigate or eliminate the failures may be difficult to locate. In addition, the industry is experiencing an increase in new employees, who may not be as experienced or familiar with available

information. The global economic downturn is also forcing plants to do more with less.

Also, although ideally, crews should look at everything during an inspection, more practically,

it might be necessary to focus more closely on items that are critical from a safety, operation, or

cost-containment point of view.

Heat recovery steam generators (HRSGs) pose a unique set of operational challenges, due in

part to their rapid startup capabilities and high operating efficiencies. Among these challenges

are the difficulty of inspection and repair, which are complicated by limited access as well as

the complexity of the equipment.

EPRIs Outage Inspection Pocket Manuals

The EPRI pocket manuals for outage inspection of conventional boilers and HRSGs help to

address these challenges. The guides detail the abnormalities, deficiencies, and signs of damage and deterioration that inspectors should look for and record, and provide tools for prioritization of actions. They are designed to be used by any maintenance engineer or inspector

entering a boiler or HRSG during planned or unplanned outages.

~ Paulo Santos, Technical

Services Manager, Endesa

Generacin (ENEL Group)

Believed to be the first of their kind, the guides summarize practical

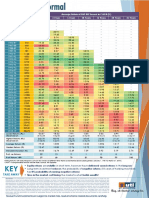

3.04%. The linear trend of this value has consistently gone down

information for plant crews in portable, pocket-sized (8.5 x 4.25 inch)

throughout the years at a rate of 0.13% per year, even with bad

ring-bound/flip-style books. Information in the guides is distilled from

years such as:

more than 35 years of EPRI research in boiler tube failure reduction

(BTFR), EPRI technical reports, and utility best practices. The guides

(a) 2011, when a single plant accumulated 60% of all BTF due to an

describe basic tools for identifying and addressing failure mechanisms,

almost prototypical OEM low-NOx combustion system installed in

and contain hundreds of color photographs that provide visual indica-

three of its units (downshot or arch boilers), which proved itself quite

tors of the conditions described in the text.

challenging

to

tune

and

therefore

significantly

hurt

the

improvements;

The outage inspection pocket manual for conventional boilers begins

by describing recommendations for a hot walk-down of the boiler. Sub-

(b) 2012, when a severe magnetite exfoliation incident made one of

sequent sections review inspection procedures for 15 specific systems

the best-performing and higher-merit plants accumulate more than

including the ash pit, furnace waterwalls, superheat/reheat pendents,

twice the forced outage rate of the previous year. This was solved

economizer banks, back-pass walls, penthouse, steam drums, dead air

in part thanks to some excellent support received by EPRI Program

spaces, and desuperheaters. Each section identifies areas to inspect

63 and Program 87 management teams.

and describes common damage or failure mechanisms that may be

evident. Accompanying photographs visually portray the areas, with

arrows indicating damage.

The HRSG outage inspection pocket manual begins with a section on

visual inspection, which describes walk-down procedures and inspection of individual components. A section on risk management describes

how to develop a risk assessment profile and establish a three-tier priority system for identifying plant items that have high, medium, and low

Savings in 2012 with relation to 2006, both in terms of avoided loss

of generation and less maintenance expenditure are of 4.42M, some

US $6.01M at the current exchange rate.

Related EPRI Work

Field Guide: Outage Inspection Pocket Manual. EPRI. Palo Alto, CA:

December 2009. 1018996.

probability of failure. A technical overview provides simple, clear

Field Guide: Heat Recovery Steam Generator Outage Inspection

descriptions of the major parts of the plant and how they work. The

Pocket Manual. EPRI. Palo Alto, CA: December 2010. 1021122.

final section reviews common failure mechanisms, including stress corrosion cracking, fatigue, flow accelerated corrosion, thermal shock,

creep, and others.

Together, these two outage inspection manuals identify situations that

require further investigation, highlight environments or trends that could

Field Guide: Boiler Tube Failure. EPRI. Palo Alto, CA. December 2009.

1017471.

Field Guide: Heat Recovery Steam Generator Tube Failure. EPRI. Palo

Alto, CA. December 2010. 1021121.

be detrimental to unit availability, and provide an opportunity to quickly

assess a suspicious situation.

For more information, contact the EPRI Customer

Assistance Center at 800.313.3774 (askepri@epri.com)

Guides Used as Part of Endesas BTFR Program

For Endesa, the EPRI pocket field guides were translated into Spanish

to facilitate greater use across the company. The guides were distributed to maintenance, operations, chemistry, and plant engineeringrelated personnel. Endesa is using the guides to train new engineers

and as references for experienced staff.

Application of the guides has played and continues to play a significant role in Endesas overall BTFR program. At the start of this program,

the associated forced outage rate on an Endesa coal-fired plant was

C O N TA C T S

Kent Coleman, Program Manager,

Boiler Life and Availability Improvement Program

704.595.2082, kcoleman@epri.com

Bill Carson, Program Manager,

Heat Recovery Steam Generator (HRSG) Dependability

704.595.2698, bcarson@epri.com

3002000049

February 2013

Electric Power Research Institute

3420 Hillview Avenue, Palo Alto, California 94304-1338PO Box 10412, Palo Alto, California 94303-0813 USA

800.313.3774 650.855.2121askepri@epri.comwww.epri.com

2013 Electric Power Research Institute (EPRI), Inc. All rights reserved. Electric Power Research Institute, EPRI, and TOGETHER...SHAPING THE FUTURE OF ELECTRICITY are

registered service marks of the Electric Power Research Institute, Inc.

You might also like

- Bottom Ash ReportDocument30 pagesBottom Ash ReportmhdsolehNo ratings yet

- Flatlapping Polishing-Lamplan 2016 Indep-Mdef PDFDocument64 pagesFlatlapping Polishing-Lamplan 2016 Indep-Mdef PDFGowtham VishvakarmaNo ratings yet

- Impact of Increasing Contribution of Dispersed Generation On The Power SystemDocument50 pagesImpact of Increasing Contribution of Dispersed Generation On The Power SystemmhdsolehNo ratings yet

- Bor1991 - Effect of Pearlite Banding On Mechanical Properties of Perlitic SteelDocument12 pagesBor1991 - Effect of Pearlite Banding On Mechanical Properties of Perlitic SteelAlejandroAcuñaMaureiraNo ratings yet

- Turbo CS 8 CO2 CorrosionDocument23 pagesTurbo CS 8 CO2 CorrosionRonald GeorgeNo ratings yet

- EGF305 Topic 5-Intro To Failure Analysis PDFDocument34 pagesEGF305 Topic 5-Intro To Failure Analysis PDFasdfasdNo ratings yet

- Development of A Material Databook For Api STD 530Document10 pagesDevelopment of A Material Databook For Api STD 530Zenon Kociuba100% (1)

- Report Failure STUB-rev-00Document38 pagesReport Failure STUB-rev-00JORGE CAICEDONo ratings yet

- Experience With Maintaining A 40 Year Old Reformer: Ajay Joshi & Stan HeaneyDocument14 pagesExperience With Maintaining A 40 Year Old Reformer: Ajay Joshi & Stan Heaneyvaratharajan g rNo ratings yet

- EdtaDocument8 pagesEdtabalajikundetiNo ratings yet

- Beer Industry Corrosion ProblemDocument6 pagesBeer Industry Corrosion ProblemHemlata ChandelNo ratings yet

- CSB - Digest - Herrig Brothers - Propane Tank Explosion (1998)Document2 pagesCSB - Digest - Herrig Brothers - Propane Tank Explosion (1998)sl1828No ratings yet

- Pages Welding High Strength Bolts: Anchor Bolt and Construction Fastener ManufacturerDocument4 pagesPages Welding High Strength Bolts: Anchor Bolt and Construction Fastener ManufacturermauricioveracorreaNo ratings yet

- Engineering Approach To Control Corrosion Under Thermal Insulation (Cuti) in Petrochemical IndustriesDocument9 pagesEngineering Approach To Control Corrosion Under Thermal Insulation (Cuti) in Petrochemical IndustriesHuynh Phuc PhungNo ratings yet

- HRSG Final InspectionDocument8 pagesHRSG Final Inspectionmkarahan100% (1)

- RF Valves Descripcion General Valvula Pinch Con Actuador NeumaticoDocument5 pagesRF Valves Descripcion General Valvula Pinch Con Actuador NeumaticoRonulfo GutierrezNo ratings yet

- Coke Drum Anchor Bolt FailuresDocument7 pagesCoke Drum Anchor Bolt FailuresmirekwaznyNo ratings yet

- G 1Document3 pagesG 1choodeshNo ratings yet

- 5083 Material FatigueDocument142 pages5083 Material Fatiguecen1510353No ratings yet

- AL 6XN SourceBookDocument56 pagesAL 6XN SourceBookdrbeyerNo ratings yet

- A Review - Weight Loss Studies On The Corrosion Behavior of Some Metals in Various MediaDocument8 pagesA Review - Weight Loss Studies On The Corrosion Behavior of Some Metals in Various MediaRonald GarciaNo ratings yet

- Centralloy G 4852 Micro R: Material Data SheetDocument8 pagesCentralloy G 4852 Micro R: Material Data SheetNest NectureNo ratings yet

- Asme-Bpvc Sec II-A Int Vol 44Document8 pagesAsme-Bpvc Sec II-A Int Vol 44mostafa aliNo ratings yet

- Polythionic Acid Stress Corrosion CrackingDocument9 pagesPolythionic Acid Stress Corrosion CrackingMedina EldesNo ratings yet

- The Key Steps in Corrosion Failure AnalysisDocument4 pagesThe Key Steps in Corrosion Failure AnalysisAnySikaNo ratings yet

- Corrosion Handbook - Morris Place March 2008Document96 pagesCorrosion Handbook - Morris Place March 2008Bilal KhashanNo ratings yet

- Corrosion in The Crude Distillation Unit Overhead Line: Contributors and SolutionsDocument16 pagesCorrosion in The Crude Distillation Unit Overhead Line: Contributors and SolutionsMaría Alejandra Quintero PinillaNo ratings yet

- Model For Microbiologically Influenced Corrosion PDFDocument16 pagesModel For Microbiologically Influenced Corrosion PDFGenis Andres Castillo VillamizarNo ratings yet

- Topic-2: Corrosion Under Isolation (More About The Procedure, And/or Example of Certain CUI Plan) "Document12 pagesTopic-2: Corrosion Under Isolation (More About The Procedure, And/or Example of Certain CUI Plan) "tcsabaiNo ratings yet

- Aluminum Welding On Ship Structure ProblemsDocument14 pagesAluminum Welding On Ship Structure ProblemsMNNo ratings yet

- III 1 Epoxy Coatings and Cement Mortar Lining - CleanedDocument17 pagesIII 1 Epoxy Coatings and Cement Mortar Lining - CleanedKok WaiNo ratings yet

- Analysis of Steam Turbine Blade Failure LOW PRESSURE TURBINEDocument7 pagesAnalysis of Steam Turbine Blade Failure LOW PRESSURE TURBINEpoojaNo ratings yet

- Coated Bolts and OvertappingDocument2 pagesCoated Bolts and OvertappingRamazan ErdinçNo ratings yet

- Advanced Boiler TubeDocument2 pagesAdvanced Boiler TubeShailendra WaniNo ratings yet

- State of Maryland Final Report Task Force To Study Pinhole Leaks in Copper PlumbingDocument65 pagesState of Maryland Final Report Task Force To Study Pinhole Leaks in Copper PlumbingSyavash EnshaNo ratings yet

- 2600 Series Catalog R3Document38 pages2600 Series Catalog R3Mohammad Dzauqi AdamNo ratings yet

- On Oxygen-Induced Corrosion of An Oil Refinery Condensate Fraction at Ion UnitDocument17 pagesOn Oxygen-Induced Corrosion of An Oil Refinery Condensate Fraction at Ion UnitAzmi Mohammed NorNo ratings yet

- AWS G1.1-G1.1M-2006 Guide For The Ultrasonic Assembly of ThermoplasticsDocument96 pagesAWS G1.1-G1.1M-2006 Guide For The Ultrasonic Assembly of ThermoplasticsJeff MNo ratings yet

- Aluminum and Aluminum Alloys: Miutary Standardization HandbookDocument106 pagesAluminum and Aluminum Alloys: Miutary Standardization HandbookStefano BarbieriNo ratings yet

- Pipe Welding With WaveformDocument39 pagesPipe Welding With Waveformprabu prasadNo ratings yet

- 58 Weld Repairs - Creep PerformanceDocument21 pages58 Weld Repairs - Creep PerformanceLTE002No ratings yet

- Sensor TechnologiesDocument10 pagesSensor TechnologiesMiguel LiceagaNo ratings yet

- 20L - Polmeric Seals - E1-20170512Document23 pages20L - Polmeric Seals - E1-20170512andrea assanelli100% (2)

- Boiler MaterialsDocument5 pagesBoiler MaterialsRavi ShankarNo ratings yet

- Cold End CorrosionDocument15 pagesCold End Corrosiondafteri11No ratings yet

- Bridge Welding ProcessDocument151 pagesBridge Welding Processcentaury2013No ratings yet

- Condition Assessmen B&W Chap 45Document22 pagesCondition Assessmen B&W Chap 45Busairi AchmadNo ratings yet

- PDS - SP 8888 - High Temperature Novolac Pipeline Coating - 2017 03 13 PDFDocument3 pagesPDS - SP 8888 - High Temperature Novolac Pipeline Coating - 2017 03 13 PDFMohamed NouzerNo ratings yet

- Aws Publications Catalog: Summer 2010Document20 pagesAws Publications Catalog: Summer 2010saeedahmad901No ratings yet

- Alcoa Aerospace Briefing June92011Document20 pagesAlcoa Aerospace Briefing June92011Mark Evan SalutinNo ratings yet

- Comparing American and British Piping StandardsDocument7 pagesComparing American and British Piping Standardsyarzar17No ratings yet

- TRISTAR-Tube Expanders For Heat ExchangersDocument24 pagesTRISTAR-Tube Expanders For Heat Exchangersapostu sorinNo ratings yet

- Ceramic Coatings Improve Boiler Reliability and PerformanceDocument8 pagesCeramic Coatings Improve Boiler Reliability and PerformancedocturboNo ratings yet

- Preventing Htha Failures With The Buckeye ModelDocument2 pagesPreventing Htha Failures With The Buckeye ModelBangkit WidayatNo ratings yet

- Corrosion PDFDocument46 pagesCorrosion PDFNixon RamsaranNo ratings yet

- Abrasion Resistant Linings For Production and Conveying SystemsDocument28 pagesAbrasion Resistant Linings For Production and Conveying SystemsJim HaigNo ratings yet

- 55 Aluminum-Zinc Alloy Coated Steel Technical Bulletin 6 - Cut Edge Protection v20153Document2 pages55 Aluminum-Zinc Alloy Coated Steel Technical Bulletin 6 - Cut Edge Protection v20153Syed Raja AdeelNo ratings yet

- TS MaterialGuide en 2015.04Document52 pagesTS MaterialGuide en 2015.04Stefano MartelliNo ratings yet

- Corrosion and Materials Selection: A Guide for the Chemical and Petroleum IndustriesFrom EverandCorrosion and Materials Selection: A Guide for the Chemical and Petroleum IndustriesNo ratings yet

- Corrosion Prevention and Protection: Practical SolutionsFrom EverandCorrosion Prevention and Protection: Practical SolutionsRating: 4 out of 5 stars4/5 (1)

- Anchorage Economic DevelopmentDocument44 pagesAnchorage Economic DevelopmentmhdsolehNo ratings yet

- Data AnalyticsDocument56 pagesData AnalyticsmhdsolehNo ratings yet

- From Research To Innovation To Enterprise: The Case of SingaporeDocument7 pagesFrom Research To Innovation To Enterprise: The Case of SingaporemhdsolehNo ratings yet

- Value Creation & Value AppropriationDocument108 pagesValue Creation & Value Appropriationmhdsoleh100% (1)

- B Biio Om Ma Assss C Co Offiirriin NG G:: A AR Re en Ne Ew Wa Ab Blle e A Alltte Errn Na Attiiv Ve e Ffo Orr U Uttiilliittiie EssDocument2 pagesB Biio Om Ma Assss C Co Offiirriin NG G:: A AR Re en Ne Ew Wa Ab Blle e A Alltte Errn Na Attiiv Ve e Ffo Orr U Uttiilliittiie EssmhdsolehNo ratings yet

- Energy Management System Based On The PN-EN ISO 50001 - Implementation in Dzierzoni ÓwDocument17 pagesEnergy Management System Based On The PN-EN ISO 50001 - Implementation in Dzierzoni ÓwmhdsolehNo ratings yet

- 1504 Metals From MWIBA R. BungeDocument68 pages1504 Metals From MWIBA R. BungemhdsolehNo ratings yet

- Proper Sizing of Steam Header Drains Prevents Water InductionDocument7 pagesProper Sizing of Steam Header Drains Prevents Water InductionmhdsolehNo ratings yet

- FP - A.1 - EGAT - EGAT Fleet Capability On Generator Rotor RepairDocument7 pagesFP - A.1 - EGAT - EGAT Fleet Capability On Generator Rotor RepairmhdsolehNo ratings yet

- FP - A.1 - EGAT - EGATÔÇÖs Capability Enhancement On Electrical Protection ImprovementDocument6 pagesFP - A.1 - EGAT - EGATÔÇÖs Capability Enhancement On Electrical Protection ImprovementmhdsolehNo ratings yet

- FP - A.1 - Consequential Damage and Inspection Techniques From Lack of Lubrication, Steam Turbine CaseDocument14 pagesFP - A.1 - Consequential Damage and Inspection Techniques From Lack of Lubrication, Steam Turbine Casemhdsoleh100% (1)

- FP - A.1 - EGAT - A Novel Vented Lead-Acid Battery Performance Test Based 50% Hour Rate With Fully Discharged Rate Condition in EGAT Power Plant Experience PDFDocument4 pagesFP - A.1 - EGAT - A Novel Vented Lead-Acid Battery Performance Test Based 50% Hour Rate With Fully Discharged Rate Condition in EGAT Power Plant Experience PDFmhdsolehNo ratings yet

- MIUI 12 Latest Update Features 2020Document5 pagesMIUI 12 Latest Update Features 2020johnson veigasNo ratings yet

- Sensex Rolling ReturnsDocument1 pageSensex Rolling Returnsmaheshtech76No ratings yet

- TikTok Marketing - Cheat SheetDocument4 pagesTikTok Marketing - Cheat Sheetmariomr0890No ratings yet

- EC287 - Presentation To Community Board 4-RRA 03032022Document12 pagesEC287 - Presentation To Community Board 4-RRA 03032022Christina WilkinsonNo ratings yet

- Disjuntor SF1 - Dados ElétricosDocument1 pageDisjuntor SF1 - Dados ElétricosotavioalcaldeNo ratings yet

- Masidlak Eagles Form 2Document2 pagesMasidlak Eagles Form 2Rubie Anne SaducosNo ratings yet

- Course Promotional 3Document15 pagesCourse Promotional 3Alexander Klain AquiatanNo ratings yet

- 43 CA CPT Dec 2010 Question Paper With Answer Key 2Document6 pages43 CA CPT Dec 2010 Question Paper With Answer Key 2Vishal Gattani100% (1)

- Indian School of Business (ISB) PGP (Intended Major: Finance) - GMAT: 740Document1 pageIndian School of Business (ISB) PGP (Intended Major: Finance) - GMAT: 740Suprateek BoseNo ratings yet

- French, J. (2011) Why Nudging Is Not EnoughDocument11 pagesFrench, J. (2011) Why Nudging Is Not EnoughFrancisco SantosNo ratings yet

- Kabale University Students HandbookDocument20 pagesKabale University Students Handbookjesseokiror21No ratings yet

- FT096 20191112 Iso A4Document64 pagesFT096 20191112 Iso A4Jeff Zeitlin100% (4)

- CPA Instagram DominationDocument19 pagesCPA Instagram Dominationvomawew647No ratings yet

- Gun Rights Groups Sue Over California Carry Permit Requirements - CRPA v. LASD ComplaintDocument41 pagesGun Rights Groups Sue Over California Carry Permit Requirements - CRPA v. LASD ComplaintAmmoLand Shooting Sports NewsNo ratings yet

- Impact of COVID-19 On People's Livelihoods, Their Health and Our Food SystemsDocument4 pagesImpact of COVID-19 On People's Livelihoods, Their Health and Our Food Systemsjungkook jeonNo ratings yet

- Motorcycle Clutch SystemDocument15 pagesMotorcycle Clutch SystemSelazinap LptNo ratings yet

- Studentzone 02 2017Document3 pagesStudentzone 02 2017YahiaEl-obidyNo ratings yet

- TC15M 65M Manual PDFDocument15 pagesTC15M 65M Manual PDFReciclando ChatarraNo ratings yet

- Reading TextsDocument6 pagesReading TextsAbd TalepNo ratings yet

- Multi V5 + Chiller Scroll PDFDocument81 pagesMulti V5 + Chiller Scroll PDFFernando CabreraNo ratings yet

- Hybrid GrandglowDocument5 pagesHybrid Grandglowmohsan bilalNo ratings yet

- Animal Health 2011 (Equipment Catalog)Document86 pagesAnimal Health 2011 (Equipment Catalog)qadir-qadisNo ratings yet

- Drug Schedules and Prescription Writing Clifford M. Knapp, PH.DDocument36 pagesDrug Schedules and Prescription Writing Clifford M. Knapp, PH.DEman ElzeftawyNo ratings yet

- Offer LetterDocument1 pageOffer Letterahmadkahan5272No ratings yet

- API 686-Suction Line Slopes and ReducersDocument1 pageAPI 686-Suction Line Slopes and ReducersjpalauguillemNo ratings yet

- Mainboard Biosta Model P4M8P M7ADocument34 pagesMainboard Biosta Model P4M8P M7ARommel LoayzaNo ratings yet

- Cargo Handling & Stability - I: Captain Nazim ErsenDocument52 pagesCargo Handling & Stability - I: Captain Nazim ErsenberNo ratings yet

- DO - s2009 - 54 - PTA GUIDELINES - RecognizedDocument11 pagesDO - s2009 - 54 - PTA GUIDELINES - RecognizedArthur AguilarNo ratings yet

- 167867-2013-Optima Realty Corp. v. Hertz Phil. ExclusiveDocument8 pages167867-2013-Optima Realty Corp. v. Hertz Phil. ExclusiveYuri NishimiyaNo ratings yet

- APSC Mains GS5 Syllabus Topic ListDocument11 pagesAPSC Mains GS5 Syllabus Topic ListAdhish Bipul BarmanNo ratings yet