Professional Documents

Culture Documents

Ramset Specifiers Anchoring Resource Book ANZ - EPCON C8 Anchor Studs

Ramset Specifiers Anchoring Resource Book ANZ - EPCON C8 Anchor Studs

Uploaded by

yyanan1118Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ramset Specifiers Anchoring Resource Book ANZ - EPCON C8 Anchor Studs

Ramset Specifiers Anchoring Resource Book ANZ - EPCON C8 Anchor Studs

Uploaded by

yyanan1118Copyright:

Available Formats

8.

1 EPCON

C8

CHEMICAL INJECTION ANCHORING

8.1 GENERAL INFORMATION

MATERIAL

INSTALLATION RELATED

HCR

Product

ETA

EPCON C8 is a High Performance Pure Epoxy Anchoring adhesive for

use in Cracked and Non-Cracked concrete. For structures subject to

external exposure , permanently damp or aggressive conditions .

ETA

European Technical Approval

ETAG 001 Part 5 Option 1

European Technical Approval

ETAG 001 Part 5 TR023

ETA 10/0309 0679-CPD-0549

ETA 07/0189 0679-CPD-0276

Benefits, Advantages and Features

European Technical Approval option1 for use in

cracked and non cracked concrete ETA-10/0309:

Highest level of European approval for chemical anchors

100 Year design life

Approved for flooded holes

Approved for floor, wall & overhead applications

Data for Sustained Loading

Installation temperature limits:

Greater productivity:

Anchors in dry, damp, wet or flooded holes

No weather delays

Fast and easy dispensing

Principal Applications

Greater security:

Highest performance in cracked concrete

Versatile pure epoxy:

Anchors all stud & bar diameters in all directions

Oversized holes

Anchors in carbide drilled and diamond cored holes

For tropical and Cold weather conditions

Greater safety:

Low odour

Non-flammable

Fire Rated : Refer Fire rated anchoring section

Anchoring into cracked & non cracked concrete

Road barrier hold down bolts

Bridge refurbishment

Ro & Raili tunnel construction

Road

i n

Reinforcing bar from 8 to 32mm

Starter Bars

Threaded studs from M8 to M30

Threaded Stud material: Zn, A4 316, HCR steels

Threaded Stud material: 5.8, 8.8, 10.9 grade

Substrate: 5C to 40C

Adhesive: 5C to 40C

Load should not be applied to anchor until the chemical has sufficiently

cured as specified.

Installation

Service temperature limits:

-40C to 80C

Setting Times EPCON C8

1. Drill recommended diameter and depth hole.

2. Important: Use Ramset Dustless Drilling System to ensure holes

are clean. Alternatively, clean dust and debris from hole with stiff wire

or nylon brush and blower in the following sequence: blow x 4, brush

x 3, blow x 4, brush x 3, blow x 4.

3. Insert mixing nozzle to bottom of hole. Fill hole to 3/4 the hole depth

slowly, ensuring no air pockets form.

4. Insert Ramset ChemSet Anchor Stud/rebar to

bottom of hole while turning.

5. Allow EPCON C8 to cure as per setting times.

6. Attach fixture.

www.ramset.co.nz

0800 RAMSET

Temperature of

base material

5C - 9C

10C - 19C

20C - 24C

25C - 29C

30C - 39C

40C

Gel Time

20 min

14 min

11 min

8 min

5 min

5 min

www.ramset.com.au

Curing time in

dry concrete

30 h

23 h

16 h

12 h

8h

6h

1300 780 063

Curing time in

wet concrete

60 h

46 h

32 h

24 h

16 h

12 h

53

Chemical Anchoring - Anchor Studs

PERFORMANCE RELATED

8.2-3

EPCON C8

Chemical Anchoring - Anchor Studs

CHEMICAL INJECTION ANCHORING

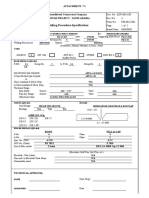

Installation and performance details:

EPCON C8 and ChemSet Anchor Studs

Anchor size, db

(mm)

M8

Drilled hole diameter,

dh (mm)

10

M10

12

Installation details

Fixture hole diameter,

Anchor effective

df (mm)

depth, h (mm)

10

80

12

Tightening torque, Tr

(Nm)

10

Edge distance, ec

(mm)

35

Optimum dimensions*

Anchor spacing, ac

(mm)

50

20

40

60

120

90

Substrate thickness bm

(mm)

100

M12

14

15

110

40

50

75

140

M16

18

20

95

65

100

M20

24

24

125

150

180

80

120

160

190

M24

26

28

M30

32

32

170

220

160

210

280

315

100

145

200

270

650

120

180

350

*Note: For shear loads acting towards an edge or where these optimum dimensions are not achievable, please use the simplified strength limit state design process to verify capacity.

Anchor size, db

(mm)

Grade 5.8 Steel Studs

Reduced Characteristic Capacity#

AISI 316 Stainless Steel Studs

Grade 8.8 Steel Studs

Concrete

Tension, Nuc (kN)**

Concrete compressive strength, fc

20 MPa

32 MPa

40 MPa

Shear, Vus(kN) Tension, Nus(kN)*** Shear, Vus(kN) Tension, Nus(kN)*** Shear, Vus(kN) Tension, Nus(kN)***

M8

8.9

14.3

14.5

23.4

10.7

14.9

17.9

18.8

19.6

M10

14.1

22.7

23.0

37.1

17.0

23.8

25.0

26.6

27.9

M12

21.0

33.8

33.5

54.0

25.3

35.3

36.6

39.4

41.4

M16

39.7

64.7

62.3

100.5

49.6

69.3

M20

59.9

97.6

97.2

156.8

74.9

104.6

M24

86.8

141.3

140.1

225.9

108.5

151.4

M30

222.6

359.0

38.7

49.0

54.8

50.9

64.4

72.1

61.4

77.7

87.0

56.0

70.9

79.4

84.2

129.7

106.6

164.2

119.4

183.9

*Note: For shear loads acting towards an edge or where these optimum dimensions are not achievable, please use the simplified strength limit state design process to verify capacity.

**Note: Reduced characteristic ultimate concrete tensile capacity = Nuc where = 0.56 and Nuc = Characteristic ultimate concrete tensile capacity.

For conversion to Working Load Limit MULTIPLY Nuc x 0.60

***Note: Reduced characteristic ultimate steel tensile capacity = Nus where = 0.8 and Nus = Characteristic ultimate steel tensile capacity (carbon steel).

For conversion to Working Load Limit MULTIPLY Nus x 0.45

#

Note: Design Tensile Capacity Nur = minimum of Nuc and Nus

Data is based on a service temperature limit of -40C to +40C

WET HOLES: Multiply Nuc x 0.5

8.2 DESCRIPTION AND PART NUMBERS

Description

Cartridge Size

Part No.

EPCON C8

450 ml

C8-450

Effective depth, h (mm)

Substrate thickness, bm (mm)

Preferred h = hn otherwise,

bm = greater of: 1.25 x h,

h + (2 x dh)

h = Le - t

h * 6 * dh

t = total thickness of material(s) being fastened.

Drilled hole depth, h1 (mm)

h1 = h

h = Effective depth

8.3 ENGINEERING PROPERTIES

Refer to Engineering Properties for ChemSet Anchor Studs on page 43.

54

www.ramset.com.au

1300 780 063

www.ramset.co.nz

0800 RAMSET

8.4 EPCON

C8

STRENGTH LIMIT STATE DESIGN

STEP 1

Chemical Anchoring - Anchor Studs

Select anchor to be evaluated

Table 1a Indicative combined loading interaction diagram

180

Notes:

~ Shear limited by Grade 5.8 steel capacity.

~ Tension limited by concrete capacity

using nominal depths.

~ No edge or spacing effects.

~ f'c = 32 MPa

160

Design tensile action effect, N* (kN)

140

120

M30

100

80

M24

60

M20

40

M16

M12

20

M10

M8

0

0

20

40

80

60

100

120

140

160

Design shear action effect, V* (kN)

Table 1b Absolute minimum edge distance and anchor spacing values, em and am (mm)

Anchor size, db

em, am

M8

25

M10

30

M12

35

M16

50

M20

60

M24

75

M30

90

Step 1c Calculate anchor effective depth, h (mm)

Refer to Description and Part Numbers table for ChemSet Anchor Studs on page 43.

Effective depth, h (mm)

Preferred h = hn otherwise,

h = Le - t

h * 6 * dh

t = total thickness of material(s) being fastened.

www.ramset.co.nz

Anchor size determined, absolute minima compliance achieved, effective depth (h) calculated.

0800 RAMSET

www.ramset.com.au

1300 780 063

55

8.4 EPCON

C8

Chemical Anchoring - Anchor Studs

STRENGTH LIMIT STATE DESIGN

STEP 2

Verify concrete tensile capacity - per anchor

Table 2a Reduced characteristic ultimate concrete tensile capacity, Nuc (kN), c = 0.56, fc = 32 MPa

Anchor size, db

Drilled hole dia, dh (mm)

Effective depth, h (mm)

65

70

80

90

100

110

120

125

140

150

160

170

180

190

200

210

240

280

320

350

400

450

480

550

600

M8

10

15.2

16.4

18.8

21.1

23.5

25.8

28.1

29.3

32.8

35.2

37.5

Combined pull-out and concrete cone resistance - Nucp

M10

M12

M16

M20

M24

12

14

18

25

28

20.7

23.7

26.6

29.6

32.6

35.5

37.0

41.4

44.4

47.4

50.3

53.3

56.2

59.2

62.2

32.3

35.9

39.4

43.0

44.8

50.2

53.8

57.4

61.0

64.5

68.1

71.7

75.3

86.1

50.2

54.8

57.1

63.9

68.5

73.1

77.6

82.2

86.7

91.3

95.9

109.6

127.8

146.1

81.4

86.8

92.2

97.6

103.1

108.5

113.9

130.2

151.9

173.6

189.9

217.0

98.5

104.6

110.8

116.9

123.1

129.2

147.7

172.3

196.9

215.4

246.1

276.9

295.4

M30

35

165.8

189.5

221.1

252.7

276.4

315.8

355.3

379.0

434.3

473.8

Concrete Cone

Resistance Nucc

18.4

20.5

25.1

29.9

35.0

40.4

46.1

49.0

58.0

64.4

70.9

77.7

84.6

91.8

99.1

106.6

130.3

164.2

200.6

229.4

280.3

334.5

368.5

452.0

515.0

Bold values are at ChemSet Anchor Stud nominal depths.

Note: Effective depth, h must be * 6 x drilled hole diameter, dh for anchor to achieve tabled shear capacities.

Wet holes: Multiply Nuc x0.5

If Service temperature limit is -40C to +80C then

Nuc = Nucp

If Service temperature limit is -40C to +40C then

Refer to Checkpoint 2

Table 2b-1 Concrete service temperature limits effect, tension, Xns

Anchor size, db

M8

Service temperature limits effect, tension, Xns

where Nuc = Nucp (from Table 2a)

M10

M12

M16

M20

M24

Service temperature (C)

-40C to +40C

-40C to +80C

1.00

0.56

Service temperature limits effect, tension, Xns

1.00

1.00

1.00

1.00

1.00

0.56

0.56

0.57

0.57

0.58

Xns

M30

where

Nuc = Nucc

(from Table 2a)

1.00

0.54

1.00

1.00

Table 2b-2 Concrete compressive strength effect, tension, Xnc

56

Anchor size, db

M8

Concrete compressive strength effect, tension, Xnc

where Nuc = Nucp (from Table 2a)

M10

M12

M16

M20

M24

f'c (MPa)

20

25

32

40

50

0.95

0.97

1.00

1.04

1.06

Concrete compressive strength effect, tension, Xnc

0.94

0.93

0.92

0.90

0.88

0.97

0.96

0.95

0.95

0.94

1.00

1.00

1.00

1.00

1.00

1.05

1.05

1.07

1.09

1.10

1.08

1.09

1.11

1.14

1.16

www.ramset.com.au

1300 780 063

Xnc

M30

where

Nuc = Nucc

(from Table 2a)

0.86

0.92

1.00

1.12

1.21

0.79

0.88

1.00

1.12

1.25

www.ramset.co.nz

0800 RAMSET

8.4 EPCON

C8

STRENGTH LIMIT STATE DESIGN

Table 2c Edge distance effect, tension, Xne

M8

0.85

0.96

1

M10

0.83

0.91

1

M12

0.81

0.88

1

M16

0.85

0.96

1

M20

0.83

0.87

0.96

1

M24

0.85

0.88

0.96

1

M30

Chemical Anchoring - Anchor Studs

Anchor size, db

Edge distance, e (mm)

25

30

35

40

50

60

65

75

80

90

100

110

120

0.83

0.88

0.94

1

Table 2d Anchor spacing effect, end of a row, tension, Xnae

For single anchor design, Xnae=1.0

Anchor size, db

Anchor Spacing, a (mm)

25

30

35

50

60

75

95

120

145

180

M8

0.76

0.81

0.86

1

M10

0.75

0.79

0.92

1

M12

0.74

0.85

0.92

1

M16

0.76

0.81

0.89

1

M20

M24

0.75

0.81

0.90

1

0.76

0.83

0.92

1

M30

0.76

0.83

0.90

1

Table 2e Anchor spacing effect, internal to a row, tension, Xnai

For single anchor design, Xnai = 1.0

Anchor size, db

Anchor Spacing, a (mm)

25

30

35

50

60

75

95

120

145

180

2

STEP 3

M8

0.52

0.63

0.73

1

M10

0.50

0.58

0.83

1

M12

0.49

0.69

0.83

1

M16

0.52

0.63

0.78

1

M20

M24

0.50

0.63

0.79

1

0.52

0.66

0.83

1

M30

0.53

0.67

0.81

1

Design reduced ultimate concrete tensile capacity, Nurc

Nurc = Nuc*Xns*Xnc*Xne*(Xnae or Xnai)

If Service temperature limit is -40C to +40C then

Nurc = minimum of Nucp*Xns*Xnc*Xne*( Xnae or Xnai ) and Nucc*Xns*Xnc*Xne*( Xnae or Xnai )

Verify anchor tensile capacity - per anchor

Table 3a Reduced characteristic ultimate steel tensile capacity, Nus (kN), n = 0.8

Anchor size, db

M8

M10

M12

M16

M20

M24

M30

ChemSet Anchor Stud

Grade 5.8 Carbon Steel

14.3

22.7

33.8

64.7

97.6

141.3

ChemSet Anchor Stud

A4/316 Stainless Steel

14.9

23.8

35.3

69.3

104.6

151.4

Typical Threaded Rod

Grade 8.8 Carbon Steel

23.4

37.1

54.0

100.5

156.8

225.9

359.0

Step 3b Reduced characteristic ultimate bolt steel tensile capacity, Ntf (kN)

Not appropriate for this product.

www.ramset.co.nz

0800 RAMSET

www.ramset.com.au

1300 780 063

57

8.4 EPCON

C8

Chemical Anchoring - Anchor Studs

STRENGTH LIMIT STATE DESIGN

Design reduced ultimate tensile capacity, Nur

Nur = minimum of Nurc, Nus

Check N*

/ Nur ) 1,

if not satisfied return to step 1

Tensile performance conversion table

Concrete Tensile Performance

Performance Required

Steel Tensile Performance

Notation

Concrete

Tension Capacity

Notation

Carbon Steel

Tension Capacity

Stainless Steel

Tension Capacity

Strength Limit State

Nurc

MULTIPLY Nurc x 1.00

Nus

MULTIPLY Nus x 1.00

MULTIPLY Nus x 1.00

Working Load Limit

Nac

MULTIPLY Nurc x 0.60

Nas

MULTIPLY Nus x 0.45

MULTIPLY Nus x 0.50

Cyclic Loading

Nyc

MULITPLY Nurc x 0.55

Nys

MULITPLY Nus x 0.45

MULITPLY Nus x 0.50

Fire Resistance

NRk,c,,t

Refer to pages 238-257

NRk,s,,t

Refer to pages 238-257

Refer to pages 238-257

Cracked Concrete/Tension Zone

N0Rd,p

Refer to pages 258-298

NRd,s

Refer to pages 258-298

Refer to pages 258-298

Refer to pages 299-325

NRd,s,sis

Refer to pages 299-325

Refer to pages 299-325

Seismic

N Rd,p,sis

NOTE: Design Tensile Capacity is the minimum of Concrete Tension and Steel Tension Capacities

STEP 4

Verify concrete shear capacity - per anchor

Table 4a Reduced characteristic ultimate concrete edge shear capacity, Vuc (kN), q = 0.6, fc = 32 MPa

Anchor size, db

M8

M10

M12

M16

M20

M24

M30

1.6

2.2

2.7

4.6

6.1

8.5

18.3

37.0

68.0

104.8

146.2

192.4

269.0

2.4

3.0

5.1

6.7

9.3

20.0

40.6

74.5

114.8

160.4

210.8

294.6

3.2

5.5

7.2

10.1

21.7

43.8

80.5

123.9

173.2

227.7

318.2

6.2

8.2

11.4

24.6

49.7

91.3

140.5

196.4

258.2

360.8

9.4

13.2

28.4

57.4

105.4

162.3

226.8

298.1

416.7

13.7

29.5

59.7

109.7

168.9

236.1

310.3

433.7

15.2

32.7

66.3

121.7

187.4

261.9

344.3

481.1

Edge distance, e (mm)

25

30

35

50

60

75

125

200

300

400

500

600

750

Note: Effective depth, h must be * 6 x drilled hole diameter, dh for anchor to achieve tabled shear capacities.

Table 4b Concrete compressive strength effect, concrete edge shear, Xvc

fc (MPa)

Xvc

20

0.79

25

0.88

32

1.00

40

1.12

50

1.25

Table 4c Load direction effect, concrete edge shear, Xvd

Load direction effect,

conc. edge shear, Xvd

58

Angle, _

Xvd

www.ramset.com.au

0

1.00

1300 780 063

10

1.04

20

1.16

30

1.32

40

1.50

50

1.66

60

1.80

70

1.91

www.ramset.co.nz

80

1.98

90 - 180

2.00

0800 RAMSET

8.4 EPCON

C8

STRENGTH LIMIT STATE DESIGN

Table 4d Anchor spacing effect, concrete edge shear, Xva

Edge distance, e (mm)

25

30

35

50

60

75

125

0.70

0.74

0.78

0.90

0.98

1.00

0.67

0.70

0.73

0.83

0.90

1.00

0.64

0.67

0.70

0.79

0.84

0.93

1.00

0.60

0.62

0.64

0.70

0.74

0.80

1.00

0.58

0.60

0.62

0.67

0.70

0.75

1.00

0.57

0.58

0.59

0.63

0.66

0.70

0.90

1.00

0.54

0.55

0.56

0.58

0.60

0.62

0.74

0.82

0.98

1.00

200

300

400

600

900

Anchor spacing, a (mm)

25

30

35

50

60

75

150

200

300

400

500

625

750

875

1000

1250

1500

2250

0.53

0.54

0.55

0.56

0.58

0.65

0.70

0.80

0.90

1.00

0.52

0.53

0.54

0.55

0.60

0.63

0.70

0.77

0.83

0.92

1.00

0.53

0.53

0.54

0.58

0.60

0.65

0.70

0.75

0.81

0.88

0.94

1.00

0.52

0.53

0.55

0.57

0.60

0.63

0.67

0.71

0.75

0.79

0.83

0.92

1.00

0.52

0.53

0.54

0.57

0.59

0.61

0.64

0.67

0.69

0.72

0.78

0.833

1.00

Table 4e Multiple anchors effect, concrete edge shear, Xvn

Note: For single anchor designs, Xvn = 1.0

Anchor spacing /

Edge distance, a / e

Number of anchors, n

2

3

4

5

6

7

8

9

10

15

20

0.20

0.40

0.60

0.80

1.00

1.20

1.40

1.60

1.80

2.00

2.25

2.50

1.00

0.72

0.57

0.49

0.43

0.39

0.36

0.34

0.32

0.26

0.23

1.00

0.76

0.64

0.57

0.52

0.48

0.46

0.44

0.42

0.37

0.35

1.00

0.80

0.69

0.63

0.59

0.56

0.54

0.52

0.51

0.47

0.45

1.00

0.83

0.74

0.69

0.66

0.63

0.61

0.60

0.59

0.55

0.54

1.00

0.86

0.79

0.74

0.71

0.69

0.68

0.67

0.66

0.63

0.61

1.00

0.88

0.82

0.79

0.77

0.75

0.74

0.73

0.72

0.70

0.68

1.00

0.91

0.86

0.83

0.81

0.80

0.79

0.78

0.77

0.76

0.75

1.00

0.93

0.89

0.87

0.85

0.84

0.84

0.83

0.82

0.81

0.80

1.00

0.95

0.92

0.90

0.89

0.88

0.88

0.87

0.87

0.86

0.85

1.00

0.96

0.94

0.93

0.93

0.92

0.92

0.91

0.91

0.90

0.90

1.00

0.98

0.97

0.97

0.96

0.96

0.96

0.96

0.96

0.95

0.95

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

Table 4f Anchor at a corner effect, concrete edge shear, Xvs

e1

Shear Force

Note: For e1/e2 > 1.25, Xvs = 1.0

Edge distance, e2 (mm)

e2

Failure

wedge

Concrete edges

ANCHOR AT A CORNER

www.ramset.co.nz

25

30

35

50

60

75

125

200

300

400

600

900

0.86

0.97

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

0.77

0.86

0.95

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

0.70

0.78

0.86

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

0.58

0.64

0.69

0.86

0.97

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

0.53

0.58

0.63

0.77

0.86

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

0.49

0.52

0.56

0.67

0.75

0.86

1.00

1.00

1.00

1.00

1.00

1.00

1.00

0.41

0.43

0.46

0.52

0.57

0.64

0.86

1.00

1.00

1.00

1.00

1.00

1.00

0.37

0.38

0.40

0.44

0.47

0.51

0.65

0.86

1.00

1.00

1.00

1.00

1.00

0.35

0.36

0.37

0.39

0.41

0.44

0.53

0.67

0.86

1.00

1.00

1.00

1.00

0.34

0.34

0.35

0.37

0.38

0.41

0.48

0.58

0.72

0.86

1.00

1.00

1.00

0.32

0.33

0.33

0.35

0.36

0.37

0.42

0.49

0.58

0.67

0.77

0.86

1.00

0.32

0.32

0.32

0.33

0.34

0.35

0.38

0.42

0.49

0.55

0.61

0.67

0.86

Edge dustance, e1 (mm)

0800 RAMSET

25

30

35

50

60

75

125

200

300

400

500

600

900

www.ramset.com.au

1300 780 063

59

Chemical Anchoring - Anchor Studs

Note: For single anchor designs, Xva = 1.0

8.4 EPCON

C8

Chemical Anchoring - Anchor Studs

STRENGTH LIMIT STATE DESIGN

STEP 5

Design reduced ultimate concrete edge shear capacity, Vurc

Vurc = Vuc * Xvc * Xvd * Xva * Xvn * Xvs

Verify anchor shear capacity - per anchor

Table 5a Reduced characteristic ultimate steel shear capacity, Vus (kN), v = 0.8

Anchor size, db

M8

M10

M12

M16

M20

M24

M30

ChemSet Anchor Stud

Grade 5.8 Carbon Steel

8.9

14.1

21.0

39.7

59.9

86.8

ChemSet Anchor Stud

A4/316 Stainless Steel

10.7

17.0

25.3

49.6

74.9

108.5

Typical Threaded Rod

Grade 8.8 Carbon Steel

14.5

23.0

33.5

62.3

97.2

140.1

222.6

Step 5b Reduced characteristic ultimate bolt steel shear capacity, Vsf (kN)

Not appropriate for this product.

Design reduced ultimate shear capacity, Vur

Vur = minimum of Vurc, Vus

Check V*

/ Vur ) 1,

if not satisfied return to step 1

Shear performance conversion table

Concrete Shear Performance

Performance Required

Steel Shear Performance

Notation

Concrete

Shear Capacity

Notation

Carbon Steel

Shear Capacity

Stainless Steel

Shear Capacity

Strength Limit State

Vuc

MULTIPLY Vuc x 1.00

Vus

MULTIPLY Vus x 1.00

MULTIPLY Vus x 1.00

Working Load Limit

Vac

MULTIPLY Vuc x 0.55

Vas

MULTIPLY Vus x 0.50

MULTIPLY Vus x 0.52

Cyclic Loading

Vyc

MULITPLY Vuc x 0.55

Vys

MULITPLY Vus x 0.50

MULITPLY Vus x 0.52

Fire Resistance

VRk,c,,t

Refer to pages 238-257

VRk,s,,t

Refer to pages 238-257

Refer to pages 238-257

Cracked Concrete/Tension Zone

V0Rd,c

Refer to pages 258-298

V0Rd,s

Refer to pages 258-298

Refer to pages 258-298

Refer to pages 299-325

0

Rd,s,sis

Refer to pages 299-325

Refer to pages 299-325

0

Rd,c,sis

Seismic

NOTE: Design Shear Capacity is the minimum of Concrete Shear and Steel Shear Capacities

Example

STEP 6

6

Combined loading and specification

Check

Ramset Ep

Epcon

on C8 with

M16 grade 5.8

ChemSet Anchor Stud (CS16190GH).

Drilled hole depth to be 125 mm.

To be installed in accordance with

Ramset Technical Data Sheet.

N*/Nur + V*/Vur ) 1.2,

if not satisfied return to step 1

Specify Threaded Stud Anchorss

Specify

Ramset Epcon C8 with (Anchor Size)

grade 5.8

ChemSet Anchor Stud

((((Anchor Stud Part Number)).

((Anchor

))

Drilled hole depth to be (h) mm.

60

www.ramset.com.au

1300 780 063

www.ramset.co.nz

0800 RAMSET

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- A Literature Review of Use of Recycled Concrete Aggregates PDFDocument61 pagesA Literature Review of Use of Recycled Concrete Aggregates PDFyyanan111875% (4)

- Tier 1 Bridge Heavy Load Assessment Criteria - 2013 (Main Road)Document85 pagesTier 1 Bridge Heavy Load Assessment Criteria - 2013 (Main Road)yyanan1118No ratings yet

- Downee Gate Catalogue PDFDocument40 pagesDownee Gate Catalogue PDFyyanan1118No ratings yet

- Analysis of Rigid Piles in Clays 2008Document11 pagesAnalysis of Rigid Piles in Clays 2008yyanan1118No ratings yet

- ASTM A 514 - A 514-00. Standard Specification For High-YieldDocument3 pagesASTM A 514 - A 514-00. Standard Specification For High-YieldHo Le QuangNo ratings yet

- Elkem - Alloying Elements and Their EffectsDocument8 pagesElkem - Alloying Elements and Their EffectsDeep Shikha Gupta100% (8)

- Steel Rerolling Mill - TMT BarDocument6 pagesSteel Rerolling Mill - TMT BarNitin Das100% (1)

- Influence of Chloride Thresholds in Service Life of RC ConcreteDocument19 pagesInfluence of Chloride Thresholds in Service Life of RC Concreteyyanan1118No ratings yet

- Design Aids For Continuous BeamsDocument13 pagesDesign Aids For Continuous Beamsyyanan1118No ratings yet

- Composite Column - Calculation ExamplesDocument62 pagesComposite Column - Calculation Examplesk1m1mak1No ratings yet

- Australia - Metro Design Guideline - Bridge - L1-CHE-STD-040Document42 pagesAustralia - Metro Design Guideline - Bridge - L1-CHE-STD-040yyanan1118No ratings yet

- Austroads - Bridge AssessmentDocument6 pagesAustroads - Bridge Assessmentyyanan1118No ratings yet

- Bridge Technical Note 2018 - 002 Bridge Approach Barriers Feb 2018Document7 pagesBridge Technical Note 2018 - 002 Bridge Approach Barriers Feb 2018yyanan1118No ratings yet

- Bridge Technical Notes Index Oct 2018Document1 pageBridge Technical Notes Index Oct 2018yyanan1118No ratings yet

- Math 9 - Chapter 2Document21 pagesMath 9 - Chapter 2yyanan1118No ratings yet

- Designs of The Retaining Wall Structures at Sydney M4 ProjectDocument24 pagesDesigns of The Retaining Wall Structures at Sydney M4 Projectyyanan1118100% (1)

- Road Design Note 0613 Guidelines For The Protection of Gantry and Cantilever Sign SupporDocument19 pagesRoad Design Note 0613 Guidelines For The Protection of Gantry and Cantilever Sign Supporyyanan1118No ratings yet

- PrecastUGirder PresentationDocument67 pagesPrecastUGirder Presentationyyanan1118No ratings yet

- Use of FRP in Strengthening of Bridge - VR BTN 2013-001 - V1Document3 pagesUse of FRP in Strengthening of Bridge - VR BTN 2013-001 - V1yyanan1118No ratings yet

- Conlift Concrete Lifting SystemsDocument24 pagesConlift Concrete Lifting Systemsyyanan1118No ratings yet

- VicRoads Standard Specification Section Changes (19 Oct 2017)Document191 pagesVicRoads Standard Specification Section Changes (19 Oct 2017)yyanan1118No ratings yet

- Background To The General Method of Shear DesignDocument14 pagesBackground To The General Method of Shear Designyyanan1118No ratings yet

- Thomas and Hsu Shear Flow Zone in Torsion of RC MemberDocument21 pagesThomas and Hsu Shear Flow Zone in Torsion of RC Memberyyanan1118100% (1)

- Test Method RC 00000 Index of VicRoads Test MethodsDocument4 pagesTest Method RC 00000 Index of VicRoads Test Methodsyyanan1118No ratings yet

- Graphite BearingsDocument12 pagesGraphite Bearingsm21m29No ratings yet

- DPR 3Document68 pagesDPR 3MITHUNNo ratings yet

- Cost & Quality Analysis of WeldingDocument13 pagesCost & Quality Analysis of Weldingswapnil pandeNo ratings yet

- Adamas Industry 4.0Document21 pagesAdamas Industry 4.0Dr JayantaNo ratings yet

- Inspection and Test Plan For Epc Gas Pipeline Project-X70mDocument15 pagesInspection and Test Plan For Epc Gas Pipeline Project-X70mFolarin Ayodeji100% (1)

- Practical Plan Som FMM LabDocument5 pagesPractical Plan Som FMM LabkganesanNo ratings yet

- CPC CC Hydraulic Cable Cutting Tools SeriesDocument0 pagesCPC CC Hydraulic Cable Cutting Tools SeriesbaolifengNo ratings yet

- Rail Specification S & CorrosionDocument94 pagesRail Specification S & CorrosionGowthami Priya HanumuthuNo ratings yet

- 3D - CparDocument32 pages3D - CparKristine AllejeNo ratings yet

- Top 50 Mechanical Engineering Interview Questions & Answers: 1) What Is The Second Law of Thermodynamics?Document7 pagesTop 50 Mechanical Engineering Interview Questions & Answers: 1) What Is The Second Law of Thermodynamics?Aslam AzeezNo ratings yet

- IK MFR Alphabetical Listing 1Document30 pagesIK MFR Alphabetical Listing 1Amin AzadNo ratings yet

- Historical Listing of Selected Structural SteelsDocument1 pageHistorical Listing of Selected Structural Steelssome_guy89No ratings yet

- Syllabus: Jai Narain Vyas University JodhpurDocument20 pagesSyllabus: Jai Narain Vyas University Jodhpurkushal deoraNo ratings yet

- Allowable StressDocument3 pagesAllowable StressYuliana SyNo ratings yet

- Design Analysis and Fabrication of Hydra PDFDocument9 pagesDesign Analysis and Fabrication of Hydra PDFMac NyandoroNo ratings yet

- Composite Construction in Structural Steel and Concrete - Code of PracticeDocument84 pagesComposite Construction in Structural Steel and Concrete - Code of PracticeRishabhNo ratings yet

- Acicular Ferrite and Bainite in C-MN and Low-Alloy Steel Arc Weld MetalsDocument15 pagesAcicular Ferrite and Bainite in C-MN and Low-Alloy Steel Arc Weld MetalsFervian VersatyNo ratings yet

- AISI 304 Vs 304L Stainless Steel Properties (UNS S30403) Difference Between 304 and 304L (SS304L)Document6 pagesAISI 304 Vs 304L Stainless Steel Properties (UNS S30403) Difference Between 304 and 304L (SS304L)masoodkamalNo ratings yet

- JDM V22Document14 pagesJDM V22X800XLNo ratings yet

- Catalogue Eng PDFDocument20 pagesCatalogue Eng PDFjojoNo ratings yet

- A&F Pump V7 Model Number Creation ChartDocument1 pageA&F Pump V7 Model Number Creation ChartPromagEnviro.comNo ratings yet

- MSE311A - Set 1 Lab ManualDocument16 pagesMSE311A - Set 1 Lab ManualHarshit RastogiNo ratings yet

- Steel and Pipes For Africa Price ListDocument1 pageSteel and Pipes For Africa Price ListLazuardhy Vozika Futur100% (1)

- Ishu ReportDocument24 pagesIshu ReportEnviro ContentNo ratings yet

- WPS 684 CS 012Document3 pagesWPS 684 CS 012siva8000100% (1)

- Reviews On Aluminum Alloy Series and Its Applications: Research PaperDocument9 pagesReviews On Aluminum Alloy Series and Its Applications: Research PaperNidhiNo ratings yet