Professional Documents

Culture Documents

1 Input Data: Profis Anchor 2.5.2

1 Input Data: Profis Anchor 2.5.2

Uploaded by

jasekan.dcCopyright:

Available Formats

You might also like

- CNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingFrom EverandCNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingNo ratings yet

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- PLJ Volume 56 First Quarter - 02 - Remigio E. Agpalo - The Philippines - From Communal To Societal Pangulo RegimeDocument43 pagesPLJ Volume 56 First Quarter - 02 - Remigio E. Agpalo - The Philippines - From Communal To Societal Pangulo Regimeabella_justin100% (2)

- H 200mm Thick Slab - Pa2Document6 pagesH 200mm Thick Slab - Pa2ihpeterNo ratings yet

- 290mm Thick Slab and 540mm EcenDocument6 pages290mm Thick Slab and 540mm EcenihpeterNo ratings yet

- Canopy M16 HIT-RE500Document5 pagesCanopy M16 HIT-RE500marchus09No ratings yet

- 1 Input Data: WWW - HiltiDocument5 pages1 Input Data: WWW - HiltiCibotaru MihaiNo ratings yet

- 6x12 BaseDocument2 pages6x12 Basejmwalker90No ratings yet

- SAMPLE HILTI SolutionDocument6 pagesSAMPLE HILTI SolutionJester AbucayNo ratings yet

- Connection d01 1Document6 pagesConnection d01 1Win ThanNo ratings yet

- Kempinski Hilti Rc-ODocument6 pagesKempinski Hilti Rc-OsobhiNo ratings yet

- 1 Input Data: WWW - Hilti.inDocument5 pages1 Input Data: WWW - Hilti.inpudumaiNo ratings yet

- 1 Input Data: Profis Anchor 2.6.0Document2 pages1 Input Data: Profis Anchor 2.6.0Collin NguNo ratings yet

- Rowad Debugging MachineDocument6 pagesRowad Debugging MachineRonnie De Joya AguirreNo ratings yet

- PROFIS Anchor 2.2.6: WWW - Hilti.inDocument6 pagesPROFIS Anchor 2.2.6: WWW - Hilti.inmeetvinayak2007No ratings yet

- 1 Input Data: Profis Anchor 2.2.4Document6 pages1 Input Data: Profis Anchor 2.2.4Safiueddin A. SafiueddinNo ratings yet

- Hilti AnchorDocument6 pagesHilti AnchorantonioNo ratings yet

- Beam End Connection ReportDocument6 pagesBeam End Connection ReportHibri HalimNo ratings yet

- 250x16 Shs Column Base - Pa2123Document5 pages250x16 Shs Column Base - Pa2123ihpeterNo ratings yet

- 1 Input Data: Profis Anchor 2.6.6Document6 pages1 Input Data: Profis Anchor 2.6.6Collin NguNo ratings yet

- 1 Input Data: WWW - Hilti.co - UkDocument6 pages1 Input Data: WWW - Hilti.co - UkihpeterNo ratings yet

- PROFIS Anchor 2.4.6: WWW - Hilti.luDocument6 pagesPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliNo ratings yet

- PES Hilti M10 HSA Report RunnerDocument4 pagesPES Hilti M10 HSA Report RunnerCollin NguNo ratings yet

- Hilti Bolt DesignDocument7 pagesHilti Bolt Designcheligp1981No ratings yet

- Pipe Rack Hilti Bolt CalculationsDocument6 pagesPipe Rack Hilti Bolt CalculationsAnonymous MAQrYFQDzVNo ratings yet

- PROFIS Anchor 2.4.6: WWW - Hilti.luDocument6 pagesPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliNo ratings yet

- PROFIS Anchor 2.1.4: WWW - Hilti.atDocument5 pagesPROFIS Anchor 2.1.4: WWW - Hilti.atfrog15No ratings yet

- PROFIS Anchor 2.4.6: WWW - Hilti.luDocument6 pagesPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliNo ratings yet

- Shaft B, Hb1 Kempinski 11-1-17.pa2Document7 pagesShaft B, Hb1 Kempinski 11-1-17.pa2sobhiNo ratings yet

- 1 Input Data: Profis Anchor 2.4.6Document6 pages1 Input Data: Profis Anchor 2.4.6Naresh KumarNo ratings yet

- Hilti AnchorDocument5 pagesHilti AnchorGopi KrishnanNo ratings yet

- Hilti Monitor - Pa2Document2 pagesHilti Monitor - Pa2Asaru DeenNo ratings yet

- B3L01 - Detail 1Document7 pagesB3L01 - Detail 1vikramjain66No ratings yet

- PROFIS Anchor 2.0.7Document4 pagesPROFIS Anchor 2.0.7Miky CastenNo ratings yet

- Profis Rebar ReportDocument5 pagesProfis Rebar ReportSowmya MajumderNo ratings yet

- Hilti Monitor - Pa2Document2 pagesHilti Monitor - Pa2Asaru DeenNo ratings yet

- Hilti Connection ReportDocument7 pagesHilti Connection ReportFrancisco BonillaNo ratings yet

- 1 Input Data: WWW - Hilti.co - UkDocument2 pages1 Input Data: WWW - Hilti.co - UkkarlrossmannNo ratings yet

- ReportDocument2 pagesReportpravincs_007No ratings yet

- PROFIS Anchor 2.2.0: WWW - Hilti.deDocument6 pagesPROFIS Anchor 2.2.0: WWW - Hilti.deCollin NguNo ratings yet

- Anchor Bolt PDFDocument7 pagesAnchor Bolt PDFRonnie Albert MonteroNo ratings yet

- HILTI HIT HY200 Injection Adhesive: Quality Management ApprovalsDocument21 pagesHILTI HIT HY200 Injection Adhesive: Quality Management ApprovalsGeorge KaridisNo ratings yet

- Hilti AnchorsDocument58 pagesHilti AnchorsPaulSwinbankNo ratings yet

- PROFIS Anchor 2.0.7: WWW - Hilti.usDocument5 pagesPROFIS Anchor 2.0.7: WWW - Hilti.usadelhelmiNo ratings yet

- 4597 AAB SC 07 Addendum 2 R0v0 78Document1 page4597 AAB SC 07 Addendum 2 R0v0 78danieldumapitNo ratings yet

- 1 Input Data: WWW - Hilti.co - UkDocument3 pages1 Input Data: WWW - Hilti.co - UkshoebNo ratings yet

- 1 Input Data: Profis Anchor 2.8.5Document1 page1 Input Data: Profis Anchor 2.8.5cherian johneyNo ratings yet

- 4597 AAB SC 07 Addendum 2 R0v0 74Document1 page4597 AAB SC 07 Addendum 2 R0v0 74danieldumapitNo ratings yet

- Hilti - Anchor Fastening Technology ManualDocument0 pagesHilti - Anchor Fastening Technology ManualDavid Salomão Pinto Castanho BizarroNo ratings yet

- Check For Anchor Bolt of Cladding Fixation: (Refer Specification Vol. 2 03025 Page 3)Document3 pagesCheck For Anchor Bolt of Cladding Fixation: (Refer Specification Vol. 2 03025 Page 3)ARYANo ratings yet

- Anchor Design - Hilti (HP)Document6 pagesAnchor Design - Hilti (HP)Harikrishnan PNo ratings yet

- Asset Doc Loc 2921271 Apc RawDocument104 pagesAsset Doc Loc 2921271 Apc RawKawser HossainNo ratings yet

- 6951943-83b921-HINO 700 Series 05 OnDocument6 pages6951943-83b921-HINO 700 Series 05 OnYohanor Saputera100% (1)

- Channel at End of SlabDocument10 pagesChannel at End of SlabOecoep IteemNo ratings yet

- Post Drilled Rebar Design Check - Cantilever Beam at Grid 16-k To LDocument20 pagesPost Drilled Rebar Design Check - Cantilever Beam at Grid 16-k To LJereme MulaNo ratings yet

- Fields - Concrete - Jan 8, 2021Document4 pagesFields - Concrete - Jan 8, 2021IlirQosjaNo ratings yet

- Product Technical Guide For HDI Drop-In Anchor Technical Information ASSET DOC LOC 1543428 PDFDocument5 pagesProduct Technical Guide For HDI Drop-In Anchor Technical Information ASSET DOC LOC 1543428 PDFsalgatranNo ratings yet

- Engineering Service Revenues World Summary: Market Values & Financials by CountryFrom EverandEngineering Service Revenues World Summary: Market Values & Financials by CountryNo ratings yet

- Irregularities, Frauds and the Necessity of Technical Auditing in Construction IndustryFrom EverandIrregularities, Frauds and the Necessity of Technical Auditing in Construction IndustryNo ratings yet

- VoIP and Unified Communications: Internet Telephony and the Future Voice NetworkFrom EverandVoIP and Unified Communications: Internet Telephony and the Future Voice NetworkNo ratings yet

- Automated X-Ray Inspection Robot: Enhancing Quality Control Through Computer VisionFrom EverandAutomated X-Ray Inspection Robot: Enhancing Quality Control Through Computer VisionNo ratings yet

- Rectification of Beam Stirrub Rebar.: 149B, Selegie Road, Selegie Court Singapore 188314Document2 pagesRectification of Beam Stirrub Rebar.: 149B, Selegie Road, Selegie Court Singapore 188314jasekan.dcNo ratings yet

- 1 1Document1 page1 1jasekan.dcNo ratings yet

- Please Confirm Transaction Status With MerchantDocument1 pagePlease Confirm Transaction Status With Merchantjasekan.dcNo ratings yet

- Tax PaymentsDocument1 pageTax Paymentsjasekan.dcNo ratings yet

- Dimensions Materials Status: Spreadsheets To Eurocode 2Document1 pageDimensions Materials Status: Spreadsheets To Eurocode 2jasekan.dcNo ratings yet

- Load AlculationsQWDDocument5 pagesLoad AlculationsQWDjasekan.dcNo ratings yet

- Check For Footing: CK CK, CubeDocument1 pageCheck For Footing: CK CK, Cubejasekan.dcNo ratings yet

- 2015-0075 1 5 KH Tann 3/20/2018 Dawson Deep Beam Formworks: 149b Selegie Road Singapore 188314Document6 pages2015-0075 1 5 KH Tann 3/20/2018 Dawson Deep Beam Formworks: 149b Selegie Road Singapore 188314jasekan.dcNo ratings yet

- T Sections's Material PropertiesDocument2 pagesT Sections's Material Propertiesjasekan.dcNo ratings yet

- 1710 TimetableDocument21 pages1710 Timetablejasekan.dcNo ratings yet

- AcknowledgementsDocument4 pagesAcknowledgementsjasekan.dcNo ratings yet

- Notes:: Building and Construction AuthorityDocument1 pageNotes:: Building and Construction Authorityjasekan.dcNo ratings yet

- TCG Civil Transmital 054Document2 pagesTCG Civil Transmital 054jasekan.dcNo ratings yet

- Structure1 REV 2Document7 pagesStructure1 REV 2jasekan.dcNo ratings yet

- MV/OHSPS/ACMV/CO2/001: Ministry of Communications and InformationDocument1 pageMV/OHSPS/ACMV/CO2/001: Ministry of Communications and Informationjasekan.dcNo ratings yet

- Lifting Proposal SuaDocument2 pagesLifting Proposal Suajasekan.dcNo ratings yet

- In OrderDocument1 pageIn Orderjasekan.dcNo ratings yet

- Pe Endorsement For Design of New FCC and Guard House BuildingDocument7 pagesPe Endorsement For Design of New FCC and Guard House Buildingjasekan.dcNo ratings yet

- BLK: 332, # 02-277 Serangoon Avenue 3, Singapore 550332. Phone: +6583697034 Dear Sir / MadamDocument3 pagesBLK: 332, # 02-277 Serangoon Avenue 3, Singapore 550332. Phone: +6583697034 Dear Sir / Madamjasekan.dcNo ratings yet

- Tann Designs & Engineers: Center of Gravity With EquipmentsDocument1 pageTann Designs & Engineers: Center of Gravity With Equipmentsjasekan.dcNo ratings yet

- Standard Certification by The Structural Engineer For Structural Integrity of Block 10 RoofDocument4 pagesStandard Certification by The Structural Engineer For Structural Integrity of Block 10 Roofjasekan.dcNo ratings yet

- Tann Designs & Engineers: Check For Wire RopeDocument1 pageTann Designs & Engineers: Check For Wire Ropejasekan.dcNo ratings yet

- Tokyo Cements, Srilanka: Roller Press House Bill of QuantitiesDocument1 pageTokyo Cements, Srilanka: Roller Press House Bill of Quantitiesjasekan.dcNo ratings yet

- In Re Jeffrey Steinberg, 837 F.2d 527, 1st Cir. (1988)Document7 pagesIn Re Jeffrey Steinberg, 837 F.2d 527, 1st Cir. (1988)Scribd Government DocsNo ratings yet

- Bulger 4th Superseding IndictmentDocument93 pagesBulger 4th Superseding IndictmentWBURNo ratings yet

- Duterte V SB PDFDocument26 pagesDuterte V SB PDFJhanna RamosNo ratings yet

- NRC Information Digest 2018-2019 PDFDocument220 pagesNRC Information Digest 2018-2019 PDFRussell ClarkNo ratings yet

- VICTORY: KVIC Ban Ivory Under PMEGP On Abhishek Kadyan and Sukanya Kadyan ComplaintsDocument7 pagesVICTORY: KVIC Ban Ivory Under PMEGP On Abhishek Kadyan and Sukanya Kadyan ComplaintsAbhishek Kadyan100% (1)

- Facebook v. Power Ventures - Order Denying Motion For Judgment On The PleadingsDocument25 pagesFacebook v. Power Ventures - Order Denying Motion For Judgment On The PleadingsVenkat Balasubramani100% (1)

- BP 22Document8 pagesBP 22Ed CarinoNo ratings yet

- Res#2024-1809 Updated List of Calculators-MergedDocument6 pagesRes#2024-1809 Updated List of Calculators-MergedallasarizamillenNo ratings yet

- Ilovepdf MergedDocument1,351 pagesIlovepdf MergedAnurag HLNo ratings yet

- William Jensen's FilingDocument50 pagesWilliam Jensen's FilingMallory DuncanNo ratings yet

- Civil Procedure Doctrines Roco 2015 1Document462 pagesCivil Procedure Doctrines Roco 2015 1Angel EiliseNo ratings yet

- Introduction To Physical Science 14th Edition Shipman Solutions ManualDocument13 pagesIntroduction To Physical Science 14th Edition Shipman Solutions Manuallaxator.rabotru5i37100% (32)

- Foxx-Brown Child Victim Privacy LettersDocument9 pagesFoxx-Brown Child Victim Privacy LettersChris HackerNo ratings yet

- In The Court of Additional Sessions Judge, Surajpur District Court Complex, Greater Noida, Gautam Budh NagarDocument7 pagesIn The Court of Additional Sessions Judge, Surajpur District Court Complex, Greater Noida, Gautam Budh NagarPatanjali RoyNo ratings yet

- TxIRP Renewal Instruction BookletDocument22 pagesTxIRP Renewal Instruction BookletTeydy RoostNo ratings yet

- Philippine Export and Foreign Loan Guarantee Corporation vs. V.P. Eusebio Construction, Inc.Document26 pagesPhilippine Export and Foreign Loan Guarantee Corporation vs. V.P. Eusebio Construction, Inc.Gab CarasigNo ratings yet

- Chung Fu Vs CA GR No 96283 (1992)Document4 pagesChung Fu Vs CA GR No 96283 (1992)Kimberly SendinNo ratings yet

- Music Law Syllabus (2011)Document4 pagesMusic Law Syllabus (2011)Christopher S. HarrisonNo ratings yet

- Notice Should Include BlacklistingDocument21 pagesNotice Should Include BlacklistingchinturaviNo ratings yet

- Annex A - Secretary's Certificate-Revised-Clean (2011)Document3 pagesAnnex A - Secretary's Certificate-Revised-Clean (2011)alwayskeepthefaith8No ratings yet

- Challenges To The Indigenous Peoples Right Act of 1997"Document3 pagesChallenges To The Indigenous Peoples Right Act of 1997"Kathleen Rose TaninasNo ratings yet

- Stephen PerkinsDocument18 pagesStephen PerkinsKayode CrownNo ratings yet

- Application For DPC For SSC (APOSS)Document3 pagesApplication For DPC For SSC (APOSS)Mrk RamNo ratings yet

- Share Tweet: Chanrobles On-Line Bar ReviewDocument4 pagesShare Tweet: Chanrobles On-Line Bar ReviewPatricia Anne GonzalesNo ratings yet

- ADR Rough Draft (INTERIM RELIEF)Document5 pagesADR Rough Draft (INTERIM RELIEF)Rishabh SinhaNo ratings yet

- People V YabutDocument2 pagesPeople V YabutMark Leo BejeminoNo ratings yet

- AnswerDocument4 pagesAnswerJustin LoredoNo ratings yet

- Warehouse Leasing Agreement - Flash ExpressDocument5 pagesWarehouse Leasing Agreement - Flash ExpressRommel Dela CruzNo ratings yet

- REPORT On AMLA - PreliminariesDocument19 pagesREPORT On AMLA - PreliminariesmonaileNo ratings yet

1 Input Data: Profis Anchor 2.5.2

1 Input Data: Profis Anchor 2.5.2

Uploaded by

jasekan.dcOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 Input Data: Profis Anchor 2.5.2

1 Input Data: Profis Anchor 2.5.2

Uploaded by

jasekan.dcCopyright:

Available Formats

Profis Anchor 2.5.

www.hilti.com.sg

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Fastening Point:

Date:

1

4/8/2016

Specifier's comments:

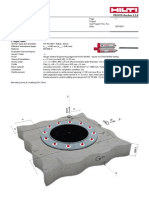

1 Input data

Anchor type and size:

HSA M12 hnom1

Effective embedment depth:

hef = 50 mm, hnom = 64 mm

Material:

Approval No.:

ETA 11/0374

Issued I Valid:

19/7/2012 | 19/7/2017

Proof:

Design method ETAG (No. 001 Annex C/2010)

Stand-off installation:

eb = 0 mm (no stand-off); t = 6 mm

Baseplate:

lx x ly x t = 120 mm x 110 mm x 6 mm; (Recommended plate thickness: not calculated)

Profile:

no profile

Base material:

uncracked concrete, C25/30, fcc = 30.00 N/mm2; h = 150 mm

Reinforcement:

No reinforcement or Reinforcement spacing >= 150 mm (any ) or >= 100 mm ( <= 10 mm)

no longitudinal edge reinforcement

Geometry [mm] & Loading [kN, kNm]

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.5.2

www.hilti.com.sg

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Fastening Point:

Date:

4/8/2016

2 Load case/Resulting anchor forces

Load case: Design loads

Anchor reactions [kN]

Tension force: (+Tension, -Compression)

Tension force

Shear force

Shear force x

Anchor

1

0.968

1.478

1.478

2

0.968

1.478

1.478

max. concrete compressive strain:

- []

max. concrete compressive stress:

- [N/mm2]

resulting tension force in (x/y)=(0/0):

1.936 [kN]

resulting compression force in (x/y)=(0/0): 0.000 [kN]

Shear force y

0.000

0.000

Tension

3 Tension load (ETAG, Annex C, Section 5.2.2)

Load [kN]

0.968

Steel failure*

Pull-out failure*

Concrete cone failure**

Splitting failure**

* most unfavourable anchor

Capacity [kN]

29.571

Utilisation bN [%]

4

Status

OK

N/A

N/A

N/A

N/A

1.936

19.472

10

OK

N/A

N/A

N/A

N/A

**anchor group (anchors in tension)

3.1 Steel failure

NRk,s [kN]

41.400

gM,s

1.400

NRd,s [kN]

29.571

NSd [kN]

0.968

Ac,N [mm2]

33600

A0c,N [mm2]

22500

ccr,N [mm]

75

scr,N [mm]

150

ec1,N [mm]

0

yec1,N

1.000

ec2,N [mm]

0

yec2,N

1.000

N0Rk,c [kN]

19.559

gM,c

1.500

NRd,c [kN]

19.472

NSd [kN]

1.936

3.2 Concrete cone failure

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

ys,N

1.000

yre,N

1.000

k1

10.100

Profis Anchor 2.5.2

www.hilti.com.sg

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Fastening Point:

Date:

4/8/2016

4 Shear load (ETAG, Annex C, Section 5.2.3)

Load [kN]

1.478

Steel failure (without lever arm)*

Steel failure (with lever arm)*

Pryout failure**

Concrete edge failure in direction **

* most unfavourable anchor

Capacity [kN]

23.600

Utilisation bV [%]

7

Status

OK

N/A

N/A

N/A

N/A

2.956

38.943

OK

N/A

N/A

N/A

N/A

**anchor group (relevant anchors)

4.1 Steel failure (without lever arm)

VRk,s [kN]

29.500

gM,s

1.250

VRd,s [kN]

23.600

VSd [kN]

1.478

Ac,N [mm2]

33600

A0c,N [mm2]

22500

ccr,N [mm]

75

scr,N [mm]

150

k-factor

2.000

ec1,V [mm]

0

yec1,N

1.000

ec2,V [mm]

0

yec2,N

1.000

ys,N

1.000

N0Rk,c [kN]

19.559

gM,c,p

1.500

VRd,c1 [kN]

38.943

VSd [kN]

2.956

4.2 Pryout failure

yre,N

1.000

5 Combined tension and shear loads (ETAG, Annex C, Section 5.2.4)

bN

0.099

a

bV

0.076

a

1.500

Utilisation bN,V [%]

6

Status

OK

bN + bV 1

6 Displacements (highest loaded anchor)

Short term loading:

NSk

0.717 [kN]

dN

0.025 [mm]

VSk

1.095 [kN]

dV

0.138 [mm]

dNV

0.140 [mm]

dN

0.059 [mm]

dV

0.210 [mm]

dNV

0.218 [mm]

Long term loading:

NSk

0.717 [kN]

VSk

1.095 [kN]

Comments: Tension displacements are valid with half of the required installation torque moment for uncracked concrete! Shear displacements

are valid without friction between the concrete and the baseplate! The gap due to the drilled hole and clearance hole tolerances are not

included in this calculation!

The acceptable anchor displacements depend on the fastened construction and must be defined by the designer!

7 Warnings

Load re-distributions on the anchors due to elastic deformations of the anchor plate are not considered. The anchor plate is assumed to be

sufficiently stiff, in order not to be deformed when subjected to the loading!

Input data and results must be checked for agreement with the

existing conditions and for plausibility!

Checking the transfer of loads into the base material is required in accordance with ETAG 001, Annex C(2010)Section 7! The software

considers that the grout is installed under the baseplate without creating air voids and before application of the loads.

The design is only valid if the clearance hole in the fixture is not larger than the value given in Table 4.1 of ETAG 001, Annex C! For larger

diameters of the clearance hole see Chapter 1.1. of ETAG 001, Annex C!

The accessory list in this report is for the information of the user only. In any case, the instructions for use provided with the product have to

be followed to ensure a proper installation.

Fastening meets the design criteria!

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.5.2

www.hilti.com.sg

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Fastening Point:

Date:

4/8/2016

8 Installation data

Baseplate, steel: Anchor type and size: HSA M12 hnom1

Profile: no profile; 0 x 0 x 0 mm

Installation torque: 0.050 kNm

Hole diameter in the fixture: df = 14 mm

Hole diameter in the base material: 12 mm

Plate thickness (input): 6 mm

Hole depth in the base material: 72 mm

Recommended plate thickness: not calculated

Minimum thickness of the base material: 100 mm

Cleaning: Manual cleaning of the drilled hole according to instructions for use is required.

8.1 Recommended accessories

Drilling

Suitable Rotary Hammer

Properly sized drill bit

Cleaning

Manual blow-out pump

Coordinates Anchor [mm]

Anchor

1

2

x

-37

37

y

0

0

c-x

-

c+x

-

Setting

Installation torque control bar with suitable

screw driver or torque wrench

Hammer

c-y

-

c+y

-

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.5.2

www.hilti.com.sg

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Fastening Point:

Date:

5

4/8/2016

9 Remarks; Your Cooperation Duties

Any and all information and data contained in the Software concern solely the use of Hilti products and are based on the principles, formulas

and security regulations in accordance with Hilti's technical directions and operating, mounting and assembly instructions, etc., that must be

strictly complied with by the user. All figures contained therein are average figures, and therefore use-specific tests are to be conducted

prior to using the relevant Hilti product. The results of the calculations carried out by means of the Software are based essentially on the

data you put in. Therefore, you bear the sole responsibility for the absence of errors, the completeness and the relevance of the data to be

put in by you. Moreover, you bear sole responsibility for having the results of the calculation checked and cleared by an expert, particularly

with regard to compliance with applicable norms and permits, prior to using them for your specific facility. The Software serves only as an

aid to interpret norms and permits without any guarantee as to the absence of errors, the correctness and the relevance of the results or

suitability for a specific application.

You must take all necessary and reasonable steps to prevent or limit damage caused by the Software. In particular, you must arrange for

the regular backup of programs and data and, if applicable, carry out the updates of the Software offered by Hilti on a regular basis. If you do

not use the AutoUpdate function of the Software, you must ensure that you are using the current and thus up-to-date version of the Software

in each case by carrying out manual updates via the Hilti Website. Hilti will not be liable for consequences, such as the recovery of lost or

damaged data or programs, arising from a culpable breach of duty by you.

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

You might also like

- CNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingFrom EverandCNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingNo ratings yet

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- PLJ Volume 56 First Quarter - 02 - Remigio E. Agpalo - The Philippines - From Communal To Societal Pangulo RegimeDocument43 pagesPLJ Volume 56 First Quarter - 02 - Remigio E. Agpalo - The Philippines - From Communal To Societal Pangulo Regimeabella_justin100% (2)

- H 200mm Thick Slab - Pa2Document6 pagesH 200mm Thick Slab - Pa2ihpeterNo ratings yet

- 290mm Thick Slab and 540mm EcenDocument6 pages290mm Thick Slab and 540mm EcenihpeterNo ratings yet

- Canopy M16 HIT-RE500Document5 pagesCanopy M16 HIT-RE500marchus09No ratings yet

- 1 Input Data: WWW - HiltiDocument5 pages1 Input Data: WWW - HiltiCibotaru MihaiNo ratings yet

- 6x12 BaseDocument2 pages6x12 Basejmwalker90No ratings yet

- SAMPLE HILTI SolutionDocument6 pagesSAMPLE HILTI SolutionJester AbucayNo ratings yet

- Connection d01 1Document6 pagesConnection d01 1Win ThanNo ratings yet

- Kempinski Hilti Rc-ODocument6 pagesKempinski Hilti Rc-OsobhiNo ratings yet

- 1 Input Data: WWW - Hilti.inDocument5 pages1 Input Data: WWW - Hilti.inpudumaiNo ratings yet

- 1 Input Data: Profis Anchor 2.6.0Document2 pages1 Input Data: Profis Anchor 2.6.0Collin NguNo ratings yet

- Rowad Debugging MachineDocument6 pagesRowad Debugging MachineRonnie De Joya AguirreNo ratings yet

- PROFIS Anchor 2.2.6: WWW - Hilti.inDocument6 pagesPROFIS Anchor 2.2.6: WWW - Hilti.inmeetvinayak2007No ratings yet

- 1 Input Data: Profis Anchor 2.2.4Document6 pages1 Input Data: Profis Anchor 2.2.4Safiueddin A. SafiueddinNo ratings yet

- Hilti AnchorDocument6 pagesHilti AnchorantonioNo ratings yet

- Beam End Connection ReportDocument6 pagesBeam End Connection ReportHibri HalimNo ratings yet

- 250x16 Shs Column Base - Pa2123Document5 pages250x16 Shs Column Base - Pa2123ihpeterNo ratings yet

- 1 Input Data: Profis Anchor 2.6.6Document6 pages1 Input Data: Profis Anchor 2.6.6Collin NguNo ratings yet

- 1 Input Data: WWW - Hilti.co - UkDocument6 pages1 Input Data: WWW - Hilti.co - UkihpeterNo ratings yet

- PROFIS Anchor 2.4.6: WWW - Hilti.luDocument6 pagesPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliNo ratings yet

- PES Hilti M10 HSA Report RunnerDocument4 pagesPES Hilti M10 HSA Report RunnerCollin NguNo ratings yet

- Hilti Bolt DesignDocument7 pagesHilti Bolt Designcheligp1981No ratings yet

- Pipe Rack Hilti Bolt CalculationsDocument6 pagesPipe Rack Hilti Bolt CalculationsAnonymous MAQrYFQDzVNo ratings yet

- PROFIS Anchor 2.4.6: WWW - Hilti.luDocument6 pagesPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliNo ratings yet

- PROFIS Anchor 2.1.4: WWW - Hilti.atDocument5 pagesPROFIS Anchor 2.1.4: WWW - Hilti.atfrog15No ratings yet

- PROFIS Anchor 2.4.6: WWW - Hilti.luDocument6 pagesPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliNo ratings yet

- Shaft B, Hb1 Kempinski 11-1-17.pa2Document7 pagesShaft B, Hb1 Kempinski 11-1-17.pa2sobhiNo ratings yet

- 1 Input Data: Profis Anchor 2.4.6Document6 pages1 Input Data: Profis Anchor 2.4.6Naresh KumarNo ratings yet

- Hilti AnchorDocument5 pagesHilti AnchorGopi KrishnanNo ratings yet

- Hilti Monitor - Pa2Document2 pagesHilti Monitor - Pa2Asaru DeenNo ratings yet

- B3L01 - Detail 1Document7 pagesB3L01 - Detail 1vikramjain66No ratings yet

- PROFIS Anchor 2.0.7Document4 pagesPROFIS Anchor 2.0.7Miky CastenNo ratings yet

- Profis Rebar ReportDocument5 pagesProfis Rebar ReportSowmya MajumderNo ratings yet

- Hilti Monitor - Pa2Document2 pagesHilti Monitor - Pa2Asaru DeenNo ratings yet

- Hilti Connection ReportDocument7 pagesHilti Connection ReportFrancisco BonillaNo ratings yet

- 1 Input Data: WWW - Hilti.co - UkDocument2 pages1 Input Data: WWW - Hilti.co - UkkarlrossmannNo ratings yet

- ReportDocument2 pagesReportpravincs_007No ratings yet

- PROFIS Anchor 2.2.0: WWW - Hilti.deDocument6 pagesPROFIS Anchor 2.2.0: WWW - Hilti.deCollin NguNo ratings yet

- Anchor Bolt PDFDocument7 pagesAnchor Bolt PDFRonnie Albert MonteroNo ratings yet

- HILTI HIT HY200 Injection Adhesive: Quality Management ApprovalsDocument21 pagesHILTI HIT HY200 Injection Adhesive: Quality Management ApprovalsGeorge KaridisNo ratings yet

- Hilti AnchorsDocument58 pagesHilti AnchorsPaulSwinbankNo ratings yet

- PROFIS Anchor 2.0.7: WWW - Hilti.usDocument5 pagesPROFIS Anchor 2.0.7: WWW - Hilti.usadelhelmiNo ratings yet

- 4597 AAB SC 07 Addendum 2 R0v0 78Document1 page4597 AAB SC 07 Addendum 2 R0v0 78danieldumapitNo ratings yet

- 1 Input Data: WWW - Hilti.co - UkDocument3 pages1 Input Data: WWW - Hilti.co - UkshoebNo ratings yet

- 1 Input Data: Profis Anchor 2.8.5Document1 page1 Input Data: Profis Anchor 2.8.5cherian johneyNo ratings yet

- 4597 AAB SC 07 Addendum 2 R0v0 74Document1 page4597 AAB SC 07 Addendum 2 R0v0 74danieldumapitNo ratings yet

- Hilti - Anchor Fastening Technology ManualDocument0 pagesHilti - Anchor Fastening Technology ManualDavid Salomão Pinto Castanho BizarroNo ratings yet

- Check For Anchor Bolt of Cladding Fixation: (Refer Specification Vol. 2 03025 Page 3)Document3 pagesCheck For Anchor Bolt of Cladding Fixation: (Refer Specification Vol. 2 03025 Page 3)ARYANo ratings yet

- Anchor Design - Hilti (HP)Document6 pagesAnchor Design - Hilti (HP)Harikrishnan PNo ratings yet

- Asset Doc Loc 2921271 Apc RawDocument104 pagesAsset Doc Loc 2921271 Apc RawKawser HossainNo ratings yet

- 6951943-83b921-HINO 700 Series 05 OnDocument6 pages6951943-83b921-HINO 700 Series 05 OnYohanor Saputera100% (1)

- Channel at End of SlabDocument10 pagesChannel at End of SlabOecoep IteemNo ratings yet

- Post Drilled Rebar Design Check - Cantilever Beam at Grid 16-k To LDocument20 pagesPost Drilled Rebar Design Check - Cantilever Beam at Grid 16-k To LJereme MulaNo ratings yet

- Fields - Concrete - Jan 8, 2021Document4 pagesFields - Concrete - Jan 8, 2021IlirQosjaNo ratings yet

- Product Technical Guide For HDI Drop-In Anchor Technical Information ASSET DOC LOC 1543428 PDFDocument5 pagesProduct Technical Guide For HDI Drop-In Anchor Technical Information ASSET DOC LOC 1543428 PDFsalgatranNo ratings yet

- Engineering Service Revenues World Summary: Market Values & Financials by CountryFrom EverandEngineering Service Revenues World Summary: Market Values & Financials by CountryNo ratings yet

- Irregularities, Frauds and the Necessity of Technical Auditing in Construction IndustryFrom EverandIrregularities, Frauds and the Necessity of Technical Auditing in Construction IndustryNo ratings yet

- VoIP and Unified Communications: Internet Telephony and the Future Voice NetworkFrom EverandVoIP and Unified Communications: Internet Telephony and the Future Voice NetworkNo ratings yet

- Automated X-Ray Inspection Robot: Enhancing Quality Control Through Computer VisionFrom EverandAutomated X-Ray Inspection Robot: Enhancing Quality Control Through Computer VisionNo ratings yet

- Rectification of Beam Stirrub Rebar.: 149B, Selegie Road, Selegie Court Singapore 188314Document2 pagesRectification of Beam Stirrub Rebar.: 149B, Selegie Road, Selegie Court Singapore 188314jasekan.dcNo ratings yet

- 1 1Document1 page1 1jasekan.dcNo ratings yet

- Please Confirm Transaction Status With MerchantDocument1 pagePlease Confirm Transaction Status With Merchantjasekan.dcNo ratings yet

- Tax PaymentsDocument1 pageTax Paymentsjasekan.dcNo ratings yet

- Dimensions Materials Status: Spreadsheets To Eurocode 2Document1 pageDimensions Materials Status: Spreadsheets To Eurocode 2jasekan.dcNo ratings yet

- Load AlculationsQWDDocument5 pagesLoad AlculationsQWDjasekan.dcNo ratings yet

- Check For Footing: CK CK, CubeDocument1 pageCheck For Footing: CK CK, Cubejasekan.dcNo ratings yet

- 2015-0075 1 5 KH Tann 3/20/2018 Dawson Deep Beam Formworks: 149b Selegie Road Singapore 188314Document6 pages2015-0075 1 5 KH Tann 3/20/2018 Dawson Deep Beam Formworks: 149b Selegie Road Singapore 188314jasekan.dcNo ratings yet

- T Sections's Material PropertiesDocument2 pagesT Sections's Material Propertiesjasekan.dcNo ratings yet

- 1710 TimetableDocument21 pages1710 Timetablejasekan.dcNo ratings yet

- AcknowledgementsDocument4 pagesAcknowledgementsjasekan.dcNo ratings yet

- Notes:: Building and Construction AuthorityDocument1 pageNotes:: Building and Construction Authorityjasekan.dcNo ratings yet

- TCG Civil Transmital 054Document2 pagesTCG Civil Transmital 054jasekan.dcNo ratings yet

- Structure1 REV 2Document7 pagesStructure1 REV 2jasekan.dcNo ratings yet

- MV/OHSPS/ACMV/CO2/001: Ministry of Communications and InformationDocument1 pageMV/OHSPS/ACMV/CO2/001: Ministry of Communications and Informationjasekan.dcNo ratings yet

- Lifting Proposal SuaDocument2 pagesLifting Proposal Suajasekan.dcNo ratings yet

- In OrderDocument1 pageIn Orderjasekan.dcNo ratings yet

- Pe Endorsement For Design of New FCC and Guard House BuildingDocument7 pagesPe Endorsement For Design of New FCC and Guard House Buildingjasekan.dcNo ratings yet

- BLK: 332, # 02-277 Serangoon Avenue 3, Singapore 550332. Phone: +6583697034 Dear Sir / MadamDocument3 pagesBLK: 332, # 02-277 Serangoon Avenue 3, Singapore 550332. Phone: +6583697034 Dear Sir / Madamjasekan.dcNo ratings yet

- Tann Designs & Engineers: Center of Gravity With EquipmentsDocument1 pageTann Designs & Engineers: Center of Gravity With Equipmentsjasekan.dcNo ratings yet

- Standard Certification by The Structural Engineer For Structural Integrity of Block 10 RoofDocument4 pagesStandard Certification by The Structural Engineer For Structural Integrity of Block 10 Roofjasekan.dcNo ratings yet

- Tann Designs & Engineers: Check For Wire RopeDocument1 pageTann Designs & Engineers: Check For Wire Ropejasekan.dcNo ratings yet

- Tokyo Cements, Srilanka: Roller Press House Bill of QuantitiesDocument1 pageTokyo Cements, Srilanka: Roller Press House Bill of Quantitiesjasekan.dcNo ratings yet

- In Re Jeffrey Steinberg, 837 F.2d 527, 1st Cir. (1988)Document7 pagesIn Re Jeffrey Steinberg, 837 F.2d 527, 1st Cir. (1988)Scribd Government DocsNo ratings yet

- Bulger 4th Superseding IndictmentDocument93 pagesBulger 4th Superseding IndictmentWBURNo ratings yet

- Duterte V SB PDFDocument26 pagesDuterte V SB PDFJhanna RamosNo ratings yet

- NRC Information Digest 2018-2019 PDFDocument220 pagesNRC Information Digest 2018-2019 PDFRussell ClarkNo ratings yet

- VICTORY: KVIC Ban Ivory Under PMEGP On Abhishek Kadyan and Sukanya Kadyan ComplaintsDocument7 pagesVICTORY: KVIC Ban Ivory Under PMEGP On Abhishek Kadyan and Sukanya Kadyan ComplaintsAbhishek Kadyan100% (1)

- Facebook v. Power Ventures - Order Denying Motion For Judgment On The PleadingsDocument25 pagesFacebook v. Power Ventures - Order Denying Motion For Judgment On The PleadingsVenkat Balasubramani100% (1)

- BP 22Document8 pagesBP 22Ed CarinoNo ratings yet

- Res#2024-1809 Updated List of Calculators-MergedDocument6 pagesRes#2024-1809 Updated List of Calculators-MergedallasarizamillenNo ratings yet

- Ilovepdf MergedDocument1,351 pagesIlovepdf MergedAnurag HLNo ratings yet

- William Jensen's FilingDocument50 pagesWilliam Jensen's FilingMallory DuncanNo ratings yet

- Civil Procedure Doctrines Roco 2015 1Document462 pagesCivil Procedure Doctrines Roco 2015 1Angel EiliseNo ratings yet

- Introduction To Physical Science 14th Edition Shipman Solutions ManualDocument13 pagesIntroduction To Physical Science 14th Edition Shipman Solutions Manuallaxator.rabotru5i37100% (32)

- Foxx-Brown Child Victim Privacy LettersDocument9 pagesFoxx-Brown Child Victim Privacy LettersChris HackerNo ratings yet

- In The Court of Additional Sessions Judge, Surajpur District Court Complex, Greater Noida, Gautam Budh NagarDocument7 pagesIn The Court of Additional Sessions Judge, Surajpur District Court Complex, Greater Noida, Gautam Budh NagarPatanjali RoyNo ratings yet

- TxIRP Renewal Instruction BookletDocument22 pagesTxIRP Renewal Instruction BookletTeydy RoostNo ratings yet

- Philippine Export and Foreign Loan Guarantee Corporation vs. V.P. Eusebio Construction, Inc.Document26 pagesPhilippine Export and Foreign Loan Guarantee Corporation vs. V.P. Eusebio Construction, Inc.Gab CarasigNo ratings yet

- Chung Fu Vs CA GR No 96283 (1992)Document4 pagesChung Fu Vs CA GR No 96283 (1992)Kimberly SendinNo ratings yet

- Music Law Syllabus (2011)Document4 pagesMusic Law Syllabus (2011)Christopher S. HarrisonNo ratings yet

- Notice Should Include BlacklistingDocument21 pagesNotice Should Include BlacklistingchinturaviNo ratings yet

- Annex A - Secretary's Certificate-Revised-Clean (2011)Document3 pagesAnnex A - Secretary's Certificate-Revised-Clean (2011)alwayskeepthefaith8No ratings yet

- Challenges To The Indigenous Peoples Right Act of 1997"Document3 pagesChallenges To The Indigenous Peoples Right Act of 1997"Kathleen Rose TaninasNo ratings yet

- Stephen PerkinsDocument18 pagesStephen PerkinsKayode CrownNo ratings yet

- Application For DPC For SSC (APOSS)Document3 pagesApplication For DPC For SSC (APOSS)Mrk RamNo ratings yet

- Share Tweet: Chanrobles On-Line Bar ReviewDocument4 pagesShare Tweet: Chanrobles On-Line Bar ReviewPatricia Anne GonzalesNo ratings yet

- ADR Rough Draft (INTERIM RELIEF)Document5 pagesADR Rough Draft (INTERIM RELIEF)Rishabh SinhaNo ratings yet

- People V YabutDocument2 pagesPeople V YabutMark Leo BejeminoNo ratings yet

- AnswerDocument4 pagesAnswerJustin LoredoNo ratings yet

- Warehouse Leasing Agreement - Flash ExpressDocument5 pagesWarehouse Leasing Agreement - Flash ExpressRommel Dela CruzNo ratings yet

- REPORT On AMLA - PreliminariesDocument19 pagesREPORT On AMLA - PreliminariesmonaileNo ratings yet