Professional Documents

Culture Documents

Shes Field Service - Job Safety Analysis

Shes Field Service - Job Safety Analysis

Uploaded by

east0 ratings0% found this document useful (0 votes)

23 views2 pagesThis document provides a job safety analysis for field re-tubing. It outlines the required personal protective equipment, sequence of job steps, potential accidents/hazards for each step, and recommended safe procedures. Some of the key safety risks include exposure to industrial and plant hazards, collisions with equipment, falls, fires, explosions, and chemical or sharp object injuries. The analysis recommends precautions like receiving safety training, using spotters, proper lifting techniques, maintaining barricades, and following shutdown procedures.

Original Description:

zb

Original Title

ZB- fieldjsaretube

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides a job safety analysis for field re-tubing. It outlines the required personal protective equipment, sequence of job steps, potential accidents/hazards for each step, and recommended safe procedures. Some of the key safety risks include exposure to industrial and plant hazards, collisions with equipment, falls, fires, explosions, and chemical or sharp object injuries. The analysis recommends precautions like receiving safety training, using spotters, proper lifting techniques, maintaining barricades, and following shutdown procedures.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

23 views2 pagesShes Field Service - Job Safety Analysis

Shes Field Service - Job Safety Analysis

Uploaded by

eastThis document provides a job safety analysis for field re-tubing. It outlines the required personal protective equipment, sequence of job steps, potential accidents/hazards for each step, and recommended safe procedures. Some of the key safety risks include exposure to industrial and plant hazards, collisions with equipment, falls, fires, explosions, and chemical or sharp object injuries. The analysis recommends precautions like receiving safety training, using spotters, proper lifting techniques, maintaining barricades, and following shutdown procedures.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

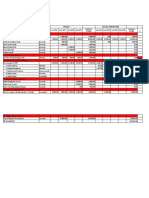

SHES FIELD SERVICE - JOB SAFETY ANALYSIS

TYPE OF JOB--FIELD RE-TUBING

REQUIRED PERSONAL PROTECTIVE EQUIPMENT

STEEL TOE BOOTS, LEATHER GLOVES, LONG SLEEVES, SAFETY GLASSES, HEARING

PROTECTION, FACE SHIELD FOR GRINDING

SEQUENCE OF JOB STEPS

POTENTIAL ACCIDENTS OR HAZARDS

RECOMMENDED SAFE JOB PROCEDURE

1. Recognition of Plant Hazards

1.1 Unauthorized Personnel

Performing Job Task.

2. Entry into Plant

2.1 Exposure to heavy industrial hazards

2.2 Exposure to specific Plant Hazards

3. Spot Equipment

3.1 Possible Collision with Plant

Equipment or Vehicles

3.2 Possible Machine Damage

1.1.1 Employee Must Have Received Plant

Safety Orientation.

1.1.2 Employee Should Receive HASC Training

2.1.1 Wear Proper PPE (See list above)

2.2.1 Use additional PPE Specified by Plant

2.2.1.A Nomex Coveralls

2.2.2.B Cartridge Respirator

2.2.3 Observe & Note Plant Safety Equipment

2.2.3.A Alarms

2.2.3.B Wind Direction Indicators

2.2.3.C Evacuation Routes

2.2.3.D Warning Signs

2.2.3.E Safety Showers

2.2.3.F Fire Extinguishers

2.2.3.G Escape Air Packs

3.1.1 Use Spotter

4. Pre-Job Survey

4.1 Exposure to Hazardous Material

4.2 Elevated Work May Require Scaffold

4.3 Poor Footing

4.4 Combustible Material

4.5 Laceration Due to Sharp Objects

3.2.1 Secure Machines Properly to Lifing Equipment

or Fixed Structure

3.2.2 Insure Machines are not Stored in Personel

or Vehicle Traffic Pattern

4.1.1 Review MSDS Sheet

4.1.2 Wear Proper PPE

4.1.3 Locate Safety Showers

4.2.1 Examine Scaffolding for Completeness,

Sturdiness, and Safety Harness

4.2.2 Insure Scaffolding is large enough for job

4.3.1 Insure Level, Slip Free Surface

4.4.1 Relocate Combustible Materials

where possible

4.4.2 Use Fire Blanket to Shield Materials

which cannot be relocated

4.4.3 Keep a Fresh Fire Extinguisher in

the Work Area

4.5.1 Wear Proper PPE

4.5.2 Flag Danger Areas

5. Set Up Machines

5.1 Machines May Swing or Drop

Causing Injury

5.2 Hazard from Air Lines

6. Secure Work Area

6.1 Unauthorized personnel in area

7. Start Re-tubing

7.1 Injury to Hands

7.2 Eye injury from cutting tubes

7.3 Lacerations

7.4 Back Injuries

7.5 Explosions

7.6 Chemical Burns

8. Secure Equipment for

Move Out

8.1 Same hazards as steps 2-6

5.1.1 Insure Proper Lifting Techniques are used to

Position Machines

5.2.1 Keep hoses out of heavy traveled areas

5.2.2 Provide boards to prevent hose damage

when hoses are on ground

5.2.3 Insure all connections are in good shape

5.2.4 Insure all connections are tight

5.2.5 Insure hoses are in good shape

5.2.6 Insure hoses are not over pressurized

6.1.1 Barricade area with danger tape

6.1.2 Do not begin with unauthorized personnel

6.1.1 Barricade area with danger tape

6.1.2 Do not begin with unauthorized personnel

in work area

6.2.2 Shut down if unauthoized personnel

enter barricaded area

7.1.1 Insure all fingers and hands are away from

clear of pinch points of Hydraulic Pullers

7.1.2 Maintain firm grip on tube roll motors to

prevent torque from twisting wrist

7.2.1 Wear face shield and goggles

7.2.2 Insure proper guards are in place on grinder

7.3.1 Insure no loose clothing during machining

7.3.2 Wear proper PPE

7.3.3 Be alert to sharp edges caused at tube cut off

7.4.1 Use team work and proper techniques when

pulling and handling loose tubing

7.5.1 Insure the object being cut on is not under

pressure

7.6.1 Insure the exchanger was properly cleaned

and no residual hazardous chemicals are

present when tubes are pulled

8.1.1 Follow proper procedures for shutdown of

machines, equipment and tools

You might also like

- Health and Safety Improvement PlanDocument3 pagesHealth and Safety Improvement Planeast67% (3)

- Emma CrocheDocument22 pagesEmma CrocheMarta Luzia Silva Bezerra100% (11)

- JHA Pneumatic Test Using N2Document4 pagesJHA Pneumatic Test Using N2Luqman Osman90% (10)

- JSA For Demobilization WorksDocument2 pagesJSA For Demobilization WorksIanne Dee85% (13)

- Making Medieval Cut HosenDocument7 pagesMaking Medieval Cut Hosensarahmichelef100% (7)

- Basf Jsa SaferadDocument3 pagesBasf Jsa SaferadExsan OthmanNo ratings yet

- JSA For Soil ImprovementDocument4 pagesJSA For Soil ImprovementHilbrecht De Pedro100% (1)

- Manual Book Mesin HDPE SHD 315 PDFDocument22 pagesManual Book Mesin HDPE SHD 315 PDFYuwantoniAl100% (1)

- 04 Jsa For Camp Constn & Associated FacilitysDocument5 pages04 Jsa For Camp Constn & Associated FacilitysHilbrecht De Pedro100% (1)

- Chilled Water Pipe Installation - ACMVDocument4 pagesChilled Water Pipe Installation - ACMVbinhjuki100% (2)

- BASF - Job Vacancy Ad - EHS OfficerDocument1 pageBASF - Job Vacancy Ad - EHS OfficereastNo ratings yet

- GBP Casing and Liner RunningDocument31 pagesGBP Casing and Liner Runninghamora33100% (1)

- Painting 15mm German TutorialDocument3 pagesPainting 15mm German Tutorialapi-117718285No ratings yet

- Crushing HandbookDocument43 pagesCrushing Handbooksunny100% (3)

- Shes Field Service - Job Safety AnalysisDocument2 pagesShes Field Service - Job Safety AnalysisNaz ッ WanyNo ratings yet

- Jha Lin FillingDocument6 pagesJha Lin FillingLuqman OsmanNo ratings yet

- Welding, Grinding, Oxy-Cutting JSA-007 PDFDocument6 pagesWelding, Grinding, Oxy-Cutting JSA-007 PDFNazmi DhiyauddinNo ratings yet

- SOP-15-Installation and Disassembly of BOP Hydraulic Control LineDocument6 pagesSOP-15-Installation and Disassembly of BOP Hydraulic Control LineDQE040 HSSENo ratings yet

- 06 Earthworks, Blinding, Screeding, Water Proofing, Form Work, Reinforcement, Concreting and Cur2Document6 pages06 Earthworks, Blinding, Screeding, Water Proofing, Form Work, Reinforcement, Concreting and Cur2Hilbrecht De PedroNo ratings yet

- Octopus Jsa For Fusion WeldingDocument2 pagesOctopus Jsa For Fusion WeldingOgunwa EmmanuelNo ratings yet

- BACKFILLINGDocument2 pagesBACKFILLINGKeith ManansalaNo ratings yet

- Installation, Operation Manual: BJW2500 Reagent Agitation TankDocument26 pagesInstallation, Operation Manual: BJW2500 Reagent Agitation Tank翟庆祥No ratings yet

- Risk Assesment-Construction SiteDocument21 pagesRisk Assesment-Construction SiteShijad Pa100% (2)

- JSA Shut Down and Tie in Work PDFDocument6 pagesJSA Shut Down and Tie in Work PDFpjosesm80% (5)

- SWP - Plastering Work (Yuanju)Document3 pagesSWP - Plastering Work (Yuanju)কাজি আরিফNo ratings yet

- 07 JSA For Concreting at Outfall AreaDocument4 pages07 JSA For Concreting at Outfall AreaHilbrecht De PedroNo ratings yet

- Notes Safety For WorkshopsDocument11 pagesNotes Safety For Workshopschileshelombe0No ratings yet

- 5X5 Matrix RA For Installation Fo CHC-2A Conveyor SystemDocument16 pages5X5 Matrix RA For Installation Fo CHC-2A Conveyor SystemSandeep Jain100% (2)

- Risk Assessment - Plaster WorksDocument3 pagesRisk Assessment - Plaster WorksMahdi DwaikatNo ratings yet

- Operating Instructions Safety Valve For Industrial ApplicationsDocument16 pagesOperating Instructions Safety Valve For Industrial ApplicationsJim JonesjrNo ratings yet

- Hyundai HY10000LEK 2 DatasheetDocument28 pagesHyundai HY10000LEK 2 Datasheetcharlesbenwari100% (1)

- SJPS120×2 - 1 Double-Screw Extruder: Operation ManualDocument31 pagesSJPS120×2 - 1 Double-Screw Extruder: Operation ManualSheraz Ashfaq100% (1)

- SOP-12-Installation and Disconnection of Live Head of Drilliing LineDocument6 pagesSOP-12-Installation and Disconnection of Live Head of Drilliing LineDQE040 HSSENo ratings yet

- Quality Assurance Management: Quality Control Inspection Safety ProceduresDocument5 pagesQuality Assurance Management: Quality Control Inspection Safety ProceduresclintonNo ratings yet

- Manual de Operacion Eq TermofusionDocument50 pagesManual de Operacion Eq Termofusioncesar diaz plasenciaNo ratings yet

- Job Safety AnalysisDocument5 pagesJob Safety AnalysisMuhammad Zarif Amir100% (2)

- Hispano InductionDocument106 pagesHispano InductionAsif ALiNo ratings yet

- METHOD STATEMENT (Traffic Epoxy Waterproofing)Document7 pagesMETHOD STATEMENT (Traffic Epoxy Waterproofing)Michael TugawenNo ratings yet

- Job Security Analysis Job DataDocument2 pagesJob Security Analysis Job DataJeffrey Sanchez RojasNo ratings yet

- Safety - Paints & Coatings-2Document3 pagesSafety - Paints & Coatings-2Just singingNo ratings yet

- Operation Inst MachineDocument22 pagesOperation Inst MachineSachin SampatNo ratings yet

- Blast Gun With Gravity Feed: Item 95793Document12 pagesBlast Gun With Gravity Feed: Item 95793Alejandro LunaNo ratings yet

- Manual A F AR FR ARD FRD05-22 EN DE RU v1 3 0Document120 pagesManual A F AR FR ARD FRD05-22 EN DE RU v1 3 0sergiokengsousaNo ratings yet

- WHD250 Worldpoly Operation ManualDocument34 pagesWHD250 Worldpoly Operation ManualalejandroNo ratings yet

- 09 JSA For Excavation and Blinding at Pump House 1 & 3Document4 pages09 JSA For Excavation and Blinding at Pump House 1 & 3Hilbrecht De Pedro100% (1)

- SWP - Tiling Work ( (Yuanju)Document4 pagesSWP - Tiling Work ( (Yuanju)কাজি আরিফNo ratings yet

- Workshop Safety: Yusron Sugiarto, STP, MP, MSCDocument40 pagesWorkshop Safety: Yusron Sugiarto, STP, MP, MSCChhetin SherpaNo ratings yet

- Sop Angle GrinderDocument3 pagesSop Angle GrinderKyaw Kyaw Aung50% (2)

- JSA FormDocument6 pagesJSA FormAjeesh CochinNo ratings yet

- Manual FD en de Ru v2 0Document36 pagesManual FD en de Ru v2 0sergiokengsousaNo ratings yet

- Jla 22 Pressure HydrotestDocument3 pagesJla 22 Pressure HydrotestHaziq BahruddinNo ratings yet

- Safety Training Hydrojetting of Exchangers GeneralDocument15 pagesSafety Training Hydrojetting of Exchangers GeneralandinumailNo ratings yet

- MS For Grounding and Cadwelding WorkDocument34 pagesMS For Grounding and Cadwelding WorkGanga Daran100% (2)

- N64 Service Instruction-ENDocument36 pagesN64 Service Instruction-ENJunior SilvaNo ratings yet

- SHD 250Document18 pagesSHD 250api-233322200100% (1)

- Method Statement For Ground Floor SlabDocument2 pagesMethod Statement For Ground Floor Slabadeniyi abiolaNo ratings yet

- HCCP Jsa Wo5992032Document2 pagesHCCP Jsa Wo5992032Forida EasminNo ratings yet

- 5-Star Safety and Health Management SystemDocument5 pages5-Star Safety and Health Management SystemSn Ahsan100% (1)

- UOW - Lecture 1-Safety in WorkshopDocument5 pagesUOW - Lecture 1-Safety in WorkshopVinnoth SrikumarNo ratings yet

- 32 - Safe WorkDocument18 pages32 - Safe WorkP Eng Suraj SinghNo ratings yet

- VHS30-03B - Valvula de Segurança Manual Serie Vhs-A-B - SMCDocument16 pagesVHS30-03B - Valvula de Segurança Manual Serie Vhs-A-B - SMCRafael EspositoNo ratings yet

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Virtual Reality, Artificial Intelligence and Specialized Logistics in HealthcareFrom EverandVirtual Reality, Artificial Intelligence and Specialized Logistics in HealthcareNo ratings yet

- Workplace Vocabulary for Esl Students: With Exercises and TestsFrom EverandWorkplace Vocabulary for Esl Students: With Exercises and TestsNo ratings yet

- Professional Rope Access: A Guide To Working Safely at HeightFrom EverandProfessional Rope Access: A Guide To Working Safely at HeightNo ratings yet

- Global Harmonization System - The Pictogram: What Are Pictograms?Document2 pagesGlobal Harmonization System - The Pictogram: What Are Pictograms?eastNo ratings yet

- Water Conservation February 2012: Environmental Training Training Month DateDocument1 pageWater Conservation February 2012: Environmental Training Training Month DateeastNo ratings yet

- April: Why Safety Belts?Document1 pageApril: Why Safety Belts?eastNo ratings yet

- JHA PaintingDocument12 pagesJHA Paintingeast100% (1)

- What Are The Labeling Requirements?: Global Harmonization System - LabelingDocument2 pagesWhat Are The Labeling Requirements?: Global Harmonization System - LabelingeastNo ratings yet

- 01backing CircleofSafetyDocument2 pages01backing CircleofSafetyeastNo ratings yet

- Team Building PDFDocument91 pagesTeam Building PDFeastNo ratings yet

- Ultra-High Pressure Water Jet: Baseline Report: Weces VedDocument38 pagesUltra-High Pressure Water Jet: Baseline Report: Weces VedeastNo ratings yet

- State Hazcom TestDocument2 pagesState Hazcom TesteastNo ratings yet

- PPE Hazard Assessment Certification Form: (Use A Separate Sheet For Each Job/task or Work Area)Document3 pagesPPE Hazard Assessment Certification Form: (Use A Separate Sheet For Each Job/task or Work Area)eastNo ratings yet

- Fall Restraint, Fall Arrest and The Hierarchy of Fall ProtectionDocument1 pageFall Restraint, Fall Arrest and The Hierarchy of Fall ProtectioneastNo ratings yet

- Crowcon Detective Transportable Gas MonitorDocument5 pagesCrowcon Detective Transportable Gas MonitoreastNo ratings yet

- 06 Hot Work PermitDocument1 page06 Hot Work PermiteastNo ratings yet

- Hazard Identification, Risk Assessment and Controls (HIRAC) LogDocument5 pagesHazard Identification, Risk Assessment and Controls (HIRAC) LogeastNo ratings yet

- Getting Approval To Deliver Managing Safely v5Document6 pagesGetting Approval To Deliver Managing Safely v5eastNo ratings yet

- Safe Management of Health Care WasteDocument20 pagesSafe Management of Health Care WasteeastNo ratings yet

- Director Leadership: Directors and Board Members Have The Key RoleDocument5 pagesDirector Leadership: Directors and Board Members Have The Key RoleeastNo ratings yet

- Keep Your Cool in Hot WeatherDocument3 pagesKeep Your Cool in Hot WeathereastNo ratings yet

- 802 Operator ManualDocument52 pages802 Operator ManualeastNo ratings yet

- Aggressive DrivingDocument8 pagesAggressive DrivingeastNo ratings yet

- DRIVER's HandbookDocument37 pagesDRIVER's HandbookeastNo ratings yet

- ContiTech RubberTrack Manual WarrantyGuide enDocument61 pagesContiTech RubberTrack Manual WarrantyGuide eneastNo ratings yet

- Drillstar CatalogueDocument16 pagesDrillstar CatalogueDon BraithwaiteNo ratings yet

- Story TellingDocument3 pagesStory Tellingwaoderosmini11No ratings yet

- Nasca Culture and ArtDocument62 pagesNasca Culture and ArtClinton LeFortNo ratings yet

- MRI Patient Preparation InformationDocument1 pageMRI Patient Preparation InformationVikrEsh Kumar100% (1)

- Architecture Thesis: Integrated Handloom Centre at HindupuramDocument82 pagesArchitecture Thesis: Integrated Handloom Centre at Hindupuramsushma75% (4)

- Work On Your VocabularyDocument128 pagesWork On Your VocabularygokagokaNo ratings yet

- Kylie Trademark Opposition PDFDocument15 pagesKylie Trademark Opposition PDFMark JaffeNo ratings yet

- Thesis WennekesDocument180 pagesThesis WennekesHải VũNo ratings yet

- Innovations in Needle Punching - Medical Textiles: Textile Machinery DivisionDocument34 pagesInnovations in Needle Punching - Medical Textiles: Textile Machinery Divisionsathish_20102010No ratings yet

- Fashion and Apparel Designing List of FiguresDocument47 pagesFashion and Apparel Designing List of FiguresChetna Shetty DikkarNo ratings yet

- Brand PersonalityDocument7 pagesBrand PersonalitySukanya BajpaiNo ratings yet

- BolonkanYork1 3Document36 pagesBolonkanYork1 3Adrienne JancsóNo ratings yet

- Robert Blagmond v. George P. Murphy, Mayor, City Hall, Easton, Maryland Herbert L. Andrew, President, 3rd, City Hall Blenda Arnistead, Manager, Talbot County Courthouse Robert W. Gurlock, Sheriff, Sheriff's Department. All of the Individually, and His Official Capacity of Their Duty Under the Color of Law and the State, 851 F.2d 356, 4th Cir. (1988)Document2 pagesRobert Blagmond v. George P. Murphy, Mayor, City Hall, Easton, Maryland Herbert L. Andrew, President, 3rd, City Hall Blenda Arnistead, Manager, Talbot County Courthouse Robert W. Gurlock, Sheriff, Sheriff's Department. All of the Individually, and His Official Capacity of Their Duty Under the Color of Law and the State, 851 F.2d 356, 4th Cir. (1988)Scribd Government DocsNo ratings yet

- Ten Serious Grammar MistakesDocument8 pagesTen Serious Grammar Mistakesrams2000No ratings yet

- Vocabsolution - Docx 3Document44 pagesVocabsolution - Docx 3Mukesh NarayanNo ratings yet

- Job Safety Analysis Skim Coating, Sanding, Painting: Preparation of All MaterialsDocument1 pageJob Safety Analysis Skim Coating, Sanding, Painting: Preparation of All MaterialsTheo Vidallon BautistaNo ratings yet

- How To Build An Oil Barrel StoveDocument26 pagesHow To Build An Oil Barrel StovepcbstepNo ratings yet

- ASHP 2022 AccomplishmentDocument4 pagesASHP 2022 AccomplishmentJoseph EncaboNo ratings yet

- Thoughts On Genshin Impact's Character DesignsDocument2 pagesThoughts On Genshin Impact's Character DesignsaapNo ratings yet

- Clothing, Personality and Impressions PDFDocument11 pagesClothing, Personality and Impressions PDFAhmad RaoNo ratings yet

- Session 5Document12 pagesSession 5ARYAN RATHORENo ratings yet

- Resume: Reporting To CMDDocument3 pagesResume: Reporting To CMDTabishNo ratings yet

- CBRN WSL1Document47 pagesCBRN WSL1Trelos1337No ratings yet

- Pashto DictionaryDocument36 pagesPashto DictionaryCălin CâmpianuNo ratings yet

- Presentation 1Document21 pagesPresentation 1api-353456972No ratings yet