Professional Documents

Culture Documents

Ujar

Ujar

Uploaded by

purnashOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ujar

Ujar

Uploaded by

purnashCopyright:

Available Formats

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 10, October 2013)

Experimental Study on Environmental Exposure Of Kevlar

Epoxy Composites

Praveen Shaju.C1, Manikandan.T2, Sai Balaji.S3

1

Assistant Professor, Department Of Aeronautical Engineering, Sri Shakthi Institute Of Engineering And Technology,

L&T By-pass Road, Coimbatore-641062.

2

Assistant Professor, Department Of Aeronautical Engineering, Sathyabama University,

Jeppiaar Nagar,Rajiv Gandhi Road, Chennai-600119

3

Department Of Aeronautical Engineering ,Sri Shakthi Institute Of Engineering And Technology,

L&T By-pass Road, Coimbatore-641062.

Aramid composites have been found to be superior to

glass fiber composites in both tensile-tensile and flexural

fatigue loading. Aramid fibers are electrical insulators. Under para-aramid comes Kevlar and Twaron. There are different types of Kevlar fibers. They are Kevlar 29, Kevlar

49, Kevlar 68, Kevlar 119, Kevlar 129, Kevlar 149, Kevlar

HT and Kevlar KM2.

Abstract This project presents the characterization of

Kevlar fiber composites exposed to different environmental

conditions.The investigation involves the study of mechanical

behavior of the specimen made up of bi-directional kevlar149

fiber

and

epoxy

resin

of

standard

size

(280mm*18mm*3.8mm), subjected to various adverse conditions of environment at different intervals of exposure.The

objective of the research endeavor is to characterize the tensile behavior of normal as well as impacted aramid fiber composites when exposed to different environmental conditions at

three different exposure times.

Kevlar 149:

Kevlar 149 is one of the newly developed fibers in the

Kevlar family. It has a very high tensile modulus and hence

the impact resistance is very high compared to other fibers.

Kevlar 149 uptakes moisture very less when compared to

Kevlar 29 and Kevlar 49.These fibers also show resistance

to flame. Hence, it is mainly applied in the aircraft industry.

Keywordscomposites, Kevlar, Tensile strength, Impact

strength

I. INTRODUCTION

In recent years composites have received considerable attention as alternatives to steel and aluminium as structural materials

in construction,,aircraft applications,aerospace industries etc.,due

to their high strength to weight ratio,competent mechanical properties and ease of handling. As aramids have 5-10% higher mechanical properties than other synthetic fibers, these are displacing

metal wires and inorganic fibers from the market of high performance uses like various structural composites for application in

aircraft, marine and automobile, ropes for offshore oil rigs and

bullet proof vests. These fibers not only have better mechanical

properties than steel and glass fibers on an equal weight basis, but

also maintain these properties at high temperatures as aramid

polymers are excellent heat and flame resistant.

Table 1.1.

Properties of Kevlar Fibers.

Properties

Units

Kevlar29

Kevlar49

Kevlar149

Density

g/cc

1.44

1.44

1.47

Diameter

12

12

12

Tensile

strength

Mpa

3600

3600-4100

3400

Tensile

Gpa

83

130

186

II. MATERIAL SELECTION

. Aramid Fibers:

Aramid fiber is the generic term for a specific type of

aromatic polyamide fiber.Aramid fibers can be separated

into two types: the para-aramids and the meta-aramids Aramid fibers offer some significant advantages over other

fibers.Due to their highly aromatic and ordered structure,

aramids have very high thermal resistance for organic materials.

Modulus

116

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 10, October 2013)

.Matrix Material:

Matrix is the combination of adhesive and hardner. Resin and also the hardner has in the different forms or types,

matrix materials are classified according to the adhesive

and hardner.

So, to predict the strength of these fibers in such conditions, the specimens are immersed in the hydraulic fluid.

. Sulphuric Acid:

Some of the least recognized contributors to corrosion

are sand, dust and volcanic ash.Volcanic ash contains chlorides and sulphates, which are extremely corrosive in the

presence of moisture. Therefore, the specimens are immersed in 20% concentrated sulphuric acid and the

strengths are determined.

Epoxy Resin:

Epoxy is one of the major Thermoset matrix materials.

Epoxy resin, which is used in structural aerospace applications, particularly with carbon fibers, and electronics

applications such as printed circuit boards. Epoxies have

less shrinkage and higher strength/stiffness at moderate

temperatures. They are also corrosion-resistant to solvents,

alkalis, and some acids. As with polyesters, epoxy resins

can be used in most composite manufacturing processes.

They are available in different formulations to provide desired properties and optimize the manufacturing process.

Epoxies are used in resins for prepregs and structural adhesives.The extensive use of epoxy resin is due to

1. The ease with which it can be processed.

2. Excellent mechanical properties.

3. High hot and wet strength properties

. Sodium Hydroxide:

In solution, the positively charged metal ions can combine with negatively charged ions to form corrosion products, such as metallic chlorides, oxides, hydroxides and

sulphides. Sodium hydroxide is used in many industries

mostly as a strong chemical base. When this comes in contact with the moisture in the atmosphere it causes corrosion. So, the specimens are immersed in 20% concentrated

sodium hydroxide solution and the strengths are determined.

IV. PREPARATION OF THE TEST SPECIMEN

The Kevlar epoxy laminate obtained from the compression moulding machine will be having the dimensions of

300x300x3.8mm. As per ASTM D3039 standard the dimensions of the tensile test specimen should be

280x18x3.8mm.To prepare the specimens from the laminate, Water jet cutting machine which uses abrasive sand

mixed with water as cutting tool is used.

III. ENVIRONMENT SELECTION

The four different environmental solutions chosen for

testing the specimens are

Salt water

20% concentrated sulphuric acid

20% concentrated sodium hydroxide

Hydraulic Fluid (MIL-PRF-5606)

Reasons for choosing the Solutions:

. Sea Water:

Salt forms a strong electrolyte when dissolved in water,

which causes rapid corrosion of unprotected material surfaces. Kevlar 149 fibers are used for making high speed

boats especially sports boats. There are chances of fibers to

get exposed to sea water over a long period of time. So, in

order to predict the strength of fibers in such a condition,

sea water is chosen.

. Hydraulic Fluid:

The lubricants used are capable of minimizing moisture

intrusion and corrosion attack. However, at high temperatures and pressures, oils can chemically react with impurities to produce acids. Kevlar 149 fibers are used in landing

gear doors and also in the control surfaces of wings of the

aircraft. There are chances of oil spilt during overhauling

process.

Fig(a). Kevlar epoxy laminate after compression

117

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 10, October 2013)

The normal as well as impacted specimens are immersed

in the four solutions and the strengths of the specimens are

determined by tensile testing at regular intervals of time say

64hrs, 128hrs and 512 hrs respectively. The results are then

compared with the results of the specimens before immersion.

Fig. (c) Load vs. Displacement graph for normal Specimen 1.

Fig(b) Specimens immersed in solutions

V. TENSILE TEST RESULTS

Tensile test results for normal specimen:

The pristine specimens are subjected to tensile testing

and a graph of load vs. displacement is obtained for specimen 1 and 2. From the graphs the ultimate tensile load

which the material can withstand is calculated and the average values are tabulated below in table

Fig (d) Load vs. Displacement graph for normal Specimen 2

. Tensile test results for impacted specimens:

The impacted specimens are then subjected to tensile

testing. The graphs are obtained and the readings are tabulated in the table

Table1.2

Tensile Testing Results for Normal Specimens

S.No.

Specimen 1

Ultimate Ten-

Ultimate

Average

sile

Tensile Load

mate

(Mpa)

(KN)

Load(KN)

194.861

14.030

Strength

UltiTensile

14.2525

Specimen 2

200.374

14.475

118

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 10, October 2013)

Fig.(g) Load vs. Displacement for normal specimens immersed in sea

water for 128 hours.

Fig. (e) Load vs. Displacement graph for impacted Specimen1.

Fig. (h) Load vs. Displacement for normal specimens immersed in

20% Conc. H2SO4 for 128 hours.

Fig. (f) Load vs. Displacement graph for impacted Specimen 2

Table 1.3.

Tensile Test Results for Impacted Specimens

S.No.

Ultimate Tensile Strength

(Mpa)

Ultimate Tensile

Load

(KN)

Average Ultimate Tensile

Load (KN)

Specimen 1

211.238

13.910

13.8125

Specimen 2

204.214

13.715

. Tensile test results for normal specimens immersed in

different solutions for 128 hours:

The tensile strength of the normal specimens immersed

in different solutions for 128 hours is found out. Fig.g,h,i,j

gives the load vs. displacement graph for normal specimens

immersed in sea water, 20% conc.H2SO4, 20% conc. NaOH

and hydraulic fluid respectively.

Fig.(i) Load vs. Displacement for normal specimens immersed in 20%

Conc. NaOH for 128 hours.

119

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 10, October 2013)

Fig.(j) Load vs. Displacement for normal specimens immersed in

Hydraulic Fluid (MIL-PRF-5606) for 128 hours.

Table.1.4

Tensile test result for normal specimens immersed in different solutions for 128 hours.

SOLUTIONS

ULTIMATE

LOAD (KN)

SALT WATER

12.355

20% CONC.H2SO4

11.450

20% CONC.NaOH

8.580

HYDRAULIC FLUID

11.135

Fig.(k) Load vs. Displacement for impacted Specimens immersed in

Sea Water for 128 hours.

TENSILE

After 128 hours salt water has the least effect towards

the specimens. The effect of 20% conc.H2SO4 and hydraulic fluid towards the specimens are also very less. But, the

effect of 20% conc.NaOH is very high.

Fig.(l) Load vs. Displacement for impacted specimen immersed in

20% Conc. H2SO4 for 128 hours.

. Tensile test results for impacted specimens immersed in

different solutions for 128 hours:

The tensile strength of impacted specimens immersed in

different solutions for 128 hours is found out. Fig.k,l,m&n

gives the load vs. displacement graphs for specimens immersed in sea water, 20% conc.H2SO4, 20% conc.NaOH

and hydraulic fluid. The results are tabulated in table 6.6.

Fig.(m) Load vs. Displacement for impacted specimens immersed in

20% Conc. NaOH for 128 hours

120

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 10, October 2013)

Fig.(n) Load vs. Displacement for impacted specimens immersed in

Hydraulic Fluid (MIL-PRF-5606) for 128 hours.

Fig.(o) Load vs. Displacement for normal specimens immersed

in Sea Water for 512 hours.

Table 1.5.

Tensile test results for impacted specimens immersed in different

solutions for 128 hours.

SOLUTIONS

ULTIMATE

LOAD (KN)

SALT WATER

11.42

20% CONC.H2SO4

9.880

20% CONC.NaOH

8.505

HYDRAULIC FLUID

10.060

TENSILE

From the table it is seen that the reaction of acid and

base on the specimens is much higher than salt water and

hydraulic fluid. But, effect of salt water is very less.

Fig.(p) Load vs. Displacement for normal specimens immersed in

20% Conc.H2SO4 for 512 hours.

Tensile test results for normal specimens immersed in different solutions for 512 hours:

The tensile strength of normal specimens immersed in

various solutions for 512 hours is found out. Fig.o,p,q&r

gives the load vs. displacement graph for specimens immersed in sea water, 20%conc.H2SO4, 20% conc.NaOH

and hydraulic fluid respectively. The ultimate tensile

strength the material can withstand is listed in table 6.7

Fig.(q) Load vs. Displacement for normal specimen immersed in 20%

Conc.NaOH for 512 hours.

121

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 10, October 2013)

Fig.(r) Loadvs.Displacement for normal specimens immersed in Hydraulic Fluid (MIL-PRF-5606) for 512 hours.

Fig.(s) Load vs. Displacement for impacted specimens immersed in

Sea Water for 512 hours.

Table 1.6

Tensile test result for normal specimen immersed in various solutions

for 512 hours

SOLUTIONS

ULTIMATE

LOAD (KN)

SALT WATER

13.195

20% CONC.H2SO4

11.025

20% CONC.NaOH

8.025

HYDRAULIC FLUID

9.115

TENSILE

From the table it is clear that the reaction of conc.NaOH

on specimens is much higher when compared with the other solutions. The effect of hydraulic fluid is also more but

less than the base solution.

Fig.(t) Load vs. Displacement for impacted specimens immersed in

20% Conc. H2SO4 for 512 hours.

Tensile test results for impacted specimens immersed in

different solutions for 512 hours:

The strength of the impacted specimens after 512 hours

of immersion in various fluids is listed below in table 6.8.

figs,t,u&v gives the load vs. displacement graphs for specimens immersed in sea water, 20% conc.H2SO4, 20% conc.

NaOH and hydraulic fluid respectively.

Fig.(u) Load vs. Displacement for impacted specimens immersed in

20% Conc. NaOH for 512 hours.

122

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 10, October 2013)

The hydraulic fluid (MIL-PRF-5606) shows about

36% reduction in tensile strength at the end of 512

hours.

It is seen that as time increases the strength of the specimen immersed in salt water decreases but the reduction is

very slow. But, the strength of the normal as well as impacted specimens immersed in sodium hydroxide solution

shows a drastic reduction in tensile strength. As the immersion period increases, the strength reduces. The sodium

hydroxide solution enters into the voids very soon and reduces the strength. The reactions of the hydraulic fluid on

the specimens are also a bit slower. Compared to acid, the

base reactions are faster on the Kevlar epoxy specimens

VII. SCOPE FOR FUTURE WORK

Fig.(v) Load vs. Displacement for impacted specimen immersed in

Hydraulic Fluid (MIL-PRF-5606) for 512 hours.

The experimental highlights an important aspect that environmental characterization of materials such as composites is essential for their widespread applications in newer

and novel fields of science and engineering. The technique

of adding various additives to make polymeric matrix composites resistant to various damaging environmental conditions is also an important research area seeking attention

from researchers and engineers belonging to the composite

fraternity.

Table 1.7

Tensile test for impacted specimens immersed in various solutions for

512 hours.

SOLUTIONS

ULTIMATE

LOAD (KN)

SALT WATER

10.140

20% CONC.H2SO4

10.000

20% CONC.NaOH

5.445

HYDRAULIC FLUID

9.355

TENSILE

REFERENCES

[1 ] A. Agarwal, S. Garg, P.K. Rakesh, I. Singh and B.K. Mishra in 2010

Tensile behaviour of glass fiber reinforced plastics subjected to different environmental conditions vol 17, pp 471-476, Indian Journal

Of Engineering and Material Sciences.

[2 ] P.Rahme, C.Bouvet, S.Rivallant, V.Fascio, G.Valembois in 2010

Experimental investigation of impact on composite laminates with

protective layers Composites Science and Technology.

[3 ] Ramazan Karakuzu, Emre Erbil, Mehmet Aktas in 2010 Impact

characterization of glass/epoxy composite plates: An experimental

and numerical study composites: Part B 41 (2010) 388395.

[4 ] R.Kamal Krishna, K.S.Sajikumar, Dr.N.Asok Kumar in 2009 Finite

Element Analysis of Composite Bonded Single Lap Joint under axial

tensile force 10th National Conference on Technological Trends

(NCTT09).

[5 ] Angela.C.Owens, Young.W.Kwon in 2009 An Experimental Study

of Fluid Structure Interaction of carbon composites under low velocity impact

[6 ] R.D.S.G.Campilho,

M.F.S.F.de

Moura,

D.A.Ramantani,

J.J.L.Morais, J.J.M.S.Domingues in 2009 Tensile behaviour of

three-dimensional carbon-epoxy adhesively bonded single- and double-strap repairs International Journal of Adhesion & Adhesives 29,

678686.

[7 ] R.Destefanis, E.Amerio, M.Briccarello, M.Belluco, M.Faraud,

E.Tracino, C.Lobascio Space Environment characterization of Kevlar

[8 ] Gerald Doyle, Richard.A.Pethrick in 2008 Environmental effects on

the ageing of epoxy adhesive joints 77-90, International Journal of

Adhesion and Adhesives 29.

From the table it is clear that the reaction of base solution is very high for the specimens as the immersion period

increases. The strength reduces to half of its original

strength. The reaction of sea water and 20% conc.H2SO4 is

more or less similar.

VI. CONCLUSION

From the results and graphs obtained the following conclusions are made.

The normal specimens immersed in salt water does

not show any rapid changes, but the impacted specimens immersed in salt water shows 26.589% changes

after 512 hours of immersion.

The normal specimens immersed in 20% concentrated

H2SO4 shows about 23% reduction in strength after

512 hours and even the impacted specimens shows

only about 26% reduction. Here it is noticed that the

reduction in strength is bit rapid in the first 128 hours

and then the reaction is slower.

123

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 10, October 2013)

[9 ] Hyonny Kim, Tulin Kayir, Stephanie L.Steber in 2004 Characterization of Transverse Impact Damage on Adhesively Bonded

Glass/Epoxy Composite Joints AIAA 2004-1564.

[10 ] Kalyani Vijayan in 2000 Effect of Environmental exposures on the

Aramid Fiber Kevlar Vol. 12, No. 2 & 3, pp. 259 268, Metals Materials And Processes.

[11 ] H. Ku, W. Jacobson, M. Trada, F. Cardona and D. Rogers in 2008

Tensile Tests of Phenol Formaldehyde SLG Reinforced Composites: Pilot Study Journal of Composite Materials.

[12 ] Marziyeh Khatibzadeh in 1997 The Strength of Angle-Ply Laminates and Composites with Misaligned Fibres

[13 ] Mei Li in 2000 Temperature and Moisture Effects on Composite

Materials for Wind Turbine Blades

[14 ] E.M.Odom, D.F.Adams in 1992 Specimen size effect during Tensile testing of an unreinforced polymer Journal of Material Science

27, 1767-1771.

[15 ] L.S.Sutherland, C.Guedes Soares in 2005 Impact behaviour of

typical marine composite laminates Composites: Part B 37, 89100.

124

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Shell Hazardous Area Classification FundamentalsDocument30 pagesShell Hazardous Area Classification Fundamentalsthekevindesai100% (17)

- HCL Technologies Hiring Mechanical Design Engineers-Call Letter-03rd December 2016 (Saturday) - ChennaiDocument2 pagesHCL Technologies Hiring Mechanical Design Engineers-Call Letter-03rd December 2016 (Saturday) - ChennaipurnashNo ratings yet

- Start 001Document1 pageStart 001purnashNo ratings yet

- FDocument3 pagesFpurnashNo ratings yet

- Pocket WorkoutsDocument210 pagesPocket WorkoutspurnashNo ratings yet

- Column Chromatography: Lab ReportDocument7 pagesColumn Chromatography: Lab ReportChiNo ratings yet

- Bekele MirkenaDocument127 pagesBekele MirkenaSAIMA ZAMEER100% (1)

- Florey Vol 32, 2005Document282 pagesFlorey Vol 32, 2005Fadli NugrahaNo ratings yet

- 5 - Cortés-Burgos (2021) - Effects of PbS-NPs Doping On The Photovoltaic Performance of Natural Dye-Sensitized TiO2 PhotoelectrodesDocument9 pages5 - Cortés-Burgos (2021) - Effects of PbS-NPs Doping On The Photovoltaic Performance of Natural Dye-Sensitized TiO2 Photoelectrodesmaria cortesNo ratings yet

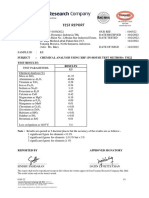

- Subject: Chemical Analysis Using XRF (In-House Test Method) : Tm22 Test Results: ResultsDocument2 pagesSubject: Chemical Analysis Using XRF (In-House Test Method) : Tm22 Test Results: Resultstri yuda khalidNo ratings yet

- A Review of Biomass Pyrolysis and Pyrolysis TechnologiesDocument82 pagesA Review of Biomass Pyrolysis and Pyrolysis TechnologiesNhean FierceghastNo ratings yet

- Case Study FRP Tank Failure JQDocument9 pagesCase Study FRP Tank Failure JQsenkuttuvanNo ratings yet

- Advanced Reservoir Sheet 1,2Document7 pagesAdvanced Reservoir Sheet 1,2Abdelazim MohamedNo ratings yet

- Dat Examinee GuideDocument23 pagesDat Examinee Guidekjk khkNo ratings yet

- CorrosionDocument4 pagesCorrosionTotis TotosNo ratings yet

- Blast Valve PV-KK-WDocument2 pagesBlast Valve PV-KK-Wyousufbasha100% (1)

- Hvof Coatings A Review PDFDocument1 pageHvof Coatings A Review PDFVTC ENGINEERINBNo ratings yet

- Chryso-Cure-Acp 8435 4632Document5 pagesChryso-Cure-Acp 8435 4632zealbalaNo ratings yet

- Emerging Technologies For Wastewater TreatmentDocument188 pagesEmerging Technologies For Wastewater TreatmentNguyen Phuc Pham100% (1)

- Soap Dispensers: Surface Push-ButtonDocument2 pagesSoap Dispensers: Surface Push-ButtonMouad MelloukiNo ratings yet

- EPRPDocument88 pagesEPRPmanoj0% (1)

- ISI-Scopus-Journals (QEC) PDFDocument567 pagesISI-Scopus-Journals (QEC) PDFZubairNo ratings yet

- Gizmo - Rna - Protein SynthesisDocument7 pagesGizmo - Rna - Protein SynthesisMarques AlsoppNo ratings yet

- Military MightDocument29 pagesMilitary MightpenuliarjaysonNo ratings yet

- Experiment 3.1Document3 pagesExperiment 3.1RAUDHATUL ASNIDA ABDUL RAZAKNo ratings yet

- JR Inter Important Question Physics (E.M)Document13 pagesJR Inter Important Question Physics (E.M)Bangi Sunil Kumar93% (28)

- Glass To Glass DetailsDocument7 pagesGlass To Glass Detailsvishalbhavar1No ratings yet

- Is - sp.57.1993 Hand Book Pipes and FittingsDocument103 pagesIs - sp.57.1993 Hand Book Pipes and FittingsMathiTwadCNo ratings yet

- DPT Fire RatioDocument12 pagesDPT Fire RatioRavi GohelNo ratings yet

- Metacam Epar Scientific Discussion - enDocument106 pagesMetacam Epar Scientific Discussion - enSamantha FauldsNo ratings yet

- Stochastic and Deterministic Effects of RadiationDocument2 pagesStochastic and Deterministic Effects of RadiationFer MoncadaNo ratings yet

- Horizontal Plate Natural Convection Equations and Calculator - Engineers EdgeDocument4 pagesHorizontal Plate Natural Convection Equations and Calculator - Engineers EdgerikardoNo ratings yet

- IP ProjectDocument4 pagesIP ProjecthoikliangNo ratings yet

- 9700 s17 Ms 41Document18 pages9700 s17 Ms 41Mushu DonNo ratings yet