Professional Documents

Culture Documents

U W Structural Slab On Grade: Facilities Services Design Guide

U W Structural Slab On Grade: Facilities Services Design Guide

Uploaded by

engmahm000uudCopyright:

Available Formats

You might also like

- Plataforma Spider Basket PB22.10OP PDFDocument165 pagesPlataforma Spider Basket PB22.10OP PDFJose Figueroa100% (1)

- Water Supply Project SpecificationDocument33 pagesWater Supply Project SpecificationHimawan Sutardjo100% (1)

- Case Study of ToyotaDocument20 pagesCase Study of ToyotaMansoor ZainNo ratings yet

- Foundation Inspection ChecklistDocument3 pagesFoundation Inspection Checklistkhemraj deore100% (1)

- Structural CommentsDocument3 pagesStructural CommentsMusherib KhanNo ratings yet

- Technical Specifications - PilingDocument16 pagesTechnical Specifications - Pilingmkpasha55mp100% (1)

- Location: M. H. Del Pilar Street, Polillo, Quezon Project Owner: Mrs. Necerina T. AzagraDocument12 pagesLocation: M. H. Del Pilar Street, Polillo, Quezon Project Owner: Mrs. Necerina T. Azagramgllacuna73% (11)

- Raised Floor Works-SpecsDocument5 pagesRaised Floor Works-SpecsdenisjayNo ratings yet

- General Specifications For The Proposed Gasoline StationDocument8 pagesGeneral Specifications For The Proposed Gasoline StationMark Anthony Capito Años100% (1)

- How to Build a Global Model Earthship Operation II: Concrete WorkFrom EverandHow to Build a Global Model Earthship Operation II: Concrete WorkNo ratings yet

- Box Culvert ExtensionDocument4 pagesBox Culvert ExtensionRonak ShahNo ratings yet

- Foundation Inspection Check ListDocument9 pagesFoundation Inspection Check Listkevin brentonNo ratings yet

- 06 3E Foundations&PilesDocument3 pages06 3E Foundations&PileslsatchithananthanNo ratings yet

- Notes For Box Culvert ExtensionsDocument4 pagesNotes For Box Culvert ExtensionssotheaNo ratings yet

- Prestressed Precast Concrete Wall Panel (Structure), Item SPV.0165.XXDocument8 pagesPrestressed Precast Concrete Wall Panel (Structure), Item SPV.0165.XXruddy sniderNo ratings yet

- Anchored WallsDocument12 pagesAnchored WallsrsadibNo ratings yet

- Bridge Construction Manual - Falsework and FormsDocument81 pagesBridge Construction Manual - Falsework and FormsRocky ChoNo ratings yet

- Addendum 2Document7 pagesAddendum 2Dan RodgersNo ratings yet

- Details of CC Pavement DesignDocument10 pagesDetails of CC Pavement DesignRajesh BabuNo ratings yet

- PDF MajidDocument5 pagesPDF Majidyara.gergesNo ratings yet

- Foundation Inspection Checklist: "Partnering To Improve Consistency & Customer Service"Document3 pagesFoundation Inspection Checklist: "Partnering To Improve Consistency & Customer Service"Wai Lin Oo100% (1)

- Sound Barrier Wall AttachmentsDocument9 pagesSound Barrier Wall AttachmentsFranklin GarciaNo ratings yet

- Slab ToleranceDocument1 pageSlab TolerancejoanarchNo ratings yet

- Building Application Checklist Approval CertificateDocument5 pagesBuilding Application Checklist Approval CertificateVictor IkeNo ratings yet

- Wall Modular Block Mechanically Stabilized Earth (Structure), Item SPV.0165.XXDocument16 pagesWall Modular Block Mechanically Stabilized Earth (Structure), Item SPV.0165.XXCekinNo ratings yet

- SPECIFICATIONDocument5 pagesSPECIFICATIONAlan CamposNo ratings yet

- BOQ Boundary WallDocument4 pagesBOQ Boundary WallVishal ShrivastavaNo ratings yet

- Two Storey House SpecificationsDocument11 pagesTwo Storey House SpecificationsIra Mae AstadanNo ratings yet

- Gutter DataDocument31 pagesGutter DataUpaliBandaraNo ratings yet

- Guidelines For Superstructure Plan Review For Pre-Fabricated Pedestrian/Bicycle BridgesDocument6 pagesGuidelines For Superstructure Plan Review For Pre-Fabricated Pedestrian/Bicycle BridgesAbdullah NajjarNo ratings yet

- Retaining Walls - Soldier Pile (LRFD)Document11 pagesRetaining Walls - Soldier Pile (LRFD)rashi1717No ratings yet

- Vacuum Dewatered FlooringDocument2 pagesVacuum Dewatered FlooringSwitech india80% (5)

- Construction Specifications LongDocument7 pagesConstruction Specifications LongLimar SetatraNo ratings yet

- Builiding Permit Plan ChecklistDocument5 pagesBuiliding Permit Plan ChecklistRania MetwaliNo ratings yet

- Canteen and Dress Changing RoomDocument43 pagesCanteen and Dress Changing RoomJeevitha DeivasigamaniNo ratings yet

- Drawing ChecklistDocument3 pagesDrawing ChecklistaanthaNo ratings yet

- Approach Form Camber Specifications With CautionDocument4 pagesApproach Form Camber Specifications With CautionDonald HamiltonNo ratings yet

- General Specification: DrawingsDocument7 pagesGeneral Specification: DrawingsiamiampauloNo ratings yet

- SpecificationsDocument5 pagesSpecificationsRomeo QuerubinNo ratings yet

- Location: M. H. Del Pilar Street, Polillo, Quezon Project Owner: Mrs. Necerina T. AzagraDocument11 pagesLocation: M. H. Del Pilar Street, Polillo, Quezon Project Owner: Mrs. Necerina T. Azagramy dlNo ratings yet

- Section XXXXX - Stone ColumnsDocument6 pagesSection XXXXX - Stone ColumnsRitunjay JhaNo ratings yet

- Proposed Boarding House (Specifications)Document7 pagesProposed Boarding House (Specifications)Marc Kenneth ConchaNo ratings yet

- 05450-Pre Engineered Metal TrussesDocument4 pages05450-Pre Engineered Metal TrussesRamsey RasmeyNo ratings yet

- 16M Outline Spec 111022Document12 pages16M Outline Spec 111022Jeffrey ArnoldNo ratings yet

- Precast Box CulvertDocument3 pagesPrecast Box CulvertAhmed KhalifNo ratings yet

- General Specifications MoryDocument7 pagesGeneral Specifications MoryHannah Cesaree Mae TadeoNo ratings yet

- 16 - Chapter16Document4 pages16 - Chapter16pravin bharatiNo ratings yet

- General specifications-GILODocument7 pagesGeneral specifications-GILOHannah Cesaree Mae TadeoNo ratings yet

- Manuscript - Apc - Guide - Spec - AD - 2-24-2022 For PublishDocument38 pagesManuscript - Apc - Guide - Spec - AD - 2-24-2022 For PublishemlNo ratings yet

- 04 42 23 - Exterior Limestone Cladding (PDF) - p14 - PDFDocument14 pages04 42 23 - Exterior Limestone Cladding (PDF) - p14 - PDFKwan YiuNo ratings yet

- 275 Stamped Surfaces Rev1703Document3 pages275 Stamped Surfaces Rev1703Prakash RajagopalanNo ratings yet

- Section I - Excavation, Grading and FillingDocument15 pagesSection I - Excavation, Grading and FillingJep MarianoNo ratings yet

- Architectural SpecificationDocument5 pagesArchitectural SpecificationJustine Alexis IngresoNo ratings yet

- Manuscript - Apc - Guide - Spec - AC - 2-24-2022 For PublishDocument40 pagesManuscript - Apc - Guide - Spec - AC - 2-24-2022 For PublishemlNo ratings yet

- Retaining Wall Design ManualDocument3 pagesRetaining Wall Design ManualAjay SinghNo ratings yet

- Ethiopian Roads Authoritycalculations, Drawings and Specifications PDFDocument4 pagesEthiopian Roads Authoritycalculations, Drawings and Specifications PDFNejbel M Ab100% (1)

- Pavement Design PDFDocument8 pagesPavement Design PDFchandru187No ratings yet

- SC Deck Chapter6 A11yDocument10 pagesSC Deck Chapter6 A11yFares abedNo ratings yet

- Micropile SpecDocument14 pagesMicropile SpecVijaya BhaskarNo ratings yet

- 275 Stamped Concrete Surfaces - Rev1005Document3 pages275 Stamped Concrete Surfaces - Rev1005easgoaNo ratings yet

- Civil Surveying and Drawing - A1Document8 pagesCivil Surveying and Drawing - A1Parangat SharmaNo ratings yet

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

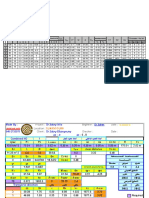

- Column Table 1: Project NumberDocument1 pageColumn Table 1: Project Numberengmahm000uudNo ratings yet

- STR01Document1 pageSTR01engmahm000uudNo ratings yet

- Design of StrapsDocument3 pagesDesign of Strapsengmahm000uudNo ratings yet

- Pca PDFDocument9 pagesPca PDFengmahm000uudNo ratings yet

- Design of Rectangular ColumnDocument4 pagesDesign of Rectangular Columnengmahm000uudNo ratings yet

- idecad-VS Etabs PDFDocument11 pagesidecad-VS Etabs PDFengmahm000uudNo ratings yet

- Cataloog PPG Eu 2016 Uk - No Prices - Cover InclDocument370 pagesCataloog PPG Eu 2016 Uk - No Prices - Cover InclenergyfishNo ratings yet

- 2014 Vdo Automotive Industry Marine Catalog enDocument296 pages2014 Vdo Automotive Industry Marine Catalog enBill NevisNo ratings yet

- Tugas Sistem Perancangan Mesin (Autosaved)Document2 pagesTugas Sistem Perancangan Mesin (Autosaved)liza mulyadianaNo ratings yet

- App Form CRSF007 Grade1 Sept2011Document4 pagesApp Form CRSF007 Grade1 Sept2011Gys Smeda100% (1)

- CWT Titrets PdsDocument2 pagesCWT Titrets PdsajitNo ratings yet

- Tabela Atual PederpartsDocument8 pagesTabela Atual Pederpartsrenanluizz1996No ratings yet

- Netting Structures Best Practice Guideline Rev2 Fv-2Document29 pagesNetting Structures Best Practice Guideline Rev2 Fv-2Asavela NotshwelekaNo ratings yet

- JNTUA EEE 3rd & 4th Year (R15) SyllabusDocument92 pagesJNTUA EEE 3rd & 4th Year (R15) Syllabusnanda vinayNo ratings yet

- 2015 Packaging PresentationDocument56 pages2015 Packaging PresentationNayeli Mendez100% (1)

- Xcs Class KT SessionDocument28 pagesXcs Class KT SessionPradyut TiwariNo ratings yet

- 04 Buttweldfitt Tee Din2615Document7 pages04 Buttweldfitt Tee Din2615ivanmatijevicNo ratings yet

- Vacon AC Drive US Version Product Catalog BC00324CDocument204 pagesVacon AC Drive US Version Product Catalog BC00324CCatalin PelinNo ratings yet

- Rieter F 20 F 40 Roving Frame Brochure 3310 v2 96623 enDocument12 pagesRieter F 20 F 40 Roving Frame Brochure 3310 v2 96623 enmrsa.313No ratings yet

- Elastomeric Catalogue - Strip BRG - W PDFDocument6 pagesElastomeric Catalogue - Strip BRG - W PDFAnonymous dxsNnL6S8hNo ratings yet

- Ind10 PDFDocument15 pagesInd10 PDFbring it onNo ratings yet

- 04 Dabel MaruDocument25 pages04 Dabel MaruNtagwabira PatrickNo ratings yet

- DIY Scissor Lift 1Document6 pagesDIY Scissor Lift 1daniel deeeNo ratings yet

- Katalog - Zaštitne Opreme PDFDocument60 pagesKatalog - Zaštitne Opreme PDFBelkisa ŠaćiriNo ratings yet

- 1 NWC Report 2011afixe - CompressedDocument78 pages1 NWC Report 2011afixe - CompressedeepabaluNo ratings yet

- NASA Eng Drawing Practices Vol1 Aerospace N Ground Support EquipmentDocument44 pagesNASA Eng Drawing Practices Vol1 Aerospace N Ground Support EquipmentWeerachart KulsirikasemNo ratings yet

- Quiz Questiob by SiarusDocument2 pagesQuiz Questiob by SiarusSiarus Sahbiat PriomNo ratings yet

- Document 3Document3 pagesDocument 3RJ VillamerNo ratings yet

- IGCSE Business Edxcel NotesDocument18 pagesIGCSE Business Edxcel NotesYasmin YehiaNo ratings yet

- Raport XI-XII Sem 1-2 2017 - 2018Document221 pagesRaport XI-XII Sem 1-2 2017 - 2018RIZKINo ratings yet

- Combat Aircraft Monthly - September 2015 UK VK Com Stopthepress PDFDocument100 pagesCombat Aircraft Monthly - September 2015 UK VK Com Stopthepress PDFAnonymous N13JdnNo ratings yet

- Turbine Meter Reference MaterialDocument8 pagesTurbine Meter Reference MaterialjsmargateNo ratings yet

- Assignment 2Document3 pagesAssignment 2Anonymous pX0vP8hNo ratings yet

- QB FinalDocument16 pagesQB Finalnolasco281No ratings yet

U W Structural Slab On Grade: Facilities Services Design Guide

U W Structural Slab On Grade: Facilities Services Design Guide

Uploaded by

engmahm000uudOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

U W Structural Slab On Grade: Facilities Services Design Guide

U W Structural Slab On Grade: Facilities Services Design Guide

Uploaded by

engmahm000uudCopyright:

Available Formats

U NIVERSITY

OF

W ASHINGTON

Facilities Services

Design Guide

Structural

Slab on Grade

Basis of Design

This section applies to the design and installation of concrete slabs on grade in buildings.

Design Criteria

Provide joints in all concrete slabs on grade.

Provide control or construction joints on all column lines and at 20-0 maximum spacing each

way in between. Structural engineer to determine closer spacing requirements.

Show the location of control and construction joints on the plan.

Reinforce with conventional reinforcing steel each way. Welded wire fabric is not allowed.

Design and specify floors that are engineered and constructed to achieve the following

minimum degree of flatness when measured in accordance with ASTM E 1155: Overall FF =

35, Localized FF = 25. Garage floors may be Overall FF = 25, Localized FF = 20.

Design and specify floors that are engineered and constructed to achieve the following

minimum degree of levelness when measured in accordance with ASTM E 1155: Overall FL

= 25, Localized FL = 17. Garage floors may be Overall FL = 17, Localized FL = 13.

The Localized F-Numbers indicated are the minimum quality acceptable in any one floor

section. This allows the contractor sufficient margin for the normal variations that occur

within a pour.

Specify the top of concrete elevation at each column or wall to be within 1/4 inch of the

elevations shown on the drawings.

Provide below slab capillary break at all slabs on grade. Provide additional details and

groundwater collection and drainage systems as required for slabs on grade located below

the ground water table. If gravel is used for a capillary break material, it shall be uniformly

well graded and compacted.

Design Evaluation

The following information is required to evaluate the design:

Schematic Design Phase: Indicate Slab on Grade thickness and proposed type of

reinforcing.

Design Development Phase: Plans showing location, thickness, reinforcing of slab on grade.

Slab joint locations. Draft specifications.

Construction Document Phase: All information required for the installation of slabs on grade

including slab thickness, location of construction and construction joints and details of joints.

Final specifications.

Construction Submittals

Submit a jointing plan to the Architect for approval a minimum of 21 days prior to first slab

pour.

REV:07 JUN2015

3F - 01

University of Washington Campus Engineering 2015

U NIVERSITY

OF

W ASHINGTON

Facilities Services

Design Guide

Structural

Slab on Grade

Products, Material and Equipment

See Facilities Services Design Guide - Concrete

Installation, Fabrication and Construction

Saw joints as soon as the joint can be cut without edges raveling and within 12 hours of slab

placement. Fill sawed joints with sealant.

END OF DESIGN GUIDE SECTION

3F - 02

REV:07 JUN2015

University of Washington Campus Engineering 2015

You might also like

- Plataforma Spider Basket PB22.10OP PDFDocument165 pagesPlataforma Spider Basket PB22.10OP PDFJose Figueroa100% (1)

- Water Supply Project SpecificationDocument33 pagesWater Supply Project SpecificationHimawan Sutardjo100% (1)

- Case Study of ToyotaDocument20 pagesCase Study of ToyotaMansoor ZainNo ratings yet

- Foundation Inspection ChecklistDocument3 pagesFoundation Inspection Checklistkhemraj deore100% (1)

- Structural CommentsDocument3 pagesStructural CommentsMusherib KhanNo ratings yet

- Technical Specifications - PilingDocument16 pagesTechnical Specifications - Pilingmkpasha55mp100% (1)

- Location: M. H. Del Pilar Street, Polillo, Quezon Project Owner: Mrs. Necerina T. AzagraDocument12 pagesLocation: M. H. Del Pilar Street, Polillo, Quezon Project Owner: Mrs. Necerina T. Azagramgllacuna73% (11)

- Raised Floor Works-SpecsDocument5 pagesRaised Floor Works-SpecsdenisjayNo ratings yet

- General Specifications For The Proposed Gasoline StationDocument8 pagesGeneral Specifications For The Proposed Gasoline StationMark Anthony Capito Años100% (1)

- How to Build a Global Model Earthship Operation II: Concrete WorkFrom EverandHow to Build a Global Model Earthship Operation II: Concrete WorkNo ratings yet

- Box Culvert ExtensionDocument4 pagesBox Culvert ExtensionRonak ShahNo ratings yet

- Foundation Inspection Check ListDocument9 pagesFoundation Inspection Check Listkevin brentonNo ratings yet

- 06 3E Foundations&PilesDocument3 pages06 3E Foundations&PileslsatchithananthanNo ratings yet

- Notes For Box Culvert ExtensionsDocument4 pagesNotes For Box Culvert ExtensionssotheaNo ratings yet

- Prestressed Precast Concrete Wall Panel (Structure), Item SPV.0165.XXDocument8 pagesPrestressed Precast Concrete Wall Panel (Structure), Item SPV.0165.XXruddy sniderNo ratings yet

- Anchored WallsDocument12 pagesAnchored WallsrsadibNo ratings yet

- Bridge Construction Manual - Falsework and FormsDocument81 pagesBridge Construction Manual - Falsework and FormsRocky ChoNo ratings yet

- Addendum 2Document7 pagesAddendum 2Dan RodgersNo ratings yet

- Details of CC Pavement DesignDocument10 pagesDetails of CC Pavement DesignRajesh BabuNo ratings yet

- PDF MajidDocument5 pagesPDF Majidyara.gergesNo ratings yet

- Foundation Inspection Checklist: "Partnering To Improve Consistency & Customer Service"Document3 pagesFoundation Inspection Checklist: "Partnering To Improve Consistency & Customer Service"Wai Lin Oo100% (1)

- Sound Barrier Wall AttachmentsDocument9 pagesSound Barrier Wall AttachmentsFranklin GarciaNo ratings yet

- Slab ToleranceDocument1 pageSlab TolerancejoanarchNo ratings yet

- Building Application Checklist Approval CertificateDocument5 pagesBuilding Application Checklist Approval CertificateVictor IkeNo ratings yet

- Wall Modular Block Mechanically Stabilized Earth (Structure), Item SPV.0165.XXDocument16 pagesWall Modular Block Mechanically Stabilized Earth (Structure), Item SPV.0165.XXCekinNo ratings yet

- SPECIFICATIONDocument5 pagesSPECIFICATIONAlan CamposNo ratings yet

- BOQ Boundary WallDocument4 pagesBOQ Boundary WallVishal ShrivastavaNo ratings yet

- Two Storey House SpecificationsDocument11 pagesTwo Storey House SpecificationsIra Mae AstadanNo ratings yet

- Gutter DataDocument31 pagesGutter DataUpaliBandaraNo ratings yet

- Guidelines For Superstructure Plan Review For Pre-Fabricated Pedestrian/Bicycle BridgesDocument6 pagesGuidelines For Superstructure Plan Review For Pre-Fabricated Pedestrian/Bicycle BridgesAbdullah NajjarNo ratings yet

- Retaining Walls - Soldier Pile (LRFD)Document11 pagesRetaining Walls - Soldier Pile (LRFD)rashi1717No ratings yet

- Vacuum Dewatered FlooringDocument2 pagesVacuum Dewatered FlooringSwitech india80% (5)

- Construction Specifications LongDocument7 pagesConstruction Specifications LongLimar SetatraNo ratings yet

- Builiding Permit Plan ChecklistDocument5 pagesBuiliding Permit Plan ChecklistRania MetwaliNo ratings yet

- Canteen and Dress Changing RoomDocument43 pagesCanteen and Dress Changing RoomJeevitha DeivasigamaniNo ratings yet

- Drawing ChecklistDocument3 pagesDrawing ChecklistaanthaNo ratings yet

- Approach Form Camber Specifications With CautionDocument4 pagesApproach Form Camber Specifications With CautionDonald HamiltonNo ratings yet

- General Specification: DrawingsDocument7 pagesGeneral Specification: DrawingsiamiampauloNo ratings yet

- SpecificationsDocument5 pagesSpecificationsRomeo QuerubinNo ratings yet

- Location: M. H. Del Pilar Street, Polillo, Quezon Project Owner: Mrs. Necerina T. AzagraDocument11 pagesLocation: M. H. Del Pilar Street, Polillo, Quezon Project Owner: Mrs. Necerina T. Azagramy dlNo ratings yet

- Section XXXXX - Stone ColumnsDocument6 pagesSection XXXXX - Stone ColumnsRitunjay JhaNo ratings yet

- Proposed Boarding House (Specifications)Document7 pagesProposed Boarding House (Specifications)Marc Kenneth ConchaNo ratings yet

- 05450-Pre Engineered Metal TrussesDocument4 pages05450-Pre Engineered Metal TrussesRamsey RasmeyNo ratings yet

- 16M Outline Spec 111022Document12 pages16M Outline Spec 111022Jeffrey ArnoldNo ratings yet

- Precast Box CulvertDocument3 pagesPrecast Box CulvertAhmed KhalifNo ratings yet

- General Specifications MoryDocument7 pagesGeneral Specifications MoryHannah Cesaree Mae TadeoNo ratings yet

- 16 - Chapter16Document4 pages16 - Chapter16pravin bharatiNo ratings yet

- General specifications-GILODocument7 pagesGeneral specifications-GILOHannah Cesaree Mae TadeoNo ratings yet

- Manuscript - Apc - Guide - Spec - AD - 2-24-2022 For PublishDocument38 pagesManuscript - Apc - Guide - Spec - AD - 2-24-2022 For PublishemlNo ratings yet

- 04 42 23 - Exterior Limestone Cladding (PDF) - p14 - PDFDocument14 pages04 42 23 - Exterior Limestone Cladding (PDF) - p14 - PDFKwan YiuNo ratings yet

- 275 Stamped Surfaces Rev1703Document3 pages275 Stamped Surfaces Rev1703Prakash RajagopalanNo ratings yet

- Section I - Excavation, Grading and FillingDocument15 pagesSection I - Excavation, Grading and FillingJep MarianoNo ratings yet

- Architectural SpecificationDocument5 pagesArchitectural SpecificationJustine Alexis IngresoNo ratings yet

- Manuscript - Apc - Guide - Spec - AC - 2-24-2022 For PublishDocument40 pagesManuscript - Apc - Guide - Spec - AC - 2-24-2022 For PublishemlNo ratings yet

- Retaining Wall Design ManualDocument3 pagesRetaining Wall Design ManualAjay SinghNo ratings yet

- Ethiopian Roads Authoritycalculations, Drawings and Specifications PDFDocument4 pagesEthiopian Roads Authoritycalculations, Drawings and Specifications PDFNejbel M Ab100% (1)

- Pavement Design PDFDocument8 pagesPavement Design PDFchandru187No ratings yet

- SC Deck Chapter6 A11yDocument10 pagesSC Deck Chapter6 A11yFares abedNo ratings yet

- Micropile SpecDocument14 pagesMicropile SpecVijaya BhaskarNo ratings yet

- 275 Stamped Concrete Surfaces - Rev1005Document3 pages275 Stamped Concrete Surfaces - Rev1005easgoaNo ratings yet

- Civil Surveying and Drawing - A1Document8 pagesCivil Surveying and Drawing - A1Parangat SharmaNo ratings yet

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- Column Table 1: Project NumberDocument1 pageColumn Table 1: Project Numberengmahm000uudNo ratings yet

- STR01Document1 pageSTR01engmahm000uudNo ratings yet

- Design of StrapsDocument3 pagesDesign of Strapsengmahm000uudNo ratings yet

- Pca PDFDocument9 pagesPca PDFengmahm000uudNo ratings yet

- Design of Rectangular ColumnDocument4 pagesDesign of Rectangular Columnengmahm000uudNo ratings yet

- idecad-VS Etabs PDFDocument11 pagesidecad-VS Etabs PDFengmahm000uudNo ratings yet

- Cataloog PPG Eu 2016 Uk - No Prices - Cover InclDocument370 pagesCataloog PPG Eu 2016 Uk - No Prices - Cover InclenergyfishNo ratings yet

- 2014 Vdo Automotive Industry Marine Catalog enDocument296 pages2014 Vdo Automotive Industry Marine Catalog enBill NevisNo ratings yet

- Tugas Sistem Perancangan Mesin (Autosaved)Document2 pagesTugas Sistem Perancangan Mesin (Autosaved)liza mulyadianaNo ratings yet

- App Form CRSF007 Grade1 Sept2011Document4 pagesApp Form CRSF007 Grade1 Sept2011Gys Smeda100% (1)

- CWT Titrets PdsDocument2 pagesCWT Titrets PdsajitNo ratings yet

- Tabela Atual PederpartsDocument8 pagesTabela Atual Pederpartsrenanluizz1996No ratings yet

- Netting Structures Best Practice Guideline Rev2 Fv-2Document29 pagesNetting Structures Best Practice Guideline Rev2 Fv-2Asavela NotshwelekaNo ratings yet

- JNTUA EEE 3rd & 4th Year (R15) SyllabusDocument92 pagesJNTUA EEE 3rd & 4th Year (R15) Syllabusnanda vinayNo ratings yet

- 2015 Packaging PresentationDocument56 pages2015 Packaging PresentationNayeli Mendez100% (1)

- Xcs Class KT SessionDocument28 pagesXcs Class KT SessionPradyut TiwariNo ratings yet

- 04 Buttweldfitt Tee Din2615Document7 pages04 Buttweldfitt Tee Din2615ivanmatijevicNo ratings yet

- Vacon AC Drive US Version Product Catalog BC00324CDocument204 pagesVacon AC Drive US Version Product Catalog BC00324CCatalin PelinNo ratings yet

- Rieter F 20 F 40 Roving Frame Brochure 3310 v2 96623 enDocument12 pagesRieter F 20 F 40 Roving Frame Brochure 3310 v2 96623 enmrsa.313No ratings yet

- Elastomeric Catalogue - Strip BRG - W PDFDocument6 pagesElastomeric Catalogue - Strip BRG - W PDFAnonymous dxsNnL6S8hNo ratings yet

- Ind10 PDFDocument15 pagesInd10 PDFbring it onNo ratings yet

- 04 Dabel MaruDocument25 pages04 Dabel MaruNtagwabira PatrickNo ratings yet

- DIY Scissor Lift 1Document6 pagesDIY Scissor Lift 1daniel deeeNo ratings yet

- Katalog - Zaštitne Opreme PDFDocument60 pagesKatalog - Zaštitne Opreme PDFBelkisa ŠaćiriNo ratings yet

- 1 NWC Report 2011afixe - CompressedDocument78 pages1 NWC Report 2011afixe - CompressedeepabaluNo ratings yet

- NASA Eng Drawing Practices Vol1 Aerospace N Ground Support EquipmentDocument44 pagesNASA Eng Drawing Practices Vol1 Aerospace N Ground Support EquipmentWeerachart KulsirikasemNo ratings yet

- Quiz Questiob by SiarusDocument2 pagesQuiz Questiob by SiarusSiarus Sahbiat PriomNo ratings yet

- Document 3Document3 pagesDocument 3RJ VillamerNo ratings yet

- IGCSE Business Edxcel NotesDocument18 pagesIGCSE Business Edxcel NotesYasmin YehiaNo ratings yet

- Raport XI-XII Sem 1-2 2017 - 2018Document221 pagesRaport XI-XII Sem 1-2 2017 - 2018RIZKINo ratings yet

- Combat Aircraft Monthly - September 2015 UK VK Com Stopthepress PDFDocument100 pagesCombat Aircraft Monthly - September 2015 UK VK Com Stopthepress PDFAnonymous N13JdnNo ratings yet

- Turbine Meter Reference MaterialDocument8 pagesTurbine Meter Reference MaterialjsmargateNo ratings yet

- Assignment 2Document3 pagesAssignment 2Anonymous pX0vP8hNo ratings yet

- QB FinalDocument16 pagesQB Finalnolasco281No ratings yet