Professional Documents

Culture Documents

Quality Protocol Supplier

Quality Protocol Supplier

Uploaded by

Ahmet HamamcıoğluOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality Protocol Supplier

Quality Protocol Supplier

Uploaded by

Ahmet HamamcıoğluCopyright:

Available Formats

QUALITY PROTOCOL : Q01-0314-1117

Created : 27-march-2015

All of the following rubber elements need to be inspected according to the test protocols below.

-

PTR314MN__

PTR315MN__

Quality Protocol Supplier:

1.

2.

3.

4.

5.

100% Visual inspection of product. Visual test report of the product.

- Visual inspection of rubber disc confirming:

o No geometric deviations.

o No tears or other inconsistencies in any surface or edge.

o No excess material from molding.

o All markings present and correct.

Dimensional test report of product*

Confirming that PTR314MN__ is according to drawing P01-0314-005

Confirming that PTR315MN__ is according to drawing P01-0315-318

Static stiffness test according to Rubber Design test protocol confirming the static stiffness of

the rubber elements*

Dynamic stiffness test according to Rubber Design test protocol confirming the dynamic

stiffness of the rubber elements.

Chemical laboratory test report confirming the compound characteristics.

All the certificates / test results have to be signed by Supplier. Certificates / test results have to be

sent by E-mail to Rubber Design.

*

Random sample size as given in table 1.

Batch size

2 up to and including 8 pieces

9 up to and including 15 pieces

16 up to and including 25 pieces

26 up to and including 50 pieces

51 up to and including 90 pieces

91 up to and including 150 pieces

151 up to and including 280 pieces

281 up to and including 500 pieces

501 up to and including 1200 pieces

1201 up to and including 3200 pieces

3201 up to and including 10000 pieces

Random sample size

2 pieces

3 pieces

5 pieces

8 pieces

13 pieces

20 pieces

32 pieces

50 pieces

80 pieces

125 pieces

200 pieces

Reject batch if

1 pieces is out of tolerance

1 pieces is out of tolerance

1 pieces is out of tolerance

1 pieces is out of tolerance

1 pieces is out of tolerance

1 pieces is out of tolerance

2 pieces is out of tolerance

2 pieces is out of tolerance

3 pieces is out of tolerance

4 pieces is out of tolerance

6 pieces is out of tolerance

Table 1, random sample size. If when you check the prescribed number of parts you get one (1) or more

failures, the entire lot should be rejected (or inspected 100%).

Printed: 13 november 2015

Owner: R&D/Div.1

QUALITY PROTOCOL : Q01-0314-1117

Created : 27-march-2015

Quality Protocol Rubber Design:

Procedure

All new purchase orders of the PTR31_MN__ rubber elements should be marked by the

purchase department of Rubber Design as Inspectie Status 2".

2. The products will be placed on stock and given the status Ongetest.

3. Quality inspection of Rubber Design will test elements according quality protocol.

4. After approval of the measurements by Quality inspection elements are tested by Division 1.

1.

Goods reception

1.

Confirm if the correct amount of items have been delivered.

Quality inspection

1.

2.

3.

4.

5.

Visual inspection of product*

- Batch size visual inspection of mountings confirming:

o No geometric deviations.

o No tears or other inconsistencies in any surface or edge.

o No excess material from molding.

o All markings present and correct.

Dimensional test report of product. Use the by Rubber Design provided layout for the

measurement report

- Confirming that PTR314MN__ is according to drawing P01-0314-005

- Confirming that PTR315MN__ is according to drawing P01-0315-318

Dynamic stiffness test according to Rubber Design test protocol confirming the dynamic

stiffness of the rubber elements*.

Confirm approval of batch to Division 1

Archive documents/reports in Quality Protocol File

Division 1

100% Static stiffness test according to Rubber Design test protocol confirming the Static

stiffness of the rubber elements.

2. Archive documents/reports.

3. Move elements to status "Vrije voorraad"

1.

* Random sample size as given in Table 1

Printed: 13 november 2015

Owner: R&D/Div.1

QUALITY PROTOCOL : Q01-0314-1117

Created : 27-march-2015

Quality inspection checklist Rubber Design

Supplier (company name)

__________________________________

Product:

__________________________________

Article code:

__________________________________

Drawing number:

__________________________________

Date:

__________________________________

PO number:

__________________________________

Number of pieces tested:

__________________________________

Batch size:

__________________________________

Visual inspection

Measurement report

Static tests

Dynamic tests

(check box if carried out)

(check box if carried out)

(check box if submitted)

(check box if carried out)

Sign below indicating that this checklist is filled out properly and truthfully.

Name:

Printed: 13 november 2015

Date:

Signature:

Owner: R&D/Div.1

You might also like

- Sae J200 PDFDocument62 pagesSae J200 PDFAhmet Hamamcıoğlu100% (4)

- SMT Generic Control PlanDocument3 pagesSMT Generic Control PlanPedro Lopez Rodriguez100% (1)

- Toyota Engineering Standard PDFDocument10 pagesToyota Engineering Standard PDFrinusNo ratings yet

- PR308 - 2+00+en - Invecchiamento BMWDocument10 pagesPR308 - 2+00+en - Invecchiamento BMWAnonymous 8Z2HZ5JP7100% (1)

- 1138-2009 - IEEE Standard For Testing and Performance For Optical Ground Wire (OPGW) For Use oDocument6 pages1138-2009 - IEEE Standard For Testing and Performance For Optical Ground Wire (OPGW) For Use ocat_rules17No ratings yet

- Toyota Engineering StandardDocument10 pagesToyota Engineering StandardAkash Kumar100% (2)

- Worksheet in SQ Checksheet Part1Document50 pagesWorksheet in SQ Checksheet Part1Jetesh Devgun100% (1)

- (A) Dimensions: (D) Cupping TestDocument5 pages(A) Dimensions: (D) Cupping Testanon_115606397100% (7)

- Blister PackingDocument2 pagesBlister PackingGovinder Kumar100% (1)

- Ppap ManualDocument79 pagesPpap ManualAhmet HamamcıoğluNo ratings yet

- Mastercool Air Conditioner Service ManualDocument2 pagesMastercool Air Conditioner Service ManualJubril Akinwande100% (1)

- Aetiology, Pathology and Management of Enterocutaneous FistulaDocument34 pagesAetiology, Pathology and Management of Enterocutaneous Fistularoselinekhadija100% (2)

- Case Study Julies BakeshopDocument3 pagesCase Study Julies BakeshopKristel Anne AquinoNo ratings yet

- Project Report On RTS Juice PlantDocument7 pagesProject Report On RTS Juice PlantEIRI Board of Consultants and PublishersNo ratings yet

- Quality Protocol SupplierDocument2 pagesQuality Protocol SupplierAhmet HamamcıoğluNo ratings yet

- Attachment #2 - Manufaturing Procedure Specification - Line Pipe CoatingDocument11 pagesAttachment #2 - Manufaturing Procedure Specification - Line Pipe CoatingLarry UbuNo ratings yet

- 1Document4 pages1Venu Gopal RaoNo ratings yet

- TMS Rubber Compound Spec 2Document2 pagesTMS Rubber Compound Spec 2vinny77No ratings yet

- SD-211 Guidance For The SGCC Quality Assurance Production TestingDocument5 pagesSD-211 Guidance For The SGCC Quality Assurance Production TestingAndrea MarquezNo ratings yet

- Third Party Inspection For Control PanelDocument6 pagesThird Party Inspection For Control PanelNedunuri.Madhav MurthyNo ratings yet

- Process Flow Diagram: 10-12-2011 Part NameDocument4 pagesProcess Flow Diagram: 10-12-2011 Part NameVenu Gopal RaoNo ratings yet

- INSTA SBC EN 13589-2 Sep 2009Document17 pagesINSTA SBC EN 13589-2 Sep 2009Kipodim100% (1)

- 101 24993-1e PDFDocument10 pages101 24993-1e PDFcristavalNo ratings yet

- Plastic Injection Mold Quality Inspection Checking List 2Document6 pagesPlastic Injection Mold Quality Inspection Checking List 2Shibu MohanNo ratings yet

- Quality Check 20141031Document3 pagesQuality Check 20141031harish puNo ratings yet

- Harness: PPE Inspection FormDocument1 pageHarness: PPE Inspection FormJUNIORMORGANNo ratings yet

- Sti - Is - 3589Document5 pagesSti - Is - 3589hhr2412No ratings yet

- Annexure A 1Document2 pagesAnnexure A 12eagyNo ratings yet

- Pre Shipment Inspection PDFDocument19 pagesPre Shipment Inspection PDFSaeed Ahmed SoomroNo ratings yet

- Crampons: PPE Inspection FormDocument1 pageCrampons: PPE Inspection FormJUNIORMORGANNo ratings yet

- Ford SpecificDocument7 pagesFord SpecificJulio ChagoyaNo ratings yet

- R05323 P 001a X009 0042 PDFDocument464 pagesR05323 P 001a X009 0042 PDFcquibajoNo ratings yet

- Sampling and Testing Procedures For Materials & Products For ConstructionDocument49 pagesSampling and Testing Procedures For Materials & Products For ConstructionN P Srinivasarao100% (1)

- Nuclear Power Corporation of India Limited: Schedule To Form Number C&MM 44 (A) 1/22 (A)Document4 pagesNuclear Power Corporation of India Limited: Schedule To Form Number C&MM 44 (A) 1/22 (A)hiren_mistry55No ratings yet

- Quality Manual: TGM IncorporatedDocument33 pagesQuality Manual: TGM Incorporatedcustro_mohaleNo ratings yet

- 3 3bb0aDocument7 pages3 3bb0aEleandro JoaquimNo ratings yet

- Quality PlanDocument3 pagesQuality PlanhjgajjarNo ratings yet

- Control Plan TemplateDocument3 pagesControl Plan TemplatePuneet SharmaNo ratings yet

- TS1-OIL Rev. UDocument7 pagesTS1-OIL Rev. UMangBedjoNo ratings yet

- Work Instruction Asslyxl PDFDocument2 pagesWork Instruction Asslyxl PDFPramod Bodne50% (2)

- Inspection Test Procedure ModelDocument8 pagesInspection Test Procedure ModelMahesh SuthaNo ratings yet

- LITHS1M1 Model 1M1 Filter HousingDocument0 pagesLITHS1M1 Model 1M1 Filter HousingcivodulNo ratings yet

- 10 Inspection PlanDocument3 pages10 Inspection PlanAmine ChahiNo ratings yet

- Chicksan Inspection ProcedureDocument9 pagesChicksan Inspection ProcedureBanu Stefan Adrian100% (7)

- IVR - 48-32-002501-Rev-01Document11 pagesIVR - 48-32-002501-Rev-01boc.dgofficeNo ratings yet

- TCCL IttihadforPrcrCmntsDocument22 pagesTCCL IttihadforPrcrCmntshisham1958No ratings yet

- Ti01f07a05 01enDocument5 pagesTi01f07a05 01enSiva ShankarNo ratings yet

- Bon-Ton Qa Inspection ManualDocument41 pagesBon-Ton Qa Inspection ManualYogesh KadianNo ratings yet

- Your Company Name 1680995-101 1680995-101 Bushing, Guide Slot E 2/1/2003 N/A 12/23/2005 0 John Smith Amy Millimen Jane Doe Bob Miller NameDocument20 pagesYour Company Name 1680995-101 1680995-101 Bushing, Guide Slot E 2/1/2003 N/A 12/23/2005 0 John Smith Amy Millimen Jane Doe Bob Miller Namekaran11deshmukhNo ratings yet

- PPE Inspection Form: Historical CheckDocument1 pagePPE Inspection Form: Historical CheckJUNIORMORGANNo ratings yet

- Supplier Training JTEKT Annual RevalidationsDocument12 pagesSupplier Training JTEKT Annual RevalidationsmehdiNo ratings yet

- High Pressure Iron Services 2Document8 pagesHigh Pressure Iron Services 2Asia BelmontNo ratings yet

- PETRO TCS Engineering Manual 682Document44 pagesPETRO TCS Engineering Manual 682paulm3565No ratings yet

- Procedure Casing Welding Steel Cast MaterialDocument4 pagesProcedure Casing Welding Steel Cast MaterialdethamrnNo ratings yet

- European Standard For Insulating Glass UnitsDocument7 pagesEuropean Standard For Insulating Glass UnitsKhurshed Alam IndiaNo ratings yet

- LIQUITAINER Paint SpecificationDocument28 pagesLIQUITAINER Paint Specificationpaulm3565No ratings yet

- 1138 2009 IEEE Standard For Testing and Performance For Optical Ground Wire OPGW For Use oDocument6 pages1138 2009 IEEE Standard For Testing and Performance For Optical Ground Wire OPGW For Use oJORGE EDUARDO TORRES HUAMANNo ratings yet

- Jig and Tool Instruction: Acceptance, Testing, Release and Inspection Marks of Special ToolingDocument8 pagesJig and Tool Instruction: Acceptance, Testing, Release and Inspection Marks of Special ToolingRafaelNo ratings yet

- Specific Rules For Nordic Certification in Accordance WithDocument16 pagesSpecific Rules For Nordic Certification in Accordance WithYUSUFNo ratings yet

- Solder Heat Resistance TestDocument3 pagesSolder Heat Resistance TestGopinathan BalakrishnanNo ratings yet

- Total Quality Process Control for Injection MoldingFrom EverandTotal Quality Process Control for Injection MoldingRating: 5 out of 5 stars5/5 (1)

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- CTV WT8344 Good-Vibrations enDocument9 pagesCTV WT8344 Good-Vibrations enAhmet HamamcıoğluNo ratings yet

- G Y in Propeller Shaft Installations: Rubber DesignDocument6 pagesG Y in Propeller Shaft Installations: Rubber DesignAhmet HamamcıoğluNo ratings yet

- CTV WT5556 Rotafrix Catalog enDocument44 pagesCTV WT5556 Rotafrix Catalog enAhmet HamamcıoğluNo ratings yet

- Kalıp Parlatma ÜrünleriDocument18 pagesKalıp Parlatma ÜrünleriAhmet HamamcıoğluNo ratings yet

- Katalog 3Document16 pagesKatalog 3Ahmet HamamcıoğluNo ratings yet

- Avl PDFDocument52 pagesAvl PDFAhmet HamamcıoğluNo ratings yet

- Technical Documentation Sheet LSDocument2 pagesTechnical Documentation Sheet LSAhmet HamamcıoğluNo ratings yet

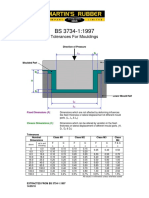

- Tolerances For MouldingsDocument1 pageTolerances For MouldingsAhmet HamamcıoğluNo ratings yet

- Documentation Sheet Steel Spring Isolator GeneralDocument2 pagesDocumentation Sheet Steel Spring Isolator GeneralAhmet HamamcıoğluNo ratings yet

- Documentation Sheet Steel Spring Isolator GeneralDocument2 pagesDocumentation Sheet Steel Spring Isolator GeneralAhmet HamamcıoğluNo ratings yet

- Documentation Sheet Steel Spring Isolator GeneralDocument2 pagesDocumentation Sheet Steel Spring Isolator GeneralAhmet HamamcıoğluNo ratings yet

- Documentation Sheet Steel Spring Isolator GeneralDocument2 pagesDocumentation Sheet Steel Spring Isolator GeneralAhmet HamamcıoğluNo ratings yet

- Documentation Sheet Steel Spring Isolator GeneralDocument2 pagesDocumentation Sheet Steel Spring Isolator GeneralAhmet HamamcıoğluNo ratings yet

- Technical Documentation Sheet SH2Document2 pagesTechnical Documentation Sheet SH2Ahmet HamamcıoğluNo ratings yet

- En Iso 1127Document2 pagesEn Iso 1127Ahmet HamamcıoğluNo ratings yet

- Documentation Sheet Steel Spring Isolator GeneralDocument2 pagesDocumentation Sheet Steel Spring Isolator GeneralAhmet HamamcıoğluNo ratings yet

- Documentation Sheet Steel Spring Isolator GeneralDocument2 pagesDocumentation Sheet Steel Spring Isolator GeneralAhmet HamamcıoğluNo ratings yet

- Sheet CM RD 114x GGGDocument2 pagesSheet CM RD 114x GGGAhmet HamamcıoğluNo ratings yet

- TN-4620190912122 Form21B Signed PDFDocument1 pageTN-4620190912122 Form21B Signed PDFDHEEN MEDICALSNo ratings yet

- Module 7: Health Care Delivery SystemDocument9 pagesModule 7: Health Care Delivery SystemDanz KieNo ratings yet

- Carbon & Its CompoundDocument13 pagesCarbon & Its CompoundNeeraj PoddarNo ratings yet

- Capinew Account June13Document7 pagesCapinew Account June13ashwinNo ratings yet

- Pop That PimpleDocument24 pagesPop That Pimpleapi-666592607No ratings yet

- VegDocument130 pagesVegAnanda PreethiNo ratings yet

- General Physics 1: ACTIVITY/ANSWER SHEET: Quarter 2Document1 pageGeneral Physics 1: ACTIVITY/ANSWER SHEET: Quarter 2Kashima KotaroNo ratings yet

- Environmental Geotechniques: Theories of Ion ExchangeDocument21 pagesEnvironmental Geotechniques: Theories of Ion ExchangeTenkurala srujanaNo ratings yet

- Sago Pudding - Recipes - Poh's KitchenDocument2 pagesSago Pudding - Recipes - Poh's KitchenXuxu TooNo ratings yet

- Barron's Bigbook Special WordDocument123 pagesBarron's Bigbook Special WordArif Al MamunNo ratings yet

- Electrical Commissioning Checklist Non LeedDocument7 pagesElectrical Commissioning Checklist Non Leedcaleb isukuruNo ratings yet

- A Review On Ultra High Performance Concrete Part II. Hydration, Microstructure and Properties PDFDocument10 pagesA Review On Ultra High Performance Concrete Part II. Hydration, Microstructure and Properties PDFNocifLyesNo ratings yet

- Stilboestrol Tablets MSDSDocument6 pagesStilboestrol Tablets MSDSIsaac lauricNo ratings yet

- Codes Standards RegulationsDocument11 pagesCodes Standards RegulationsEslNo ratings yet

- Parental/Guardian Permission and Liability Waiver Name of Student BirthDocument2 pagesParental/Guardian Permission and Liability Waiver Name of Student BirthlifeteenministryNo ratings yet

- Hydraulic and Pneumatic Power SystemsDocument52 pagesHydraulic and Pneumatic Power SystemsPokemon GoNo ratings yet

- Science G7 Q2 LP4Document13 pagesScience G7 Q2 LP4Lovely GuintoNo ratings yet

- BOQUILLASDocument2 pagesBOQUILLASEDUARDONo ratings yet

- Natural Rubber WikiDocument9 pagesNatural Rubber WikiMyra Wardati SNo ratings yet

- Planning and Facilities: Building StorageDocument31 pagesPlanning and Facilities: Building Storagequsai migdadiNo ratings yet

- Why Aws Is Even Better With CloudcheckrDocument7 pagesWhy Aws Is Even Better With CloudcheckrPardha SaradhiNo ratings yet

- Autoconceito ShavelsonDocument15 pagesAutoconceito ShavelsonJuliana SchwarzNo ratings yet

- MASB7 Construction Contract7Document3 pagesMASB7 Construction Contract7hyraldNo ratings yet

- CHINT Installation Operation Manual For Inverter of 50-60KTLDocument98 pagesCHINT Installation Operation Manual For Inverter of 50-60KTLr.pimentel.souzaNo ratings yet

- Calculating Parenteral FeedingsDocument5 pagesCalculating Parenteral FeedingsekramsNo ratings yet

- Effect of Bread Making Process On Aflatoxin LevelDocument8 pagesEffect of Bread Making Process On Aflatoxin LevelFaiza NoorNo ratings yet