Professional Documents

Culture Documents

Usda-Ars Western Regional Research Center Healthy Processed Foods Research Unit

Usda-Ars Western Regional Research Center Healthy Processed Foods Research Unit

Uploaded by

Erin WalkerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Usda-Ars Western Regional Research Center Healthy Processed Foods Research Unit

Usda-Ars Western Regional Research Center Healthy Processed Foods Research Unit

Uploaded by

Erin WalkerCopyright:

Available Formats

Solar Thermal Specialty Crop Drying Research at the

USDA Agricultural Research Service

Fatima S. Alleyne, Research General Engineer; Rebecca R. Milczarek, Research Agricultural Engineer

Healthy Processed Foods Research Unit

USDA-ARS Western Regional Research Center

Albany, California

Western Regional Research Center

USDA-ARS

The Agricultural Research Service (ARS) is the U.S. Department of

Agriculture's chief scientific research agency. Our job is finding solutions to

agricultural problems that affect Americans every day, from field to table.

Here are a few numbers to illustrate the scope of our organization:

800 research projects within 17 National Programs

2,100 scientists and post docs

$1.1 billion fiscal year 2009 budget

100 research locations including a few overseas

http://www.ars.usda.gov/AboutUs/AboutUs.htm

Healthy Processed Foods Research Unit

Solar thermal processing of specialty crops is a project that is part of the Healthy

Processed Foods Research Unit (HPFR) at the USDA-ARS WRRC location.

The mission of HPFR is to enhance the marketability and healthfulness of

agricultural commodities and processed products. Cereal grains, legumes, and

fruits and vegetables are the focus of this research. Both fundamental and

applied research approaches are used to solve problems and develop new

value-added products which will benefit the consumer, producer, economy and

environment. Important consideration is given to fundamental food properties,

nutritional attributes, and consumer preferences. Research approaches are

multidisciplinary.

California

WRRC

San Francisco

http://www.ars.usda.gov/pwa/wrrc/pfru

Motivations

Research Approach

Solar dehydration (drying) of crops is an ancient food preservation technology.

Previously, research in this area was primarily performed by academics in Africa and

South Asia; however, it is gaining renewed interest from U.S. food processors due to

the increasing cost of energy from fossil fuels and product variability using traditional

solar drying methods. These studies have three common characteristics:

Time-consuming prototyping of cabinet and solar collector (air heating unit)

Researchers physically construct a cabinet dryer and then determine the drying times of

various agricultural products within that dryer. Drying experiments can only be

performed during conducive times of the year.

Static treatment of material Once the crop is placed in the dryer, it is left in the

same location with no changes to processing conditions beyond natural shifts in

temperature due to changing insolation.

Construction materials selected for convenience Wood, sheet metal, and plastic

sheeting are the most often-used materials due to their low cost and ubiquity.

The overarching goal of ARSs program in this area is to develop solar or solar-assisted cabinet dryer designs optimized for a given

specialty crop* and location. We will do this by addressing the three shortfalls of the current research, as described at left. Our target

customers are small- and medium-sized specialty crop processors in the American West who currently dry their crops using natural gasfired cabinet dryers. In our experiments, we will

Test dryer designs using multiphysics modeling software, then construct prototypes We will develop a multiphysics computer

model of a simple dryer using the software package COMSOL Multiphysics. We will then validate the model against experimental runs

in a physical version of this dryer, and use the model to direct design of solar collectors, modifications to the cabinet, and possible

addition of an auxiliary component (e.g. fan) to create an active (forced convection) system.

Employ dynamic feedback and feedforward control of dryer configuration based on real-time measurements We cannot

control the weather; however, we can measure ambient temperature, humidity, insolation, etc. as well as the mass, temperature, etc. of

the product. This information will be utilized to adjust product location within the dryer, orientation of the solar collector, fan speed, etc.

to enable the most efficient use of the solar energy that is available at any given time and thereby, optimize drying conditions.

Select smart dryer construction materials to minimize drying time and improve product quality Current dryer construction

materials have suboptimal optical properties. Improving these properties, while keeping an eye on material costs, will shorten drying

time and improve product quality. We will also consider incorporating a thermal energy storage unit in the design to enable drying

outside of daylight hours. However, prior to implementation of the latter, certain parameters must be attained to ensure thermal

conditions are met to utilize the heat storage capacity of phase change materials.

Challenge 1: Multiphysics Modeling of the

Food/Dryer/Environment System

* Specialty crops include fruits, vegetables, nuts and other horticultural crops defined by the USDA Agricultural Marketing Service.

Our goal is to develop a robust, 3-dimensional model of the entire drying system, including the food

material, the dryer, and the environment immediately surrounding the dryer. Once validated against

experimental data, this model could be used to perform virtual experiments and test out refinements in

dryer design outside of the harvest season for a given specialty crop.

Progress To Date

Modeled temperature in and air flow through a bench-scale convection dehydrator.

Constructed outdoor solar drying cabinet with geometry that mirrors lab dehydrator.

Conducted full sponge-drying experiments with lab dehydrator.

Determined spatial variation in drying rate.

Conducted preliminary sponge-drying experiments with solar drying cabinet.

Measured multiple weather metrics (temperature, humidity, insolation, etc.) during drying experiments.

Time = 0

Slice: (K)

330

328

Time = 10

Slice: (K)

Slice: (K)

Time = 30

344

316

311

330

329

328

328

325

322

305

316

322

300

319

294

311

305

288

300

316

294

314

Benchtop Dehydrator and Close-up of Fan

Slice: (K)

331

330

339

333

328

322

327

326

325

324

323

323

312

289

COMSOL Model: Temperature Distribution at Center Tray at Time = 0 Seconds, 1 Second, 10 Seconds, and 30 Seconds

12:40 hours

Next Steps

Validate multiphysics model with experimental data from box-type solar cabinet using various optical

materials. (Fall 2014)

Collect additional data on sponge drying in box-type solar drying cabinet. (Fall 2014)

Add time-varying insolation to multiphysics model. (Spring 2015)

Model cabinet temperature in box-type cabinet dryer using location specific, time-varying insolation.

(Spring 2015)

Time = 1

321

11:40 hours

321

336

335

11:20 hours

320

320

330

10

320 K

321 K

315

315

336 K

320

310

310

325

315

18.5

305

16.5

Box-type Solar Thermal Dryer Design

as Modeled in COMSOL

(Units are in Inches)

300

305

310

300

305

300

295

295

295

COMSOL Model: Temperature Distribution at Peak Temperature Time = 12:40 hours (O), 11:40 hours (H), 11:20 Hours (R)

Absorptivity and Emissivity: Original (O) 0.2 and 0.8; Half-Half (H) 0.5 and 0.5; Reversed (R) 0.8 and 0.2

Challenge 2: Design a Feedback/Feedforward Dryer

Control System

Challenge 3: Determine Optimal Dryer Construction

Materials

Solar thermal drying of food crops is, fundamentally, a food processing unit operation. Unit operations

produce the best results when they are controlled by an appropriate feedback and/or feedforward

algorithm. Our team aims to develop modern control systems that will enable the most efficient use of the

solar energy that is available at any given time. Feedback control involves measurement of the system

state (product moisture content and product temperature, for example) and adjustment of independent

variables (fan speed, solar collector orientation, and so on) to bring the system state closer to a desired

setpoint. Feedforward control involves measurement of external disturbances (external temperature and

insolation, for example) and similar adjustment of independent variables to compensate for these

disturbances.

Throughout the literature we find a myriad of solar dryer designs: box-type, chimney, tunnel. However, to

date, very few attempts have been made to optimize the optical characteristics of solar dryer cabinet

construction materials. Previous research at the USDA-ARS and elsewhere has shown that laboratorygenerated light in various parts of the solar spectrum can aid in dehydration and can increase certain

nutritious components of specialty crops. Unfortunately, exposure to sunlight is also known to degrade

the quality of some fruit and vegetable products. Our team will test multiple solar spectrum-filtering

materials for their effects on drying time and product nutritional quality.

Progress To Date

Measured 2 years of microclimate data for the Albany, California solar dryer testing area.

Set up temperature data logging system for interior of solar dryer cabinet.

Next Steps

Set up humidity data logging system for interior of solar dryer cabinet. (Spring 2015)

Determine appropriate feedback and feedforward algorithms and software for implementation. (Spring

2015)

Configure lab dehydrator for dynamic feedback control. (Summer 2015)

Outfit solar dryer cabinet with auxiliary fan and heater. (Summer 2015)

Progress To Date

Conducted literature survey of postharvest effects of various parts of the solar spectrum on fruit and

vegetable crops.

Screened filter materials using a portable spectrophotometer.

Incorporated interchangeable filter materials into solar drying cabinet.

Conducted side-by-side comparisons of fruit dried under different filtered-sunlight environments.

phone: 510-559-5797

email: fatima.alleyne@ars.usda.gov

UV-blocking

Collaborations

IR-blocking

USDA-ARS is eager to collaborate with UC

Solar faculty, staff, and students on projects of

mutual interest. If you are interested in learning

more about USDA-ARSs solar thermal food

processing program, please contact

Dr. Fatima Alleyne or Dr. Rebecca Milczarek.

Researcher Rebecca Milczarek Removes

a Tray from the Box-Type Solar Dryer

Next Steps

Incorporate interchangeable optical materials into solar drying cabinet. (Fall 2014)

Confirm emissivity values of selected materials. (Winter 2014)

Conduct side-by-side comparisons of fruit dried under different solar drying conditions. (Spring 2015)

Clear

Fatima Alleyne, Ph.D.

USDA-ARS-WRRC-HPFR

800 Buchanan Street

Albany, CA 94710

Sponge Drying Experiment in Benchtop Dehydrators

Black

Black, IR

transmitting

Single Layer Solar Drying Unit using Different Cover Materials

Dried Fruit under Different Filtered-Sunlight Environments

Sponge Drying Experiment in Box-Type Solar Dryer

You might also like

- Bamboo Construction & TechniquesDocument43 pagesBamboo Construction & TechniquesSurabhi Shandil60% (15)

- Solar Dryer FYDP Proposal-1Document10 pagesSolar Dryer FYDP Proposal-1faizanNo ratings yet

- Solar Dryer ThesisDocument8 pagesSolar Dryer ThesisHelpWithWritingPaperSingapore100% (2)

- BE Project 2Document14 pagesBE Project 2MithileshNo ratings yet

- Solar Drying ThesisDocument6 pagesSolar Drying Thesisdwpeprje100% (1)

- 12.chapter 3Document18 pages12.chapter 3Vedhas WalimbeNo ratings yet

- Literature Review On Solar DryingDocument5 pagesLiterature Review On Solar Dryingc5rggj4c100% (1)

- Performance of A Forced Convection Solar Dryer Integrated With Latent Heat Storage UnitDocument7 pagesPerformance of A Forced Convection Solar Dryer Integrated With Latent Heat Storage UnitVishvesh T SNo ratings yet

- Design and Development of Solar Dryer Cabinet With Thermal Energy StorageDocument5 pagesDesign and Development of Solar Dryer Cabinet With Thermal Energy Storage11751175No ratings yet

- FYP Presentation-Fall 2019Document11 pagesFYP Presentation-Fall 2019Salman Tariq100% (1)

- Drying of Chilli Pepper Using A Solar Dryer With A Back-Up Incinerator Under Makurdi Humid ClimateDocument6 pagesDrying of Chilli Pepper Using A Solar Dryer With A Back-Up Incinerator Under Makurdi Humid ClimateAJER JOURNALNo ratings yet

- Experimental Studies of Drying of Potato Chips With A New Design of Solar DryerDocument5 pagesExperimental Studies of Drying of Potato Chips With A New Design of Solar DryerFrozen ElsaNo ratings yet

- PGD Project ProposalDocument4 pagesPGD Project Proposalenyi kennethNo ratings yet

- Design and Fabrication of Solar DryerDocument10 pagesDesign and Fabrication of Solar DryerAdeela Umar100% (1)

- Universidad Autónoma Del Estado de MéxicoDocument10 pagesUniversidad Autónoma Del Estado de MéxicoKathNo ratings yet

- Design and Evaluation of Combined Solar and Biomass Dryer For Small and Medium Enterprises For Developing CountriesDocument9 pagesDesign and Evaluation of Combined Solar and Biomass Dryer For Small and Medium Enterprises For Developing Countries11751175No ratings yet

- Development of A Mini CoolerDocument13 pagesDevelopment of A Mini Coolerreysinogbuhan1No ratings yet

- Refrigeration TrainerDocument12 pagesRefrigeration TrainerEugine BalomagaNo ratings yet

- Nergy and Nvironment: A Greenhouse Type Solar Dryer For Small-Scale Dried Food Industries: Development and DisseminationDocument16 pagesNergy and Nvironment: A Greenhouse Type Solar Dryer For Small-Scale Dried Food Industries: Development and Disseminationshribavan2373No ratings yet

- A Project Proposal On DesignDocument8 pagesA Project Proposal On DesignBlessine BlessineNo ratings yet

- Humiditu Controleed Solar Pepper DryerDocument5 pagesHumiditu Controleed Solar Pepper Dryergirish b bNo ratings yet

- Development of Solar Dryer Incorporated With Evacuated Tube CollectorDocument4 pagesDevelopment of Solar Dryer Incorporated With Evacuated Tube Collectormailsk123No ratings yet

- Solar Drying of Fruits, Vegetables, Spices, Medicinal Plants and Fish PDFDocument24 pagesSolar Drying of Fruits, Vegetables, Spices, Medicinal Plants and Fish PDFashisbhuniyaNo ratings yet

- Format New Edited 11 22Document25 pagesFormat New Edited 11 22balaji xeroxNo ratings yet

- Project DeliverableDocument6 pagesProject DeliverableDissanayakeNo ratings yet

- Irjet V5i1241 PDFDocument7 pagesIrjet V5i1241 PDF11751175No ratings yet

- Application of A Multi-Model Control With TS Fuzzy Switching To An Indirect Solar Dryer Operated in Natural ConvectionDocument9 pagesApplication of A Multi-Model Control With TS Fuzzy Switching To An Indirect Solar Dryer Operated in Natural Convectionhicham El FeroualiNo ratings yet

- Literature Review On Solar DryerDocument8 pagesLiterature Review On Solar Dryerc5m82v4x100% (1)

- Project On Construction of Solar DryerDocument31 pagesProject On Construction of Solar DryerK-Tech SystemsNo ratings yet

- Solar Food DehydatorDocument41 pagesSolar Food DehydatorRara GarciaNo ratings yet

- Design Construction and Evaluation of A Small Scale Solar DryerDocument15 pagesDesign Construction and Evaluation of A Small Scale Solar DryerDashaddNo ratings yet

- Drying Characteristics of Lemongrass in Solar Assisted Chemical Heat Pump DryerDocument5 pagesDrying Characteristics of Lemongrass in Solar Assisted Chemical Heat Pump DryerMuhammad Maulana SidikNo ratings yet

- Design Features of The DryerDocument8 pagesDesign Features of The DryersanthoshkumarNo ratings yet

- UniformityDocument34 pagesUniformityPUBG SORRYNo ratings yet

- Drying Kinetics of Tomato Slices in Solar CabinetDocument9 pagesDrying Kinetics of Tomato Slices in Solar CabinetNarcisse AkatiNo ratings yet

- Design and Performance Evaluation of Solar Dryer: P. K. Wankhade, Dr. R.S.Sapkal, Dr. V.S.SapkalDocument4 pagesDesign and Performance Evaluation of Solar Dryer: P. K. Wankhade, Dr. R.S.Sapkal, Dr. V.S.SapkalBahynorerama DpNo ratings yet

- Design, Development and Performance Evaluation of Solar Dryer With Mirror Booster For Red Chilli (Capsicum Annum)Document7 pagesDesign, Development and Performance Evaluation of Solar Dryer With Mirror Booster For Red Chilli (Capsicum Annum)seventhsensegroupNo ratings yet

- Rice Dryer ThesisDocument6 pagesRice Dryer Thesismaureennonweilertulsa100% (2)

- 13 Ijasrdec201813Document6 pages13 Ijasrdec201813TJPRC PublicationsNo ratings yet

- 1 PDFDocument8 pages1 PDFmohsin razaNo ratings yet

- Solar Vaccine StorageDocument18 pagesSolar Vaccine StorageKiran SatputeNo ratings yet

- Performance Evaluation of A Developed Multipurpose Solar DryerDocument8 pagesPerformance Evaluation of A Developed Multipurpose Solar DryerEditor IJTSRDNo ratings yet

- SolartrocknungDocument9 pagesSolartrocknungrichard.schumacherNo ratings yet

- Project Proposal: Innovative Solar Dryer For Agricultural CropsDocument11 pagesProject Proposal: Innovative Solar Dryer For Agricultural CropsChristine Joy S Ortigas100% (2)

- Cocoa Solar Dryer ProjectDocument4 pagesCocoa Solar Dryer Projectiky77No ratings yet

- Chilly Tunnel DryingDocument3 pagesChilly Tunnel Dryingdeepakmehta2812No ratings yet

- Performance Analysis of A Solar DryerDocument11 pagesPerformance Analysis of A Solar DryerSerge KewouNo ratings yet

- Low Cost Material Used To Construct Effective Box Type Solar DryerDocument7 pagesLow Cost Material Used To Construct Effective Box Type Solar DryerndvprsdNo ratings yet

- Mechanical Design of Smart Solar Tunnel DryerDocument5 pagesMechanical Design of Smart Solar Tunnel DryerashisbhuniyaNo ratings yet

- Cold StoresDocument24 pagesCold StoresbassouadNo ratings yet

- How Contextual Insights Improve Reproducibility in Experimental ResearchDocument9 pagesHow Contextual Insights Improve Reproducibility in Experimental ResearchCao Minh TríNo ratings yet

- Utilization of Renewable Energy For Agriculture Sector: January 2016Document5 pagesUtilization of Renewable Energy For Agriculture Sector: January 2016vishalNo ratings yet

- literatrue review4Document14 pagesliteratrue review4vasanthamuruganrNo ratings yet

- Design and Construction of A Solar Dryer For MangoDocument8 pagesDesign and Construction of A Solar Dryer For MangoIboyaima singhNo ratings yet

- Development of A Solar-Biomass Integrated Drying System For Spice CropsDocument30 pagesDevelopment of A Solar-Biomass Integrated Drying System For Spice CropsSantosh AngadiNo ratings yet

- PHD ProposalDocument7 pagesPHD ProposalJohn Taulo100% (1)

- Mathematical Modeling of Solar Drying Systems: C Ajaymugundan 202119006 M.Tech Chemical Engineering 3 SemesterDocument7 pagesMathematical Modeling of Solar Drying Systems: C Ajaymugundan 202119006 M.Tech Chemical Engineering 3 SemesterAjayMugundan ChandranNo ratings yet

- Geothermal Energy: From Theoretical Models to Exploration and DevelopmentFrom EverandGeothermal Energy: From Theoretical Models to Exploration and DevelopmentNo ratings yet

- Career as an Air Conditioning TechnicanFrom EverandCareer as an Air Conditioning TechnicanRating: 5 out of 5 stars5/5 (2)

- Blooms in Glass : Unveiling the Secrets of Greenhouse HorticultureFrom EverandBlooms in Glass : Unveiling the Secrets of Greenhouse HorticultureNo ratings yet

- Reaction Pathways and Mechanisms in Thermocatalytic Biomass Conversion IIDocument206 pagesReaction Pathways and Mechanisms in Thermocatalytic Biomass Conversion IIErin WalkerNo ratings yet

- English For Ethiopia: Student Textbook Grade 1 Book 2Document111 pagesEnglish For Ethiopia: Student Textbook Grade 1 Book 2Erin Walker97% (29)

- Workbook On The Epistle To The: HebrewsDocument36 pagesWorkbook On The Epistle To The: HebrewsErin WalkerNo ratings yet

- English For Ethiopia: Student Textbook Grade 2 Book 1Document230 pagesEnglish For Ethiopia: Student Textbook Grade 2 Book 1Erin WalkerNo ratings yet

- Course Materials: TextDocument32 pagesCourse Materials: TextErin WalkerNo ratings yet

- MATH408: Probability & Statistics Summer 1999 Week 1Document54 pagesMATH408: Probability & Statistics Summer 1999 Week 1Erin WalkerNo ratings yet

- (Ray C. Stedman, Haddon W. Robinson, Grant R. Osbo (B-Ok - Xyz) PDFDocument94 pages(Ray C. Stedman, Haddon W. Robinson, Grant R. Osbo (B-Ok - Xyz) PDFErin WalkerNo ratings yet

- Review On Factors Which Affect Coffee (Coffea Arabica L.) Quality in South Western, EthiopiaDocument8 pagesReview On Factors Which Affect Coffee (Coffea Arabica L.) Quality in South Western, EthiopiaErin WalkerNo ratings yet

- Arriaga 10a PDFDocument7 pagesArriaga 10a PDFErin WalkerNo ratings yet

- Maheshwari 1996-InfiltrometerDocument7 pagesMaheshwari 1996-InfiltrometerErin WalkerNo ratings yet

- Ergonomic DesignDocument132 pagesErgonomic DesignErin WalkerNo ratings yet

- Hand Pump Spare Part ShopsDocument1 pageHand Pump Spare Part ShopsErin WalkerNo ratings yet

- SET Manual English 08 PDFDocument77 pagesSET Manual English 08 PDFErin Walker0% (1)

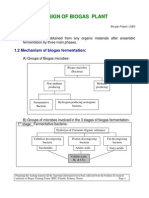

- Publications - Design Biogas PlantDocument12 pagesPublications - Design Biogas Planttssa100% (15)

- Country Pasture/Forage Resource Profiles: by Francisco A. MoogDocument23 pagesCountry Pasture/Forage Resource Profiles: by Francisco A. MoogAl PavillonNo ratings yet

- Wildlife Fact File - Birds - Pgs. 91-100Document20 pagesWildlife Fact File - Birds - Pgs. 91-100ClearMind84No ratings yet

- Spices ExportsDocument70 pagesSpices ExportsDiwakar TiwariNo ratings yet

- C Sec cp1Document212 pagesC Sec cp1Piyush BishnoiNo ratings yet

- 1st Day PRADocument19 pages1st Day PRARudra GoudNo ratings yet

- Punt Sag 2014Document22 pagesPunt Sag 2014Arvidechment Ëç TNo ratings yet

- Traditional Three (5) Trento, Agusan Del Sur: Scheme of Practice No. of Farmers Interviewed Farm LocationDocument24 pagesTraditional Three (5) Trento, Agusan Del Sur: Scheme of Practice No. of Farmers Interviewed Farm Locationsheil.cogayNo ratings yet

- Catalago Paradise SeedsDocument16 pagesCatalago Paradise SeedsJeanCarlosKrausNo ratings yet

- New Forest Fact File: Timber Production and UsesDocument5 pagesNew Forest Fact File: Timber Production and UsesLuis LacsonNo ratings yet

- Par Veen 2002Document14 pagesPar Veen 2002Enamul Hoque TauheedNo ratings yet

- Cotton ReportDocument21 pagesCotton Reportprince24100% (1)

- First Quarter Exam in Tle 7Document3 pagesFirst Quarter Exam in Tle 7Mark Gilbert TandocNo ratings yet

- Biology Mock Paper IGCSEDocument19 pagesBiology Mock Paper IGCSEyelloworangesNo ratings yet

- Legumes - Post Harvest TechnologyDocument7 pagesLegumes - Post Harvest TechnologyAsquare Cepl100% (1)

- Soil Mech II - Plate No. 4Document8 pagesSoil Mech II - Plate No. 4Angeline PinonNo ratings yet

- Chinese CuisineDocument22 pagesChinese Cuisinealejandro jean0% (1)

- Breeding Holstein or NRF in AlbaniaDocument7 pagesBreeding Holstein or NRF in AlbaniabicokuyNo ratings yet

- Pathway To Prosperity: Make Agriculture Profitable Improve Farmer Livelihoods Reduce PovertyDocument4 pagesPathway To Prosperity: Make Agriculture Profitable Improve Farmer Livelihoods Reduce PovertyChukwudi Eyeiwunmi ObiriNo ratings yet

- Commonwealth Act No 141Document59 pagesCommonwealth Act No 141Daniel PioquintoNo ratings yet

- Potato KZ Orods TfuDocument4 pagesPotato KZ Orods TfuRed DiggerNo ratings yet

- I.G.P. MahoganyDocument10 pagesI.G.P. MahoganyAdor Isip100% (1)

- 11 Geography Notes 22 Soils PDFDocument4 pages11 Geography Notes 22 Soils PDFsusmita sadhukhanNo ratings yet

- Valeriana Jatamansi DC.Document5 pagesValeriana Jatamansi DC.TusharNo ratings yet

- Identification of Directions For Yield Effect in AgricultureDocument3 pagesIdentification of Directions For Yield Effect in AgriculturesnehashbioinfoNo ratings yet

- Rubus EllipticusDocument5 pagesRubus EllipticusdancercelNo ratings yet

- A Study On Awareness, Purchase Benefits and Satisfaction Level Towards Crop InsuranceDocument8 pagesA Study On Awareness, Purchase Benefits and Satisfaction Level Towards Crop Insurancekeenu23No ratings yet

- Group P2 - HarvesterDocument14 pagesGroup P2 - HarvesterHarshit Bhattaram100% (1)

- Assignment On FertilizersDocument8 pagesAssignment On Fertilizerspurti_npk94220% (1)

- Auto Motives For The Farm Sector Auto Motives of TheDocument1 pageAuto Motives For The Farm Sector Auto Motives of TheSansarwal JattNo ratings yet