Professional Documents

Culture Documents

LDPE

LDPE

Uploaded by

OkePreciousEmmanuelCopyright:

Available Formats

You might also like

- A Requiem To Mother EarthDocument5 pagesA Requiem To Mother EarthSandra SabuNo ratings yet

- Quantification of The Maleic Anhydride Grafted Onto Polypropylene by Chemical and Viscosimetric Titrations, and FTIR Spectros PDFDocument11 pagesQuantification of The Maleic Anhydride Grafted Onto Polypropylene by Chemical and Viscosimetric Titrations, and FTIR Spectros PDFThinh DangNo ratings yet

- Lesson 30. Thermoplastic and Thermosetting PolymersDocument11 pagesLesson 30. Thermoplastic and Thermosetting PolymersNizar AbrorNo ratings yet

- Alumina (Al2O3) Electrical Insulators - Properties and Applications by Precision CeramicsDocument3 pagesAlumina (Al2O3) Electrical Insulators - Properties and Applications by Precision CeramicsRing MasterNo ratings yet

- Measuring Thermal Crystallinity in PET: Spe Antec Indianapolis 2016Document5 pagesMeasuring Thermal Crystallinity in PET: Spe Antec Indianapolis 2016Silviani SilvyNo ratings yet

- Chapter 6 Work, Energy and PowerDocument12 pagesChapter 6 Work, Energy and PowerZhu Jiankun100% (1)

- Airport Literature StudyDocument15 pagesAirport Literature StudySoundar Rajan100% (2)

- Structure Loadbearing Crosswall PDFDocument41 pagesStructure Loadbearing Crosswall PDFSKhandelwalNo ratings yet

- POLYPROPYLENE I Thesis (Final)Document8 pagesPOLYPROPYLENE I Thesis (Final)falmubaddelNo ratings yet

- Characterization and Treatments of Pineapple Leaf PDFDocument71 pagesCharacterization and Treatments of Pineapple Leaf PDFRekki StgNo ratings yet

- Binders: 1. Compaction Behaviour of Organic Binders in Alumina Ceramics (PVA & PEG) General FactsDocument13 pagesBinders: 1. Compaction Behaviour of Organic Binders in Alumina Ceramics (PVA & PEG) General FactsPranav KumarNo ratings yet

- Mold SinkmarkDocument16 pagesMold SinkmarkharryNo ratings yet

- 1.PPT II Plastics Processing Technology II 20 222 wtb2654Document1 page1.PPT II Plastics Processing Technology II 20 222 wtb2654Raj ThakurNo ratings yet

- Injection Molded Part Problems & Solutions With: SkillbuilderDocument2 pagesInjection Molded Part Problems & Solutions With: SkillbuilderКонстантин ГавриловNo ratings yet

- Structural Composites or Layered CompositesDocument3 pagesStructural Composites or Layered CompositesPritam100% (1)

- StainingDocument5 pagesStainingyuppie_raj2175No ratings yet

- Electrical Properties of Plastics: Sachin C S PGDDocument19 pagesElectrical Properties of Plastics: Sachin C S PGDSarumathiNo ratings yet

- Mem671 Case Study March 2023Document11 pagesMem671 Case Study March 2023AIMAN ASYRAAF BIN ROSLANNo ratings yet

- Polyethylene Properties - VinidexDocument8 pagesPolyethylene Properties - VinidexalexNo ratings yet

- Corona Film Pada Bopp PDFDocument6 pagesCorona Film Pada Bopp PDFNuril HidayatiNo ratings yet

- D 1694 - 95 R00 - Rde2otq - PDFDocument4 pagesD 1694 - 95 R00 - Rde2otq - PDFAndre CasteloNo ratings yet

- Waste Management: Yasser ZareDocument7 pagesWaste Management: Yasser ZarebokugairuNo ratings yet

- Cerium Doped HydroxyapatiteDocument16 pagesCerium Doped Hydroxyapatitekelvinhoh83No ratings yet

- Matrix MaterialDocument51 pagesMatrix MaterialA-13-M Ibrahim OMARNo ratings yet

- Analisis Sterategi Pemasaran Marmer (CITATAH)Document12 pagesAnalisis Sterategi Pemasaran Marmer (CITATAH)abdul qodirNo ratings yet

- Bicomponent FiberDocument2 pagesBicomponent FiberAshishn ThakurNo ratings yet

- Unit-Iii MANUFACTURING METHODS: Autoclave, Tape Production, Moulding Methods, FilamentDocument13 pagesUnit-Iii MANUFACTURING METHODS: Autoclave, Tape Production, Moulding Methods, FilamentSaisurendra VeerlaNo ratings yet

- Internal MixerDocument5 pagesInternal MixerFaisal IqbalNo ratings yet

- Characteristics, Applications and Processing of Polymers Chapter 15Document53 pagesCharacteristics, Applications and Processing of Polymers Chapter 15tjandelkier100% (1)

- DLVO Theory PDFDocument7 pagesDLVO Theory PDFshashank mishraNo ratings yet

- Zeus Weathering of PlasticsDocument7 pagesZeus Weathering of PlasticsDiego Fernado AvendañoNo ratings yet

- Cerium OxideDocument5 pagesCerium Oxiderrivera7396No ratings yet

- NYLON 6,6 (Nylon 6) : OverviewDocument4 pagesNYLON 6,6 (Nylon 6) : OverviewKaruppiah VigneshNo ratings yet

- Ha SpongeDocument45 pagesHa SpongeSantoso NugrohoNo ratings yet

- Comparison of Jute Fiber Over Glass FibeDocument5 pagesComparison of Jute Fiber Over Glass FibeBobby LupangoNo ratings yet

- Biomaterials and Implants (Bmeg3183) 2.1 Metallic BiomaterialDocument50 pagesBiomaterials and Implants (Bmeg3183) 2.1 Metallic BiomaterialZeynu Kulizeyn100% (1)

- Polymer Melt Spin Pack FiltrationDocument11 pagesPolymer Melt Spin Pack FiltrationbheenwaramNo ratings yet

- NetShape MIM Design GuideDocument13 pagesNetShape MIM Design Guidegnk68No ratings yet

- Rheological Study of The Plasticizer On Fusion Processes of PVC Plastisol PDFDocument8 pagesRheological Study of The Plasticizer On Fusion Processes of PVC Plastisol PDFvampireheart_soulNo ratings yet

- Naoki Ota 1B 022216Document13 pagesNaoki Ota 1B 022216MagsNo ratings yet

- PPO SlideDocument29 pagesPPO SlideRadhashyam GiriNo ratings yet

- RadiciPlastics Poliammidi Feb2014 WebDocument28 pagesRadiciPlastics Poliammidi Feb2014 WebFolpoNo ratings yet

- 20 Faust Porcelain Vitreous EnamelsDocument9 pages20 Faust Porcelain Vitreous Enamelsyanda prNo ratings yet

- Design Guide DSM GuideDocument0 pagesDesign Guide DSM GuideDavid García SalvatierraNo ratings yet

- STruture and Properties of PolymersDocument35 pagesSTruture and Properties of PolymersWasif Razzaq100% (1)

- Silicon CarbideDocument5 pagesSilicon Carbiderockeysuseelan100% (2)

- Casting MethodDocument15 pagesCasting MethodGabriela Maira Sanches VolpiNo ratings yet

- CMP in Semiconductor ManufacturingDocument8 pagesCMP in Semiconductor Manufacturingjana kNo ratings yet

- De AssignmentDocument9 pagesDe AssignmentManish MohapatraNo ratings yet

- Methanol SimulationDocument9 pagesMethanol SimulationMaria Jose TorresNo ratings yet

- Accelerated Weathering Test Conditions and Procedures For Bituminous Materials (Fluorescent UV, Water Spray, and Condensation Method)Document3 pagesAccelerated Weathering Test Conditions and Procedures For Bituminous Materials (Fluorescent UV, Water Spray, and Condensation Method)Satya kaliprasad vangaraNo ratings yet

- The Pultrusion Process PDFDocument2 pagesThe Pultrusion Process PDFSan SvsNo ratings yet

- Synthesis and Property Comparison of Silicone PolymersDocument3 pagesSynthesis and Property Comparison of Silicone PolymersDaniel RodmanNo ratings yet

- AntimicrobialDocument6 pagesAntimicrobialmniederer5268No ratings yet

- Compression MouldingDocument15 pagesCompression MouldingPradeep MahalikNo ratings yet

- Squeeze Casting - An Overview PDFDocument9 pagesSqueeze Casting - An Overview PDFDian Try SaputriNo ratings yet

- Solidification ShrinkageDocument4 pagesSolidification ShrinkagesubavlNo ratings yet

- 6830 en 7 Myths About PVC DebunkedDocument5 pages6830 en 7 Myths About PVC DebunkedNishi JhaNo ratings yet

- Bioplastics: Chemistry Investigatory ProjectDocument16 pagesBioplastics: Chemistry Investigatory ProjectDhanyaa vaitheeswaranNo ratings yet

- Functional and Physical Properties of Polymer NanocompositesFrom EverandFunctional and Physical Properties of Polymer NanocompositesAravind DasariNo ratings yet

- Comparing Effect of Adding LDPE, PP, PMMA On The Mechanical Properties of Polystyrene (PS)Document12 pagesComparing Effect of Adding LDPE, PP, PMMA On The Mechanical Properties of Polystyrene (PS)Jawad K. OleiwiNo ratings yet

- Project PaperDocument7 pagesProject PaperSandeep KulharNo ratings yet

- Effect of EPDM As A Compatibilizer On Mechanical Properties and Morphology of PP/LDPE BlendsDocument13 pagesEffect of EPDM As A Compatibilizer On Mechanical Properties and Morphology of PP/LDPE BlendsOumaima BenNo ratings yet

- The Effects of Epoxy Resin Nano ParticleDocument29 pagesThe Effects of Epoxy Resin Nano ParticleWellington C. de AraujoNo ratings yet

- Recycling Plastic 3Document7 pagesRecycling Plastic 3OkePreciousEmmanuelNo ratings yet

- Chemical Engineering Department Ahmadu Bello University, ZariaDocument2 pagesChemical Engineering Department Ahmadu Bello University, ZariaOkePreciousEmmanuelNo ratings yet

- CHEN505 Note 1Document6 pagesCHEN505 Note 1OkePreciousEmmanuelNo ratings yet

- Chapter Four Risk Assessment of NLNGDocument8 pagesChapter Four Risk Assessment of NLNGOkePreciousEmmanuelNo ratings yet

- TinyMobileRobots TinySurveyor FlyerDocument4 pagesTinyMobileRobots TinySurveyor FlyerfelipeNo ratings yet

- RPT CasesDocument13 pagesRPT CasesSNLTNo ratings yet

- Supplement Guide Memory FocusDocument41 pagesSupplement Guide Memory Focusgogov.digitalNo ratings yet

- Exit Poll CedatosDocument1 pageExit Poll CedatosEcuadorenvivoNo ratings yet

- Costing By-Product and Joint ProductsDocument36 pagesCosting By-Product and Joint ProductseltantiNo ratings yet

- Cne CatalogoDocument4 pagesCne CatalogoPaulo SergioNo ratings yet

- Transport Phenomena: τ =μ dv dyDocument2 pagesTransport Phenomena: τ =μ dv dySYED ASGHAR ALI SULTANNo ratings yet

- MEP MyanmarDocument27 pagesMEP Myanmarempty87No ratings yet

- Low Noise Amplifier Basics: by V. M. García-ChocanoDocument4 pagesLow Noise Amplifier Basics: by V. M. García-ChocanoPranjal Jalan100% (1)

- Stages of SleepDocument2 pagesStages of SleepCamilia Hilmy FaidahNo ratings yet

- LAB 2 - Running Speed (Method 2) OEL 1Document3 pagesLAB 2 - Running Speed (Method 2) OEL 1ZULFAQAR BIN MOHAMMAD NIZAMNo ratings yet

- Surveillance, Torture and Contr - Rosanne Marie SchneiderDocument135 pagesSurveillance, Torture and Contr - Rosanne Marie SchneiderMagic MikeNo ratings yet

- Ultimate GuideDocument11 pagesUltimate GuideIgor SucevicNo ratings yet

- 5 25 17 Migraines PowerPointDocument40 pages5 25 17 Migraines PowerPointSaifi AlamNo ratings yet

- SSP 604 - Audi 30l v6 Tdi Biturbo Engine EngDocument23 pagesSSP 604 - Audi 30l v6 Tdi Biturbo Engine Engfrancois.garcia31100% (1)

- Delhi Public School, Greater Noida Pre-Mid Term Exam Class X Mathematics SESSION 2020-21 Set 1 MM: 40 Time: 1.5 Hours InstructionsDocument3 pagesDelhi Public School, Greater Noida Pre-Mid Term Exam Class X Mathematics SESSION 2020-21 Set 1 MM: 40 Time: 1.5 Hours InstructionsAnishikaNo ratings yet

- Filipino BasicDocument21 pagesFilipino BasicReiko Nakayama100% (1)

- Credit Card Fraud Detection Using Improved Deep Learning ModelsDocument22 pagesCredit Card Fraud Detection Using Improved Deep Learning ModelsrauhNo ratings yet

- DC Jow Ga Beginner CurriculumDocument2 pagesDC Jow Ga Beginner CurriculumKevinNo ratings yet

- Control of Spinal Anesthesia-Induced Hypotension in Adults - PMCDocument14 pagesControl of Spinal Anesthesia-Induced Hypotension in Adults - PMCAkash SharmaNo ratings yet

- Advanced Landscape DesignDocument10 pagesAdvanced Landscape DesignSomhita DasNo ratings yet

- Bronchial Cancer Case StudyDocument3 pagesBronchial Cancer Case StudyericaNo ratings yet

- SONTU Flat Panel Dectector CatalogDocument6 pagesSONTU Flat Panel Dectector CatalogWajahat SheikhNo ratings yet

- Neisseria Gonorrhoeae and Neisseria MeningitidesDocument3 pagesNeisseria Gonorrhoeae and Neisseria MeningitidesAmador Gielas0% (1)

- Data Sheet USB5 II 2019 05 ENDocument1 pageData Sheet USB5 II 2019 05 ENJanne LaineNo ratings yet

- Chapter8-Campuran Pada Tingkat Molekuler - Part 1Document58 pagesChapter8-Campuran Pada Tingkat Molekuler - Part 1Uswatun KhasanahNo ratings yet

LDPE

LDPE

Uploaded by

OkePreciousEmmanuelCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LDPE

LDPE

Uploaded by

OkePreciousEmmanuelCopyright:

Available Formats

Polymer Testing 24 (2005) 468473

www.elsevier.com/locate/polytest

Material Properties

Tensile and impact behavior of polypropylene/low density

polyethylene blends

R. Strapasson, S.C. Amico*, M.F.R. Pereira, T.H.D. Sydenstricker

Mechanical Engineering Department, Federal University of Parana (UFPR), P.O. Box 19.011, 81.531-990 Curitiba-PR, Brazil

Received 18 November 2004; accepted 7 January 2005

Abstract

Blends of polypropylene (PP) and low-density polyethylene (LDPE) may contribute to make recycling more economically

attractive. The aim of this work was to make PP/LDPE blends (0/100, 25/75, 50/50, 75/25 and 100/0 w/w) via injection molding

carried out under various injection temperatures and to evaluate their tensile and impact properties. The blends yielded tensile

stressstrain curves very dependent on their composition, especially regarding elongation at break and the presence of necking.

An irregular behavior for the 50/50 w/w blend is reported. Nevertheless, a linear variation of the yield strength and elastic

modulus with the blend composition was observed. The behavior of the blend was also very dependent on processing

temperature. Addition of 25% of LDPE to the PP may result in similar degradation of its mechanical properties to that caused by

a 10 8C processing temperature increase. Statistical analyses proved valuable when reporting results concerning blends.

q 2005 Elsevier Ltd. All rights reserved.

Keywords: Low-density polyethylene; Polypropylene; Blends; Tensile and impact properties

1. Introduction

As the economy achieves global status, many factors

regarding the competitiveness of a nation come under

investigation. More recently, together with important areas

such as technology advancement and technology transfer,

issues related to sustainable development and environment

preservation are receiving increasing attention from the

world community.

Advantages of the mechanical recycling of polymers

include reduction of oil and energy consumption compared

with the synthesis of virgin polymers, reduced disposal of

plastic waste in municipal garbage and generation of

employment and income. The recycling of industrial scrap

is an ongoing successful practice due to the low level of

contamination. However, recycling of municipal plastic

waste is often an arduous task due to the fact that this

* Corresponding author. Tel.: C55 41 361 3430; fax: C55 41 361

3129.

E-mail address: amico@ufpr.br (S.C. Amico).

0142-9418/$ - see front matter q 2005 Elsevier Ltd. All rights reserved.

doi:10.1016/j.polymertesting.2005.01.001

material is usually a mixture of several polymers, which

makes processing more difficult and also limits the number

of potential applications [1].

The most abundant plastics in Brazilian municipal waste

are polypropylene (PP), poly(ethylene-terephthalate) and

polyethylene (PE), the latter being available in different

grades such as low density polyethylene (LDPE), linear low

density polyethylene (LLDPE) and high density polyethylene (HDPE).

A few methods have been used to classify plastics from

municipal post-consumer waste. With the flotation method,

two fractions are obtained: a lighter fraction, floating on

water, and a heavier fraction. The former is essentially

constituted of LDPE, HDPE and PP [2], polyolefins that

exhibit of similar density. It is uneconomic to separate them

using alcohol solutions in a subsequent stage. Thus, the

usual practice in small recycling units in Brazil is to

indiscriminately mix different amounts of PE and PP during

recycling, leading to incompatible blends of varying and

poor properties.

Aiming at good performance materials, it is important to

consider processing conditions, blend composition and its

R. Strapasson et al. / Polymer Testing 24 (2005) 468473

behavior in the solid state from the melt. While the

crystallization of a homopolymer is controlled by nucleation, spherulite growth, rate of cooling and degree of super

cooling, crystallization behavior of polymer blends is more

complex due to the existence of a second component,

usually resulting in an incompatible mixture. Blends of PP

and LLDPE (20/80 w/w), for instance, are partially miscible

and its crystallization is controlled by nucleation and

diffusion [3].

The incompatibility between LDPE and PP has already

been reported by various authors [4,5], following

microscopy and calorimetric studies. In LDPE rich blends,

a heterogeneous PP dispersion in the LDPE matrix produces

two phases in the melt. The low interfacial adhesion

between the phases is responsible for a decrease in

mechanical properties especially related to its morphology,

including impact strength, strain at break and ductile to

brittle transition. According to Shanks [6], the immiscibility

between the phases makes the rule of mixtures ineffective in

predicting some properties of interest.

To overcome this difficulty, the use of various coupling

agents have been reported. Amongst others [79], Yang [10]

showed that the addition of a commercial ethylene/

propylene block copolymer improved the ductility of

LDPE/PP blends, particularly for PP rich blends. Bertin

[5] studied and characterized virgin and recycled LDPE/PP

blends and the use of compatilizing agents, such as

ethylene-propylene-diene monomer copolymer (EPDM) or

PE-g (2-methyl-1,3-butadiene)graft copolymer, to enhance

their impact strength and elongation at break. Although this

may solve the compatibility problem, the use of compatibilizers adds cost to the recycled product, usually resulting

in loss of interest from the recycling sector.

In this work, the evaluation of tensile and impact

properties of PP/LDPE blends was carried out to investigate

the composition range for better mechanical performance

and also to define the impact of PE addition on PP for

composition adjustment of blends used in a commercial

recycling unit in Almirante Tamandare/PR, Brazil.

469

machine (Model DL10000), in general accordance with

ASTM D638. Data for yield strength, elastic modulus and

elongation at break were obtained in tests carried out at a

crosshead speed of 5 mm/min. For low elongations, an

EMIC extensometer having a gage length of 25 mm was

used. Impact tests were performed on a PANTEC equipment

(model PW-4), in general accordance with ASTM D256.

Between 10 and 20 measurements were taken for each

experimental condition, and the reported results include the

mean values and their standard deviations.

The statistical analysis of variance of tensile and impact

results has been carried out using commercial software. A

one-way ANOVA and a series of Tukey HSD post hoc were

used to check for statistical difference among groups (for

p!0.05).

3. Results and discussion

3.1. Tensile tests

2. Materials and methods

The stressstrain curves for the various blends injected at

170, 180, 190 and 200 8C are shown in Figs. 14,

respectively. The 170 and 200 8C curves for the PP0 (pure

LDPE) were not included since there were flow difficulties

relating to the high viscosity of the melt for the former and

severe degradation for the latter, both resulting in nonhomogeneous test specimens.

Analysis of these figures shows the importance of

controlling the injection temperature, for example,

elongation at break for pure polypropylene (PP100)

decreases from 650% to less than 10%, when the

temperature reaches 190 8C, indicating severe degradation.

In fact, Figs. 3 and 4 demonstrate PP degradation with

severe changes on curve profiles and on yielding. Therefore,

the retrieved data for the 190 and 200 8C injection

temperature should not be directly compared to data

obtained for the other injection temperatures.

Observation of these figures also shows for the PP50 a

very distinct behavior. Yielding is not seen for any injection

temperature, and very low yield strength and elongation at

break are found, in comparison to the other blends.

Polypropylene (H301-Braskem) and low density polyethylene (BC 818-Braskem) were used. The specific gravity

of the PP is 0.905 and that of the LDPE is 0.918 g/cm3, with

melt flow index of 10.0 and 7.5 g/10 min, respectively.

Pure PP, pure LDPE and their blends were processed in

an injection-molding machine with various PP/LDPE

weight contents, namely 100/0, 75/25, 50/50, 25/75 and

0/100. These blends are called PP100, PP75, PP50, PP25

and PP0, respectively, throughout the text, and each of them

was processed at several injection temperatures (170, 180,

190 and 200 8C).

For the evaluation of the blend mechanical properties,

tensile tests were performed on an EMIC universal testing

Fig. 1. Stressstrain curves for the different blends injected at

170 8C.

470

R. Strapasson et al. / Polymer Testing 24 (2005) 468473

Fig. 2. Stressstrain curves for the different blends injected at

180 8C.

Fig. 4. Stressstrain curves for the different blends injected at

200 8C.

Surprisingly, further increase in the LDPE content causes a

recovery of elongation at break yielding for the lower

temperatures. Thus, the elongation at break (see Table 1) did

not follow the rule of mixtures and also showed a minimum

for PP50 for the temperatures of interest.

Other observations from Figs. 14 include: (i) The 170

180 8C injection temperature range was shown to be the

most suitable to maintain the PP properties, whereas the

180190 8C temperature range was the most suitable for

pure LDPE processing; (ii) The stressstrain tensile curves

were shown to be very dependent on the composition of the

blends, with very distinct curve shapes regarding yielding,

modulus and elongation at break; (iii) For all compositions,

the stressstrain curves were very dependent on the

temperature and the elongation at break decreased with

the temperature; (iv) Elongation at break evidenced blend

incompatibility, unambiguously seen for the 50% polypropylene content blend, which showed the lowest

elongation at break of all compositions studied. Also, no

yielding was observed for this blend at any temperature; (v)

Figs. 1 and 2 show that a 25% replacement of PP by LDPE

(i.e. the PP75) causes a severe change of elongation at break,

with a decrease in ductility, and (vi) Fig. 2 shows that a 25%

replacement of LDPE by PP (i.e. the PP25) also changes the

stressstrain curve and causes an increase of elastic modulus

and yield strength, as was observed by Bertin [5], with

yielding only for the 170 and 180 8C temperatures.

Table 1 compiles the yield strength and elastic modulus

results for the different blends. The results were in the same

range of those reported by Albano [11] for pure LDPE

values at 180 8C and those by Bertin [5] for their LDPE/PP

(90/10) blends.

From the statistical analysis presented in Table 1, it can

also be concluded that if pure PP is processed at 190 8C,

only 10 8C higher than the optimum temperature, a yield

strength and a elastic modulus reduction similar to that

obtained with the inclusion of 25% of LDPE (PP75) may

result.

Figs. 5 and 6 show the variation of yield strength and

elastic modulus, respectively, for the different materials. Fig.

5 shows a linear variation with the composition for the 170

and 180 8C injection temperatures, with high coefficient of

determination (R-squared) values of 0.98 and 0.95, respectively. This suggests that yield strength varied according to

the rule of mixtures, i.e. the yield strength is basically

dependent on the blend composition. This of course was not

seen for the temperatures at which polymer degradation was

the determinant factor. Further observation of this figure also

reveals that the values for 170 and 180 8C are the highest,

being statistically similar (see Table 1) for all compositions

except for the PP50, again showing that this blend has a

particular behavior, being more prone to degradation.

Every polymer has its optimal processing temperature

profile to maximize a certain property and the same occurs

for the different blends. Furthermore, the PP optimal

temperatures appear to be dominating the blend behavior,

i.e. 170 and 180 8C give the best results for all compositions,

followed respectively by 190 and 200 8C, although for pure

LDPE (PP100), 180 and 190 8C give the best results.

The variation of elastic modulus followed the same

trends as yield strength, namely the modulus varied linearly

with the LDPE weight fraction (R2 of 0.98 for both 170 and

180 8C), suggesting agreement with the rule of mixtures.

The PP50 here again shows a different trend to the other

blends, where the 190 8C result differed from the other

temperatures.

It can be said from the results that a replacement of 25%

of PP with LDPE (PP75), even for the best temperatures,

Fig. 3. Stressstrain curves for the different blends injected at

190 8C.

R. Strapasson et al. / Polymer Testing 24 (2005) 468473

471

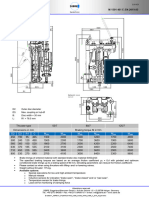

Table 1

Influence of the composition and the injection temperature on the tensile properties

Injection

temperature

(8C)

Composition (%)

PP

PE

Mean

170

100

75

50

25

0

100

75

50

25

0

100

75

50

25

0

100

75

50

25

0

0

25

50

75

100

0

25

50

75

100

0

25

50

75

100

0

25

50

75

100

24.8 a

0.9

22.4 b

0.9

16.7 c

0.8

11.5 d

0.8

Irregular injection

25.1 a

0.8

22.8 b

1.1

13.8 e

0.8

11.4 d

0.6

7.6 f

0.2

23.4 b

1.3

19.6 g

1.5

10.9 g

2.4

7.9 f

0.6

7.9 f

0.3

16.9 c

1.1

14.2 e

2.3

7.5 f

0.7

6.9

0.7

Irregular injection

180

190

200

a

b

Yield strength (MPa)

a

SD

Elastic modulus (MPa)

a

Elongation at break (%)

Mean

SD

Mean

SDb

1327 ag

1143 b

731 c

436 d

187

109

95

43

O800

170

17.7

400512

7.1

2.2

1304 ag

1149 b

845 ce

435 d

157 f

1240 ab

1085 b

932 e

404 d

191 fh

1452 g

1209 ab

403 dh

350 dh

172

137

141

54

24

101

153

184

53

32

258

133

36

51

600700

100

3.7

400529

111

5.7

4.9

2.1

4.1

66

1.9

1.9

3.7

25

0.7

13

1.9

1.7

0.9

0.9

24.1

0.4

0.6

0.8

3.2

Different letters mean statistically significant differences at 5% confidence level.

Standard deviation.

causes a statistically significant reduction in yield strength

and elastic modulus, but, from the slope of the linear trends

of Figs. 5 and 6, one may infer that a replacement of around

10% PP with LDPE may not cause significant variations in

these properties. This finding may be of interest to recycling

companies to lower the cost of the product by partial

replacement of PP by LDPE.

The observed results of this work, namely, a linear

variation of elastic modulus and yield strength with the

blend composition and a minimum for the elongation at

break for the PP50 blend, are in agreement with those from

Kolarik [12]. This researcher found that the modulus and the

yield strength upper boundary are monotonic functions of

the blend composition and the yield strength lower limit

shows a minimum near 50/50. However, there are other

reports found in the literature. For instance Liang [13]

reported an increase of elastic modulus with the PP content

according to a logarithm rule of mixture. The yield strength

increased in an irregular way with the PP content, whereas

the elongation at break showed a minimum at 80%PP. The

same author found a distinct behavior for another PP (with a

lower melt flow index) for which the elongation at break

showed two minimums, one for 20%PP and another for

100%PP. Tselios [14] found a minimum for the tensile

strength and elongation at break for 25%PP. Yang [15]

found a monotonic variation of the yield strength and elastic

modulus. The elongation at break and tensile strength,

however, reached a maximum for 3050%PP blends, with

the material behavior changing from ductile to brittle.

Possible explanations for the apparent divergence may

reside in the processing history and in the incompatibility of

these

blends,

and

consequent

morphological

Fig. 5. Variation of yield strength with blend composition.

Fig. 6. Variation of elastic modulus with blend composition.

472

R. Strapasson et al. / Polymer Testing 24 (2005) 468473

Table 2

Influence of the composition and the injection temperature on impact strength

Injection temperature (8C)

Composition (%)

PP

PE

Mean

SDb

170

100

75

50

25

0

100

75

50

25

0

100

75

50

25

0

100

75

50

25

0

0

25

50

75

100

0

25

50

75

100

0

25

50

75

100

0

25

50

75

100

0.12

0.26

0.42

O4.0

0.10

0.26

0.37

O4.0

0.09

0.25

0.28

O4.0

0.05

0.16

0.29

O4.0

0.01

0.10

0.08

0.01

0.10

0.06

0.01

0.09

0.06

0.01

0.11

0.07

180

190

200

a

b

Energy (J)

Impact strength (J/

m)a

12.2 ae

26.1 b

41.7 c

Partial breakage

Irregular injection

10.3 ae

25.8 b

37.3 cd

Partial breakage

No breakage

8.5 ae

25.2 b

28.0 d

Partial breakage

No breakage

4.5 a

16.3 e

28.5 bd

Partial breakage

Irregular injection

Different letters mean statistically significant differences at 5% confidence level.

Standard deviation.

(microstructural) changes that occur upon blending, with the

different phases assuming distinct behavior for different

compositions, as discussed in detail by Tselios [14].

3.2. Impact tests

Table 2 shows the results for the impact tests. The pure

LDPE injected samples did not fracture at the test conditions

used, even for a 4J hammer.

When PP is incorporated in the LDPE, however, there is

a significant impact strength reduction (as in Yang [15] and

Wang [16]), shown by the partial specimen fracture. Higher

PP content causes a further reduction until 10 J/m is

achieved by the pure PP, with the fracture mode changing

from ductile to brittle in the range of 25 to 50%PP (PP25 to

PP50), due to the low interfacial adhesion and, consequently, low stress transfer between the phases. This

behavior was observed for all temperatures, namely, the

higher the PP content, the lower the impact strength, in

agreement with Tselios [14].

For pure PP, degradation is evident only at 200 8C, thus

impact strength was found to be less sensitive to the

injection temperature than the tensile properties, this trend

being followed by the intermediate composition blends.

Similiarly, it can be noticed that the 170 and 180 8C

temperatures appear to be more suitable for the processing

of these blends.

Combining the results of tensile and impact tests it may

be said that, although the addition of LDPE in the PP

improves the impact characteristics, it has a detrimental

effect on the tensile properties. Therefore, it appears that the

only way of improving these two blend properties would be

with the addition of a compatibilizer such as in Hope [17]

and Yang [10]. The latter reported the use of ethylene/

propylene block copolymer to increase the ductility of these

blends by improving the interfacial adhesion without

significant loss in elastic modulus, especially for blends

with high PP content.

4. Conclusions

The widespread presence of polypropylene and lowdensity polyethylene in municipal wastes and their common

combined use by the recycling industry makes the study of

the mechanical behavior of these blends valuable for

practical every-day use.

The stressstrain tensile curves were very dependent

on the composition of the blends, with the curve shapes

being very distinct as regards yielding, modulus and

elongation at break. The linear law of mixtures was

obeyed for all blends regarding elastic modulus and yield

strength, except those in which polymer degradation was

the determinant factor. Elongation at break, however,

R. Strapasson et al. / Polymer Testing 24 (2005) 468473

demonstrated incompatibility for this blend, unambiguously seen for the 50% PP content blend, which showed

the lowest elongation at break of all compositions

studied.

For each composition, the behavior was very dependent on the processing temperature, and the blends

showed an optimum injection temperature around 170

180 8C. The replacing of 25% of PP by LDPE may be as

harmful to the mechanical properties as the use of an

injection temperature 10 8C higher than the optimum

temperature range. For a partial substitution of polypropylene without a statistically significant loss in elastic

modulus or yield strength, an LDPE content of around

10% may be allowed in the mixture.

When polypropylene is added to the polyethylene, there is

a significant reduction in impact strength, with partial sample

fracture for the 25%LDPE content blend. Further PP addition

makes the blend behavior change from ductile to brittle.

References

[1] H.P. Blom, J.W. Teh, A. Rudin, PP/PE blends. IV.

Characterization and compatibilization of blends of postconsumer resin with virgin PP and HDPE, J. Appl. Polym. Sci. 70

(11) (1998) 20812095.

[2] N.T. Dintcheva, F.P. La Mantia, F. Trotta, M.P. Luda,

G. Camino, M. Paci, L. Di Maio, D. Acierno, Effects of filler

type and processing apparatus on the properties of the recycled

light fraction from municipal post-consumer plastics, Polym.

Adv. Technol. 12 (9) (2001) 552560.

[3] J. Li, R.A. Shanks, Y. Long, Miscibility and crystallisation of

polypropylene-linear low density polyethylene blends, Polymer 42 (5) (2001) 19411951.

[4] J.W. Teh, A. Rudin, J.C. Keung, A review of polyethylenepolypropylene blends and their compatibilization, Adv.

Polym. Tech. 13 (1) (1994) 123.

[5] S. Bertin, J.J. Robin, Study and characterization of virgin and

recycled LDPE/PP blends, Eur. Polym. J. 38 (11) (2002)

22552264.

473

[6] R.A. Shanks, J. Li, F. Chen, G. Amarasinghe, Timetemperature-miscibility and morphology of polyolefin blends,

Chin. J. Polym. Sci. 18 (3) (2000) 263270.

[7] G. Radonjic, N. Gubeljak, The use of ethylene/propylene

copolymers as compatibilizers for recycled polyolefin blends,

Macromol. Mater. Eng. 287 (2) (2002) 122132.

[8] A.G. Andreopoulos, P.A. Tarantili, P. Anastassakis, Compatibilizers for Low Density Polyethylene/Polypropylene

Blends, J. Macromol. Sci. Pure 36 (9) (1999) 11131122.

[9] E. Vaccaro, A.T. Dibenedetto, S.J. Huang, Yield strength of

low-density polyethylene-polypropylene blends, J. Appl.

Polym. Sci. 63 (3) (1997) 275281.

[10] M.B. Yang, K. Wang, L. Ye, Y.W. Mai, J.S. Wu, Low density

polyethylene-polypropylene blends Part 2strengthening and

toughening with copolymer, Plast. Rubber Compos. 32 (1)

(2003) 2731.

[11] C. Albano, J. Reyes, M. Ichazo, J. Gonzalez, M. Hernandez,

M. Rodriguez, Mechanical, thermal and morphological

behaviour of the polystyrene/polypropylene (80/20) blend,

irradiated with gamma-rays at low doses (070 kGy), Polym.

Degrad. Stabil. 80 (2) (2003) 251261.

[12] J. Kolarik, Simultaneous prediction of the modulus and yield

strength of binary polymer blends, Polym. Eng. Sci. 36 (20)

(1996) 25182524.

[13] J.Z. Liang, C.Y. Tang, H.C. Man, Flow and mechanical

properties of polypropylene low density polyethylene blends,

J. Mater. Process Tech. 66 (1-3) (1997) 158164.

[14] C. Tselios, D. Bikiaris, V. Maslis, C. Panayiotou, In situ

compatibilization of polypropylene-polyethylene blends: a

thermomechanical and spectroscopic study, Polymer 39 (26)

(1998) 68076817.

[15] M.B. Yang, K. Wang, L. Ye, Y.W. Mi, J.S. Wu, Low

density polyethylene-polypropylene blends. Part 1ductility and tensile properties, Plast. Rubber Compos. 32 (1)

(2003) 2126.

[16] Z. Wang, Toughening and reinforcing of polypropylene,

J. Appl. Polym. Sci. 60 (12) (1996) 22392243.

[17] P.S. Hope, J.G. Bonner, A.F. Miles, A study of

compatibilisers for recovering the mechanical-properties of

recycled polyethylenes, Plast. Rubber Compos. 22 (3)

(1994) 147158.

You might also like

- A Requiem To Mother EarthDocument5 pagesA Requiem To Mother EarthSandra SabuNo ratings yet

- Quantification of The Maleic Anhydride Grafted Onto Polypropylene by Chemical and Viscosimetric Titrations, and FTIR Spectros PDFDocument11 pagesQuantification of The Maleic Anhydride Grafted Onto Polypropylene by Chemical and Viscosimetric Titrations, and FTIR Spectros PDFThinh DangNo ratings yet

- Lesson 30. Thermoplastic and Thermosetting PolymersDocument11 pagesLesson 30. Thermoplastic and Thermosetting PolymersNizar AbrorNo ratings yet

- Alumina (Al2O3) Electrical Insulators - Properties and Applications by Precision CeramicsDocument3 pagesAlumina (Al2O3) Electrical Insulators - Properties and Applications by Precision CeramicsRing MasterNo ratings yet

- Measuring Thermal Crystallinity in PET: Spe Antec Indianapolis 2016Document5 pagesMeasuring Thermal Crystallinity in PET: Spe Antec Indianapolis 2016Silviani SilvyNo ratings yet

- Chapter 6 Work, Energy and PowerDocument12 pagesChapter 6 Work, Energy and PowerZhu Jiankun100% (1)

- Airport Literature StudyDocument15 pagesAirport Literature StudySoundar Rajan100% (2)

- Structure Loadbearing Crosswall PDFDocument41 pagesStructure Loadbearing Crosswall PDFSKhandelwalNo ratings yet

- POLYPROPYLENE I Thesis (Final)Document8 pagesPOLYPROPYLENE I Thesis (Final)falmubaddelNo ratings yet

- Characterization and Treatments of Pineapple Leaf PDFDocument71 pagesCharacterization and Treatments of Pineapple Leaf PDFRekki StgNo ratings yet

- Binders: 1. Compaction Behaviour of Organic Binders in Alumina Ceramics (PVA & PEG) General FactsDocument13 pagesBinders: 1. Compaction Behaviour of Organic Binders in Alumina Ceramics (PVA & PEG) General FactsPranav KumarNo ratings yet

- Mold SinkmarkDocument16 pagesMold SinkmarkharryNo ratings yet

- 1.PPT II Plastics Processing Technology II 20 222 wtb2654Document1 page1.PPT II Plastics Processing Technology II 20 222 wtb2654Raj ThakurNo ratings yet

- Injection Molded Part Problems & Solutions With: SkillbuilderDocument2 pagesInjection Molded Part Problems & Solutions With: SkillbuilderКонстантин ГавриловNo ratings yet

- Structural Composites or Layered CompositesDocument3 pagesStructural Composites or Layered CompositesPritam100% (1)

- StainingDocument5 pagesStainingyuppie_raj2175No ratings yet

- Electrical Properties of Plastics: Sachin C S PGDDocument19 pagesElectrical Properties of Plastics: Sachin C S PGDSarumathiNo ratings yet

- Mem671 Case Study March 2023Document11 pagesMem671 Case Study March 2023AIMAN ASYRAAF BIN ROSLANNo ratings yet

- Polyethylene Properties - VinidexDocument8 pagesPolyethylene Properties - VinidexalexNo ratings yet

- Corona Film Pada Bopp PDFDocument6 pagesCorona Film Pada Bopp PDFNuril HidayatiNo ratings yet

- D 1694 - 95 R00 - Rde2otq - PDFDocument4 pagesD 1694 - 95 R00 - Rde2otq - PDFAndre CasteloNo ratings yet

- Waste Management: Yasser ZareDocument7 pagesWaste Management: Yasser ZarebokugairuNo ratings yet

- Cerium Doped HydroxyapatiteDocument16 pagesCerium Doped Hydroxyapatitekelvinhoh83No ratings yet

- Matrix MaterialDocument51 pagesMatrix MaterialA-13-M Ibrahim OMARNo ratings yet

- Analisis Sterategi Pemasaran Marmer (CITATAH)Document12 pagesAnalisis Sterategi Pemasaran Marmer (CITATAH)abdul qodirNo ratings yet

- Bicomponent FiberDocument2 pagesBicomponent FiberAshishn ThakurNo ratings yet

- Unit-Iii MANUFACTURING METHODS: Autoclave, Tape Production, Moulding Methods, FilamentDocument13 pagesUnit-Iii MANUFACTURING METHODS: Autoclave, Tape Production, Moulding Methods, FilamentSaisurendra VeerlaNo ratings yet

- Internal MixerDocument5 pagesInternal MixerFaisal IqbalNo ratings yet

- Characteristics, Applications and Processing of Polymers Chapter 15Document53 pagesCharacteristics, Applications and Processing of Polymers Chapter 15tjandelkier100% (1)

- DLVO Theory PDFDocument7 pagesDLVO Theory PDFshashank mishraNo ratings yet

- Zeus Weathering of PlasticsDocument7 pagesZeus Weathering of PlasticsDiego Fernado AvendañoNo ratings yet

- Cerium OxideDocument5 pagesCerium Oxiderrivera7396No ratings yet

- NYLON 6,6 (Nylon 6) : OverviewDocument4 pagesNYLON 6,6 (Nylon 6) : OverviewKaruppiah VigneshNo ratings yet

- Ha SpongeDocument45 pagesHa SpongeSantoso NugrohoNo ratings yet

- Comparison of Jute Fiber Over Glass FibeDocument5 pagesComparison of Jute Fiber Over Glass FibeBobby LupangoNo ratings yet

- Biomaterials and Implants (Bmeg3183) 2.1 Metallic BiomaterialDocument50 pagesBiomaterials and Implants (Bmeg3183) 2.1 Metallic BiomaterialZeynu Kulizeyn100% (1)

- Polymer Melt Spin Pack FiltrationDocument11 pagesPolymer Melt Spin Pack FiltrationbheenwaramNo ratings yet

- NetShape MIM Design GuideDocument13 pagesNetShape MIM Design Guidegnk68No ratings yet

- Rheological Study of The Plasticizer On Fusion Processes of PVC Plastisol PDFDocument8 pagesRheological Study of The Plasticizer On Fusion Processes of PVC Plastisol PDFvampireheart_soulNo ratings yet

- Naoki Ota 1B 022216Document13 pagesNaoki Ota 1B 022216MagsNo ratings yet

- PPO SlideDocument29 pagesPPO SlideRadhashyam GiriNo ratings yet

- RadiciPlastics Poliammidi Feb2014 WebDocument28 pagesRadiciPlastics Poliammidi Feb2014 WebFolpoNo ratings yet

- 20 Faust Porcelain Vitreous EnamelsDocument9 pages20 Faust Porcelain Vitreous Enamelsyanda prNo ratings yet

- Design Guide DSM GuideDocument0 pagesDesign Guide DSM GuideDavid García SalvatierraNo ratings yet

- STruture and Properties of PolymersDocument35 pagesSTruture and Properties of PolymersWasif Razzaq100% (1)

- Silicon CarbideDocument5 pagesSilicon Carbiderockeysuseelan100% (2)

- Casting MethodDocument15 pagesCasting MethodGabriela Maira Sanches VolpiNo ratings yet

- CMP in Semiconductor ManufacturingDocument8 pagesCMP in Semiconductor Manufacturingjana kNo ratings yet

- De AssignmentDocument9 pagesDe AssignmentManish MohapatraNo ratings yet

- Methanol SimulationDocument9 pagesMethanol SimulationMaria Jose TorresNo ratings yet

- Accelerated Weathering Test Conditions and Procedures For Bituminous Materials (Fluorescent UV, Water Spray, and Condensation Method)Document3 pagesAccelerated Weathering Test Conditions and Procedures For Bituminous Materials (Fluorescent UV, Water Spray, and Condensation Method)Satya kaliprasad vangaraNo ratings yet

- The Pultrusion Process PDFDocument2 pagesThe Pultrusion Process PDFSan SvsNo ratings yet

- Synthesis and Property Comparison of Silicone PolymersDocument3 pagesSynthesis and Property Comparison of Silicone PolymersDaniel RodmanNo ratings yet

- AntimicrobialDocument6 pagesAntimicrobialmniederer5268No ratings yet

- Compression MouldingDocument15 pagesCompression MouldingPradeep MahalikNo ratings yet

- Squeeze Casting - An Overview PDFDocument9 pagesSqueeze Casting - An Overview PDFDian Try SaputriNo ratings yet

- Solidification ShrinkageDocument4 pagesSolidification ShrinkagesubavlNo ratings yet

- 6830 en 7 Myths About PVC DebunkedDocument5 pages6830 en 7 Myths About PVC DebunkedNishi JhaNo ratings yet

- Bioplastics: Chemistry Investigatory ProjectDocument16 pagesBioplastics: Chemistry Investigatory ProjectDhanyaa vaitheeswaranNo ratings yet

- Functional and Physical Properties of Polymer NanocompositesFrom EverandFunctional and Physical Properties of Polymer NanocompositesAravind DasariNo ratings yet

- Comparing Effect of Adding LDPE, PP, PMMA On The Mechanical Properties of Polystyrene (PS)Document12 pagesComparing Effect of Adding LDPE, PP, PMMA On The Mechanical Properties of Polystyrene (PS)Jawad K. OleiwiNo ratings yet

- Project PaperDocument7 pagesProject PaperSandeep KulharNo ratings yet

- Effect of EPDM As A Compatibilizer On Mechanical Properties and Morphology of PP/LDPE BlendsDocument13 pagesEffect of EPDM As A Compatibilizer On Mechanical Properties and Morphology of PP/LDPE BlendsOumaima BenNo ratings yet

- The Effects of Epoxy Resin Nano ParticleDocument29 pagesThe Effects of Epoxy Resin Nano ParticleWellington C. de AraujoNo ratings yet

- Recycling Plastic 3Document7 pagesRecycling Plastic 3OkePreciousEmmanuelNo ratings yet

- Chemical Engineering Department Ahmadu Bello University, ZariaDocument2 pagesChemical Engineering Department Ahmadu Bello University, ZariaOkePreciousEmmanuelNo ratings yet

- CHEN505 Note 1Document6 pagesCHEN505 Note 1OkePreciousEmmanuelNo ratings yet

- Chapter Four Risk Assessment of NLNGDocument8 pagesChapter Four Risk Assessment of NLNGOkePreciousEmmanuelNo ratings yet

- TinyMobileRobots TinySurveyor FlyerDocument4 pagesTinyMobileRobots TinySurveyor FlyerfelipeNo ratings yet

- RPT CasesDocument13 pagesRPT CasesSNLTNo ratings yet

- Supplement Guide Memory FocusDocument41 pagesSupplement Guide Memory Focusgogov.digitalNo ratings yet

- Exit Poll CedatosDocument1 pageExit Poll CedatosEcuadorenvivoNo ratings yet

- Costing By-Product and Joint ProductsDocument36 pagesCosting By-Product and Joint ProductseltantiNo ratings yet

- Cne CatalogoDocument4 pagesCne CatalogoPaulo SergioNo ratings yet

- Transport Phenomena: τ =μ dv dyDocument2 pagesTransport Phenomena: τ =μ dv dySYED ASGHAR ALI SULTANNo ratings yet

- MEP MyanmarDocument27 pagesMEP Myanmarempty87No ratings yet

- Low Noise Amplifier Basics: by V. M. García-ChocanoDocument4 pagesLow Noise Amplifier Basics: by V. M. García-ChocanoPranjal Jalan100% (1)

- Stages of SleepDocument2 pagesStages of SleepCamilia Hilmy FaidahNo ratings yet

- LAB 2 - Running Speed (Method 2) OEL 1Document3 pagesLAB 2 - Running Speed (Method 2) OEL 1ZULFAQAR BIN MOHAMMAD NIZAMNo ratings yet

- Surveillance, Torture and Contr - Rosanne Marie SchneiderDocument135 pagesSurveillance, Torture and Contr - Rosanne Marie SchneiderMagic MikeNo ratings yet

- Ultimate GuideDocument11 pagesUltimate GuideIgor SucevicNo ratings yet

- 5 25 17 Migraines PowerPointDocument40 pages5 25 17 Migraines PowerPointSaifi AlamNo ratings yet

- SSP 604 - Audi 30l v6 Tdi Biturbo Engine EngDocument23 pagesSSP 604 - Audi 30l v6 Tdi Biturbo Engine Engfrancois.garcia31100% (1)

- Delhi Public School, Greater Noida Pre-Mid Term Exam Class X Mathematics SESSION 2020-21 Set 1 MM: 40 Time: 1.5 Hours InstructionsDocument3 pagesDelhi Public School, Greater Noida Pre-Mid Term Exam Class X Mathematics SESSION 2020-21 Set 1 MM: 40 Time: 1.5 Hours InstructionsAnishikaNo ratings yet

- Filipino BasicDocument21 pagesFilipino BasicReiko Nakayama100% (1)

- Credit Card Fraud Detection Using Improved Deep Learning ModelsDocument22 pagesCredit Card Fraud Detection Using Improved Deep Learning ModelsrauhNo ratings yet

- DC Jow Ga Beginner CurriculumDocument2 pagesDC Jow Ga Beginner CurriculumKevinNo ratings yet

- Control of Spinal Anesthesia-Induced Hypotension in Adults - PMCDocument14 pagesControl of Spinal Anesthesia-Induced Hypotension in Adults - PMCAkash SharmaNo ratings yet

- Advanced Landscape DesignDocument10 pagesAdvanced Landscape DesignSomhita DasNo ratings yet

- Bronchial Cancer Case StudyDocument3 pagesBronchial Cancer Case StudyericaNo ratings yet

- SONTU Flat Panel Dectector CatalogDocument6 pagesSONTU Flat Panel Dectector CatalogWajahat SheikhNo ratings yet

- Neisseria Gonorrhoeae and Neisseria MeningitidesDocument3 pagesNeisseria Gonorrhoeae and Neisseria MeningitidesAmador Gielas0% (1)

- Data Sheet USB5 II 2019 05 ENDocument1 pageData Sheet USB5 II 2019 05 ENJanne LaineNo ratings yet

- Chapter8-Campuran Pada Tingkat Molekuler - Part 1Document58 pagesChapter8-Campuran Pada Tingkat Molekuler - Part 1Uswatun KhasanahNo ratings yet