Professional Documents

Culture Documents

Bolted Joints:: Lecture Notes: CRB/CIV/MSEC

Bolted Joints:: Lecture Notes: CRB/CIV/MSEC

Uploaded by

rameshbabu_1979Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bolted Joints:: Lecture Notes: CRB/CIV/MSEC

Bolted Joints:: Lecture Notes: CRB/CIV/MSEC

Uploaded by

rameshbabu_1979Copyright:

Available Formats

Lecture notes: CRB/CIV/MSEC

Bolted Joints:

The Bolted joints transmit the forces from the members connected and

comply with the requirements of SECTION 10. of IS 800:2007. The

bolted connections could be used in locations where there are no

vibrations.

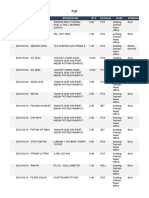

Sr. No.

ITEM

IS

DIN

ISO

ASTM

BS

AS

1.

HEX BOLT

1363-1

1364-1

601

931

4016

4014

4190

3692

1111

-

2.

HEX SCREW

1363-1

1364-11

933

4018

4017

4190

1111

3692

3.

HEX NUT

1363-111

1364-111

24034

24032

4034

4032

4190

1112

3692

4.

COACH BOLT

2609

603

4933

1390

5.

HEX

BOLT(STRUCTURAL)

12427

6639

7990

A-394

4190

1559

6.

SPRING WASHER

3063

127

4464

7.

PLAIN WASHER

2016

125

126

7089

7091

4320

8.

PACK WASHER

6610

7989

9.

HIGH STRENGTH

STRUCTURAL BOLY

(HEAVY SERIES)

3757

6914

7411

7412

A-325M

4395

1252

10.

HIGH STRENGTH

STRUCTURAL NUT

(HEAVY SERIES)

6623

6915

7414

A-563M

4395

1252

Lecture notes: CRB/CIV/MSEC

11.

HEAVY WASHER

6649

6916

7415

F-436M

12.

MECHANICAL

PROPERTIES OF BOLT

& NUT

1367

20898

898

20898

13

HOT DIP

GALVANISING

1367

267

1461

A-153M

729

Threads in the shear plane:

1252

Lecture notes: CRB/CIV/MSEC

Types of Bolts:

Bolts used in steel structures are of three types: 1) Black Bolts, 2)

Turned and Fitted Bolts and 3) High Strength Friction Grip (HSFG) Bolts.

The International Standards Organisation designation for bolts, also

followed in India, is given by Grade x.y. In this nomenclature, x

indicates one-tenth of the minimum ultimate tensile strength of the

bolt in kgf/mm2 and the second number, y, indicates one-tenth of the

ratio of the yield stress to ultimate stress, expressed as a percentage.

Thus, for example, grade 4.6 bolt will have a minimum ultimate

strength 40 kgf/mm2 (392 Mpa) and minimum yield strength of 0.6

times 40, which is 24 kgf/mm2 (235 Mpa).

Black Bolts:(Should conform to IS:1363 - 1984 and are made

from low and medium carbon steels)

These are also called Unfinished bolts or ordinary or common

and rough bolts.

Black bolts are unfinished and are made of mild steel and are usually of

Grade 4.6. Black bolts have adequate strength and ductility when used

properly; but while tightening the nut snug tight (Snug tight is

defined as the tightness that exists when all plies in a joint are in firm

contact) will twist off easily if tightened too much. Turned and- fitted

bolts have uniform shanks and are inserted in close tolerance drilled

holes and made snug tight by box spanners. The diameter of the hole

is about 1.5 to 2.0 mm larger than the bolt diameter for ease in fitting.

High strength black bolts (grade 8.8) may also be used in connections

in which the bolts are tightened snug fit.

In these bearing type of connections, the plates are in firm contact

3

Lecture notes: CRB/CIV/MSEC

but may slip under loading until the hole surface bears against the bolt

.The load transmitted from plate to bolt is therefore by bearing and the

bolt is in shear. Under dynamic loads, the nuts are liable to become

loose and so these bolts are not allowed for use under such loading. In

situations where small slips can cause significant effects as in beam

splices, black bolts are not preferred. However, due to the lower cost of

the bolt and its installation, black bolts are quite popular in simple

structures subjected to static loading.

Turned and fitted bolts:

Turned and fitted bolts are available from grade 4.6 to grade 8.8.

For the higher grades there is no definite yield point and so 0.2% proof

stress is used.

High Strength Friction Grip Bolts (HSFG):

High Strength Friction Grip bolts (HSFG) provide extremely efficient

connections and perform well under fluctuating/fatigue load conditions.

These bolts should be tightened to their proof loads and require

hardened washers to distribute the load under the bolt heads. The

washers are usually tapered when used on rolled steel sections. The

tension in the bolt ensures that no slip takes place under working

conditions and so the load transmission from plate to the bolt is

through friction and not by bearing. However, under ultimate load, the

friction may be overcome leading to a slip and so bearing will govern

the design. HSFG bolts are made from quenched and tempered alloy

steels with grades from 8.8 to 10.9. The most common are, the socalled, general grade of 8.8 and have medium carbon content, which

makes them less ductile. The 10.9 grade have a much higher tensile

strength, but lower ductility and the margin between the 0.2% yield

strength and the ultimate strength is also lower.

Standard clearances for fastener holes:

Lecture notes: CRB/CIV/MSEC

Spacing:

(Clause 10.2.2 of IS 800:2007)

Clause 10.2.3 of IS 800:2007

Lecture notes: CRB/CIV/MSEC

Clause 10.2.4 of IS 800:2007

Lecture notes: CRB/CIV/MSEC

You might also like

- Farymann 15W 18W 32 W Workshop ManualDocument80 pagesFarymann 15W 18W 32 W Workshop ManualAgatha Keisha86% (7)

- Edc17 SystemDocument96 pagesEdc17 SystemNutan60% (5)

- Hino Electrical Wiring DiagramDocument382 pagesHino Electrical Wiring DiagramABDUL SAMAD100% (2)

- Impact Load FactorsDocument13 pagesImpact Load FactorsMuralidharan ShanmugamNo ratings yet

- Col - Stiff Properties - SAFE - CSIDocument1 pageCol - Stiff Properties - SAFE - CSIkilmasterNo ratings yet

- NCCI: Determination of Moments On Columns in Simple ConstructionDocument5 pagesNCCI: Determination of Moments On Columns in Simple ConstructionBobaru MariusNo ratings yet

- Wood Frame Illustrations PDFDocument26 pagesWood Frame Illustrations PDFZoe MarinescuNo ratings yet

- ConRepair 04 JurcemNonshirk GP Ed01Document2 pagesConRepair 04 JurcemNonshirk GP Ed01Tuntun Tat0% (1)

- Warrior Samurai 20000 Winch User ManualDocument18 pagesWarrior Samurai 20000 Winch User ManualNhung HoangNo ratings yet

- FSR 2012 Camber FSR ManualDocument20 pagesFSR 2012 Camber FSR Manualnecko77No ratings yet

- Rtlo 16718BDocument42 pagesRtlo 16718Bjames santiago100% (1)

- SV Maintenance V1.2 CONE VALEDocument64 pagesSV Maintenance V1.2 CONE VALEVictor Alberto Ramos BarronNo ratings yet

- Use of Control Charts in The Production of Concrete: by Ian Gibb and Tom Harrison October 2010Document55 pagesUse of Control Charts in The Production of Concrete: by Ian Gibb and Tom Harrison October 2010Henock ShewasemaNo ratings yet

- Eb 034981Document6 pagesEb 034981gauravmeucerNo ratings yet

- Analysis and Design For End Effects in Twisted Double TeesDocument20 pagesAnalysis and Design For End Effects in Twisted Double TeesFabrizio BisernaNo ratings yet

- Experiment-3 Using The Weighing in Water Method To Determine Particle Density and Water Absorption of Coarse AggregateDocument8 pagesExperiment-3 Using The Weighing in Water Method To Determine Particle Density and Water Absorption of Coarse AggregateanushaNo ratings yet

- 2 Bolts: Table 2.1 Basic Mechanical Properties of Structural BoltsDocument11 pages2 Bolts: Table 2.1 Basic Mechanical Properties of Structural BoltsSafrul EfendiNo ratings yet

- Bridge Bearing2Document10 pagesBridge Bearing2sandbad2No ratings yet

- Safety BarrierDocument5 pagesSafety BarrierKC PangNo ratings yet

- Compact or Class 1 Limits For Rectangular Hollow Sections in BendingDocument8 pagesCompact or Class 1 Limits For Rectangular Hollow Sections in BendingKolumbán ZoltánNo ratings yet

- Iso 3506-1-2009Document11 pagesIso 3506-1-2009sharma.sumeet2290No ratings yet

- PERI TRIO en PDFDocument88 pagesPERI TRIO en PDFMilan GligsNo ratings yet

- The Design and Construction of The Westgate Shopping Centre Suspended Post Tensioned SlabDocument13 pagesThe Design and Construction of The Westgate Shopping Centre Suspended Post Tensioned SlabtoddNo ratings yet

- Stress-Strain Test 2015 SpringDocument6 pagesStress-Strain Test 2015 SpringRich GarrNo ratings yet

- Elastomeric Bearings - CosmecDocument6 pagesElastomeric Bearings - CosmecGermar PorquerinoNo ratings yet

- Wilson Anchor Bolt Sleeve PdsDocument2 pagesWilson Anchor Bolt Sleeve Pdsdinu69inNo ratings yet

- CE5510B Advanced Structural Concrete Design To EC2: 10. Flat Slab SystemDocument17 pagesCE5510B Advanced Structural Concrete Design To EC2: 10. Flat Slab SystemwinminthetgeoNo ratings yet

- Bearing Design - Steel ReinforcementDocument10 pagesBearing Design - Steel ReinforcementRajesh SarswaNo ratings yet

- TECHNICAL NOTE 011 Lateral Loads On Falsework - Is Cross-Bracing Really Not Required at All PDFDocument2 pagesTECHNICAL NOTE 011 Lateral Loads On Falsework - Is Cross-Bracing Really Not Required at All PDFmyduyen75No ratings yet

- Guidance To The Engineering Properties of Concrete 061129Document36 pagesGuidance To The Engineering Properties of Concrete 061129Shahir ShaikhNo ratings yet

- Composite - Design ProjectDocument6 pagesComposite - Design ProjectSomen DasNo ratings yet

- Namanact 150616123113 Lva1 App6892 PDFDocument38 pagesNamanact 150616123113 Lva1 App6892 PDFjohnNo ratings yet

- Fourth ScheduleDocument22 pagesFourth ScheduleChai Lin NyokNo ratings yet

- Technical Datasheet HUS4 Technical Information ASSET DOC 16702828Document25 pagesTechnical Datasheet HUS4 Technical Information ASSET DOC 16702828James100% (1)

- 12.7 7 Wire Strand Proprieties VSLDocument1 page12.7 7 Wire Strand Proprieties VSLAbu BiduNo ratings yet

- Bracing Design To Eurocode 3Document13 pagesBracing Design To Eurocode 3B.A H100% (1)

- Early Age Striking of Formwork To GGBS Concretes A Decision Making ToolDocument8 pagesEarly Age Striking of Formwork To GGBS Concretes A Decision Making ToolJagdish Chhugani100% (1)

- Method Statement For CoringDocument4 pagesMethod Statement For CoringNasir Nagoor PitchaiNo ratings yet

- Design Aid For Triangular Bracket Plates Using AISC SpecificationsDocument10 pagesDesign Aid For Triangular Bracket Plates Using AISC SpecificationsRicardo MendozaNo ratings yet

- Pe's CalDocument27 pagesPe's CalSơn Nguyễn-LêNo ratings yet

- Temperature - 1Document2 pagesTemperature - 1ksshashidharNo ratings yet

- Chapter05 - Plane Frame and Grid EqDocument63 pagesChapter05 - Plane Frame and Grid EqAgus BaeNo ratings yet

- Nascc2015 DurasquirtDocument2 pagesNascc2015 DurasquirtSquidwardNo ratings yet

- AnchorsDocument8 pagesAnchors2Suraj2100% (2)

- Masterflex 700 PGDocument3 pagesMasterflex 700 PGHaresh BhavnaniNo ratings yet

- Composite Materials Lection - 9Document13 pagesComposite Materials Lection - 9yigitciftci_No ratings yet

- 028 CCC 2014 NavratilDocument6 pages028 CCC 2014 NavratilkstayroskNo ratings yet

- Repair and Strengthening Methods of Flat Slabs For Punching - António M. P. Ramos, Válter J.G. Lúcio, Paul ReganDocument9 pagesRepair and Strengthening Methods of Flat Slabs For Punching - António M. P. Ramos, Válter J.G. Lúcio, Paul ReganVálter LúcioNo ratings yet

- Formwork Design For Settling TankDocument6 pagesFormwork Design For Settling TankPartha GorainNo ratings yet

- 22f-UC Runway Beam DesignDocument2 pages22f-UC Runway Beam DesignParthiban ArivazhaganNo ratings yet

- 2018 JC2 H1 Economics SA2 Hwa Chong Institution PDFDocument18 pages2018 JC2 H1 Economics SA2 Hwa Chong Institution PDFAryan GanjuNo ratings yet

- Continental Steel - Structural SteelDocument191 pagesContinental Steel - Structural SteelDesmond TongNo ratings yet

- BoltDocument2 pagesBoltmuhannedNo ratings yet

- Impact LoadDocument16 pagesImpact Loaddeepak_dce_meNo ratings yet

- Concrete 17 - Autogenous Shrinkage 1Document8 pagesConcrete 17 - Autogenous Shrinkage 1Robert CoelhoNo ratings yet

- 000000000030198701Document54 pages000000000030198701MohdhafizFaiz MdAliNo ratings yet

- Stability of Steel Framed Structures: Ir. Prof. Dr. Jeffrey ChiangDocument30 pagesStability of Steel Framed Structures: Ir. Prof. Dr. Jeffrey Chiangsam19961No ratings yet

- Schoeck Isokorb Type KST User Selection GuideDocument16 pagesSchoeck Isokorb Type KST User Selection GuideJoseph BookerNo ratings yet

- Rules For Reusing BoltsDocument4 pagesRules For Reusing Boltsaataylor83No ratings yet

- Myton Mag-70 Assembly and Parts List: No. Part No. Part Name Q'ty PriceDocument1 pageMyton Mag-70 Assembly and Parts List: No. Part No. Part Name Q'ty PriceAnonymous DjTnqWXUNo ratings yet

- Slip Form (Our Report)Document16 pagesSlip Form (Our Report)Simran DeepNo ratings yet

- Install Guide Spunlite Poles 2015Document6 pagesInstall Guide Spunlite Poles 2015Balaji PalaniNo ratings yet

- KDS 41 17 00 건축물 내진설계기준Document131 pagesKDS 41 17 00 건축물 내진설계기준colt0No ratings yet

- Chapter 2 Bolted ConnectionsDocument29 pagesChapter 2 Bolted ConnectionsKishan Purohit100% (1)

- By Tushar Dev Lecturer (Civil Engineering) : Class 3Document47 pagesBy Tushar Dev Lecturer (Civil Engineering) : Class 3ayush kumarNo ratings yet

- Connections-I Bolted ConnectionsDocument21 pagesConnections-I Bolted ConnectionsA.k.MandalNo ratings yet

- BoltsDocument167 pagesBoltsce14b058No ratings yet

- Crack Detection Techniques in Concrete StructuresDocument23 pagesCrack Detection Techniques in Concrete Structuresrameshbabu_1979No ratings yet

- 15cea01 Industrial Pollution Prevention and ControlDocument273 pages15cea01 Industrial Pollution Prevention and Controlrameshbabu_1979No ratings yet

- Technical Note On Using CNTs As ReinforcementsDocument7 pagesTechnical Note On Using CNTs As Reinforcementsrameshbabu_1979No ratings yet

- Shear Strength of Soils: Mr.C.Rameshbabu M.E., (PH.D.,)Document48 pagesShear Strength of Soils: Mr.C.Rameshbabu M.E., (PH.D.,)rameshbabu_1979No ratings yet

- Unit 7Document25 pagesUnit 7rameshbabu_1979No ratings yet

- 15cea01 Industrial Pollution Prevention and ControlDocument33 pages15cea01 Industrial Pollution Prevention and Controlrameshbabu_1979No ratings yet

- Environmental Science and Disaster ManagementDocument52 pagesEnvironmental Science and Disaster Managementrameshbabu_1979100% (1)

- Finite Element Analysis of Different Types of Composite ColumnDocument7 pagesFinite Element Analysis of Different Types of Composite Columnrameshbabu_1979No ratings yet

- Forest Fire PDFDocument302 pagesForest Fire PDFrameshbabu_1979No ratings yet

- mUNICIPAL sOLID WASTEDocument470 pagesmUNICIPAL sOLID WASTErameshbabu_1979No ratings yet

- Earthquake Awareness AGPDocument103 pagesEarthquake Awareness AGPrameshbabu_1979No ratings yet

- Environmental Science and Disaster ManagementDocument568 pagesEnvironmental Science and Disaster Managementrameshbabu_1979No ratings yet

- 15sea06 Bridge Maintenance and ManagementDocument1 page15sea06 Bridge Maintenance and Managementrameshbabu_1979No ratings yet

- Fast Track Course - 13CE915 Construction Safety PracticesDocument2 pagesFast Track Course - 13CE915 Construction Safety Practicesrameshbabu_1979No ratings yet

- 13CE915 Construction Safety PracticesDocument129 pages13CE915 Construction Safety Practicesrameshbabu_1979No ratings yet

- VD-000016-Fit Tolerances and Applications - Mec Engineering SpreadsheetsDocument8 pagesVD-000016-Fit Tolerances and Applications - Mec Engineering SpreadsheetsThùyNo ratings yet

- 2012 Chevrolet Volt X2Document5 pages2012 Chevrolet Volt X2Men PanhaNo ratings yet

- Avant 200 Series Parts List: STARTING FROM SERIAL NO.:30001-30026 43509 AVANT 216 A2978Document21 pagesAvant 200 Series Parts List: STARTING FROM SERIAL NO.:30001-30026 43509 AVANT 216 A2978Павел Хромов100% (1)

- HTP-ER-OM-B-1 Maintenance Regulation For Diesel Engine System PDFDocument538 pagesHTP-ER-OM-B-1 Maintenance Regulation For Diesel Engine System PDFJorge Luis Vera AlmeidaNo ratings yet

- Caterpillar Cat 320D Excavator (Prefix KZF) Service Repair Manual (KZF00001 and Up)Document24 pagesCaterpillar Cat 320D Excavator (Prefix KZF) Service Repair Manual (KZF00001 and Up)kfmuseddk100% (1)

- Messprotokoll Gear Pro BevelDocument2 pagesMessprotokoll Gear Pro Bevelalecandro_90No ratings yet

- United Motors GP1 125Document32 pagesUnited Motors GP1 125Vegueta AguirreNo ratings yet

- Instruction and Maintenance Manual: FP FPX S PumpsDocument32 pagesInstruction and Maintenance Manual: FP FPX S PumpsajcepedaNo ratings yet

- Motor Flange-Universal InputDocument4 pagesMotor Flange-Universal InputAgus Yulfizar100% (1)

- 34C2 (1h34c450e1) Yd125t STX125Document49 pages34C2 (1h34c450e1) Yd125t STX125RenNo ratings yet

- 3662F471 ListaDocument6 pages3662F471 ListaDouglas Lamonica PintoNo ratings yet

- DA-H Series Datenblaetter EngDocument31 pagesDA-H Series Datenblaetter EngAbdukayyum JililNo ratings yet

- D3E8034DF5E Gearbox 09GDocument216 pagesD3E8034DF5E Gearbox 09GVasile-Cristian Rusu50% (2)

- Featherlite 2006-05 Trimmer WeedeatherDocument5 pagesFeatherlite 2006-05 Trimmer Weedeathericandyne100% (1)

- VOLVO EW160B-5 BrakeDocument24 pagesVOLVO EW160B-5 BrakePIKO MOB100% (1)

- Acura TSX 2004 Manual and Power Steering, Steering Column, Gear and LinkageDocument144 pagesAcura TSX 2004 Manual and Power Steering, Steering Column, Gear and Linkagejorge antonio guillenNo ratings yet

- Difference Between The Fuel Injector and Spark Plug PDFDocument4 pagesDifference Between The Fuel Injector and Spark Plug PDFraghavNo ratings yet

- Form2 Maintenance of Cylinder HeadDocument3 pagesForm2 Maintenance of Cylinder HeadmakinaNo ratings yet

- GM 4L60E and 4L80E: B&M Part Numbers: 117308 - 117309 118001 - 118002 - 118003Document5 pagesGM 4L60E and 4L80E: B&M Part Numbers: 117308 - 117309 118001 - 118002 - 118003Juan IdrovoNo ratings yet

- No Tanggal Material Spesifikasi QTY Satuan Dari KondisiDocument16 pagesNo Tanggal Material Spesifikasi QTY Satuan Dari KondisiAgus WinNo ratings yet

- Harga Penawaran 22-07-2021Document110 pagesHarga Penawaran 22-07-2021Maintenance Officer, PT SBSNo ratings yet

- Appendix2 Hand Tools Final - Wartsila 16/20V34SGDocument2 pagesAppendix2 Hand Tools Final - Wartsila 16/20V34SGudelmark100% (1)

- MY21 200duke SPCDocument53 pagesMY21 200duke SPCeeve.nakharaNo ratings yet