Professional Documents

Culture Documents

The Design of Pressure Windows: Notes To Calculate Thickness of Optical Windows Used in Vacuum or Pressure Applications

The Design of Pressure Windows: Notes To Calculate Thickness of Optical Windows Used in Vacuum or Pressure Applications

Uploaded by

carlette11Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Design of Pressure Windows: Notes To Calculate Thickness of Optical Windows Used in Vacuum or Pressure Applications

The Design of Pressure Windows: Notes To Calculate Thickness of Optical Windows Used in Vacuum or Pressure Applications

Uploaded by

carlette11Copyright:

Available Formats

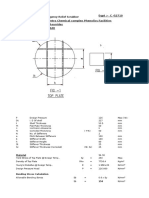

The Design of Pressure Windows

Notes to calculate thickness of optical windows used in vacuum or pressure applications

The maximum stress Smax on a uniformly loaded window is given by:

Smax = ( K . D2 . P ) / ( 4 . T2 ) and also Smax = Fa / SF

(See Safety Factor Box)

and then solving for thickness T

T

= D. ( SF . K / 4 ) . ( P /Fa )

(CIRCULAR WINDOWS)

2

T

= L . ( SF . K / 2 ) . ( P / ( Fa . ( 1 + R ))) (RECTANGULAR WINDOWS)

DEFINITIONS

Smax = Maximum stress

SF = Safety Factor

Fa = Apparent Elastic Limit

= or Rupture Modulus

K = Empirical Constant

D

= Unsupported for

circular window

L,W = Length & Width for

rectangular window

R = L/W

T

= Thickness of window

P

Unclamped, Smax at centre

Clamped, Smax at edge

CLAMPED

Circular Window (Safety Factor of 4 & Kc = 0.75)

T

= 0.866 D ( P / Fa )

Rectangular Window (Safety Factor of 4 & Kc = 0.75)

T

1.23 L

( P / ( Fa . ( 1 + R2 )))

UNCLAMPED

Circular Window (Safety Factor of 4 & Ku = 1.125)

T

= 1.06 D ( P / Fa )

Rectangular Window (Safety Factor of 4 & Ku = 1.125)

T

1.50 L

= Load per unit area

( P / ( Fa . ( 1 + R2 )))

CONSTANT K

The value of K depends on the

method of support, upon the

force introduced in clamping

and upon the brittle / ductile

character of the window material

involved.

Empirically, a K value of 0.75 is

found suitable for most optical

crystals when the perimeter is

clamped, and a value 50%

greater when unclamped.

Kc

Ku

=

=

0.75

1.125

SAFETY FACTOR

To avoid plastic deformation, the maximum stress (Smax ) should be less than the Apparent Elastic Limit (Fa) by an appropriate

Safety Factor (SF)

Smax

=

Fa / SF

A modest safety factor of 4 (i.e., maximum stress equals one quarter of the elastic limit) seems to suffice for many laboratory

applications where the operating conditions are reasonably under control. Severe conditions such as thermal shock require

special consideration and may even result in a decision to use a reduced thickness. The published Apparent Elastic Limit of

some materials may not be completely reliable. Crystals vary and cleavage may occur according to grain boundaries or the

particular cut of the ingot. Ultimately, the final design thickness must be a carefully considered decision and may need to be

empirically tested. Crystran Ltd can accept no responsibilty for the adoption of these calculations and recommendations.

CRYSTRAN LTD

1 Broom Road Business Park, Poole, Dorset, UK BH12 4PA

TEL: +44 1202 307650

FAX +44 1202 307651

Email: sales@crystran.co.uk

www.crystran.co.uk

Crystran Ltd October 2014

The Design of Pressure Windows

Worked Examples

CaF2 window 50mm with 1 atmosphere P.D

Safety factor of 4

T

=

2.8mm unclamped

T

=

2.3mm clamped

CaF2 window 52mm x 20mm with 1 atmosphere P.D

Safety factor of 4

T

=

1.5mm unclamped

T

=

1.2mm clamped

Sapphire window 25mm with 3800 psi P.D

Safety factor of 4

T

=

7.7mm unclamped

T

=

6.3mm clamped

With sapphire, for pressures above 500psi it is recommended

to use windows with the axis of the crystal parallel to the axis

of the window. (Perpendicular to the surface)

KRS5 window 40 with 1 atmosphere P.D

Safety factor of 4

T

=

2.6mm unclamped

T

=

2.2mm clamped

COMMON APPARENT ELASTIC LIMITS

Al2O3 (Sapphire) = 276Mpa = 45000psi

BaF2

= 26.9MPa = 3900psi

BK7 glass

= 63.5Mpa = 9210psi

CaF2

= 36.5MPa = 5300psi

Germanium

= 89.6MPa = 13000psi

KRS5

= 26.2Mpa = 3800psi

LiF

= 11.2MPa = 1620psi

MgF2

= 49.6MPa = 7200psi

Silica glass

= 55.0Mpa = 7980psi

ZnS (FLIR)

= 103.4MPa = 15000psi

ZnSe

= 55.1MPa = 8000psi

NORMAL ATMOSPHERIC PRESSURE

Traditionally measured in:

(1)

pounds/sq inch

14.7 psi

(2)

inches of mercury 29.9213"

(3)

mm of mercury

760 mm

(4)

millibar

1013.240 mBar

Now measured in SI units:

(5)

Pascals

101.324 kPa

(2) and (3) are straightforward measures of a

column of mercury supported by 1 atmosphere.

1" = 25.4mm

Fused silica window 100mm with 1000 kPa P.D

Safety factor of 10

T

=

22.6mm unclamped

T

=

18.5mm clamped

ZnSe window 80mm with 1 atmosphere P.D

Safety factor of 4

T

=

3.6mm unclamped

T

=

3.0mm clamped

1mm = 0.03937"

(4) and (5) are actual measures of pressure

(force/area) and take account of the density of

mercury (13.595gm/cc at 0degC) and the

acceleration due to gravity (980.665 cm/sec2) when

converting from a mercury barometer reference.

Pressure at 1 atmosphere

= 0.76m x 13595 kgm.m-3 x 9.80665 m . s-1

= 101324 Pa (N/m2) (m-1.kgm.s-1)

= 101.324kPa

NOTES:

A carefully designed window may still break before any significant loading if the mounting

introduces any localised stress.

Mismatch of expansion coefficients generally dictates the use of resilient material between window

and mounting.

Thermal outgassing used in UHV systems should be undertaken with caution with crystal windows as

thermal shock may initial cleavage in some crystals

The constant for clamped mounting allows for no flexure at the wall. The use of soft gaskets may

allow flexure so the formula for the "unclamped" condition should be used.

CRYSTRAN LTD

1 Broom Road Business Park, Poole, Dorset, UK BH12 4PA

TEL: +44 1202 307650

FAX +44 1202 307651

Email: sales@crystran.co.uk

www.crystran.co.uk

Crystran Ltd October 2014

You might also like

- Design Calculation-Glass BalustradeDocument8 pagesDesign Calculation-Glass Balustrademsiddiq1100% (2)

- Design Calculations For The Dome Structure-Type 1Document6 pagesDesign Calculations For The Dome Structure-Type 1msiddiq1100% (2)

- DESIGN CALCULATIONS - CW-13794 - Mullion 3.8m at 5m HeightDocument15 pagesDESIGN CALCULATIONS - CW-13794 - Mullion 3.8m at 5m Heightmsiddiq1100% (2)

- Design of Flat Head For HydrotestDocument12 pagesDesign of Flat Head For HydrotestSAGARNo ratings yet

- Design Calculations For Aluminium Profile-13940Document9 pagesDesign Calculations For Aluminium Profile-13940msiddiq1100% (1)

- CHM 207 Report 2Document8 pagesCHM 207 Report 2Salazar ZawawiNo ratings yet

- Design of HCL FRP Storage TANKDocument21 pagesDesign of HCL FRP Storage TANKEleazar Mendoza88% (8)

- Design Calculations For Aluminium Profile-13795Document8 pagesDesign Calculations For Aluminium Profile-13795msiddiq1100% (1)

- Selected LP Apps Handouts 3 PDFDocument88 pagesSelected LP Apps Handouts 3 PDFcarlette110% (1)

- Siemens Wincc FlexibleDocument428 pagesSiemens Wincc Flexibleibrahim100% (1)

- Montero WSM enDocument1,853 pagesMontero WSM enesyjam100% (7)

- Fleck 9000 9100 9500 Service Manual 40944Document52 pagesFleck 9000 9100 9500 Service Manual 40944rhusseinpos4765No ratings yet

- Design of Pressure Windows PDFDocument2 pagesDesign of Pressure Windows PDFMoisés SolisNo ratings yet

- Sky Light - 1Document32 pagesSky Light - 1Nazar Bazaraa100% (1)

- Eyeplate Ramp LCT. Adinda DizaDocument4 pagesEyeplate Ramp LCT. Adinda DizaherlambangNo ratings yet

- Design Cal IndoramaDocument13 pagesDesign Cal IndoramaKUNALJAYNo ratings yet

- FR-4 Spec'sDocument2 pagesFR-4 Spec'splakkampelliNo ratings yet

- Plant DesignDocument11 pagesPlant DesignGrey DaveNo ratings yet

- 2009W ENGI 8673 L12 Ex 01 Mathcad PDFDocument5 pages2009W ENGI 8673 L12 Ex 01 Mathcad PDFThyago de Lellys100% (1)

- Manual Design of One Way Slab (Continous Slab)Document5 pagesManual Design of One Way Slab (Continous Slab)Struct Soft CentreNo ratings yet

- 04 LloydDocument107 pages04 LloydAgung Pramu AjiNo ratings yet

- Vessel, BS5500 Cat-3, Is Followed. The Chamber Is Designed As A Pressure VesselDocument19 pagesVessel, BS5500 Cat-3, Is Followed. The Chamber Is Designed As A Pressure Vesselbhalchandrak1867No ratings yet

- CSTR DesignDocument9 pagesCSTR DesignKushal KayalNo ratings yet

- Data Sheet: General Purpose Chip ResistorsDocument9 pagesData Sheet: General Purpose Chip ResistorsJamesSmith2014No ratings yet

- Chapter 1 Chemical & MechanicalDocument25 pagesChapter 1 Chemical & MechanicalcykinNo ratings yet

- Structural Design ReportDocument99 pagesStructural Design ReportCitizen Kwadwo AnsongNo ratings yet

- RT Duroid 6006 6010 Laminate Data SheetDocument2 pagesRT Duroid 6006 6010 Laminate Data SheetdrhammoudaNo ratings yet

- Corona Performance of KaptonDocument4 pagesCorona Performance of KaptonAlfChenNo ratings yet

- EFK-EHR01-LIFT-CAL-PS-007 (Lifting Calculation For Triplex Engine Skid Offshore Frame)Document10 pagesEFK-EHR01-LIFT-CAL-PS-007 (Lifting Calculation For Triplex Engine Skid Offshore Frame)LAryo YogisworoNo ratings yet

- Pilkor PCX2 335MDocument7 pagesPilkor PCX2 335MadminagentNo ratings yet

- Pilkor PCX2 335Document7 pagesPilkor PCX2 335Claudia Alejandra López100% (1)

- Slab DesignDocument5 pagesSlab DesignMuhammed Shafeek K TNo ratings yet

- Bhubaneswar Airport - Glazing Report - 4.26 KpaDocument55 pagesBhubaneswar Airport - Glazing Report - 4.26 KpaArdrick BoscoNo ratings yet

- Dupont Nomex 410Document8 pagesDupont Nomex 410jalilemadiNo ratings yet

- Total Middle East New Bitumen Terminal in TlbuDocument25 pagesTotal Middle East New Bitumen Terminal in TlbuAnupam Jana100% (2)

- DESIGN CALCULATIONS - GL-03 2509 - 4.0mDocument17 pagesDESIGN CALCULATIONS - GL-03 2509 - 4.0mmsiddiq1No ratings yet

- 12Document119 pages12Salihin FhooziNo ratings yet

- Impreso - Leido - 2014 - Hala - Etal - Grow Prop Hihg Index Ta2O5 Opt Coat Prep HiPIMS MethDocument17 pagesImpreso - Leido - 2014 - Hala - Etal - Grow Prop Hihg Index Ta2O5 Opt Coat Prep HiPIMS Methphdeza2000No ratings yet

- Technor TnupDocument4 pagesTechnor Tnupsteam100deg8229No ratings yet

- 132kv Cables For Transformer Feeder, Cables in Duct at 9029Document4 pages132kv Cables For Transformer Feeder, Cables in Duct at 9029Muhammad MahmudNo ratings yet

- Design Calculations For Aluminium Profile 13794Document14 pagesDesign Calculations For Aluminium Profile 13794Wilson PesantezNo ratings yet

- Louvre Jamb Strength CalculationDocument3 pagesLouvre Jamb Strength CalculationZikri Al-asy'ariNo ratings yet

- Design Calculation-CYL VERTICAL 1.0mDIA X 1.10m ST HT TankDocument17 pagesDesign Calculation-CYL VERTICAL 1.0mDIA X 1.10m ST HT TankEleazar Mendoza50% (2)

- Design 9Document7 pagesDesign 9June PlantillaNo ratings yet

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocument31 pagesStorage Tank Design Calculation - Api 650: Close Floating RoofNguyễn Duy HưngNo ratings yet

- Arcelormittal Beams Calculator V3.02: D:/... /Vários/Estruturas Mistas/Madre Escada Apoio 2.PmxDocument6 pagesArcelormittal Beams Calculator V3.02: D:/... /Vários/Estruturas Mistas/Madre Escada Apoio 2.PmxSílvio GonçalvesNo ratings yet

- Glass CheckDocument6 pagesGlass CheckMuraleedharanNo ratings yet

- Wind Load CalculationDocument98 pagesWind Load CalculationAnonymous HJ7hmihhNo ratings yet

- Dymax GA-142 UV Curable Gasket Data SheetDocument3 pagesDymax GA-142 UV Curable Gasket Data SheetJoshua WallesNo ratings yet

- The Dubai Chamber of Commerce and Industry Building ExtensionDocument22 pagesThe Dubai Chamber of Commerce and Industry Building ExtensionAhammad KabeerNo ratings yet

- NOTES SeviceabilityDocument81 pagesNOTES Seviceabilitydileep 443No ratings yet

- High Frequency Laminates Product Selector Guide and Standard Thicknesses and Tolerances Low ResolutionDocument12 pagesHigh Frequency Laminates Product Selector Guide and Standard Thicknesses and Tolerances Low ResolutionPriyanka ChoudharyNo ratings yet

- Appendix F - Mechanical DesignDocument37 pagesAppendix F - Mechanical DesignPDPPPMAT0621 Ruhilin Binti NasserNo ratings yet

- EG7005 STEEL DESIGN-BATCH 21-22: Lijose Jacob 2235791Document83 pagesEG7005 STEEL DESIGN-BATCH 21-22: Lijose Jacob 2235791lijosejacobNo ratings yet

- High Frequency Laminates - Product Selector Guide and Standard Thicknesses and Tolerances Low Resolution PDFDocument12 pagesHigh Frequency Laminates - Product Selector Guide and Standard Thicknesses and Tolerances Low Resolution PDFrahul05singhaNo ratings yet

- Elasto-Hydrodynamic Lubrication: International Series on Materials Science and TechnologyFrom EverandElasto-Hydrodynamic Lubrication: International Series on Materials Science and TechnologyNo ratings yet

- Compendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)From EverandCompendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)No ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Next Generation Optical Wireless Communication Systems: A Systems ApproachFrom EverandNext Generation Optical Wireless Communication Systems: A Systems ApproachNo ratings yet

- Tsim Sha Tsui Symphony of Lights: 8 PM: Macau Day Tour-Outer HarborDocument11 pagesTsim Sha Tsui Symphony of Lights: 8 PM: Macau Day Tour-Outer Harborcarlette11No ratings yet

- WritingaResearchAbstract CompI-BDocument2 pagesWritingaResearchAbstract CompI-Bcarlette11No ratings yet

- Introduction To Fluid Mechanics: Intended Learning OutcomesDocument4 pagesIntroduction To Fluid Mechanics: Intended Learning Outcomescarlette11No ratings yet

- SadafDocument24 pagesSadafcarlette11No ratings yet

- Aerogel Drying: Published in "State of The Art Book On Supercritical Fluids", Valencia:AINIA, 2004, Pp. 129-134Document6 pagesAerogel Drying: Published in "State of The Art Book On Supercritical Fluids", Valencia:AINIA, 2004, Pp. 129-134carlette11No ratings yet

- Introduction To Process Dynamics and Control, and Instrumentation Laboratory yDocument27 pagesIntroduction To Process Dynamics and Control, and Instrumentation Laboratory ycarlette11No ratings yet

- Nanomaterials: Lecture #4 Surface ScienceDocument44 pagesNanomaterials: Lecture #4 Surface Sciencecarlette11No ratings yet

- Thermal Conductivity Determination of Small Polymer Samples by Differential Scanning CalorimetryDocument5 pagesThermal Conductivity Determination of Small Polymer Samples by Differential Scanning Calorimetrycarlette11No ratings yet

- FDSGFDocument5 pagesFDSGFcarlette11No ratings yet

- Technopreneurship Business Plan II. Executive Summary: Mission StatementDocument3 pagesTechnopreneurship Business Plan II. Executive Summary: Mission Statementcarlette11No ratings yet

- Lipids and Proteins Are Associated in Biological Membranes: What Is A LipidDocument20 pagesLipids and Proteins Are Associated in Biological Membranes: What Is A Lipidcarlette11No ratings yet

- Biochemistry: - Organic Chemistry: The Study of The Compounds of CarbonDocument7 pagesBiochemistry: - Organic Chemistry: The Study of The Compounds of Carboncarlette11No ratings yet

- What Is The Integral of CSC U Du A. LN (CSC U - Cot U) + C B. LN (CSC U + Cot U) + C C.LN (Sec U - Tan U) + C D. LN (Sec U + Tan U) + CDocument1 pageWhat Is The Integral of CSC U Du A. LN (CSC U - Cot U) + C B. LN (CSC U + Cot U) + C C.LN (Sec U - Tan U) + C D. LN (Sec U + Tan U) + Ccarlette11No ratings yet

- FdafsfDocument9 pagesFdafsfcarlette11No ratings yet

- Unendinggrace Engineering Unendinggrace Engineering Unendinggrace EngineeringDocument87 pagesUnendinggrace Engineering Unendinggrace Engineering Unendinggrace Engineeringcarlette11No ratings yet

- DsadaDocument4 pagesDsadacarlette11No ratings yet

- Unit 11 PDFDocument15 pagesUnit 11 PDFcarlette11No ratings yet

- DfafsafsaDocument1 pageDfafsafsacarlette11No ratings yet

- Biochemistry: - Organic Chemistry: The Study of The Compounds of CarbonDocument7 pagesBiochemistry: - Organic Chemistry: The Study of The Compounds of Carboncarlette11No ratings yet

- DsadadDocument5 pagesDsadadcarlette11No ratings yet

- The Three-Dimensional Structure of ProteinsDocument21 pagesThe Three-Dimensional Structure of Proteinscarlette11No ratings yet

- Unit 9 PDFDocument16 pagesUnit 9 PDFcarlette11No ratings yet

- Centrifugation I.: Centrifuge Selection - Tubular Bowl CentrifugeDocument3 pagesCentrifugation I.: Centrifuge Selection - Tubular Bowl Centrifugecarlette11No ratings yet

- Ch.E. Applications in Fluid Statics: Intended Learning OutcomesDocument8 pagesCh.E. Applications in Fluid Statics: Intended Learning Outcomescarlette11No ratings yet

- Amount of Feed EnteringDocument1 pageAmount of Feed Enteringcarlette11No ratings yet

- Alkali Metals NotesDocument23 pagesAlkali Metals Notesaayush basnetNo ratings yet

- Check List For: Installation of Fahu: Project Name & LogosDocument2 pagesCheck List For: Installation of Fahu: Project Name & LogosSamer AliNo ratings yet

- Toshiba - E STUDIO - 350 352 353 450 452 453Document302 pagesToshiba - E STUDIO - 350 352 353 450 452 453asirirNo ratings yet

- Sustainability Presentation On RecyclingDocument25 pagesSustainability Presentation On Recyclingapi-280793093No ratings yet

- 11 - Space Frames ConstructionDocument11 pages11 - Space Frames ConstructionJCLL50% (2)

- Chemxseal 32 18 Fire Stop SealantDocument20 pagesChemxseal 32 18 Fire Stop SealantAbdel Mongy AhmedNo ratings yet

- Matter 1A Forms Properties and ChangesDocument47 pagesMatter 1A Forms Properties and ChangesSamKris Guerrero Malasaga100% (2)

- Multiaxial Fatigue Life Prediction On S355 StructuDocument12 pagesMultiaxial Fatigue Life Prediction On S355 Structubaja2011No ratings yet

- O & M Manual SS PenstocksDocument39 pagesO & M Manual SS PenstocksMabel LimNo ratings yet

- Pump Station (Lago Agrio)Document163 pagesPump Station (Lago Agrio)Rous MeryNo ratings yet

- Cement Aggregate Concrete Durability LectureDocument33 pagesCement Aggregate Concrete Durability LectureManoj Kumar SinghNo ratings yet

- Tube Bender HMP 200 FinalDocument18 pagesTube Bender HMP 200 Finaltigre_fiel100% (1)

- JACE 2 Mounting&WiringDocument28 pagesJACE 2 Mounting&WiringroshanlNo ratings yet

- Rebar Splicing HandbookDocument72 pagesRebar Splicing HandbookKenshin HimuraNo ratings yet

- Laprak Distilasi UapDocument11 pagesLaprak Distilasi UapRetnani Arum PertiwiNo ratings yet

- T F /,, - The Skid-Mounted Blower AssemblyDocument2 pagesT F /,, - The Skid-Mounted Blower Assemblyprihartono_diasNo ratings yet

- 1 s2.0 S0167663614001665 MainDocument18 pages1 s2.0 S0167663614001665 MainyasminaNo ratings yet

- Installation, Operation & Maintenance Manual: Sliding-Vane Stationary Pumps For LPG and NHDocument40 pagesInstallation, Operation & Maintenance Manual: Sliding-Vane Stationary Pumps For LPG and NHEmanuelCalmaYandocNo ratings yet

- C. Pollutants (Paper Making) : Titanium Dioxide, Dyes, Optical Brightening Agents)Document2 pagesC. Pollutants (Paper Making) : Titanium Dioxide, Dyes, Optical Brightening Agents)Lywell TanedoNo ratings yet

- Manual Usua RioDocument132 pagesManual Usua RioSDL ElectricistasNo ratings yet

- Poe PresentationDocument29 pagesPoe Presentationsarath.kp.storage1No ratings yet

- AW60Document1 pageAW60Fitra VertikalNo ratings yet

- The Affinity Laws of Centrifugal Pumps or Fans Indicates The Influence On Volume CapacityDocument7 pagesThe Affinity Laws of Centrifugal Pumps or Fans Indicates The Influence On Volume CapacityAKHILNo ratings yet

- Vahle Enclosed Conductor System - KBHDocument24 pagesVahle Enclosed Conductor System - KBHKS Chee0% (1)

- Ingersoll Rand Oil Free Centac Compressor PDFDocument16 pagesIngersoll Rand Oil Free Centac Compressor PDFAlejandro Martinez R100% (1)

- Introduction To DSC PresentationDocument102 pagesIntroduction To DSC Presentationimdad_buetNo ratings yet