Professional Documents

Culture Documents

Concrete Finishes F1-F4

Concrete Finishes F1-F4

Uploaded by

Kyle MoolmanCopyright:

Available Formats

You might also like

- Ellison Throttle Body Injector ManualDocument33 pagesEllison Throttle Body Injector ManualFRRNo ratings yet

- Sans5862 1Document9 pagesSans5862 1Kyle Moolman100% (2)

- Sans 51008Document21 pagesSans 51008Kyle MoolmanNo ratings yet

- Sans5862 2Document9 pagesSans5862 2Kyle MoolmanNo ratings yet

- What Constitute A Variation in Construction From Legal PerspectiveDocument131 pagesWhat Constitute A Variation in Construction From Legal PerspectiveAnggoro PutroNo ratings yet

- 16a Bill 1 PreliminariesDocument41 pages16a Bill 1 PreliminariesdophongxdNo ratings yet

- Sri Lanka Air Force: Bidding DocumentDocument89 pagesSri Lanka Air Force: Bidding DocumentSudu BandaNo ratings yet

- Ballast Less Track DesignDocument8 pagesBallast Less Track DesignSanjoy SanyalNo ratings yet

- Sans 1200 AdDocument9 pagesSans 1200 AdKyle MoolmanNo ratings yet

- Residential and Low-Rise Steel Framing NZ-Public CommentDocument59 pagesResidential and Low-Rise Steel Framing NZ-Public CommentpengenbangetNo ratings yet

- MF8250 PDFDocument1,463 pagesMF8250 PDFAnonymous 9fCAFynMNo ratings yet

- Dynamic Cone Penetrometer (DCP)Document2 pagesDynamic Cone Penetrometer (DCP)Harcana AdriantaraNo ratings yet

- Specification For Highway Works UK - SERIES 1900Document78 pagesSpecification For Highway Works UK - SERIES 1900Kévin JacobNo ratings yet

- Calculating and Using Float: Core Scheduling Papers: #5Document11 pagesCalculating and Using Float: Core Scheduling Papers: #5Traci Reed100% (1)

- BWKDocument13 pagesBWKan_taniaNo ratings yet

- Tek 01-01FDocument4 pagesTek 01-01FHisham MohamedNo ratings yet

- CLJ 4 Barry ArticleDocument14 pagesCLJ 4 Barry ArticleGwapito TresNo ratings yet

- Sri Lanka Construction - Sept 15 FinalDocument37 pagesSri Lanka Construction - Sept 15 Finalsha_cadNo ratings yet

- Https - WWW - Unra.go - Ug - Media - 2023 - 03 - JAN-2023-PROJECT-REPORT-ROADSDocument17 pagesHttps - WWW - Unra.go - Ug - Media - 2023 - 03 - JAN-2023-PROJECT-REPORT-ROADSDunstan SendiwalaNo ratings yet

- RC 1 Course OutlineDocument1 pageRC 1 Course Outlinehanose100% (1)

- Construction Contract Law-1 For ShiftyDocument13 pagesConstruction Contract Law-1 For ShiftyStíofán BánNo ratings yet

- BKSURCO - Certified - NEC Professional - Preparatory - CourseDocument57 pagesBKSURCO - Certified - NEC Professional - Preparatory - CourseASKA LIN100% (1)

- 9449 Macalloy Tension StructuresDocument16 pages9449 Macalloy Tension StructuresYam BalaoingNo ratings yet

- Tender Evaluation ReportDocument20 pagesTender Evaluation ReportastudentNo ratings yet

- Engineering Audit of CHOGM ActivitiesDocument231 pagesEngineering Audit of CHOGM ActivitiesDaniel WilsonNo ratings yet

- Ijser: Effects of Design Errors On Construction ProjectsDocument16 pagesIjser: Effects of Design Errors On Construction ProjectsDaramola Samuel OlaNo ratings yet

- Clause 13: Variations and Adjustments: The Power To Vary and Its LimitationsDocument7 pagesClause 13: Variations and Adjustments: The Power To Vary and Its Limitationssilence_10007No ratings yet

- Span Tables TQ 07 Timber-Deck FinalDocument7 pagesSpan Tables TQ 07 Timber-Deck Finaljon kolmneNo ratings yet

- Standard Method of Measurement FOR Building Elements: Architectural Services DepartmentDocument69 pagesStandard Method of Measurement FOR Building Elements: Architectural Services DepartmentEka Budhi PrasetyaNo ratings yet

- For Civil Engineering Works: July 3, 2021 UDSM, TM 322 1Document26 pagesFor Civil Engineering Works: July 3, 2021 UDSM, TM 322 1mozNo ratings yet

- Bailey Fact SheetDocument2 pagesBailey Fact Sheetcaballerolang100% (1)

- BS 5628Document10 pagesBS 5628chowchsNo ratings yet

- Rebar Shape CodesDocument1 pageRebar Shape CodesJoshua HobsonNo ratings yet

- The Adoption of CESMM 3Document3 pagesThe Adoption of CESMM 3raashidhvNo ratings yet

- Comparative Study On Cementitious Content of GrounDocument5 pagesComparative Study On Cementitious Content of Grounkristine coteloNo ratings yet

- Application of Infrared Thermography Technique in Uilding Finish EvaluationDocument9 pagesApplication of Infrared Thermography Technique in Uilding Finish EvaluationNicolas De NadaiNo ratings yet

- McDermott International Inc Vs Burn Standard Co LtS060394COM134123Document41 pagesMcDermott International Inc Vs Burn Standard Co LtS060394COM134123rishi100% (1)

- Preamble Civil 2008Document4 pagesPreamble Civil 2008erickyfmNo ratings yet

- Standard Drawings - Kerb and Wheel Stopper DetailsDocument1 pageStandard Drawings - Kerb and Wheel Stopper DetailsprmraoNo ratings yet

- BEM 1.2003 Guidelines For Checking The Work of Another EngineerDocument11 pagesBEM 1.2003 Guidelines For Checking The Work of Another EngineerVong Kee SinNo ratings yet

- Asphalt Concrete Report Final VersionDocument11 pagesAsphalt Concrete Report Final VersionLorraine Custodio100% (1)

- Steel BS Parameter PDFDocument8 pagesSteel BS Parameter PDFdpkNo ratings yet

- Construction Specification Chain Link FenceDocument2 pagesConstruction Specification Chain Link Fenceyamanta_rajNo ratings yet

- SAITO Twin-Cylinder Four-Stroke ManualDocument32 pagesSAITO Twin-Cylinder Four-Stroke ManualAngelLazarteNo ratings yet

- MSC CPM (HRE) Individual Assignment - Shepherd Nhanga Rev 00Document11 pagesMSC CPM (HRE) Individual Assignment - Shepherd Nhanga Rev 00Shepherd NhangaNo ratings yet

- Masonry and Concrete - FinDocument12 pagesMasonry and Concrete - FinSarah Marie Nueva Sierra100% (1)

- Welcome To The Institute For Timber Construction-South Africa Itc-SaDocument75 pagesWelcome To The Institute For Timber Construction-South Africa Itc-SaMclyb GumbieNo ratings yet

- Exams For Lead and Senior EngineersDocument4 pagesExams For Lead and Senior EngineerslamesginNo ratings yet

- Ebcs-5 18Document4 pagesEbcs-5 18eyerusalemh100% (1)

- Soils and EngineeringDocument8 pagesSoils and Engineeringuntoni100% (1)

- Revised Drainage Structures 24082015Document22 pagesRevised Drainage Structures 24082015soleb100% (1)

- Reinforced Concrete Designers Handbook 10th Edition Reynolds Steedman 2 Part PrintDocument7 pagesReinforced Concrete Designers Handbook 10th Edition Reynolds Steedman 2 Part Printikanyu79No ratings yet

- Fosroc Fibreboard - DtsDocument2 pagesFosroc Fibreboard - Dtsaljhun_1966No ratings yet

- Surface Water DrainageDocument8 pagesSurface Water DrainageronyNo ratings yet

- Timber Connectors Characteristic Loadings DataDocument8 pagesTimber Connectors Characteristic Loadings DataDinh Nam NguyenNo ratings yet

- Spacing of Rebars Steel Bars 1Document4 pagesSpacing of Rebars Steel Bars 1talatzahoor0% (1)

- Types of FootingDocument3 pagesTypes of FootingRonald DolorNo ratings yet

- Bac Iem 2Document2 pagesBac Iem 2Lee Wen ZheNo ratings yet

- Chapter 11 Steep Slope ProtectionDocument8 pagesChapter 11 Steep Slope ProtectionVinod TiwariNo ratings yet

- Bridge Works SubstructureDocument26 pagesBridge Works SubstructureRoyal_gkNo ratings yet

- An Overview of The Cadastral System in TanzaniaDocument17 pagesAn Overview of The Cadastral System in TanzaniasiwalazeNo ratings yet

- College of Engineering &technology Departement of Cotm Presentation On InternshipDocument33 pagesCollege of Engineering &technology Departement of Cotm Presentation On InternshipLij AbelNo ratings yet

- CESSM Guidance Note May 1994Document3 pagesCESSM Guidance Note May 1994Sachith SeneviratnaNo ratings yet

- CIPAADocument118 pagesCIPAAKent TamNo ratings yet

- Foundations For WallsDocument9 pagesFoundations For WallsAnamaria SuzanaNo ratings yet

- Concrete FormworkDocument8 pagesConcrete Formworksethu1091No ratings yet

- Pile Test and Concrete FaceDocument6 pagesPile Test and Concrete FaceEngineeri TadiyosNo ratings yet

- Concrete FormworkDocument43 pagesConcrete Formworkyrdgcgf5664100% (4)

- Reinforced Earth Consultant Data SheetDocument9 pagesReinforced Earth Consultant Data SheetKyle MoolmanNo ratings yet

- RIB CCS Candy Standard Stand Alone Proposal - ZA - 40th Jubilee Promotion - (1 User) - SignedDocument10 pagesRIB CCS Candy Standard Stand Alone Proposal - ZA - 40th Jubilee Promotion - (1 User) - SignedKyle MoolmanNo ratings yet

- Precast Manufacture Guidance NotesDocument11 pagesPrecast Manufacture Guidance NotesKyle MoolmanNo ratings yet

- Journal of Rock Mechanics and Geotechnical Engineering: Sadok Benmebarek, Samir Attallaoui, Naïma BenmebarekDocument6 pagesJournal of Rock Mechanics and Geotechnical Engineering: Sadok Benmebarek, Samir Attallaoui, Naïma BenmebarekKyle MoolmanNo ratings yet

- Analysis of Mechanically Stabilised Earth (MSE) Retaining Wall Using Finite Element and AASHTO MethodsDocument13 pagesAnalysis of Mechanically Stabilised Earth (MSE) Retaining Wall Using Finite Element and AASHTO MethodsKyle MoolmanNo ratings yet

- Appendix-I Closure CostsDocument30 pagesAppendix-I Closure CostsKyle MoolmanNo ratings yet

- DSA Region 1 Sales - June 2016Document19 pagesDSA Region 1 Sales - June 2016Kyle MoolmanNo ratings yet

- State of The Practice of MSE Wall Design For Highway StructuresDocument21 pagesState of The Practice of MSE Wall Design For Highway StructuresKyle MoolmanNo ratings yet

- MSE-Wall-Inspectors-Handbook GEM 2020Document54 pagesMSE-Wall-Inspectors-Handbook GEM 2020Kyle MoolmanNo ratings yet

- Mfwetus Profile 2022V1Document9 pagesMfwetus Profile 2022V1Kyle MoolmanNo ratings yet

- Circular - JBCC Clause 29 - ID 331615Document3 pagesCircular - JBCC Clause 29 - ID 331615Kyle MoolmanNo ratings yet

- SANS1200MMDocument15 pagesSANS1200MMKyle MoolmanNo ratings yet

- SANS1200NBDocument19 pagesSANS1200NBKyle MoolmanNo ratings yet

- Project Management Basics / IntroductionDocument29 pagesProject Management Basics / IntroductionKyle MoolmanNo ratings yet

- Sans50934 2Document27 pagesSans50934 2Kyle MoolmanNo ratings yet

- South Or.': ZED ONDocument18 pagesSouth Or.': ZED ONKyle Moolman100% (1)

- Sans 5865Document11 pagesSans 5865Kyle Moolman67% (3)

- Civil Engineering Manual Gcc2004Document185 pagesCivil Engineering Manual Gcc2004Paul Sony100% (1)

- Ficha Tecnica XR6C-LEDDocument4 pagesFicha Tecnica XR6C-LEDEfrain MateoNo ratings yet

- BEME Eletrical TemplateDocument19 pagesBEME Eletrical TemplateAbdulyekini Ahmadu100% (3)

- Centres and Peripheries in Ottoman Architecture Rediscovering A Balkan Heritage Ed Maximilian Hartmuth Sarajevo Stockholm Cultural Heritage Witho PDFDocument173 pagesCentres and Peripheries in Ottoman Architecture Rediscovering A Balkan Heritage Ed Maximilian Hartmuth Sarajevo Stockholm Cultural Heritage Witho PDFRebecca378No ratings yet

- Environmental Responsive Design: Case Study - Cii - Sohrabji Godrej GreenDocument19 pagesEnvironmental Responsive Design: Case Study - Cii - Sohrabji Godrej Green052 Deepak NaralaNo ratings yet

- AR-102-ground Floor Masonry Lineout PlanDocument1 pageAR-102-ground Floor Masonry Lineout Plandimpy khattarNo ratings yet

- MSE 227 HW9 F10 SolutionsDocument5 pagesMSE 227 HW9 F10 Solutionsputri nur shahidaNo ratings yet

- EstimateDocument5 pagesEstimatesreek009ark3350No ratings yet

- Estimation Templates For CalculationDocument15 pagesEstimation Templates For CalculationSyed MohammedNo ratings yet

- Abratec 6715: WeldingDocument2 pagesAbratec 6715: Weldingmohamed AdelNo ratings yet

- ENV - Design Guide Retaining Walls - 01.16Document45 pagesENV - Design Guide Retaining Walls - 01.16iosamNo ratings yet

- Welding ElectrodesDocument13 pagesWelding ElectrodesArimoro Cyril ObuseNo ratings yet

- Modelim StrukturorDocument22 pagesModelim StrukturorAnisa Biba100% (1)

- Practical Strategies: HotelsDocument15 pagesPractical Strategies: HotelsSNEHA DEVARAJUNo ratings yet

- From August 1995: For Relay Location and Multiple Connectors See Also Section "Component Locations"Document5 pagesFrom August 1995: For Relay Location and Multiple Connectors See Also Section "Component Locations"Niine 4No ratings yet

- Leo Laser 17 Izumi TricycleDocument12 pagesLeo Laser 17 Izumi TricycleRea Cleare TampusNo ratings yet

- Types and Causes of Deterioration of Steel StructureDocument24 pagesTypes and Causes of Deterioration of Steel Structuresnehakudale21100% (1)

- APT10 and APT14: For Effective Condensate Drainage and RemovalDocument12 pagesAPT10 and APT14: For Effective Condensate Drainage and RemovalwimpievdsNo ratings yet

- 2020-06-25 Method Statement of RCBC Construction CH402+737Document33 pages2020-06-25 Method Statement of RCBC Construction CH402+737施智捷100% (2)

- API 598 Valves Inspection and TestingDocument1 pageAPI 598 Valves Inspection and TestingCRISTHIAN PIERR PAUSIC BAZALARNo ratings yet

- Heyles Fentoes Trainnig ReportDocument58 pagesHeyles Fentoes Trainnig ReportayeshmanthabroNo ratings yet

- Rsp-Prc014-En Wood WayDocument44 pagesRsp-Prc014-En Wood WayRuiz Caldera Eloy E.No ratings yet

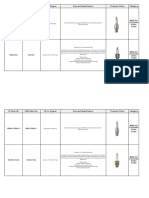

- Mercury Outboard Spark PlugsDocument10 pagesMercury Outboard Spark PlugsJSMarine Parts ChinaNo ratings yet

- Beam Deflection When The Moment of Inertia Is VariableDocument9 pagesBeam Deflection When The Moment of Inertia Is VariableandrewsugihartoNo ratings yet

- Weight Control Report For Regas Platform TopsidesDocument42 pagesWeight Control Report For Regas Platform TopsidesinnovativekarthiNo ratings yet

- 109002-TSP-417 Specification For Landfall Construction and Pipeline Pull-InDocument41 pages109002-TSP-417 Specification For Landfall Construction and Pipeline Pull-InMohd. Fadhil JamirinNo ratings yet

- GPT Nadu NeduDocument222 pagesGPT Nadu NeduSwarna LathaNo ratings yet

Concrete Finishes F1-F4

Concrete Finishes F1-F4

Uploaded by

Kyle MoolmanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Concrete Finishes F1-F4

Concrete Finishes F1-F4

Uploaded by

Kyle MoolmanCopyright:

Available Formats

Finish F1.

--This finish applies to surfaces where roughness is not objectionable, such as those upon or against

which fill material or concrete will be placed, the upstream faces of concrete dams that will normally be under

water, or surfaces that will otherwise be permanently concealed. The only surface treatment required is repair

of defective concrete, correction of surface depressions deeper than 1 inch, and filling of tie-rod holes where the

surface is to be coated with dampproofing or where the holes are deeper than 1 inch in walls less than 12 inches

thick. Form sheathing may be any material that will not leak mortar when the concrete is vibrated. Forms may

be built with a minimum of refinement.

Finish F2.--This finish is required on all permanently exposed surfaces for which other finishes are not

specified, such as the surfaces of canal structures; the inside surfaces of siphons, culverts, and tunnel linings;

outlet works and open spillways; small power and pumping plants; bridges and retaining walls not prominently

exposed to public inspection; galleries and tunnels in dams; and concrete dams except where F1 finishes are

permitted on the upstream faces. Form sheathing may be shiplap, plywood, or steel. Thin steel sheets (steel

lining) supported by a backing of wood boards may be used on approval, but the use of steel lining is not

encouraged. To obtain an F2 surface the forms must be built in a workmanlike manner to the required

dimensions and alignment, without conspicuous offsets or bulges.

Finish F3.--This finish is designated for surfaces of structures prominently exposed to public view where

appearance is of special importance. This category includes superstructures of large power and pumping plants;

parapets, railings, and decorative features on dams and bridges; and permanent buildings. To meet the

requirements for the F3 finish it is necessary for the forms to be built in a skillful, workmanlike manner,

accurately to dimensions. Occasionally tongue-and-groove boards or plywood sheets may be required for

specific F3 surfaces. However, specifications usually permit either tongue-and-groove boards or plywood at the

contractor's option. Steel lining is not permitted. There should be no visible offsets, bulges, or misalignment of

the concrete. At construction joints the forms should be tightly reset and securely anchored close to the joint, as

described in section 97.

Finish F4.--This finish is required for formed concrete surfaces where accurate alignment and evenness of

surface are essential for prevention of destructive effects of water action. Such surfaces include portions of

outlets, draft tubes, and spillway tunnels of high dams. The forms must be strong and held rigidly and

accurately to the prescribed alignment. Any form material or sheathing that will produce the required surface

(such as close-fitting shiplap, tongue-and-groove lumber, plywood, or steel) may be used. For warped surfaces,

the forms should be built up of laminated splines cut to make tight, smooth form surfaces after which the form

surfaces are dressed and sanded to the required curvature. Finish F5.--This finish is required for formed

concrete surfaces where plaster, stucco, or wainscoting is to be applied. Since a coarse-textured surface is

needed for bond, the concrete should be cast against rough-faced (S1S2E) form boards. Form oil should not be

used. Steel lining or steel sheathing is not permitted.

Incidentally, copies of the seventh edition of the 642-page Concrete Manual are again available from the Book

Department, CONCRETE CONSTRUCTION Publications.

You might also like

- Ellison Throttle Body Injector ManualDocument33 pagesEllison Throttle Body Injector ManualFRRNo ratings yet

- Sans5862 1Document9 pagesSans5862 1Kyle Moolman100% (2)

- Sans 51008Document21 pagesSans 51008Kyle MoolmanNo ratings yet

- Sans5862 2Document9 pagesSans5862 2Kyle MoolmanNo ratings yet

- What Constitute A Variation in Construction From Legal PerspectiveDocument131 pagesWhat Constitute A Variation in Construction From Legal PerspectiveAnggoro PutroNo ratings yet

- 16a Bill 1 PreliminariesDocument41 pages16a Bill 1 PreliminariesdophongxdNo ratings yet

- Sri Lanka Air Force: Bidding DocumentDocument89 pagesSri Lanka Air Force: Bidding DocumentSudu BandaNo ratings yet

- Ballast Less Track DesignDocument8 pagesBallast Less Track DesignSanjoy SanyalNo ratings yet

- Sans 1200 AdDocument9 pagesSans 1200 AdKyle MoolmanNo ratings yet

- Residential and Low-Rise Steel Framing NZ-Public CommentDocument59 pagesResidential and Low-Rise Steel Framing NZ-Public CommentpengenbangetNo ratings yet

- MF8250 PDFDocument1,463 pagesMF8250 PDFAnonymous 9fCAFynMNo ratings yet

- Dynamic Cone Penetrometer (DCP)Document2 pagesDynamic Cone Penetrometer (DCP)Harcana AdriantaraNo ratings yet

- Specification For Highway Works UK - SERIES 1900Document78 pagesSpecification For Highway Works UK - SERIES 1900Kévin JacobNo ratings yet

- Calculating and Using Float: Core Scheduling Papers: #5Document11 pagesCalculating and Using Float: Core Scheduling Papers: #5Traci Reed100% (1)

- BWKDocument13 pagesBWKan_taniaNo ratings yet

- Tek 01-01FDocument4 pagesTek 01-01FHisham MohamedNo ratings yet

- CLJ 4 Barry ArticleDocument14 pagesCLJ 4 Barry ArticleGwapito TresNo ratings yet

- Sri Lanka Construction - Sept 15 FinalDocument37 pagesSri Lanka Construction - Sept 15 Finalsha_cadNo ratings yet

- Https - WWW - Unra.go - Ug - Media - 2023 - 03 - JAN-2023-PROJECT-REPORT-ROADSDocument17 pagesHttps - WWW - Unra.go - Ug - Media - 2023 - 03 - JAN-2023-PROJECT-REPORT-ROADSDunstan SendiwalaNo ratings yet

- RC 1 Course OutlineDocument1 pageRC 1 Course Outlinehanose100% (1)

- Construction Contract Law-1 For ShiftyDocument13 pagesConstruction Contract Law-1 For ShiftyStíofán BánNo ratings yet

- BKSURCO - Certified - NEC Professional - Preparatory - CourseDocument57 pagesBKSURCO - Certified - NEC Professional - Preparatory - CourseASKA LIN100% (1)

- 9449 Macalloy Tension StructuresDocument16 pages9449 Macalloy Tension StructuresYam BalaoingNo ratings yet

- Tender Evaluation ReportDocument20 pagesTender Evaluation ReportastudentNo ratings yet

- Engineering Audit of CHOGM ActivitiesDocument231 pagesEngineering Audit of CHOGM ActivitiesDaniel WilsonNo ratings yet

- Ijser: Effects of Design Errors On Construction ProjectsDocument16 pagesIjser: Effects of Design Errors On Construction ProjectsDaramola Samuel OlaNo ratings yet

- Clause 13: Variations and Adjustments: The Power To Vary and Its LimitationsDocument7 pagesClause 13: Variations and Adjustments: The Power To Vary and Its Limitationssilence_10007No ratings yet

- Span Tables TQ 07 Timber-Deck FinalDocument7 pagesSpan Tables TQ 07 Timber-Deck Finaljon kolmneNo ratings yet

- Standard Method of Measurement FOR Building Elements: Architectural Services DepartmentDocument69 pagesStandard Method of Measurement FOR Building Elements: Architectural Services DepartmentEka Budhi PrasetyaNo ratings yet

- For Civil Engineering Works: July 3, 2021 UDSM, TM 322 1Document26 pagesFor Civil Engineering Works: July 3, 2021 UDSM, TM 322 1mozNo ratings yet

- Bailey Fact SheetDocument2 pagesBailey Fact Sheetcaballerolang100% (1)

- BS 5628Document10 pagesBS 5628chowchsNo ratings yet

- Rebar Shape CodesDocument1 pageRebar Shape CodesJoshua HobsonNo ratings yet

- The Adoption of CESMM 3Document3 pagesThe Adoption of CESMM 3raashidhvNo ratings yet

- Comparative Study On Cementitious Content of GrounDocument5 pagesComparative Study On Cementitious Content of Grounkristine coteloNo ratings yet

- Application of Infrared Thermography Technique in Uilding Finish EvaluationDocument9 pagesApplication of Infrared Thermography Technique in Uilding Finish EvaluationNicolas De NadaiNo ratings yet

- McDermott International Inc Vs Burn Standard Co LtS060394COM134123Document41 pagesMcDermott International Inc Vs Burn Standard Co LtS060394COM134123rishi100% (1)

- Preamble Civil 2008Document4 pagesPreamble Civil 2008erickyfmNo ratings yet

- Standard Drawings - Kerb and Wheel Stopper DetailsDocument1 pageStandard Drawings - Kerb and Wheel Stopper DetailsprmraoNo ratings yet

- BEM 1.2003 Guidelines For Checking The Work of Another EngineerDocument11 pagesBEM 1.2003 Guidelines For Checking The Work of Another EngineerVong Kee SinNo ratings yet

- Asphalt Concrete Report Final VersionDocument11 pagesAsphalt Concrete Report Final VersionLorraine Custodio100% (1)

- Steel BS Parameter PDFDocument8 pagesSteel BS Parameter PDFdpkNo ratings yet

- Construction Specification Chain Link FenceDocument2 pagesConstruction Specification Chain Link Fenceyamanta_rajNo ratings yet

- SAITO Twin-Cylinder Four-Stroke ManualDocument32 pagesSAITO Twin-Cylinder Four-Stroke ManualAngelLazarteNo ratings yet

- MSC CPM (HRE) Individual Assignment - Shepherd Nhanga Rev 00Document11 pagesMSC CPM (HRE) Individual Assignment - Shepherd Nhanga Rev 00Shepherd NhangaNo ratings yet

- Masonry and Concrete - FinDocument12 pagesMasonry and Concrete - FinSarah Marie Nueva Sierra100% (1)

- Welcome To The Institute For Timber Construction-South Africa Itc-SaDocument75 pagesWelcome To The Institute For Timber Construction-South Africa Itc-SaMclyb GumbieNo ratings yet

- Exams For Lead and Senior EngineersDocument4 pagesExams For Lead and Senior EngineerslamesginNo ratings yet

- Ebcs-5 18Document4 pagesEbcs-5 18eyerusalemh100% (1)

- Soils and EngineeringDocument8 pagesSoils and Engineeringuntoni100% (1)

- Revised Drainage Structures 24082015Document22 pagesRevised Drainage Structures 24082015soleb100% (1)

- Reinforced Concrete Designers Handbook 10th Edition Reynolds Steedman 2 Part PrintDocument7 pagesReinforced Concrete Designers Handbook 10th Edition Reynolds Steedman 2 Part Printikanyu79No ratings yet

- Fosroc Fibreboard - DtsDocument2 pagesFosroc Fibreboard - Dtsaljhun_1966No ratings yet

- Surface Water DrainageDocument8 pagesSurface Water DrainageronyNo ratings yet

- Timber Connectors Characteristic Loadings DataDocument8 pagesTimber Connectors Characteristic Loadings DataDinh Nam NguyenNo ratings yet

- Spacing of Rebars Steel Bars 1Document4 pagesSpacing of Rebars Steel Bars 1talatzahoor0% (1)

- Types of FootingDocument3 pagesTypes of FootingRonald DolorNo ratings yet

- Bac Iem 2Document2 pagesBac Iem 2Lee Wen ZheNo ratings yet

- Chapter 11 Steep Slope ProtectionDocument8 pagesChapter 11 Steep Slope ProtectionVinod TiwariNo ratings yet

- Bridge Works SubstructureDocument26 pagesBridge Works SubstructureRoyal_gkNo ratings yet

- An Overview of The Cadastral System in TanzaniaDocument17 pagesAn Overview of The Cadastral System in TanzaniasiwalazeNo ratings yet

- College of Engineering &technology Departement of Cotm Presentation On InternshipDocument33 pagesCollege of Engineering &technology Departement of Cotm Presentation On InternshipLij AbelNo ratings yet

- CESSM Guidance Note May 1994Document3 pagesCESSM Guidance Note May 1994Sachith SeneviratnaNo ratings yet

- CIPAADocument118 pagesCIPAAKent TamNo ratings yet

- Foundations For WallsDocument9 pagesFoundations For WallsAnamaria SuzanaNo ratings yet

- Concrete FormworkDocument8 pagesConcrete Formworksethu1091No ratings yet

- Pile Test and Concrete FaceDocument6 pagesPile Test and Concrete FaceEngineeri TadiyosNo ratings yet

- Concrete FormworkDocument43 pagesConcrete Formworkyrdgcgf5664100% (4)

- Reinforced Earth Consultant Data SheetDocument9 pagesReinforced Earth Consultant Data SheetKyle MoolmanNo ratings yet

- RIB CCS Candy Standard Stand Alone Proposal - ZA - 40th Jubilee Promotion - (1 User) - SignedDocument10 pagesRIB CCS Candy Standard Stand Alone Proposal - ZA - 40th Jubilee Promotion - (1 User) - SignedKyle MoolmanNo ratings yet

- Precast Manufacture Guidance NotesDocument11 pagesPrecast Manufacture Guidance NotesKyle MoolmanNo ratings yet

- Journal of Rock Mechanics and Geotechnical Engineering: Sadok Benmebarek, Samir Attallaoui, Naïma BenmebarekDocument6 pagesJournal of Rock Mechanics and Geotechnical Engineering: Sadok Benmebarek, Samir Attallaoui, Naïma BenmebarekKyle MoolmanNo ratings yet

- Analysis of Mechanically Stabilised Earth (MSE) Retaining Wall Using Finite Element and AASHTO MethodsDocument13 pagesAnalysis of Mechanically Stabilised Earth (MSE) Retaining Wall Using Finite Element and AASHTO MethodsKyle MoolmanNo ratings yet

- Appendix-I Closure CostsDocument30 pagesAppendix-I Closure CostsKyle MoolmanNo ratings yet

- DSA Region 1 Sales - June 2016Document19 pagesDSA Region 1 Sales - June 2016Kyle MoolmanNo ratings yet

- State of The Practice of MSE Wall Design For Highway StructuresDocument21 pagesState of The Practice of MSE Wall Design For Highway StructuresKyle MoolmanNo ratings yet

- MSE-Wall-Inspectors-Handbook GEM 2020Document54 pagesMSE-Wall-Inspectors-Handbook GEM 2020Kyle MoolmanNo ratings yet

- Mfwetus Profile 2022V1Document9 pagesMfwetus Profile 2022V1Kyle MoolmanNo ratings yet

- Circular - JBCC Clause 29 - ID 331615Document3 pagesCircular - JBCC Clause 29 - ID 331615Kyle MoolmanNo ratings yet

- SANS1200MMDocument15 pagesSANS1200MMKyle MoolmanNo ratings yet

- SANS1200NBDocument19 pagesSANS1200NBKyle MoolmanNo ratings yet

- Project Management Basics / IntroductionDocument29 pagesProject Management Basics / IntroductionKyle MoolmanNo ratings yet

- Sans50934 2Document27 pagesSans50934 2Kyle MoolmanNo ratings yet

- South Or.': ZED ONDocument18 pagesSouth Or.': ZED ONKyle Moolman100% (1)

- Sans 5865Document11 pagesSans 5865Kyle Moolman67% (3)

- Civil Engineering Manual Gcc2004Document185 pagesCivil Engineering Manual Gcc2004Paul Sony100% (1)

- Ficha Tecnica XR6C-LEDDocument4 pagesFicha Tecnica XR6C-LEDEfrain MateoNo ratings yet

- BEME Eletrical TemplateDocument19 pagesBEME Eletrical TemplateAbdulyekini Ahmadu100% (3)

- Centres and Peripheries in Ottoman Architecture Rediscovering A Balkan Heritage Ed Maximilian Hartmuth Sarajevo Stockholm Cultural Heritage Witho PDFDocument173 pagesCentres and Peripheries in Ottoman Architecture Rediscovering A Balkan Heritage Ed Maximilian Hartmuth Sarajevo Stockholm Cultural Heritage Witho PDFRebecca378No ratings yet

- Environmental Responsive Design: Case Study - Cii - Sohrabji Godrej GreenDocument19 pagesEnvironmental Responsive Design: Case Study - Cii - Sohrabji Godrej Green052 Deepak NaralaNo ratings yet

- AR-102-ground Floor Masonry Lineout PlanDocument1 pageAR-102-ground Floor Masonry Lineout Plandimpy khattarNo ratings yet

- MSE 227 HW9 F10 SolutionsDocument5 pagesMSE 227 HW9 F10 Solutionsputri nur shahidaNo ratings yet

- EstimateDocument5 pagesEstimatesreek009ark3350No ratings yet

- Estimation Templates For CalculationDocument15 pagesEstimation Templates For CalculationSyed MohammedNo ratings yet

- Abratec 6715: WeldingDocument2 pagesAbratec 6715: Weldingmohamed AdelNo ratings yet

- ENV - Design Guide Retaining Walls - 01.16Document45 pagesENV - Design Guide Retaining Walls - 01.16iosamNo ratings yet

- Welding ElectrodesDocument13 pagesWelding ElectrodesArimoro Cyril ObuseNo ratings yet

- Modelim StrukturorDocument22 pagesModelim StrukturorAnisa Biba100% (1)

- Practical Strategies: HotelsDocument15 pagesPractical Strategies: HotelsSNEHA DEVARAJUNo ratings yet

- From August 1995: For Relay Location and Multiple Connectors See Also Section "Component Locations"Document5 pagesFrom August 1995: For Relay Location and Multiple Connectors See Also Section "Component Locations"Niine 4No ratings yet

- Leo Laser 17 Izumi TricycleDocument12 pagesLeo Laser 17 Izumi TricycleRea Cleare TampusNo ratings yet

- Types and Causes of Deterioration of Steel StructureDocument24 pagesTypes and Causes of Deterioration of Steel Structuresnehakudale21100% (1)

- APT10 and APT14: For Effective Condensate Drainage and RemovalDocument12 pagesAPT10 and APT14: For Effective Condensate Drainage and RemovalwimpievdsNo ratings yet

- 2020-06-25 Method Statement of RCBC Construction CH402+737Document33 pages2020-06-25 Method Statement of RCBC Construction CH402+737施智捷100% (2)

- API 598 Valves Inspection and TestingDocument1 pageAPI 598 Valves Inspection and TestingCRISTHIAN PIERR PAUSIC BAZALARNo ratings yet

- Heyles Fentoes Trainnig ReportDocument58 pagesHeyles Fentoes Trainnig ReportayeshmanthabroNo ratings yet

- Rsp-Prc014-En Wood WayDocument44 pagesRsp-Prc014-En Wood WayRuiz Caldera Eloy E.No ratings yet

- Mercury Outboard Spark PlugsDocument10 pagesMercury Outboard Spark PlugsJSMarine Parts ChinaNo ratings yet

- Beam Deflection When The Moment of Inertia Is VariableDocument9 pagesBeam Deflection When The Moment of Inertia Is VariableandrewsugihartoNo ratings yet

- Weight Control Report For Regas Platform TopsidesDocument42 pagesWeight Control Report For Regas Platform TopsidesinnovativekarthiNo ratings yet

- 109002-TSP-417 Specification For Landfall Construction and Pipeline Pull-InDocument41 pages109002-TSP-417 Specification For Landfall Construction and Pipeline Pull-InMohd. Fadhil JamirinNo ratings yet

- GPT Nadu NeduDocument222 pagesGPT Nadu NeduSwarna LathaNo ratings yet