Professional Documents

Culture Documents

Resistoflex Fluoropolymer Innovation

Resistoflex Fluoropolymer Innovation

Uploaded by

Anonymous PkAjjOZBCopyright:

Available Formats

You might also like

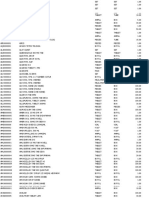

- Abigail Escobar - Weathering and Erosion - Google MapsDocument3 pagesAbigail Escobar - Weathering and Erosion - Google Mapsapi-43588540929% (7)

- 7 Minute Safety Trainer - EConfDocument17 pages7 Minute Safety Trainer - EConfmileperez78100% (1)

- Drilling and Workover Aramco Training 2013 - 2 PDFDocument479 pagesDrilling and Workover Aramco Training 2013 - 2 PDFAnonymous 40IGqsR3jc90% (20)

- Shop Manual Hm400-1 SN 1001 Up GeneralDocument234 pagesShop Manual Hm400-1 SN 1001 Up GeneralSamsul Hadi Wong Nenjap71% (7)

- Pharmaceutical Unit Operation (Solid Dosage)Document8 pagesPharmaceutical Unit Operation (Solid Dosage)Sangram KendreNo ratings yet

- NR526 2017-09Document158 pagesNR526 2017-09Simen EllingsenNo ratings yet

- 2Document8 pages2api-3700944No ratings yet

- API RP 941 Industry Alert - Carbon Steel Degradation in High Temperature Hydrogen ServiceDocument1 pageAPI RP 941 Industry Alert - Carbon Steel Degradation in High Temperature Hydrogen ServiceVinh Do ThanhNo ratings yet

- SSS Heben 2018 EN-web-2 PDFDocument32 pagesSSS Heben 2018 EN-web-2 PDFAbdul HaseebNo ratings yet

- HDPE-100 Catalogue PDFDocument9 pagesHDPE-100 Catalogue PDFkumar sandeepNo ratings yet

- As 2809.1-2008 Road Tank Vehicles For Dangerous Goods General Requirements For All Road Tank VehiclesDocument7 pagesAs 2809.1-2008 Road Tank Vehicles For Dangerous Goods General Requirements For All Road Tank VehiclesSAI Global - APACNo ratings yet

- Swire Mini Containers Spec SheetDocument2 pagesSwire Mini Containers Spec Sheetsopian320No ratings yet

- Bulk Materials Solve Solids Flow Probs PDFDocument10 pagesBulk Materials Solve Solids Flow Probs PDFEverton DuarteNo ratings yet

- جداول دكتايل مواصفاتDocument52 pagesجداول دكتايل مواصفاتMohammad MohammadNo ratings yet

- 1926.1400 Cranes Derricks in ConstructionDocument24 pages1926.1400 Cranes Derricks in Constructionlobitoferoz81No ratings yet

- Gauge HatchDocument3 pagesGauge HatchbramantiyaNo ratings yet

- Experience, Qualification and Depth of Service: Presentation To: ExhibitionDocument29 pagesExperience, Qualification and Depth of Service: Presentation To: ExhibitionCharlene Begley100% (1)

- Anchors: Handling, Storage, Installation and Maintenance ManualDocument30 pagesAnchors: Handling, Storage, Installation and Maintenance Manualpandu lambangNo ratings yet

- IFU 5903794 Rollgliss Rescue Pole HookDocument8 pagesIFU 5903794 Rollgliss Rescue Pole HookValentinNo ratings yet

- Cargo Securement Truck Loading ChecklistDocument5 pagesCargo Securement Truck Loading ChecklistHammy SariNo ratings yet

- Technical Ghide - Anchors For ETICSDocument49 pagesTechnical Ghide - Anchors For ETICSandrew_sfiNo ratings yet

- Onesteel Catalouge - Pipe FittingsDocument48 pagesOnesteel Catalouge - Pipe Fittingsmlennon9910No ratings yet

- GasketDocument12 pagesGasketAbraham BongòNo ratings yet

- Az.342750 Manitowoc 999 250 T Farina Man Riding Safety ProceduresDocument17 pagesAz.342750 Manitowoc 999 250 T Farina Man Riding Safety Proceduresdan antonNo ratings yet

- 5 API RP 521 97 Pressure Relieving & Depressurizing GuidlineDocument113 pages5 API RP 521 97 Pressure Relieving & Depressurizing GuidlineSaDia AshrafNo ratings yet

- 288 Doe-Hdbk-1169-2003Document395 pages288 Doe-Hdbk-1169-2003Justinas Rimkus100% (1)

- Rollgliss InstructionsDocument28 pagesRollgliss InstructionsCarlos Ernesto Flores AlbinoNo ratings yet

- FIBC Handling Guidelines Parts1-6Document20 pagesFIBC Handling Guidelines Parts1-6Andrei OlteanuNo ratings yet

- Brand & Product CatalogDocument36 pagesBrand & Product Catalogayşe çolak100% (1)

- Fpmotor Vehicle Fuel DispensingDocument6 pagesFpmotor Vehicle Fuel DispensingEvert AlexNo ratings yet

- Design of Pressure VesselDocument136 pagesDesign of Pressure VesselHarshal JadhavNo ratings yet

- MSHA Regulation EZcomplianceDocument12 pagesMSHA Regulation EZcompliancehazopmanNo ratings yet

- Lifting+Matters+Q4+2019 Final WEB LRDocument44 pagesLifting+Matters+Q4+2019 Final WEB LRMeleti Meleti MeletiouNo ratings yet

- American Structural ShapesDocument16 pagesAmerican Structural ShapesSYedZYnAleNo ratings yet

- Section 1-2 Safety Eyewash ShowersDocument9 pagesSection 1-2 Safety Eyewash ShowersGanesh KashinathNo ratings yet

- Y-Bc0035 GBDocument4 pagesY-Bc0035 GBYousef AlipourNo ratings yet

- NACM Welded Chain SpecificationsDocument12 pagesNACM Welded Chain SpecificationsAmpera marzelaNo ratings yet

- Socket Head Cap Screws Alloy SteelDocument5 pagesSocket Head Cap Screws Alloy SteelChris MedeirosNo ratings yet

- As 4100Document1 pageAs 4100shiruhanNo ratings yet

- Brochure April 2019 PDFDocument284 pagesBrochure April 2019 PDFMike Michal Rry100% (1)

- Emergency Eyewash Station and Safety Shower GuidelinesDocument15 pagesEmergency Eyewash Station and Safety Shower GuidelinesMAHMUD100% (1)

- FRP ManholesDocument15 pagesFRP ManholesshagogalNo ratings yet

- ASME VIII Div 1 Part UCL Welded Pressure Vessels Constructed of Material With Corrosion Resistant Integral Cladding, Weld Metal Overlay Cladding, or With Applied LiningsDocument3 pagesASME VIII Div 1 Part UCL Welded Pressure Vessels Constructed of Material With Corrosion Resistant Integral Cladding, Weld Metal Overlay Cladding, or With Applied LiningsAmanda Ariesta ApriliaNo ratings yet

- Conveyor Belt Catalog 2010Document50 pagesConveyor Belt Catalog 2010ganesh_350% (2)

- 2 RollersDocument128 pages2 RollersCésarRenatoCopacondoriCuaylaNo ratings yet

- OSHA 1926.1053 Subpart X LaddersDocument2 pagesOSHA 1926.1053 Subpart X LaddersEmmanNo ratings yet

- Safety Data Sheet SDS For HIT-RE 500 V3 Epoxy Adhesive Documentation ASSET DOC LOC 5384987Document24 pagesSafety Data Sheet SDS For HIT-RE 500 V3 Epoxy Adhesive Documentation ASSET DOC LOC 5384987Librany RioNo ratings yet

- SweeperDocument8 pagesSweeperstainless31620039126No ratings yet

- 4-Wheeler Forklift For Industrial WarehouseDocument16 pages4-Wheeler Forklift For Industrial WarehouseJay BhimaniNo ratings yet

- Spill ProceduresDocument3 pagesSpill ProceduresLuisga ChicoNo ratings yet

- Single Bolt Embedment Design - Aci 349Document1 pageSingle Bolt Embedment Design - Aci 349Akhtar BahramNo ratings yet

- Alloy Master LinksDocument1 pageAlloy Master LinksAnonymous 48jYxR1C0% (1)

- Gmsi10 Um013 - en PDocument216 pagesGmsi10 Um013 - en PAnonymous XM3KoTUTgNo ratings yet

- ISOtankDocument21 pagesISOtankFernando Pereira Jr100% (1)

- HazCom With GhsDocument33 pagesHazCom With GhsAnonymous iI88LtNo ratings yet

- Can/Csa-CSA S157-17 Strength Design in Aluminum Welding RequirementsDocument2 pagesCan/Csa-CSA S157-17 Strength Design in Aluminum Welding RequirementsChris MedeirosNo ratings yet

- Winch, Casing Stabbing Board (FA2BMR) Manual SupplementDocument13 pagesWinch, Casing Stabbing Board (FA2BMR) Manual SupplementTony100% (2)

- Durapac Gatos HidraulicosDocument108 pagesDurapac Gatos Hidraulicosgechaves1No ratings yet

- Key Changes: Increased For Snaphooks and CarabinDocument7 pagesKey Changes: Increased For Snaphooks and CarabinJamesNo ratings yet

- Design Category and Service Class Selection For Below-the-Hook Lifting DevicesDocument5 pagesDesign Category and Service Class Selection For Below-the-Hook Lifting DevicesjdcervantesNo ratings yet

- Introduction To Vessel and Vessel OrientationDocument22 pagesIntroduction To Vessel and Vessel OrientationprembindNo ratings yet

- Elastomer PropertiesDocument72 pagesElastomer PropertiesBashu PoudelNo ratings yet

- HPD 4400 CatalogDocument412 pagesHPD 4400 Catalogfabricio.m.gomesNo ratings yet

- Energy BrochuraDocument6 pagesEnergy Brochuraa100acomNo ratings yet

- JW Wellhead Sealing GuideDocument4 pagesJW Wellhead Sealing GuideClOudyo VirgílioNo ratings yet

- Hay PulleysDocument1 pageHay PulleysAnonymous PkAjjOZBNo ratings yet

- Pressure Transmitter For General Industrial Applications Model A-10Document12 pagesPressure Transmitter For General Industrial Applications Model A-10Anonymous PkAjjOZBNo ratings yet

- Specialty Maintenance Product Catalog and Price ListDocument30 pagesSpecialty Maintenance Product Catalog and Price ListAnonymous PkAjjOZBNo ratings yet

- Wagner-Meinert Disciplinary ProgramDocument4 pagesWagner-Meinert Disciplinary ProgramAnonymous PkAjjOZBNo ratings yet

- FirstDefender RMX SpecSheet ArabicDocument2 pagesFirstDefender RMX SpecSheet ArabicAnonymous PkAjjOZBNo ratings yet

- 1-12 To 4 Guardsman G SeriesDocument6 pages1-12 To 4 Guardsman G SeriesAnonymous PkAjjOZBNo ratings yet

- 18 WMI-Disciplinary ProgramDocument4 pages18 WMI-Disciplinary ProgramAnonymous PkAjjOZBNo ratings yet

- HE 850 Horziontal Boring MachineDocument1 pageHE 850 Horziontal Boring MachineAnonymous PkAjjOZBNo ratings yet

- UTP MaintenanceDocument28 pagesUTP MaintenanceAnonymous PkAjjOZBNo ratings yet

- Liebherr Brochure Lubricants enDocument20 pagesLiebherr Brochure Lubricants enAnonymous PkAjjOZB67% (3)

- Advertising Solutions - Company ProfileDocument12 pagesAdvertising Solutions - Company ProfileAnonymous PkAjjOZBNo ratings yet

- SAEP-127 - Security and Control of Saudi Aramco Engineering DataDocument9 pagesSAEP-127 - Security and Control of Saudi Aramco Engineering DataAnonymous PkAjjOZBNo ratings yet

- FlowMeter CalculationSheetDocument1 pageFlowMeter CalculationSheetAnonymous PkAjjOZBNo ratings yet

- Satuan KecilDocument144 pagesSatuan KecilWahyuNo ratings yet

- ExamSlip - 148865 - 20190401 - 1520 VladDocument23 pagesExamSlip - 148865 - 20190401 - 1520 VladNikolaus PanjaitanNo ratings yet

- LEWA Katalog ProizvodaDocument12 pagesLEWA Katalog ProizvodaAnonymous ItzBhUGoiNo ratings yet

- Sealants and Lubricants PDFDocument3 pagesSealants and Lubricants PDFhyyziaNo ratings yet

- Experimental Organic Chemistry Post-Lab 2 Cross-Aldol CondensationDocument5 pagesExperimental Organic Chemistry Post-Lab 2 Cross-Aldol Condensationapi-235187189No ratings yet

- Fy NuclearDocument28 pagesFy NuclearNeelam KapoorNo ratings yet

- Upper Leathers in Shoe Manufacturing: January 2013Document6 pagesUpper Leathers in Shoe Manufacturing: January 2013api-420810577No ratings yet

- Lecture21 PDFDocument4 pagesLecture21 PDFMIzan NursiadiNo ratings yet

- Hydrocarbon-Resins by TCVDocument11 pagesHydrocarbon-Resins by TCVparth_manchanda10No ratings yet

- Chemistry 14B AnswersDocument4 pagesChemistry 14B AnswersJong.Gun.KimNo ratings yet

- Emergency KitsDocument7 pagesEmergency Kitsjonathan layaNo ratings yet

- Assessment of A Thermostable Xylanase From Paenibacillus Sp. ASCF@ For Application in Prebleaching of Eucalyptus Kraft PulpDocument6 pagesAssessment of A Thermostable Xylanase From Paenibacillus Sp. ASCF@ For Application in Prebleaching of Eucalyptus Kraft PulpAlonsoNo ratings yet

- Watts 1990Document13 pagesWatts 1990Luis Andres Romero ZambranoNo ratings yet

- Shell Gadus S2 A320 From Rhodina EPLFDocument2 pagesShell Gadus S2 A320 From Rhodina EPLFAnonymous oAbjbl4HNo ratings yet

- Solar-Riat, US Highway 190 West, Killeen, TX 76541, USADocument13 pagesSolar-Riat, US Highway 190 West, Killeen, TX 76541, USAShafira RiskinaNo ratings yet

- Chemistry 0620 - 2011 - QPDocument12 pagesChemistry 0620 - 2011 - QPMinakshiNo ratings yet

- Fire DiamondDocument33 pagesFire DiamondArun HarpalaniNo ratings yet

- 24 SAJET NEC-watermarkDocument6 pages24 SAJET NEC-watermarkraviteja036No ratings yet

- AAS Perkin ElmerDocument5 pagesAAS Perkin ElmerdedisumarnoNo ratings yet

- 300-Foundations & Equipment Mounting PDFDocument32 pages300-Foundations & Equipment Mounting PDFStephen KokoNo ratings yet

- Rumen FermentationDocument49 pagesRumen FermentationIgnacioRugbeerMoneta100% (1)

- Gas Welding Equipment PowerpointDocument12 pagesGas Welding Equipment PowerpointChristian RexNo ratings yet

- Product Data Sheet: Harmony XB4, Flush Mounted Blanking Plug Ø 30.5 MM 1.20 InchDocument4 pagesProduct Data Sheet: Harmony XB4, Flush Mounted Blanking Plug Ø 30.5 MM 1.20 InchJuscelio DamascenaNo ratings yet

- Eco Ice Concentrate 9108 SdsDocument6 pagesEco Ice Concentrate 9108 Sdscafiwek448No ratings yet

- T47D Whole Cell Lysate Ab14899 T47D Whole Cell Lysate Ab14899Document2 pagesT47D Whole Cell Lysate Ab14899 T47D Whole Cell Lysate Ab14899Rahmailla Khanza Diana FebriliantriNo ratings yet

Resistoflex Fluoropolymer Innovation

Resistoflex Fluoropolymer Innovation

Uploaded by

Anonymous PkAjjOZBCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Resistoflex Fluoropolymer Innovation

Resistoflex Fluoropolymer Innovation

Uploaded by

Anonymous PkAjjOZBCopyright:

Available Formats

brands you trust.

Resistoflex Plastic Lined Pipe

Leader in Fluoropolymer Innovations

Since 1936

Copyright 2013 CRANE ChemPharma & Energy

www.cranecpe.com

PIONEER OF FLUOROPOLYMER INNOVATION

HERITAGE OF INNOVATION

1936

1953

1956

1957

1962

1964

1982

1992

2011

Resistoflex was founded

Invented PTFE-Lined Hose

Invented PTFE-Lined Pipe

PTFE Expansion Joints

Patented PTFE-Lined Pipe

(Thermalok)

PP, PVDF, and Field Fabrication

High Integrity FlangeTM

MULTI-AXIS Precision Bent Plastic

Lined Piping System

Advanced Technology Liner (ATL)

320,000 sqft plant, Marion, NC

Thanks to our vast experience with PTFE, we have

advanced in-house knowledge of PTFE processing

Resistoflex patented ThermalokTM locked-in design results

in unmatched thermal cycling stability.

Loose lining will result in flare suck-in, buckling, and other

catastrophic failures.

As many competitors buy liner on the open market,

one cannot be sure who manufactured their liner,

and whether or not it meets necessary standards

manufacture isostatic molded liner, paste extruded

liner, and ram extruded liner

R

Special coatings from the factory, free of runs

and sags (due to pipe being rotated while being

painted)

Thermalok & Swaged designs

for resolving permeation issues in severe service

applications

D

audit program, with full-time resources dedicated

to training & audits

coated with a chemical and temperature resistant

paint rated to 450F (232C) that can be used under

insulation

2

www.cranecpe.com

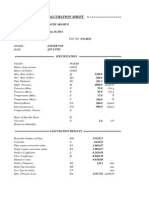

RESISTOFLEX MEETS CRITICAL STANDARDS

IS ASME B31.3 PIPING CODE

IMPORTANT TO YOU?

ASTM F1545 is a listed component standard in

ASME B31.3. A manufacturer that does not meet

ASTM F1545 does not comply with B31.3.

TO ENSURE SUPERIOR QUALITY,

RESISTOFLEX ALSO PERFORMS

THE FOLLOWING TESTS

Stringent quality testing of liners before installing

in the housing:

Dimensional Checks

Mechanical Roll Testing of Liners

Dimensional Requirements, Inspection &

Light Candling of Liners

Testing, Markings

Tensile & Elongation

Requiring a minimum qualification and manu

facturing standard such as ASTM F1545 is crucial to

complying with OSHA 1910: Process Safety ManS

agement for Highly Hazardous Chemicals. ASTM is a

Dimensional Checks

national testing laboratory, specifically recognized by

Electrostatic testing at 18.5KV

OSHA. OSHA does not recognize the CE mark or

accept certifications from foreign testing organizations.

Hydrostatic Pressure Testing

RELY ON RESISTOFLEX FOR

SEVERE SERVICE APPLICATIONS

CONFORMS TO CRITICAL

STANDARDS

Full compliance to ASTM F1545 requires passing the

following tests:

Temperature Aging (Hot) - (3) 12 hours cycles

at rated maximum temperatures, followed by

electrostatic liner inspection

Temperature Aging (Cold) - 48 hours each at

minimum temperatures, followed by electrostatic

liner inspection

Steam-Cold Water Cycling - 100 cycles of steam,

ambient temperature water

Vacuum Testing - 48 hours of full vacuum at

rated temperature

If resin grades or suppliers change, the product must

suppliers or any manufacturing processes are

altered

Competitors that buy liner on the open market

should not be automatically presumed to meet

ASTM F1545

ASTM Compliance Statement

This is to certify that Crane ChemPharma Flow Solutions, Resistoflex piping products are in

full compliance with all ASTM F1545-97 (Reapproved 2009) requirements. This includes the

four design qualification tests specified in Section 6, comprising the following:

Elevated Temperature Vacuum Test

Low Temperature Aging Test

High Temperature Cycling Test

Steam/Cold Water Cycling Test

Test reports are available for customer viewing upon request.

Respectfully submitted,

David Yanik

Resistoflex Engineering Manager

When you buy a R

from many decades of experience and expertise

is a part of Crane Co., and has been a

partner to its customers since 1936; Crane Co. was

established in 1855

products are supported by

comprehensive global distribution with manufacturing sites in Europe, China, Singapore, Thailand,

and Australia

solutions toprovides

its customers

in local

marketsand

Resistoflex

technical

assistance

worldwide

solutions to its customers in local markets worldwide

www.cranecpe.com

CRANE ChemPharma & Energy

RESISTOFLEX

One Quality Way, Marion

North Carolina 28752

United States

PHONE + 1 828 724 4000 | FAX +1 828 724 4783

sales@resistoflex.com

www.flowoffluids.com

CP-RESISTOFLEX-XLB-BU-EN-TO-10/13

brands you trust.

Crane Co., and its subsidiaries cannot accept responsibility for possible errors in catalogues, brochures, other printed materials, and website

information. Crane Co. reserves the right to alter its products without notice, including products already on order provided that such

alteration can be made without changes being necessary in specifications already agreed. All trademarks in this material are property of the

Crane Co. or its subsidiaries. The Crane and Crane brands logotype, in alphabetical order, (ALOYCO, CENTER LINE, COMPAC-NOZ, CRANE,

DEPA & ELRO, DUO-CHEK, FLOWSEAL, JENKINS, KROMBACH, NOZ-CHEK, PACIFIC, RESISTOFLEX, REVO, SAUNDERS, STOCKHAM,

TRIANGLE, UNI-CHEK, VALVES, WTA, and XOMOX) are registered trademarks of Crane Co. All rights reserved.

You might also like

- Abigail Escobar - Weathering and Erosion - Google MapsDocument3 pagesAbigail Escobar - Weathering and Erosion - Google Mapsapi-43588540929% (7)

- 7 Minute Safety Trainer - EConfDocument17 pages7 Minute Safety Trainer - EConfmileperez78100% (1)

- Drilling and Workover Aramco Training 2013 - 2 PDFDocument479 pagesDrilling and Workover Aramco Training 2013 - 2 PDFAnonymous 40IGqsR3jc90% (20)

- Shop Manual Hm400-1 SN 1001 Up GeneralDocument234 pagesShop Manual Hm400-1 SN 1001 Up GeneralSamsul Hadi Wong Nenjap71% (7)

- Pharmaceutical Unit Operation (Solid Dosage)Document8 pagesPharmaceutical Unit Operation (Solid Dosage)Sangram KendreNo ratings yet

- NR526 2017-09Document158 pagesNR526 2017-09Simen EllingsenNo ratings yet

- 2Document8 pages2api-3700944No ratings yet

- API RP 941 Industry Alert - Carbon Steel Degradation in High Temperature Hydrogen ServiceDocument1 pageAPI RP 941 Industry Alert - Carbon Steel Degradation in High Temperature Hydrogen ServiceVinh Do ThanhNo ratings yet

- SSS Heben 2018 EN-web-2 PDFDocument32 pagesSSS Heben 2018 EN-web-2 PDFAbdul HaseebNo ratings yet

- HDPE-100 Catalogue PDFDocument9 pagesHDPE-100 Catalogue PDFkumar sandeepNo ratings yet

- As 2809.1-2008 Road Tank Vehicles For Dangerous Goods General Requirements For All Road Tank VehiclesDocument7 pagesAs 2809.1-2008 Road Tank Vehicles For Dangerous Goods General Requirements For All Road Tank VehiclesSAI Global - APACNo ratings yet

- Swire Mini Containers Spec SheetDocument2 pagesSwire Mini Containers Spec Sheetsopian320No ratings yet

- Bulk Materials Solve Solids Flow Probs PDFDocument10 pagesBulk Materials Solve Solids Flow Probs PDFEverton DuarteNo ratings yet

- جداول دكتايل مواصفاتDocument52 pagesجداول دكتايل مواصفاتMohammad MohammadNo ratings yet

- 1926.1400 Cranes Derricks in ConstructionDocument24 pages1926.1400 Cranes Derricks in Constructionlobitoferoz81No ratings yet

- Gauge HatchDocument3 pagesGauge HatchbramantiyaNo ratings yet

- Experience, Qualification and Depth of Service: Presentation To: ExhibitionDocument29 pagesExperience, Qualification and Depth of Service: Presentation To: ExhibitionCharlene Begley100% (1)

- Anchors: Handling, Storage, Installation and Maintenance ManualDocument30 pagesAnchors: Handling, Storage, Installation and Maintenance Manualpandu lambangNo ratings yet

- IFU 5903794 Rollgliss Rescue Pole HookDocument8 pagesIFU 5903794 Rollgliss Rescue Pole HookValentinNo ratings yet

- Cargo Securement Truck Loading ChecklistDocument5 pagesCargo Securement Truck Loading ChecklistHammy SariNo ratings yet

- Technical Ghide - Anchors For ETICSDocument49 pagesTechnical Ghide - Anchors For ETICSandrew_sfiNo ratings yet

- Onesteel Catalouge - Pipe FittingsDocument48 pagesOnesteel Catalouge - Pipe Fittingsmlennon9910No ratings yet

- GasketDocument12 pagesGasketAbraham BongòNo ratings yet

- Az.342750 Manitowoc 999 250 T Farina Man Riding Safety ProceduresDocument17 pagesAz.342750 Manitowoc 999 250 T Farina Man Riding Safety Proceduresdan antonNo ratings yet

- 5 API RP 521 97 Pressure Relieving & Depressurizing GuidlineDocument113 pages5 API RP 521 97 Pressure Relieving & Depressurizing GuidlineSaDia AshrafNo ratings yet

- 288 Doe-Hdbk-1169-2003Document395 pages288 Doe-Hdbk-1169-2003Justinas Rimkus100% (1)

- Rollgliss InstructionsDocument28 pagesRollgliss InstructionsCarlos Ernesto Flores AlbinoNo ratings yet

- FIBC Handling Guidelines Parts1-6Document20 pagesFIBC Handling Guidelines Parts1-6Andrei OlteanuNo ratings yet

- Brand & Product CatalogDocument36 pagesBrand & Product Catalogayşe çolak100% (1)

- Fpmotor Vehicle Fuel DispensingDocument6 pagesFpmotor Vehicle Fuel DispensingEvert AlexNo ratings yet

- Design of Pressure VesselDocument136 pagesDesign of Pressure VesselHarshal JadhavNo ratings yet

- MSHA Regulation EZcomplianceDocument12 pagesMSHA Regulation EZcompliancehazopmanNo ratings yet

- Lifting+Matters+Q4+2019 Final WEB LRDocument44 pagesLifting+Matters+Q4+2019 Final WEB LRMeleti Meleti MeletiouNo ratings yet

- American Structural ShapesDocument16 pagesAmerican Structural ShapesSYedZYnAleNo ratings yet

- Section 1-2 Safety Eyewash ShowersDocument9 pagesSection 1-2 Safety Eyewash ShowersGanesh KashinathNo ratings yet

- Y-Bc0035 GBDocument4 pagesY-Bc0035 GBYousef AlipourNo ratings yet

- NACM Welded Chain SpecificationsDocument12 pagesNACM Welded Chain SpecificationsAmpera marzelaNo ratings yet

- Socket Head Cap Screws Alloy SteelDocument5 pagesSocket Head Cap Screws Alloy SteelChris MedeirosNo ratings yet

- As 4100Document1 pageAs 4100shiruhanNo ratings yet

- Brochure April 2019 PDFDocument284 pagesBrochure April 2019 PDFMike Michal Rry100% (1)

- Emergency Eyewash Station and Safety Shower GuidelinesDocument15 pagesEmergency Eyewash Station and Safety Shower GuidelinesMAHMUD100% (1)

- FRP ManholesDocument15 pagesFRP ManholesshagogalNo ratings yet

- ASME VIII Div 1 Part UCL Welded Pressure Vessels Constructed of Material With Corrosion Resistant Integral Cladding, Weld Metal Overlay Cladding, or With Applied LiningsDocument3 pagesASME VIII Div 1 Part UCL Welded Pressure Vessels Constructed of Material With Corrosion Resistant Integral Cladding, Weld Metal Overlay Cladding, or With Applied LiningsAmanda Ariesta ApriliaNo ratings yet

- Conveyor Belt Catalog 2010Document50 pagesConveyor Belt Catalog 2010ganesh_350% (2)

- 2 RollersDocument128 pages2 RollersCésarRenatoCopacondoriCuaylaNo ratings yet

- OSHA 1926.1053 Subpart X LaddersDocument2 pagesOSHA 1926.1053 Subpart X LaddersEmmanNo ratings yet

- Safety Data Sheet SDS For HIT-RE 500 V3 Epoxy Adhesive Documentation ASSET DOC LOC 5384987Document24 pagesSafety Data Sheet SDS For HIT-RE 500 V3 Epoxy Adhesive Documentation ASSET DOC LOC 5384987Librany RioNo ratings yet

- SweeperDocument8 pagesSweeperstainless31620039126No ratings yet

- 4-Wheeler Forklift For Industrial WarehouseDocument16 pages4-Wheeler Forklift For Industrial WarehouseJay BhimaniNo ratings yet

- Spill ProceduresDocument3 pagesSpill ProceduresLuisga ChicoNo ratings yet

- Single Bolt Embedment Design - Aci 349Document1 pageSingle Bolt Embedment Design - Aci 349Akhtar BahramNo ratings yet

- Alloy Master LinksDocument1 pageAlloy Master LinksAnonymous 48jYxR1C0% (1)

- Gmsi10 Um013 - en PDocument216 pagesGmsi10 Um013 - en PAnonymous XM3KoTUTgNo ratings yet

- ISOtankDocument21 pagesISOtankFernando Pereira Jr100% (1)

- HazCom With GhsDocument33 pagesHazCom With GhsAnonymous iI88LtNo ratings yet

- Can/Csa-CSA S157-17 Strength Design in Aluminum Welding RequirementsDocument2 pagesCan/Csa-CSA S157-17 Strength Design in Aluminum Welding RequirementsChris MedeirosNo ratings yet

- Winch, Casing Stabbing Board (FA2BMR) Manual SupplementDocument13 pagesWinch, Casing Stabbing Board (FA2BMR) Manual SupplementTony100% (2)

- Durapac Gatos HidraulicosDocument108 pagesDurapac Gatos Hidraulicosgechaves1No ratings yet

- Key Changes: Increased For Snaphooks and CarabinDocument7 pagesKey Changes: Increased For Snaphooks and CarabinJamesNo ratings yet

- Design Category and Service Class Selection For Below-the-Hook Lifting DevicesDocument5 pagesDesign Category and Service Class Selection For Below-the-Hook Lifting DevicesjdcervantesNo ratings yet

- Introduction To Vessel and Vessel OrientationDocument22 pagesIntroduction To Vessel and Vessel OrientationprembindNo ratings yet

- Elastomer PropertiesDocument72 pagesElastomer PropertiesBashu PoudelNo ratings yet

- HPD 4400 CatalogDocument412 pagesHPD 4400 Catalogfabricio.m.gomesNo ratings yet

- Energy BrochuraDocument6 pagesEnergy Brochuraa100acomNo ratings yet

- JW Wellhead Sealing GuideDocument4 pagesJW Wellhead Sealing GuideClOudyo VirgílioNo ratings yet

- Hay PulleysDocument1 pageHay PulleysAnonymous PkAjjOZBNo ratings yet

- Pressure Transmitter For General Industrial Applications Model A-10Document12 pagesPressure Transmitter For General Industrial Applications Model A-10Anonymous PkAjjOZBNo ratings yet

- Specialty Maintenance Product Catalog and Price ListDocument30 pagesSpecialty Maintenance Product Catalog and Price ListAnonymous PkAjjOZBNo ratings yet

- Wagner-Meinert Disciplinary ProgramDocument4 pagesWagner-Meinert Disciplinary ProgramAnonymous PkAjjOZBNo ratings yet

- FirstDefender RMX SpecSheet ArabicDocument2 pagesFirstDefender RMX SpecSheet ArabicAnonymous PkAjjOZBNo ratings yet

- 1-12 To 4 Guardsman G SeriesDocument6 pages1-12 To 4 Guardsman G SeriesAnonymous PkAjjOZBNo ratings yet

- 18 WMI-Disciplinary ProgramDocument4 pages18 WMI-Disciplinary ProgramAnonymous PkAjjOZBNo ratings yet

- HE 850 Horziontal Boring MachineDocument1 pageHE 850 Horziontal Boring MachineAnonymous PkAjjOZBNo ratings yet

- UTP MaintenanceDocument28 pagesUTP MaintenanceAnonymous PkAjjOZBNo ratings yet

- Liebherr Brochure Lubricants enDocument20 pagesLiebherr Brochure Lubricants enAnonymous PkAjjOZB67% (3)

- Advertising Solutions - Company ProfileDocument12 pagesAdvertising Solutions - Company ProfileAnonymous PkAjjOZBNo ratings yet

- SAEP-127 - Security and Control of Saudi Aramco Engineering DataDocument9 pagesSAEP-127 - Security and Control of Saudi Aramco Engineering DataAnonymous PkAjjOZBNo ratings yet

- FlowMeter CalculationSheetDocument1 pageFlowMeter CalculationSheetAnonymous PkAjjOZBNo ratings yet

- Satuan KecilDocument144 pagesSatuan KecilWahyuNo ratings yet

- ExamSlip - 148865 - 20190401 - 1520 VladDocument23 pagesExamSlip - 148865 - 20190401 - 1520 VladNikolaus PanjaitanNo ratings yet

- LEWA Katalog ProizvodaDocument12 pagesLEWA Katalog ProizvodaAnonymous ItzBhUGoiNo ratings yet

- Sealants and Lubricants PDFDocument3 pagesSealants and Lubricants PDFhyyziaNo ratings yet

- Experimental Organic Chemistry Post-Lab 2 Cross-Aldol CondensationDocument5 pagesExperimental Organic Chemistry Post-Lab 2 Cross-Aldol Condensationapi-235187189No ratings yet

- Fy NuclearDocument28 pagesFy NuclearNeelam KapoorNo ratings yet

- Upper Leathers in Shoe Manufacturing: January 2013Document6 pagesUpper Leathers in Shoe Manufacturing: January 2013api-420810577No ratings yet

- Lecture21 PDFDocument4 pagesLecture21 PDFMIzan NursiadiNo ratings yet

- Hydrocarbon-Resins by TCVDocument11 pagesHydrocarbon-Resins by TCVparth_manchanda10No ratings yet

- Chemistry 14B AnswersDocument4 pagesChemistry 14B AnswersJong.Gun.KimNo ratings yet

- Emergency KitsDocument7 pagesEmergency Kitsjonathan layaNo ratings yet

- Assessment of A Thermostable Xylanase From Paenibacillus Sp. ASCF@ For Application in Prebleaching of Eucalyptus Kraft PulpDocument6 pagesAssessment of A Thermostable Xylanase From Paenibacillus Sp. ASCF@ For Application in Prebleaching of Eucalyptus Kraft PulpAlonsoNo ratings yet

- Watts 1990Document13 pagesWatts 1990Luis Andres Romero ZambranoNo ratings yet

- Shell Gadus S2 A320 From Rhodina EPLFDocument2 pagesShell Gadus S2 A320 From Rhodina EPLFAnonymous oAbjbl4HNo ratings yet

- Solar-Riat, US Highway 190 West, Killeen, TX 76541, USADocument13 pagesSolar-Riat, US Highway 190 West, Killeen, TX 76541, USAShafira RiskinaNo ratings yet

- Chemistry 0620 - 2011 - QPDocument12 pagesChemistry 0620 - 2011 - QPMinakshiNo ratings yet

- Fire DiamondDocument33 pagesFire DiamondArun HarpalaniNo ratings yet

- 24 SAJET NEC-watermarkDocument6 pages24 SAJET NEC-watermarkraviteja036No ratings yet

- AAS Perkin ElmerDocument5 pagesAAS Perkin ElmerdedisumarnoNo ratings yet

- 300-Foundations & Equipment Mounting PDFDocument32 pages300-Foundations & Equipment Mounting PDFStephen KokoNo ratings yet

- Rumen FermentationDocument49 pagesRumen FermentationIgnacioRugbeerMoneta100% (1)

- Gas Welding Equipment PowerpointDocument12 pagesGas Welding Equipment PowerpointChristian RexNo ratings yet

- Product Data Sheet: Harmony XB4, Flush Mounted Blanking Plug Ø 30.5 MM 1.20 InchDocument4 pagesProduct Data Sheet: Harmony XB4, Flush Mounted Blanking Plug Ø 30.5 MM 1.20 InchJuscelio DamascenaNo ratings yet

- Eco Ice Concentrate 9108 SdsDocument6 pagesEco Ice Concentrate 9108 Sdscafiwek448No ratings yet

- T47D Whole Cell Lysate Ab14899 T47D Whole Cell Lysate Ab14899Document2 pagesT47D Whole Cell Lysate Ab14899 T47D Whole Cell Lysate Ab14899Rahmailla Khanza Diana FebriliantriNo ratings yet