Professional Documents

Culture Documents

4C5 PDF

4C5 PDF

Uploaded by

RameshNayakaCopyright:

Available Formats

You might also like

- Lab Report Radius of GyrationDocument4 pagesLab Report Radius of GyrationShahzaibali AfaqNo ratings yet

- Numerical Analysis of Load Test On Bored Pile (Wehnert & Veermer) PDFDocument6 pagesNumerical Analysis of Load Test On Bored Pile (Wehnert & Veermer) PDFAnonymous BuFjdLNo ratings yet

- Computer-Aided Development of Stress Fields For The Analysis of Structural ConcreteDocument8 pagesComputer-Aided Development of Stress Fields For The Analysis of Structural ConcreteAndré PeraroNo ratings yet

- Simplified Procedures For Calculation of Instantaneous and Long-Term Deflections of Reinforced Concrete BeamsDocument12 pagesSimplified Procedures For Calculation of Instantaneous and Long-Term Deflections of Reinforced Concrete BeamssukolikNo ratings yet

- A Composite Plasticity Model For Concrete: Pergamon 0020-7683 (95) 0006&7Document24 pagesA Composite Plasticity Model For Concrete: Pergamon 0020-7683 (95) 0006&7ngNo ratings yet

- XC Tension StiffeningDocument6 pagesXC Tension StiffeningLuis C. Pérez Tato100% (1)

- Modelling The Tensile Behavior of Plain Concrete Under Flexural LoadingDocument7 pagesModelling The Tensile Behavior of Plain Concrete Under Flexural LoadingAhmad MensaNo ratings yet

- Lab 4 Manual - Concrete Testing - F15Document18 pagesLab 4 Manual - Concrete Testing - F15kaligleean100% (1)

- Ultimate Resistance of Reinforced Concrete Columns Strengthened With Angles and Battens: Theoretical Model and Experimental ValidationDocument15 pagesUltimate Resistance of Reinforced Concrete Columns Strengthened With Angles and Battens: Theoretical Model and Experimental ValidationUcok DedyNo ratings yet

- 139C-Modelling of Reinforced Concrete structures-KAMIŃSKI-2011Document14 pages139C-Modelling of Reinforced Concrete structures-KAMIŃSKI-2011Ziyad12No ratings yet

- Implementation of The Modified Compression Field TheoryDocument33 pagesImplementation of The Modified Compression Field TheoryDang Bao TranNo ratings yet

- Some Aspects On Three-Dimensional Numerical Modelling of Reinforced Concrete Structures Using The ®nite Element MethodDocument21 pagesSome Aspects On Three-Dimensional Numerical Modelling of Reinforced Concrete Structures Using The ®nite Element Methodp71089No ratings yet

- Fracture in Quasi-Brittle Materials, A Review of Continum DamagDocument18 pagesFracture in Quasi-Brittle Materials, A Review of Continum DamagNasr-eddine OudniNo ratings yet

- Numerical Simulation of Concrete Block Masonry Under CompressionDocument10 pagesNumerical Simulation of Concrete Block Masonry Under CompressionRameshNayakaNo ratings yet

- A Lode Angle Dependent Formulation of The HS ModelDocument8 pagesA Lode Angle Dependent Formulation of The HS ModelGuido BentivoglioNo ratings yet

- M N M N: S Eared Crack Model For Reinforced Co Crete Asonry Shear Wall A AlysisDocument10 pagesM N M N: S Eared Crack Model For Reinforced Co Crete Asonry Shear Wall A AlysisRelu MititeluNo ratings yet

- International Journal of Fracture Volume 159 Issue 1 2009 (Doi 10.1007 - s10704-009-9384-x) A. D. Drozdov J. DeC. Christiansen - Creep Failure of Polypropylene - Experiments and Constitutive ModelingDocument17 pagesInternational Journal of Fracture Volume 159 Issue 1 2009 (Doi 10.1007 - s10704-009-9384-x) A. D. Drozdov J. DeC. Christiansen - Creep Failure of Polypropylene - Experiments and Constitutive ModelingalifaramarzNo ratings yet

- Mohr-Coulomb Parameters For Modelling of Concrete StructuresDocument4 pagesMohr-Coulomb Parameters For Modelling of Concrete StructuresDiego Alejandro Flores OrtízNo ratings yet

- Size Effects in Structural Concrete: A Numerical ExperimentDocument11 pagesSize Effects in Structural Concrete: A Numerical ExperimentMohammad DaudNo ratings yet

- 3.1. Cracking Moment-110923Document6 pages3.1. Cracking Moment-110923muktadirulgamingNo ratings yet

- A New Multi-Axial Failure Criterion For Concrete: M. Como R. LucianoDocument7 pagesA New Multi-Axial Failure Criterion For Concrete: M. Como R. LucianoRico PadillaNo ratings yet

- Publ en 462 VSU PaperDocument6 pagesPubl en 462 VSU PapertinchofranNo ratings yet

- Teorija - Experimental Determination Mechanical Properties Clay Brick MasonryDocument19 pagesTeorija - Experimental Determination Mechanical Properties Clay Brick Masonrypedja0% (1)

- Effect of Stacking Sequence On Notch Strength in LaminatesDocument10 pagesEffect of Stacking Sequence On Notch Strength in Laminatesசெல்வ குமார்No ratings yet

- Application of Physical and Mathematical Modelling in Underground ExcavationsDocument8 pagesApplication of Physical and Mathematical Modelling in Underground ExcavationsrannscribdNo ratings yet

- Finite Element Study of Concrete-Filled Steel Tubes Using A New Confinement-Sensitive Concrete Compression ModelDocument20 pagesFinite Element Study of Concrete-Filled Steel Tubes Using A New Confinement-Sensitive Concrete Compression ModelSaliNo ratings yet

- Design Procedure For Prestressed Concret PDFDocument19 pagesDesign Procedure For Prestressed Concret PDFvrajan1988No ratings yet

- Size Effect in Concrete StructuresDocument28 pagesSize Effect in Concrete StructureslifeadventureNo ratings yet

- Hoek-Brown A Mohr-CoulombDocument7 pagesHoek-Brown A Mohr-CoulombUriel Vélez OrejuelaNo ratings yet

- Hoek-Brown 파괴기준-2Document7 pagesHoek-Brown 파괴기준-2xmlnzkNo ratings yet

- Stress - Strain Relationship For Concrete in Compr PDFDocument13 pagesStress - Strain Relationship For Concrete in Compr PDFpiu dasNo ratings yet

- Collapse Simulation of Reinforced Concrete Natural Draught Cooling Towers 1992Document9 pagesCollapse Simulation of Reinforced Concrete Natural Draught Cooling Towers 1992ciscoNo ratings yet

- AbaqusDocument9 pagesAbaquscarl_zaissNo ratings yet

- RC Chapter 3 (PART 01)Document24 pagesRC Chapter 3 (PART 01)Yohannes EndaleNo ratings yet

- New Interaction Formulae For Beam-Columns in EC3-The French-Belgian Approach-JCSRDocument11 pagesNew Interaction Formulae For Beam-Columns in EC3-The French-Belgian Approach-JCSRkostas formulagrNo ratings yet

- Final Report PlasticityDocument45 pagesFinal Report PlasticityriganNo ratings yet

- Static Resistance Bolted Circular Flange JointsDocument9 pagesStatic Resistance Bolted Circular Flange JointsBálint Vaszilievits-SömjénNo ratings yet

- Plasticity ReportDocument43 pagesPlasticity ReportriganNo ratings yet

- Extended AbstractDocument10 pagesExtended AbstractRohan ReddyNo ratings yet

- Comparison of Different Soil Models For Excavation Using Retaining WallsDocument6 pagesComparison of Different Soil Models For Excavation Using Retaining WallsnithuNo ratings yet

- COMPLAS2013-87 - Recent Progress in MicroplaneDocument12 pagesCOMPLAS2013-87 - Recent Progress in Microplanefs jiNo ratings yet

- DACHDocument8 pagesDACHMohammad Reza AzadiNo ratings yet

- Ijce V4i3p110Document6 pagesIjce V4i3p110falcone87No ratings yet

- 5 Ijlemr 55554Document14 pages5 Ijlemr 55554Maicon ArcineNo ratings yet

- 4.1. Modelling Confinement in Concrete Columns and Bridge Piers Through 3D Nonlinear Finite Element AnalysisDocument8 pages4.1. Modelling Confinement in Concrete Columns and Bridge Piers Through 3D Nonlinear Finite Element AnalysisFaraaz FaisalNo ratings yet

- A General Finite Element Approach To The Form Finding of Tensile Structures by The Updated Reference StrategyDocument15 pagesA General Finite Element Approach To The Form Finding of Tensile Structures by The Updated Reference StrategyMauro SogniNo ratings yet

- CLIMACO E REGAN - Evaluation of Bond Strength Between Old and New Concrete in Structural RepairsDocument14 pagesCLIMACO E REGAN - Evaluation of Bond Strength Between Old and New Concrete in Structural RepairsMaurício FerreiraNo ratings yet

- Artigo 5Document8 pagesArtigo 5Edmilson LimaNo ratings yet

- 6 Concrete TestingDocument6 pages6 Concrete TestingMohammed AbdoNo ratings yet

- Research Article: A Stress-Strain Model For Brick Prism Under Uniaxial CompressionDocument11 pagesResearch Article: A Stress-Strain Model For Brick Prism Under Uniaxial Compressionnazmul hassanNo ratings yet

- Discussion of "Strain of Concrete at Peak Compressive Stress For A Wide Range of Compressive Strengths" by B.de Nicolo, L.Pani and E.PozzoDocument5 pagesDiscussion of "Strain of Concrete at Peak Compressive Stress For A Wide Range of Compressive Strengths" by B.de Nicolo, L.Pani and E.PozzoHatef SardariNo ratings yet

- Tension Softeneing Curves For Plain Concrete PDFDocument12 pagesTension Softeneing Curves For Plain Concrete PDFjs kalyana ramaNo ratings yet

- 2 Behaviour of Member Subjected To Axial LoadsDocument5 pages2 Behaviour of Member Subjected To Axial LoadsFoisulAlamNo ratings yet

- Characterization of The Toughness of FRC Using Load CMOD ResponseDocument14 pagesCharacterization of The Toughness of FRC Using Load CMOD ResponseourebooksNo ratings yet

- Modelling The Flexural Tensile Strength of MasonryDocument10 pagesModelling The Flexural Tensile Strength of MasonryRameshNayakaNo ratings yet

- Dynamic Damage and FragmentationFrom EverandDynamic Damage and FragmentationDavid Edward LambertNo ratings yet

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsFrom EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNo ratings yet

- Design of PavementDocument82 pagesDesign of PavementRameshNayaka100% (1)

- Effect of Palm Oil Fuel Ash Fineness On Packing Effect and Pozzolanic Reaction of Blended Cement PasteDocument9 pagesEffect of Palm Oil Fuel Ash Fineness On Packing Effect and Pozzolanic Reaction of Blended Cement PasteRameshNayakaNo ratings yet

- Guidebook Confined Masonry TS EnglishDocument28 pagesGuidebook Confined Masonry TS EnglishRameshNayakaNo ratings yet

- 2.b.2.5. Mechanical Properties of Reactive Powder Concrete Containing Mineral Admixtures Under Different Curing Regimes - 3 PDFDocument9 pages2.b.2.5. Mechanical Properties of Reactive Powder Concrete Containing Mineral Admixtures Under Different Curing Regimes - 3 PDFHammad SalahuddinNo ratings yet

- 4.2 - Masonry Buildings Not Requiring Specific Engineering DesignDocument58 pages4.2 - Masonry Buildings Not Requiring Specific Engineering DesignRameshNayakaNo ratings yet

- The Effect of Silica Fume and High-Volume Class C Fly Ash PDFDocument7 pagesThe Effect of Silica Fume and High-Volume Class C Fly Ash PDFRameshNayakaNo ratings yet

- Calculated Fire Resistance RatingsDocument8 pagesCalculated Fire Resistance RatingsRameshNayakaNo ratings yet

- SCM Tech Brief USDocument8 pagesSCM Tech Brief USRameshNayakaNo ratings yet

- The Influence of Mortar Bedding On The Compressive Strength of Concrete Block Masonry StructuresDocument10 pagesThe Influence of Mortar Bedding On The Compressive Strength of Concrete Block Masonry StructuresRameshNayakaNo ratings yet

- Construction and Building Materials: S. Barr, W.J. Mccarter, B. SuryantoDocument8 pagesConstruction and Building Materials: S. Barr, W.J. Mccarter, B. SuryantoRameshNayakaNo ratings yet

- Sustainable Masonry: The Importance of Mortar QualityDocument10 pagesSustainable Masonry: The Importance of Mortar QualityRameshNayakaNo ratings yet

- Numerical Simulation of Concrete Block Masonry Under CompressionDocument10 pagesNumerical Simulation of Concrete Block Masonry Under CompressionRameshNayakaNo ratings yet

- Effects of Dewatering On Long Term Movement Characteristics of Lime MortarsDocument10 pagesEffects of Dewatering On Long Term Movement Characteristics of Lime MortarsRameshNayakaNo ratings yet

- Speed and Acceleration v1.0Document46 pagesSpeed and Acceleration v1.0Ramesh Iyer100% (1)

- Analysis and Design of Plate Girder BridgesDocument58 pagesAnalysis and Design of Plate Girder Bridgesadnan-651358No ratings yet

- VibrationTrainingActivityBooklet CatII MobiusDocument49 pagesVibrationTrainingActivityBooklet CatII MobiusNelver Daniel Sánchez Barba100% (1)

- Lecture 4 - Reinforced Concrete - Bond, Development LengthDocument55 pagesLecture 4 - Reinforced Concrete - Bond, Development LengthChristopher PaladioNo ratings yet

- Alternating Current (AC) Resistance of Helically Stranded ConductorsDocument3 pagesAlternating Current (AC) Resistance of Helically Stranded ConductorsSahilMirzaNo ratings yet

- ME 22015 (Engineering Mechanics II) : Yangon Technological University Department of Mechanical EngineeringDocument22 pagesME 22015 (Engineering Mechanics II) : Yangon Technological University Department of Mechanical Engineeringarkarminkhant734No ratings yet

- Mechanics of MachineDocument25 pagesMechanics of Machinecarthik_rajaNo ratings yet

- Foundations For Auto Shredders : - Hammer / / / / / / / / / IDocument6 pagesFoundations For Auto Shredders : - Hammer / / / / / / / / / ISandraNo ratings yet

- Propeller TheoryDocument14 pagesPropeller Theoryponian25No ratings yet

- MCQ Phy 11th Units and Dimensions Test Paper 03-05-2013Document3 pagesMCQ Phy 11th Units and Dimensions Test Paper 03-05-2013E panditNo ratings yet

- Etabs 2015 PDFDocument53 pagesEtabs 2015 PDFtarek0% (1)

- Newton's Cart LabDocument4 pagesNewton's Cart LabMartin MeierNo ratings yet

- 1991-1-Damage Detection From Changes in Mode Shape - Pandey Biswas Samman PDFDocument12 pages1991-1-Damage Detection From Changes in Mode Shape - Pandey Biswas Samman PDFankurshah1986No ratings yet

- Design of A Slab Bridge On Abeya River A PDFDocument13 pagesDesign of A Slab Bridge On Abeya River A PDFAbera Mamo Jaleta100% (1)

- Torsional Onboard Swire Pacific MV TitanDocument21 pagesTorsional Onboard Swire Pacific MV TitanRashyd RidhaNo ratings yet

- Prob 06.71Document2 pagesProb 06.71Venkat DalaiNo ratings yet

- 01 - Fundamentals of MetalworkingDocument50 pages01 - Fundamentals of MetalworkingriyamondalNo ratings yet

- DISCFLO Sanitary BrochureDocument8 pagesDISCFLO Sanitary BrochureyusufNo ratings yet

- Smit Singapore Pte LTD: Peter Zhang 1 of 1Document8 pagesSmit Singapore Pte LTD: Peter Zhang 1 of 1Myatmyat SwewinNo ratings yet

- AS Dynamics 22Document37 pagesAS Dynamics 22Arham ImranNo ratings yet

- Tarea 2 FisicaDocument5 pagesTarea 2 FisicaNestor UlloaNo ratings yet

- 1 Performance Task G8 Science Q1Document5 pages1 Performance Task G8 Science Q1jaja genterolaNo ratings yet

- Assignment XiDocument3 pagesAssignment XiKamran AliNo ratings yet

- Recall Machine Design Past Board Cebu Mar 2011 11 PDFDocument12 pagesRecall Machine Design Past Board Cebu Mar 2011 11 PDFCMD100% (1)

- Coloumb's Law LectureDocument69 pagesColoumb's Law LectureArslan Kiani100% (1)

- Statics of Rigid Bodies: Sample ProblemsDocument25 pagesStatics of Rigid Bodies: Sample Problemsruel_galutan67% (3)

- MCQDocument8 pagesMCQBhawani DevkotaNo ratings yet

- Thermodynamics Cycles: Umar TariqDocument16 pagesThermodynamics Cycles: Umar TariqHasib IslamNo ratings yet

- Design Chart and TablesDocument21 pagesDesign Chart and TablesGirum MindayeNo ratings yet

4C5 PDF

4C5 PDF

Uploaded by

RameshNayakaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4C5 PDF

4C5 PDF

Uploaded by

RameshNayakaCopyright:

Available Formats

15th International Brick and Block

Masonry Conference

Florianpolis Brazil 2012

STRESS-STRAIN BEHAVIOR OF CONCRETE BLOCK MASONRY

PRISMS UNDER COMPRESSION

Mohamad, Gihad1; Loureno, Paulo Brando2; Roman, Humberto Ramos3; Barbosa,

Claudius de Souza4; Rizzatti, Eduardo1

1

Dr., Professor, Federal University of Santa Maria, Civil Engineering Department, gihad.civil@gmail.com;

edu_rizzatti@yahoo.com.br

2

PhD, Professor, University of Minho, Civil Engineering Department, pbl@civil.uminho.pt

PhD, Professor, Federal University of Santa Catarina, Civil Engineering Department, humberto@ecv.ufsc.br

4

Dr., Professor, So Paulo University, So Carlos School of Engeneering, Structural Department,

claudiusbarbosa@yahoo.com.br

The aim of this work is to critically assess a stress-strain model using experimental masonry

prisms constructed from different blocks and mortar. The following conclusion may be drawn

from this work: mortar is mostly responsible for the non-linear behavior of masonry. The

initial tangent modulus, obtained taking into account the compressive strength, provides a

strongly non-linear relationship between elasticity modulus and compressive strength.

Keywords: Concrete Block, Masonry Prisms Stress-Strain

INTRODUCTION

Masonry is a material built from units and mortar that induce an anisotropic behavior for the

composite. The lack of knowledge on the properties of the composite material imposes low

assessments of the strength capacity of the masonry wall. Atkinson, Noland, Abrams and

McNary (1985) state that the prediction of compressive strength and deformation of full scale

masonry based on compressive tests of stack-bond masonry prism and the interpretation of

the results of prism tests have a significant influence on the allowable stress and stiffness used

in masonry design. When structural masonry is subjected to vertical and horizontal loading,

one of the most important parameters for design is the stress-strain relationship. In particular,

elasticity modulus is a mechanical property influenced by different factors, such as: the large

scatter of experimental tests, compressive strength of unit, shape of unit (hollow or solid),

compressive strength of mortar and state of stress developed during loading. Knutson (1993)

evaluated the stress-strain diagrams for various masonry materials and showed that they can

be cast into a mathematical form. At present, a complete understanding of the mechanisms

involved in the deformation and failure are not fully explained and it is believed that the

development of a theoretical model of universal application is a rather hard task. But the

failure mechanism of masonry depends on the difference of elasticity modulus between unit

and mortar.

15th International Brick and Block

Masonry Conference

Florianpolis Brazil 2012

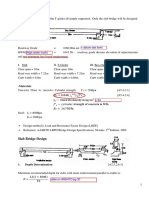

MODEL OF KNUTSON [2] FOR STRESS-STRAIN DIAGRAM

The model aims at representing the complexity of material assembly and requires several

shape and materials parameters. Therefore, simplified models of the stress-strain diagram

have been proposed. Knutson (1993) assessed the masonry strain-stress diagram for different

combinations of mortar and brick (three solid and one hollow), as shown in Figure 1, and

concluded that the stress-strain relationship could be approximated through Eq. (1) and Eq.

(2). Here, is the normal stress, is the normal strain, fcmas is the masonry compressive

strength and E0 is the initial tangent elasticity modulus. The study carried out shows that the

strain-stress diagrams were significantly different as a result of the unit type and mortar.

Figure 1: Compressive stress-strain diagram of masonry.

=

= 4

f cmas

ln1

E0

f

cmas

f cmas

E0

0.403

f cmas

if / fcmas. 0.75

if / fcmas > 0.75

(1)

(2)

The stress-strain diagram of Figure 1 showed a continuous line (solid bricks) and dotted line

(hollow bricks). The numbers are the brick strength and * is a stronger mortar, Knutson

(1993). The elasticity modulus could be represented through its secant or tangent modulus.

The latter is given by Et = d / d (Eq. (3)).

The tangent modulus can be used as an approach of the relation between stress and strain in

the neighborhood of a given point. Knutson (1993) reports that Ritter suggests that Et=E0.(1/fcmas) (Eq. (4)) to determine the elasticity modulus from the ratio between actual stress and

ultimate strength. Introducing Eq. (4) in Eq. (3), integrating and rearranging, it is possible to

obtain:

=

E.1

f

cmas

.d

(5)

15th International Brick and Block

Masonry Conference

Florianpolis Brazil 2012

Eq. (6) links logarithmically two non-dimensional values, namely the normalized strain Kr.

and the normalized stress /fcmas.

Kr. = ln1

f

cmas

E

, with Kr = o

f

cmas

(6)

Here, Kr is the so-called Ritter constant, which for concrete assumes a value of 1000. The

normalized stress-strain relation was obtained using Eq. (1), for a strength level smaller than

0.75, and Eq. (2), for a strength level higher than 0.75, see Figure 2. Here, in the graph

marked 45-1060 for a hollow brick in weak mortar, the normalized strain is reduced to 0.7

Kr.. In the Knutson (1993) studies, the normalized curves show a good agreement with Ritter

curve, except for higher relatives stress (/fcmas. 1.0 Kr. ). The numbers indicate

the brick strength followed by the Ritter constant.

(a)

(b)

Figure 2: (a) Normalized stress-strain curve obtained from Knutson (1993). (b)

Normalized stress-strain curves for hollow bricks in a weak mortar (half lime and half

cement).

According to Knutson (1993), the results show that masonry built with hollow blocks and

weak mortar may not be treated as the others, i.e., the normalized strain should be multiplied

by a factor (0.7). Only using this correction, the stress vs. strain diagram would become

similar to experimental results. The conclusion of Knutson (1993) is that, independently of

the material used, it is possible to use the standard stress-strain diagram, suggesting a curve

identical to the Ritters for stresses 0.75 fcmas as and, for > 0.75 fcmas, adopting the

tangent of Ritter curve.

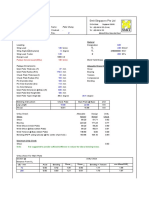

EXPERIMENTAL TESTS IN CONCRETE BLOCK PRISMS

Experimental tests in masonry prisms were carried at the Federal University of Santa

Catarina, Brazil, to determine the response of masonry subjected to compression, Mohamad

(1998). The strains have been calculated from the average displacement values measured at

both sides of prism, as shown in Figure 3.

15th International Brick and Block

Masonry Conference

Florianpolis Brazil 2012

Stress (MPa)

8

7

6

5

Prism-M1-1:0.25:3

Prism-M1-1:0.5:4.5

Prism-M1-1:1:6

Prism-M1-1:2:9

Knutson-Curve1:0.25:3

Knutson-Curve1:0.5:4.5

Knutson-Curve1:1:6

KnutsonCurve1:2:9

4

3

2

1

0

0

0.0005

0.001

0.0015

0.002

0.0025

0.003

0.0035

Strain

0.004

0.0045

Figure 3: Stress-strain diagrams for concrete blocks masonry prisms.

The stress-strain diagrams shown in Figure 3 were obtained with prisms made of concrete

blocks and a wide range of mortar strengths. The strength of the blocks fb is 18.2 MPa,

measured in the net area. The model formulated by Knutson (1993) and the experimental

results obtained for the prisms made with mortars type 1:0.25:3 (fmortar= 19.9 MPa), 1:0.5:4.5

(fmortar= 8.63 MPa), 1:1:6 (fmortar= 4.2 MPa) and 1:2:9 (fmortar= 2.90 MPa) are considered for

further analysis. Here, c:l:s indicates the cement:hydraulic lime:sand proportions in volume.

The mortar type 1:0.5:4.5 agrees well with experimental results, while mortars 1:0.25:3 and

1:2:9 exhibit reasonable agreement for the initial stress, but only moderate agreement close to

the ultimate stress.

Figure 3 shows the stress-strain diagram up to peak load for prisms obtained in the

experimental study and the theoretical model. Good agreement is found for mortars 1:0.5:4.5

and 1:1:6. For masonry prisms made using mortar type 1:0.25:3, the proposed model and the

experimental results did not show good agreement for a stress level higher than 50% of

ultimate compressive strength of prisms. Therefore, the type of unit (solid or hollow), material

(ceramic, calcium silicate or concrete) and number of horizontal and vertical joints can

increase the non-linear characteristics of the response. For mortar 1:2:9 this non-linear

behavior seems even more severe and occurs at stress levels below 0.3 of the ultimate

compressive strength of masonry. Therefore the possibility to adopt another mathematical

function is considered next.

As a new attempt, a hyperbolic function is adopted to determine the initial tangent modulus

from stress-strain diagram of masonry as shown in Eq. (7). This proposal has been made

originally by Kondner (1963) to represent the non-linear behavior of cohesive soils. In this

equation, a and b are constants, whose values need to be determined experimentally and

whose graphical meaning is indicated in Figure 4. Kondner (1963) showed that the values of

the coefficients a and b may be readily determined if the stress-strain data are plotted on the

transformed axes shown in Figure 5 and Figure 6. Recasting Eq. (7) as Eq. (8), constants a

and b are, respectively, the interception with the vertical axes and the slope of the resulting

straight line.

15th International Brick and Block

Masonry Conference

Florianpolis Brazil 2012

a + b

= a + b.

(7)

(8)

Figure 4: Hyperbolic stress-strain curve and transformed hyperbolic stress-strain curve.

Figures 5 and 6 present the linear correlation that best fits the test data, together with the test

data. As it is shown, the correlation coefficient r2 is rather high, meaning that the agreement

between the theoretical law and the test data is excellent.

Figure 5: Transformed hyperbolic stress-strain curve for prisms.

Figure 6: Transformed hyperbolic stress-strain curve for prisms.

Constants a and b were obtained from Eq. (8), where it is noted that Eo is equal to 1/a. Figure

7 plots the relation between constant a (MPa)-1 and masonry compressive strength. From this

15th International Brick and Block

Masonry Conference

Florianpolis Brazil 2012

relation it is possible to determinate the relation between the elasticity modulus of masonry

and compressive strength.

Figure 7: Relationship between the constant a (MPa)-1 and compressive strength of

masonry.

With the best fit curve shown in Figure 7, it is possible to predict the initial tangent modulus

from compressive strength of masonry as shown in Eq. (9). Introducing Eq. (9) in Eq. (1) and

Eq. (2) it is possible to predict the trajectory of the full stress vs. strain relationship for the

masonry. Notice that / fcmas should be < 1.

E 0 = 188. f cmas1.6853

(9)

Table 1 presents the experimental results from prisms built using four types of mortars, two

strengths of blocks and individual elasticity modulus obtained from experimental tests. The

prediction of elasticity modulus obtained by linearization (Eq. 9) is also shown. Here, E0 is

the initial tangent elasticity modulus (MPa) of prism obtained from linearization of stress vs.

strain; the compressive strength of block (fb) was 18.2 MPa using the net area. (*) indicates

prisms built with block with a strength in net area equal to 27 MPa; fprism is the compressive

strength of prisms measurements in full area, built with three blocks and two mortar joints;

Emortar is the uniaxial results of mortar elasticity modulus obtained from cylinder cast, at a

strain level corresponding to 30% of the mortar strength.

Table 1: Results obtained from linearization of stress-strain curve of concrete block prism.

E0=1/a

fmortar

fprism

Emortar

Type of mortar

a

(MPa)

(MPa)

(MPa)

(MPa)

1:0.25:3

19.9

10.56

9.857E-5

10145

11230

1:0.5:4.5

8.63

8.6

1.1404E-4

8787

6409

1:1:6

4.2

8.17

1.6135E-4

6197

4033

1:2:9

2.9

7.54

1.9122E-4

5229

2042

1:0.25:3*

19.2

11.7

8.826E-5

11330

11055

1:1:6*

5.41

8.84

1.44E-4

6944

4527

From the experimental tests, it can be concluded that the prisms built with mortar types 1:1:6

and 1:2:9 showed similar results in terms of initial tangent modulus, as well as prisms built

with mortar types 1:0.25:3 and 1:0.5:4.5. The tests indicate that the strength of prism should

15th International Brick and Block

Masonry Conference

Florianpolis Brazil 2012

increase with the compressive strength of blocks, and with increase in the compressive

strength of mortar. The effect of joint thickness on the initial tangent modulus does not show

a good agreement with uniaxial tests made in cylinders. Thus, it is possible to conclude that

uniaxial tests in mortar are not representative of the mortar bed joint. Subsequent tests will be

planned aiming at quantifying the mechanical behavior of mortar for different specimen shape

and triaxial state of stress. In Table 2, the six cases studied in experimental tests are shown,

indicating the block strength, relationship between initial elasticity modulus and prism

strength, mortar strength and the Ritter constant.

Table 2: Results of strength blocks, relationship between initial tangent modulus (E0) and

prism strength (fprism), mortar strength and Ritter constant.

Case

fb (MPa)

fmortar (MPa)

E0/fprism

Kr

1

18.2

10145 / 10.56

19.9

960

2

18.2

8787 / 8.6

8.63

1021

3

18.2

6197 / 8.17

4.2

758

4

18.2

5229 / 7.54

2.9

693

5

27

11330 / 11.7

19.2

968

6

27

6944 / 8.84

5.41

785

The first conclusion is that the Ritter constant is independent from the strength of the block.

For cases 1 and 5, the value was rather close, as well as for cases 3 and 6. For masonry of

concrete block bedding with weak mortar types (cases 3, 4 and 6) the Ritter constant obtained

was 0.7 of obtained for stronger mortar types (cases 1, 2 and 5). This is in complete

agreement with the conclusions of Knutson (1993). The results also show that an increase in

the compressive strength of the block from 18.2 MPa to 27 MPa, using same mortar, does not

change the Ritter constant significantly. This suggests that the non-linear strain is governed by

the mortar bedding strain. Eurocode 6 (1996) states that, in the absence of experimental

results, the secant elasticity modulus can be obtained from E mas. = kE . f k mas (Eq. (10)). Here,

the recommended value of kE is equal to 1000, independently of the unit geometry, the mortar

type or the joint thickness.

CONCLUSIONS

The main conclusions of the present study are:

- The mortar governs the non-linear behavior of masonry.

- A polynomial expression is the best fit curve between the elasticity modulus and

compressive strength of masonry. This demonstrates that there is a non-linear relation

between strength and the elasticity modulus. In opposition, Eurocode 6 (1996) establishes a

linear relation between strength and elasticity modulus.

- There is clear evidence that the elasticity modulus of mortar measurements from cylinders is

very distinct from bed joint actual behavior.

- The initial tangent modulus of masonry obtained from transformed hyperbolic stress-strain

diagram shows values rather similar for prisms built with mortar types 1:1:6 and 1:2:9.

- Further studies to determine the correlation between the mechanical behaviors of mortar in

the joint compared with cylinders specimens is essential to understand the failure mechanism

of masonry under compression.

15th International Brick and Block

Masonry Conference

Florianpolis Brazil 2012

REFERENCES

Atkinson RH, Noland JL, Abrams DP, McNary S. A deformation failure theory for stackbond brick masonry prisms in compression. Proceedings 3rd NAMC, Arlington, 1985, p. 181 to 18-18.

Knutson HH. The Stress-Strain Relationship for Masonry, Masonry International 1993,

7(1):31-33.

Mohamad G. Mechanical behavior at collapse for concrete block masonry wallets. MSc

Thesis. Florianpolis, Federal University of Santa Catarina, Brazil, 1998 (in Portuguese).

Kondner RL. Hyperbolic Stress-Strain Response: Cohesive Soils, Journal of the Soil

Mechanics and Foundation Division, ASCE, 1963;89(1):115-143.

CENTC/250. Eurocode 6: Design of masonry structures-Part 1-1: Common rules for

reinforced and unreinforced masonry structures, EN 1996, 131p.

You might also like

- Lab Report Radius of GyrationDocument4 pagesLab Report Radius of GyrationShahzaibali AfaqNo ratings yet

- Numerical Analysis of Load Test On Bored Pile (Wehnert & Veermer) PDFDocument6 pagesNumerical Analysis of Load Test On Bored Pile (Wehnert & Veermer) PDFAnonymous BuFjdLNo ratings yet

- Computer-Aided Development of Stress Fields For The Analysis of Structural ConcreteDocument8 pagesComputer-Aided Development of Stress Fields For The Analysis of Structural ConcreteAndré PeraroNo ratings yet

- Simplified Procedures For Calculation of Instantaneous and Long-Term Deflections of Reinforced Concrete BeamsDocument12 pagesSimplified Procedures For Calculation of Instantaneous and Long-Term Deflections of Reinforced Concrete BeamssukolikNo ratings yet

- A Composite Plasticity Model For Concrete: Pergamon 0020-7683 (95) 0006&7Document24 pagesA Composite Plasticity Model For Concrete: Pergamon 0020-7683 (95) 0006&7ngNo ratings yet

- XC Tension StiffeningDocument6 pagesXC Tension StiffeningLuis C. Pérez Tato100% (1)

- Modelling The Tensile Behavior of Plain Concrete Under Flexural LoadingDocument7 pagesModelling The Tensile Behavior of Plain Concrete Under Flexural LoadingAhmad MensaNo ratings yet

- Lab 4 Manual - Concrete Testing - F15Document18 pagesLab 4 Manual - Concrete Testing - F15kaligleean100% (1)

- Ultimate Resistance of Reinforced Concrete Columns Strengthened With Angles and Battens: Theoretical Model and Experimental ValidationDocument15 pagesUltimate Resistance of Reinforced Concrete Columns Strengthened With Angles and Battens: Theoretical Model and Experimental ValidationUcok DedyNo ratings yet

- 139C-Modelling of Reinforced Concrete structures-KAMIŃSKI-2011Document14 pages139C-Modelling of Reinforced Concrete structures-KAMIŃSKI-2011Ziyad12No ratings yet

- Implementation of The Modified Compression Field TheoryDocument33 pagesImplementation of The Modified Compression Field TheoryDang Bao TranNo ratings yet

- Some Aspects On Three-Dimensional Numerical Modelling of Reinforced Concrete Structures Using The ®nite Element MethodDocument21 pagesSome Aspects On Three-Dimensional Numerical Modelling of Reinforced Concrete Structures Using The ®nite Element Methodp71089No ratings yet

- Fracture in Quasi-Brittle Materials, A Review of Continum DamagDocument18 pagesFracture in Quasi-Brittle Materials, A Review of Continum DamagNasr-eddine OudniNo ratings yet

- Numerical Simulation of Concrete Block Masonry Under CompressionDocument10 pagesNumerical Simulation of Concrete Block Masonry Under CompressionRameshNayakaNo ratings yet

- A Lode Angle Dependent Formulation of The HS ModelDocument8 pagesA Lode Angle Dependent Formulation of The HS ModelGuido BentivoglioNo ratings yet

- M N M N: S Eared Crack Model For Reinforced Co Crete Asonry Shear Wall A AlysisDocument10 pagesM N M N: S Eared Crack Model For Reinforced Co Crete Asonry Shear Wall A AlysisRelu MititeluNo ratings yet

- International Journal of Fracture Volume 159 Issue 1 2009 (Doi 10.1007 - s10704-009-9384-x) A. D. Drozdov J. DeC. Christiansen - Creep Failure of Polypropylene - Experiments and Constitutive ModelingDocument17 pagesInternational Journal of Fracture Volume 159 Issue 1 2009 (Doi 10.1007 - s10704-009-9384-x) A. D. Drozdov J. DeC. Christiansen - Creep Failure of Polypropylene - Experiments and Constitutive ModelingalifaramarzNo ratings yet

- Mohr-Coulomb Parameters For Modelling of Concrete StructuresDocument4 pagesMohr-Coulomb Parameters For Modelling of Concrete StructuresDiego Alejandro Flores OrtízNo ratings yet

- Size Effects in Structural Concrete: A Numerical ExperimentDocument11 pagesSize Effects in Structural Concrete: A Numerical ExperimentMohammad DaudNo ratings yet

- 3.1. Cracking Moment-110923Document6 pages3.1. Cracking Moment-110923muktadirulgamingNo ratings yet

- A New Multi-Axial Failure Criterion For Concrete: M. Como R. LucianoDocument7 pagesA New Multi-Axial Failure Criterion For Concrete: M. Como R. LucianoRico PadillaNo ratings yet

- Publ en 462 VSU PaperDocument6 pagesPubl en 462 VSU PapertinchofranNo ratings yet

- Teorija - Experimental Determination Mechanical Properties Clay Brick MasonryDocument19 pagesTeorija - Experimental Determination Mechanical Properties Clay Brick Masonrypedja0% (1)

- Effect of Stacking Sequence On Notch Strength in LaminatesDocument10 pagesEffect of Stacking Sequence On Notch Strength in Laminatesசெல்வ குமார்No ratings yet

- Application of Physical and Mathematical Modelling in Underground ExcavationsDocument8 pagesApplication of Physical and Mathematical Modelling in Underground ExcavationsrannscribdNo ratings yet

- Finite Element Study of Concrete-Filled Steel Tubes Using A New Confinement-Sensitive Concrete Compression ModelDocument20 pagesFinite Element Study of Concrete-Filled Steel Tubes Using A New Confinement-Sensitive Concrete Compression ModelSaliNo ratings yet

- Design Procedure For Prestressed Concret PDFDocument19 pagesDesign Procedure For Prestressed Concret PDFvrajan1988No ratings yet

- Size Effect in Concrete StructuresDocument28 pagesSize Effect in Concrete StructureslifeadventureNo ratings yet

- Hoek-Brown A Mohr-CoulombDocument7 pagesHoek-Brown A Mohr-CoulombUriel Vélez OrejuelaNo ratings yet

- Hoek-Brown 파괴기준-2Document7 pagesHoek-Brown 파괴기준-2xmlnzkNo ratings yet

- Stress - Strain Relationship For Concrete in Compr PDFDocument13 pagesStress - Strain Relationship For Concrete in Compr PDFpiu dasNo ratings yet

- Collapse Simulation of Reinforced Concrete Natural Draught Cooling Towers 1992Document9 pagesCollapse Simulation of Reinforced Concrete Natural Draught Cooling Towers 1992ciscoNo ratings yet

- AbaqusDocument9 pagesAbaquscarl_zaissNo ratings yet

- RC Chapter 3 (PART 01)Document24 pagesRC Chapter 3 (PART 01)Yohannes EndaleNo ratings yet

- New Interaction Formulae For Beam-Columns in EC3-The French-Belgian Approach-JCSRDocument11 pagesNew Interaction Formulae For Beam-Columns in EC3-The French-Belgian Approach-JCSRkostas formulagrNo ratings yet

- Final Report PlasticityDocument45 pagesFinal Report PlasticityriganNo ratings yet

- Static Resistance Bolted Circular Flange JointsDocument9 pagesStatic Resistance Bolted Circular Flange JointsBálint Vaszilievits-SömjénNo ratings yet

- Plasticity ReportDocument43 pagesPlasticity ReportriganNo ratings yet

- Extended AbstractDocument10 pagesExtended AbstractRohan ReddyNo ratings yet

- Comparison of Different Soil Models For Excavation Using Retaining WallsDocument6 pagesComparison of Different Soil Models For Excavation Using Retaining WallsnithuNo ratings yet

- COMPLAS2013-87 - Recent Progress in MicroplaneDocument12 pagesCOMPLAS2013-87 - Recent Progress in Microplanefs jiNo ratings yet

- DACHDocument8 pagesDACHMohammad Reza AzadiNo ratings yet

- Ijce V4i3p110Document6 pagesIjce V4i3p110falcone87No ratings yet

- 5 Ijlemr 55554Document14 pages5 Ijlemr 55554Maicon ArcineNo ratings yet

- 4.1. Modelling Confinement in Concrete Columns and Bridge Piers Through 3D Nonlinear Finite Element AnalysisDocument8 pages4.1. Modelling Confinement in Concrete Columns and Bridge Piers Through 3D Nonlinear Finite Element AnalysisFaraaz FaisalNo ratings yet

- A General Finite Element Approach To The Form Finding of Tensile Structures by The Updated Reference StrategyDocument15 pagesA General Finite Element Approach To The Form Finding of Tensile Structures by The Updated Reference StrategyMauro SogniNo ratings yet

- CLIMACO E REGAN - Evaluation of Bond Strength Between Old and New Concrete in Structural RepairsDocument14 pagesCLIMACO E REGAN - Evaluation of Bond Strength Between Old and New Concrete in Structural RepairsMaurício FerreiraNo ratings yet

- Artigo 5Document8 pagesArtigo 5Edmilson LimaNo ratings yet

- 6 Concrete TestingDocument6 pages6 Concrete TestingMohammed AbdoNo ratings yet

- Research Article: A Stress-Strain Model For Brick Prism Under Uniaxial CompressionDocument11 pagesResearch Article: A Stress-Strain Model For Brick Prism Under Uniaxial Compressionnazmul hassanNo ratings yet

- Discussion of "Strain of Concrete at Peak Compressive Stress For A Wide Range of Compressive Strengths" by B.de Nicolo, L.Pani and E.PozzoDocument5 pagesDiscussion of "Strain of Concrete at Peak Compressive Stress For A Wide Range of Compressive Strengths" by B.de Nicolo, L.Pani and E.PozzoHatef SardariNo ratings yet

- Tension Softeneing Curves For Plain Concrete PDFDocument12 pagesTension Softeneing Curves For Plain Concrete PDFjs kalyana ramaNo ratings yet

- 2 Behaviour of Member Subjected To Axial LoadsDocument5 pages2 Behaviour of Member Subjected To Axial LoadsFoisulAlamNo ratings yet

- Characterization of The Toughness of FRC Using Load CMOD ResponseDocument14 pagesCharacterization of The Toughness of FRC Using Load CMOD ResponseourebooksNo ratings yet

- Modelling The Flexural Tensile Strength of MasonryDocument10 pagesModelling The Flexural Tensile Strength of MasonryRameshNayakaNo ratings yet

- Dynamic Damage and FragmentationFrom EverandDynamic Damage and FragmentationDavid Edward LambertNo ratings yet

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsFrom EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNo ratings yet

- Design of PavementDocument82 pagesDesign of PavementRameshNayaka100% (1)

- Effect of Palm Oil Fuel Ash Fineness On Packing Effect and Pozzolanic Reaction of Blended Cement PasteDocument9 pagesEffect of Palm Oil Fuel Ash Fineness On Packing Effect and Pozzolanic Reaction of Blended Cement PasteRameshNayakaNo ratings yet

- Guidebook Confined Masonry TS EnglishDocument28 pagesGuidebook Confined Masonry TS EnglishRameshNayakaNo ratings yet

- 2.b.2.5. Mechanical Properties of Reactive Powder Concrete Containing Mineral Admixtures Under Different Curing Regimes - 3 PDFDocument9 pages2.b.2.5. Mechanical Properties of Reactive Powder Concrete Containing Mineral Admixtures Under Different Curing Regimes - 3 PDFHammad SalahuddinNo ratings yet

- 4.2 - Masonry Buildings Not Requiring Specific Engineering DesignDocument58 pages4.2 - Masonry Buildings Not Requiring Specific Engineering DesignRameshNayakaNo ratings yet

- The Effect of Silica Fume and High-Volume Class C Fly Ash PDFDocument7 pagesThe Effect of Silica Fume and High-Volume Class C Fly Ash PDFRameshNayakaNo ratings yet

- Calculated Fire Resistance RatingsDocument8 pagesCalculated Fire Resistance RatingsRameshNayakaNo ratings yet

- SCM Tech Brief USDocument8 pagesSCM Tech Brief USRameshNayakaNo ratings yet

- The Influence of Mortar Bedding On The Compressive Strength of Concrete Block Masonry StructuresDocument10 pagesThe Influence of Mortar Bedding On The Compressive Strength of Concrete Block Masonry StructuresRameshNayakaNo ratings yet

- Construction and Building Materials: S. Barr, W.J. Mccarter, B. SuryantoDocument8 pagesConstruction and Building Materials: S. Barr, W.J. Mccarter, B. SuryantoRameshNayakaNo ratings yet

- Sustainable Masonry: The Importance of Mortar QualityDocument10 pagesSustainable Masonry: The Importance of Mortar QualityRameshNayakaNo ratings yet

- Numerical Simulation of Concrete Block Masonry Under CompressionDocument10 pagesNumerical Simulation of Concrete Block Masonry Under CompressionRameshNayakaNo ratings yet

- Effects of Dewatering On Long Term Movement Characteristics of Lime MortarsDocument10 pagesEffects of Dewatering On Long Term Movement Characteristics of Lime MortarsRameshNayakaNo ratings yet

- Speed and Acceleration v1.0Document46 pagesSpeed and Acceleration v1.0Ramesh Iyer100% (1)

- Analysis and Design of Plate Girder BridgesDocument58 pagesAnalysis and Design of Plate Girder Bridgesadnan-651358No ratings yet

- VibrationTrainingActivityBooklet CatII MobiusDocument49 pagesVibrationTrainingActivityBooklet CatII MobiusNelver Daniel Sánchez Barba100% (1)

- Lecture 4 - Reinforced Concrete - Bond, Development LengthDocument55 pagesLecture 4 - Reinforced Concrete - Bond, Development LengthChristopher PaladioNo ratings yet

- Alternating Current (AC) Resistance of Helically Stranded ConductorsDocument3 pagesAlternating Current (AC) Resistance of Helically Stranded ConductorsSahilMirzaNo ratings yet

- ME 22015 (Engineering Mechanics II) : Yangon Technological University Department of Mechanical EngineeringDocument22 pagesME 22015 (Engineering Mechanics II) : Yangon Technological University Department of Mechanical Engineeringarkarminkhant734No ratings yet

- Mechanics of MachineDocument25 pagesMechanics of Machinecarthik_rajaNo ratings yet

- Foundations For Auto Shredders : - Hammer / / / / / / / / / IDocument6 pagesFoundations For Auto Shredders : - Hammer / / / / / / / / / ISandraNo ratings yet

- Propeller TheoryDocument14 pagesPropeller Theoryponian25No ratings yet

- MCQ Phy 11th Units and Dimensions Test Paper 03-05-2013Document3 pagesMCQ Phy 11th Units and Dimensions Test Paper 03-05-2013E panditNo ratings yet

- Etabs 2015 PDFDocument53 pagesEtabs 2015 PDFtarek0% (1)

- Newton's Cart LabDocument4 pagesNewton's Cart LabMartin MeierNo ratings yet

- 1991-1-Damage Detection From Changes in Mode Shape - Pandey Biswas Samman PDFDocument12 pages1991-1-Damage Detection From Changes in Mode Shape - Pandey Biswas Samman PDFankurshah1986No ratings yet

- Design of A Slab Bridge On Abeya River A PDFDocument13 pagesDesign of A Slab Bridge On Abeya River A PDFAbera Mamo Jaleta100% (1)

- Torsional Onboard Swire Pacific MV TitanDocument21 pagesTorsional Onboard Swire Pacific MV TitanRashyd RidhaNo ratings yet

- Prob 06.71Document2 pagesProb 06.71Venkat DalaiNo ratings yet

- 01 - Fundamentals of MetalworkingDocument50 pages01 - Fundamentals of MetalworkingriyamondalNo ratings yet

- DISCFLO Sanitary BrochureDocument8 pagesDISCFLO Sanitary BrochureyusufNo ratings yet

- Smit Singapore Pte LTD: Peter Zhang 1 of 1Document8 pagesSmit Singapore Pte LTD: Peter Zhang 1 of 1Myatmyat SwewinNo ratings yet

- AS Dynamics 22Document37 pagesAS Dynamics 22Arham ImranNo ratings yet

- Tarea 2 FisicaDocument5 pagesTarea 2 FisicaNestor UlloaNo ratings yet

- 1 Performance Task G8 Science Q1Document5 pages1 Performance Task G8 Science Q1jaja genterolaNo ratings yet

- Assignment XiDocument3 pagesAssignment XiKamran AliNo ratings yet

- Recall Machine Design Past Board Cebu Mar 2011 11 PDFDocument12 pagesRecall Machine Design Past Board Cebu Mar 2011 11 PDFCMD100% (1)

- Coloumb's Law LectureDocument69 pagesColoumb's Law LectureArslan Kiani100% (1)

- Statics of Rigid Bodies: Sample ProblemsDocument25 pagesStatics of Rigid Bodies: Sample Problemsruel_galutan67% (3)

- MCQDocument8 pagesMCQBhawani DevkotaNo ratings yet

- Thermodynamics Cycles: Umar TariqDocument16 pagesThermodynamics Cycles: Umar TariqHasib IslamNo ratings yet

- Design Chart and TablesDocument21 pagesDesign Chart and TablesGirum MindayeNo ratings yet