Professional Documents

Culture Documents

Storage Incoming Process Flow: F U N C T I O N S

Storage Incoming Process Flow: F U N C T I O N S

Uploaded by

Raunaq Singh0 ratings0% found this document useful (0 votes)

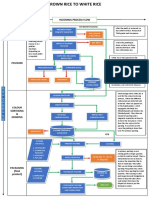

14 views1 pagePaddy rice is sent to a cleaning and drying process where it undergoes sela processing including steaming, soaking, and further steaming. This is a parboiling process. The paddy is then mechanically dried, rested, and stored. It is later milled by removing foreign materials and husks to produce brown rice, with separators removing the paddy for additional processing.

Original Description:

how paddy is converted to brown rice is done here

Original Title

Paddy to Rice

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPaddy rice is sent to a cleaning and drying process where it undergoes sela processing including steaming, soaking, and further steaming. This is a parboiling process. The paddy is then mechanically dried, rested, and stored. It is later milled by removing foreign materials and husks to produce brown rice, with separators removing the paddy for additional processing.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

14 views1 pageStorage Incoming Process Flow: F U N C T I O N S

Storage Incoming Process Flow: F U N C T I O N S

Uploaded by

Raunaq SinghPaddy rice is sent to a cleaning and drying process where it undergoes sela processing including steaming, soaking, and further steaming. This is a parboiling process. The paddy is then mechanically dried, rested, and stored. It is later milled by removing foreign materials and husks to produce brown rice, with separators removing the paddy for additional processing.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

PADDY TO RICE

INCOMING PROCESS FLOW

STORAGE

Paddy from the storage is sent

for the Cleaning and Drying

process.

STORAGE

SELA PROCESS

REMOVAL OF

FOREIGN

MATERIAL

PRE CLEANING

STEAM

STEAMING

CLEANING

&

DRYING

PROCESS

DRYING (IF

REQUIRED)

STEAM

SOAKING/STEEPING

Sela Process is the

process where the

paddy is sent under 3

processes Steam,

Soaking & Steam (par

boiling process). Then

the paddy is dried

mechanically by the

dryers, put for rest and

stored.

STORING

F

U

N

C

T

I

O

N

S

HOT

AIR

MECHANICAL DRYING

Rice from storage is pre

cleaned by removing

foreign material and then

dried if necessary and then

finally storing it in silos.

RESTING

PRE CLEANING (MTRA)

(MAGNETIC SEPARATORS)

PARBOILING PROCESS

FOREIGN MATTERS

IRON PIECES

MILLING

PROCESS

In soaking / steeping

operation we use1 Cream Sela = cold water

2 Golden Sela = hot water

DE-STONING

STONES

RICE HUSK

DE-HUSKING (MAGNETIC

SEPARATOS)

IRON PIECES

PADDY

PADDY SEPARATOR

BROWN RICE

In the milling process the paddy

from storage is pre cleaned by

MTRA separator, it separates

coarse and fine impurities from

the paddy. And in process

magnetic separation is done to

remove the iron pieces

Then the process id followed by

De-Stoning that is removing all

the stones.

Then De-Husking is done where

husk is removed to get brown

rice. And then the separators

are used to separate the paddy

from Brown Rice. The paddy

removed is again de husked to

get more efficient.

You might also like

- Week #50 - CoffeeDocument1 pageWeek #50 - CoffeeGareth James Parry100% (4)

- Technical Study Gabi FlourDocument24 pagesTechnical Study Gabi Flourrozele gandaNo ratings yet

- Starch WestfaliaDocument5 pagesStarch WestfaliaLTE002No ratings yet

- Malting - WikipediaDocument4 pagesMalting - WikipediaguidogiglioNo ratings yet

- "Preparation of Tamarind Paste": Seminar OnDocument15 pages"Preparation of Tamarind Paste": Seminar Onraja singamNo ratings yet

- Corn MillingDocument22 pagesCorn MillingNoshaba FiazNo ratings yet

- 3.1. Procurement of Raw Materials: Chapter - 3 Materials and MethodsDocument21 pages3.1. Procurement of Raw Materials: Chapter - 3 Materials and MethodsAkshaya RavichandranNo ratings yet

- Almond ProcessingDocument7 pagesAlmond ProcessingLuis Gustavo BarascoutNo ratings yet

- Cold StorageDocument28 pagesCold StorageparasuramanNo ratings yet

- RAC Introduction 1 2021-22Document17 pagesRAC Introduction 1 2021-22Aniket BhattaNo ratings yet

- Saba Rez 1993Document8 pagesSaba Rez 1993Trần Minh ChinhNo ratings yet

- Freeze DryingDocument20 pagesFreeze DryingWanda Suryadinata100% (1)

- Sugarbeet ProcessingDocument12 pagesSugarbeet ProcessingyanatryNo ratings yet

- Process Control in Fruit Canning, Milk Frezzing and Vegetable FreezingDocument37 pagesProcess Control in Fruit Canning, Milk Frezzing and Vegetable FreezingSharmina RituNo ratings yet

- Principles of MillingDocument5 pagesPrinciples of MillingjasmenenojasNo ratings yet

- General Principles of Canning and Bottling of FoodsDocument8 pagesGeneral Principles of Canning and Bottling of FoodsDavid Uribe100% (2)

- NAME Eng. Waziri Maulidi Discipline Bioprocess and Postharvest EngineeringDocument5 pagesNAME Eng. Waziri Maulidi Discipline Bioprocess and Postharvest Engineeringwaziri maulidiNo ratings yet

- Coconut Value Added Products Processing TechnologyDocument9 pagesCoconut Value Added Products Processing TechnologyjsphemilNo ratings yet

- Cement ManufacturingDocument10 pagesCement Manufacturinglawrence catipayNo ratings yet

- Presentation Dry Milling of WheatDocument14 pagesPresentation Dry Milling of Wheatayesha shafiqueNo ratings yet

- Malting: Current Practice in MaltingDocument7 pagesMalting: Current Practice in MaltingLokraj PantNo ratings yet

- Oil and Fat Technology Lectures IIDocument24 pagesOil and Fat Technology Lectures IIaulger100% (1)

- Plant Visit SagaDocument6 pagesPlant Visit SagaSalah Eldin Abdalla100% (3)

- SoxhletDocument1 pageSoxhletCedric Fabricante RustiaNo ratings yet

- 2.milk Processing - NDDocument13 pages2.milk Processing - NDAbhithNo ratings yet

- Cashew Nut Processing: Sources of Environmental Pollution and StandardsDocument7 pagesCashew Nut Processing: Sources of Environmental Pollution and StandardsDeoo Milton EximoNo ratings yet

- TQM Assignment PDFDocument14 pagesTQM Assignment PDFFayyz RasulNo ratings yet

- Feed Raw Material Handling and StorageDocument57 pagesFeed Raw Material Handling and StorageDr Anais AsimNo ratings yet

- Summer Training Presentation at UNITED BREWERIES LTD. LUDHIANADocument21 pagesSummer Training Presentation at UNITED BREWERIES LTD. LUDHIANAketan171092No ratings yet

- Cashew Nut Processing1Document5 pagesCashew Nut Processing1Noo ThailandNo ratings yet

- Principle, Construction, Working, Uses, Merits and Demerits of Freeze Dryer - PharmaguidelineDocument4 pagesPrinciple, Construction, Working, Uses, Merits and Demerits of Freeze Dryer - PharmaguidelineKaren Pachchigar 1No ratings yet

- Sterilization and Ultra-High-Temperature ProcessingDocument15 pagesSterilization and Ultra-High-Temperature ProcessingNishkarsh AgarwalNo ratings yet

- Sugarcane Processing Technologies: by Md. Akram HossainDocument16 pagesSugarcane Processing Technologies: by Md. Akram HossainDeva Mk100% (1)

- Manual Corn OilDocument22 pagesManual Corn OilFernando CálixNo ratings yet

- Parboiling and Dryer MILLTEC MACHINERY LTD PDFDocument22 pagesParboiling and Dryer MILLTEC MACHINERY LTD PDFMilltec MachineryNo ratings yet

- Basic Cashew Processing StepsDocument3 pagesBasic Cashew Processing StepsAquarianTruthsNo ratings yet

- Flowchart of The Rice Production ProcessDocument4 pagesFlowchart of The Rice Production ProcessScribdTranslationsNo ratings yet

- Term Paper MidtermDocument15 pagesTerm Paper MidtermMahonyNo ratings yet

- Pre-Cooling and RefrigerationDocument9 pagesPre-Cooling and RefrigerationOliver TalipNo ratings yet

- The Production of Sugar From Sugar CaneDocument9 pagesThe Production of Sugar From Sugar CaneNeiliah Jackson50% (2)

- ExtractionDocument19 pagesExtractionSauptik DattaNo ratings yet

- Tray DryerDocument9 pagesTray DryerElwa SzaboNo ratings yet

- cooling and storage presentation (1)Document13 pagescooling and storage presentation (1)Juwon AkeemNo ratings yet

- Canning of Fruits & Vegetables: Aarti Nimesh SRF (Icar-Ciphet)Document32 pagesCanning of Fruits & Vegetables: Aarti Nimesh SRF (Icar-Ciphet)Zohaib ArshadNo ratings yet

- Agriculture Microbiology ManualDocument38 pagesAgriculture Microbiology ManualYugNo ratings yet

- Hotpoint HF 1801 e f1 Uk enDocument6 pagesHotpoint HF 1801 e f1 Uk enJohn WalesNo ratings yet

- Anil PresentationDocument39 pagesAnil Presentationanil rautNo ratings yet

- Introduction and Manufacturing ProcessDocument9 pagesIntroduction and Manufacturing ProcesspototoygangbangNo ratings yet

- Wheat MillingDocument11 pagesWheat MillingFaizanAhmad100% (1)

- Verka Complete Traning FilrDocument46 pagesVerka Complete Traning FilrSaab Rana100% (1)

- 1 Production Section 11Document44 pages1 Production Section 11Kunal RanaNo ratings yet

- Milling of Legume PulsesDocument7 pagesMilling of Legume Pulsessuresh100% (1)

- Seminar Presentation On Freeze Drying: Prsented byDocument26 pagesSeminar Presentation On Freeze Drying: Prsented byBibhuti B. RoulNo ratings yet

- CORN Processing Write-UpDocument12 pagesCORN Processing Write-UpHarbaaz SinghNo ratings yet

- Lesson 1 Basic Refrigeration Cycle and Concepts, Standard Rating of Refrigerating MachinesDocument3 pagesLesson 1 Basic Refrigeration Cycle and Concepts, Standard Rating of Refrigerating MachinesEdrielleNo ratings yet

- Cereal ManufacturingDocument2 pagesCereal Manufacturingmikko.monaresNo ratings yet

- Wheat ProcessingDocument11 pagesWheat ProcessingHimadri Shekhar KonarNo ratings yet

- 1 Dipl. Brew. Module 1: Unit 1.2 - The Malting Process - Section 1.2.1Document13 pages1 Dipl. Brew. Module 1: Unit 1.2 - The Malting Process - Section 1.2.1RiyanNo ratings yet

- Dried & True: The Magic of Your Dehydrator in 80 Delicious Recipes and Inspiring TechniquesFrom EverandDried & True: The Magic of Your Dehydrator in 80 Delicious Recipes and Inspiring TechniquesRating: 3 out of 5 stars3/5 (1)

- Laser Guidance Is A Technique of Guiding A Missile or Other Projectile or Vehicle To A TargetDocument22 pagesLaser Guidance Is A Technique of Guiding A Missile or Other Projectile or Vehicle To A TargetRaunaq SinghNo ratings yet

- Wind TurbineDocument38 pagesWind TurbineRaunaq Singh100% (1)

- Plasma Propelled Rocket EnginesDocument24 pagesPlasma Propelled Rocket EnginesRaunaq Singh100% (1)

- Dual Clutch TransmissionDocument18 pagesDual Clutch TransmissionRaunaq SinghNo ratings yet

- Science and Technology Literature Survey of Wind Power Integration With Hydroelectric EnergyDocument8 pagesScience and Technology Literature Survey of Wind Power Integration With Hydroelectric EnergyRaunaq SinghNo ratings yet

- Lean Implementation: Lean Implementation For Business Outcomes-Cost, Quality, and Process ImprovementDocument2 pagesLean Implementation: Lean Implementation For Business Outcomes-Cost, Quality, and Process ImprovementRaunaq SinghNo ratings yet

- Security For WindowDocument48 pagesSecurity For WindowRaunaq SinghNo ratings yet

- Standard Operating Procedures (SOPs)Document19 pagesStandard Operating Procedures (SOPs)Raunaq SinghNo ratings yet

- Rice To Rice Flow Diagram 1Document1 pageRice To Rice Flow Diagram 1Raunaq SinghNo ratings yet

- Vertical Axis Wind TurbineDocument50 pagesVertical Axis Wind TurbineRaunaq Singh100% (2)